ASTM A65-01

(Specification)Standard Specification for Steel Track Spikes

Standard Specification for Steel Track Spikes

SCOPE

1.1 This specification covers steel track spikes used as fastenings between railroad rails, tie plates, and ties.

1.2 Two grades of spikes are described, Grades 1 and 2, previously known as "soft" and "high carbon" steel.

1.3 Supplementary Requirement (S1) specifying copper content is provided. It shall apply only when specified by the purchaser.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 65 – 01

Standard Specification for

1

Steel Track Spikes

ThisstandardisissuedunderthefixeddesignationA65;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

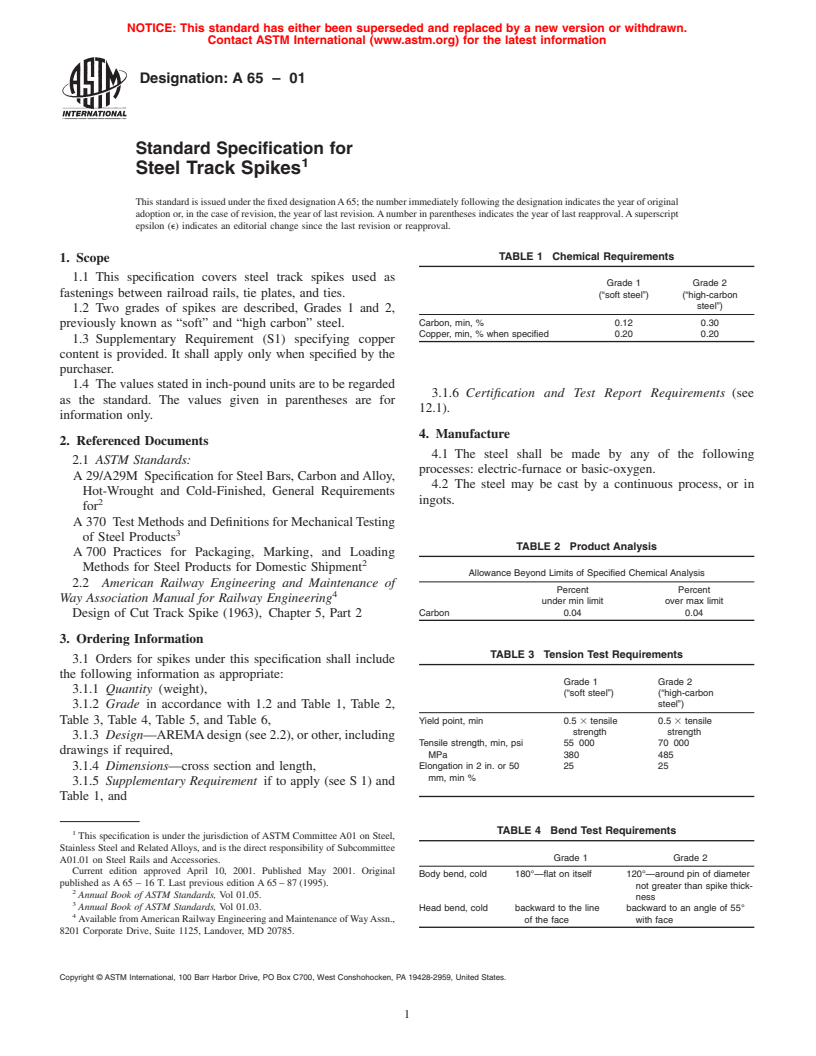

TABLE 1 Chemical Requirements

1. Scope

1.1 This specification covers steel track spikes used as

Grade 1 Grade 2

fastenings between railroad rails, tie plates, and ties.

(“soft steel”) (“high-carbon

steel”)

1.2 Two grades of spikes are described, Grades 1 and 2,

Carbon, min, % 0.12 0.30

previously known as “soft” and “high carbon” steel.

Copper, min, % when specified 0.20 0.20

1.3 Supplementary Requirement (S1) specifying copper

content is provided. It shall apply only when specified by the

purchaser.

