ASTM E646-07e1

(Test Method)Standard Test Method for Tensile Strain-Hardening Exponents (n -Values) of Metallic Sheet Materials

Standard Test Method for Tensile Strain-Hardening Exponents (<emph type="bdit">n</emph > -Values) of Metallic Sheet Materials

SIGNIFICANCE AND USE

5.1 This test method is useful for estimating the strain at the onset of necking in a uniaxial tension test (1). Practically, it provides an empirical parameter for appraising the relative stretch formability of similar metallic systems. The strain-hardening exponent is also a measure of the increase in strength of a material due to plastic deformation.

5.2 The strain-hardening exponent may be determined over the entire plastic stress-strain curve or any portion(s) of the stress-strain curve specified in a product specification.Note 3—The strain interval 10–20% is commonly utilized for determining the n-value of formable low carbon steel products.

5.3 This test method is not intended to apply to any portion of the true-stress versus true-strain curve that exhibits discontinuous behavior; however, the method may be applied by curve-smoothing techniques as agreed upon.Note 4—For example, those portions of the stress-strain curves for mild steel or aluminum alloys which exhibit yield-point elongation or Lüders bands may be characterized as behaving discontinuously.Note 5—Caution should be observed in the use of curve-smoothing techniques as they may affect the n-value.

5.4 This test method is suitable for determining the tensile stress-strain response of metallic sheet materials in the plastic region prior to the onset of necking.

5.5 The n-value may vary with the displacement rate or strain rate used, depending on the metal and test temperature.

SCOPE

1.1 This test method covers the determination of a strain-hardening exponent by tension testing of metallic sheet materials for which plastic-flow behavior obeys the power curve given in the Introduction. Note 1—A single power curve may not fit the entire stress-strain curve between yield and necking. If such is the case, more than one value of the strain-hardening exponent can be obtained (2).

1.2 This test method is for metallic sheet materials with thicknesses of at least 0.005 in. (0.13 mm) but not greater than 0.25 in. (6.4 mm).

1.3 The values stated in inch-pound units are to be regarded as the standard. The SI equivalents shown may be approximate.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: E646 − 07

StandardTest Method for

Tensile Strain-Hardening Exponents (n -Values) of Metallic

1

Sheet Materials

This standard is issued under the fixed designation E646; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—The equation in 10.3 was editorially corrected in January 2014.

INTRODUCTION

This test method for determining tensile strain-hardening exponents n utilizes stress-stain data

obtained in a uniaxial tension test. Tensile data are obtained in a continuous and rate-controlled

manner via displacement or strain control. The strain-hardening exponents are determined from an

empirical representation over the range of interest of the true-stress versus true-strain curve. The

2

mathematical representation used in this method is a power curve (Note 1) of the form (1) :

n

σ = Kε

where:

σ = true stress,

ε = true plastic strain,

K = strength coefficient, and

n = strain-hardening exponent

1. Scope 2. Referenced Documents

3

2.1 ASTM Standards:

1.1 This test method covers the determination of a strain-

E4 Practices for Force Verification of Testing Machines

hardening exponent by tension testing of metallic sheet mate-

E6 Terminology Relating to Methods of Mechanical Testing

rials for which plastic-flow behavior obeys the power curve

E8 Test Methods for Tension Testing of Metallic Materials

given in the Introduction.

E29 Practice for Using Significant Digits in Test Data to

NOTE 1—Asingle power curve may not fit the entire stress-strain curve

between yield and necking. If such is the case, more than one value of the Determine Conformance with Specifications

strain-hardening exponent can be obtained (2).

E83 Practice for Verification and Classification of Exten-

someter Systems

1.2 This test method is for metallic sheet materials with

E177 Practice for Use of the Terms Precision and Bias in

thicknesses of at least 0.005 in. (0.13 mm) but not greater than

ASTM Test Methods

0.25 in. (6.4 mm).

E691 Practice for Conducting an Interlaboratory Study to

1.3 The values stated in inch-pound units are to be regarded

Determine the Precision of a Test Method

asthestandard.TheSIequivalentsshownmaybeapproximate.

3. Terminology

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 3.1 Definitions:

3.1.1 ThedefinitionsoftermsgiveninTerminologyE6shall

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- apply, with the addition of the following special terms used in

bility of regulatory limitations prior to use. this method.

3.1.2 engineering strain (e)—a dimensionless value that is

the change in length (∆L) per unit length of original linear

dimension (L ) along the loading axis of the specimen; that is,

1 0

This test method is under the jurisdiction of ASTM Committee E28 on

e=(∆L)⁄L .

Mechanical Testing and is the direct responsibility of Subcommittee E28.02 on 0

Ductility and Formability.

Current edition approved . Published December 2007. Originally approved in

3

1978. Last previous edition approved in 2000 as E646 - 00. DOI: 10.1520/E0646- For referenced ASTM standards, visit the ASTM website, www.astm.org, or

07E01. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

The boldface numbers in parentheses refer to the list of references appended to Standards volume information, refer to the standard’s Document Summary page on

this method. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