1.4 The values stated in inch-pound units are to be regarded

3.1.6 Certification and Test Report Requirements (see

as the standard. The values given in parentheses are for

12.1).

information only.

4. Manufacture

2. Referenced Documents

4.1 The steel shall be made by any of the following

2.1 ASTM Standards:

processes: electric-furnace or basic-oxygen.

A 29/A29M Specification for Steel Bars, Carbon andAlloy,

4.2 The steel may be cast by a continuous process, or in

Hot-Wrought and Cold-Finished, General Requirements

ingots.

2

for

A 370 Test Methods and Definitions for MechanicalTesting

3

of Steel Products

TABLE 2 Product Analysis

A 700 Practices for Packaging, Marking, and Loading

2

Methods for Steel Products for Domestic Shipment

Allowance Beyond Limits of Specified Chemical Analysis

2.2 American Railway Engineering and Maintenance of

Percent Percent

4

Way Association Manual for Railway Engineering

under min limit over max limit

Carbon 0.04 0.04

Design of Cut Track Spike (1963), Chapter 5, Part 2

3. Ordering Information

TABLE 3 Tension Test Requirements

3.1 Orders for spikes under this specification shall include

the following information as appropriate:

Grade 1 Grade 2

3.1.1 Quantity (weight),

(“soft steel”) (“high-carbon

steel”)

3.1.2 Grade in accordance with 1.2 and Table 1, Table 2,

Table 3, Table 4, Table 5, and Table 6, Yield point, min 0.5 3 tensile 0.5 3 tensile

strength strength

3.1.3 Design—AREMAdesign (see 2.2), or other, including

Tensile strength, min, psi 55 000 70 000

drawings if required,

MPa 380 485

Elongation in 2 in. or 50 25 25

3.1.4 Dimensions—cross section and length,

mm, min %

3.1.5 Supplementary Requirement if to apply (see S 1) and

Table 1, and

1 TABLE 4 Bend Test Requirements

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and RelatedAlloys, and is the direct responsibility of Subcommittee

Grade 1 Grade 2

A01.01 on Steel Rails and Accessories.

Current edition approved April 10, 2001. Published May 2001. Original

Body bend, cold 180°—flat on itself 120°—around pin of diameter

published as A 65 – 16 T. Last previous edition A 65 – 87 (1995).

not greater than spike thick-

2

Annual Book of ASTM Standards, Vol 01.05.

ness

3

Annual Book of ASTM Standards, Vol 01.03.

Head bend, cold backward to the line backward to an angle of 55°

4

Available fromAmerican Railway Engineering and Maintenance ofWayAssn., of the face with face

8201 Corporate Drive, Suite 1125, Landover, MD 20785.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A65–01

TABLE 5 Permissible Variations in DImensions

7. Dimensions and Permissible Variations

7.1 The finished spikes shall conform to the dimensions

Over Under

specified by the purchaser, subject to the permissible variations

in. mm in. mm

prescribed in Table 5.

Cross section 1 32 0.8 1 64 0.4

/ /

Head 3 32 2.4 1 32 0.8

/ /

8. Workmanship, Finish, and Appearance

Length, under head to point 1 8 3.2 183.2

/ /

Angle, under side of head 1° 1° 1° 1°

8.1 The finished spikes shall be straight, with well-formed

heads and sharp points and shall be free of injurious and other

imperfections not consistent with good commercial practice.

TABLE 6 Markings

9. Retests

Grade 1 Grade 2

9.1 If, during the tension or bend tests, a previously undis-

Steel, copper not manufacturer’s symbol manufacturer’s symbol and

covered material or manufacturing flaw should be disclosed

specified HC

Steel, copper speci- manufacturer’s symbol manufacturer’s symbol and that interferes with the test or the interpretation of results, the

fied and CU HC and CU

substitution of another sample spike shall be permitted after it

is demonstrated to the satisfaction of the purchaser or his

representative,thattheconditionisnottypicaloftheremainder

5. Chemical or Alternative Tension Test Requirements

of the lot

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.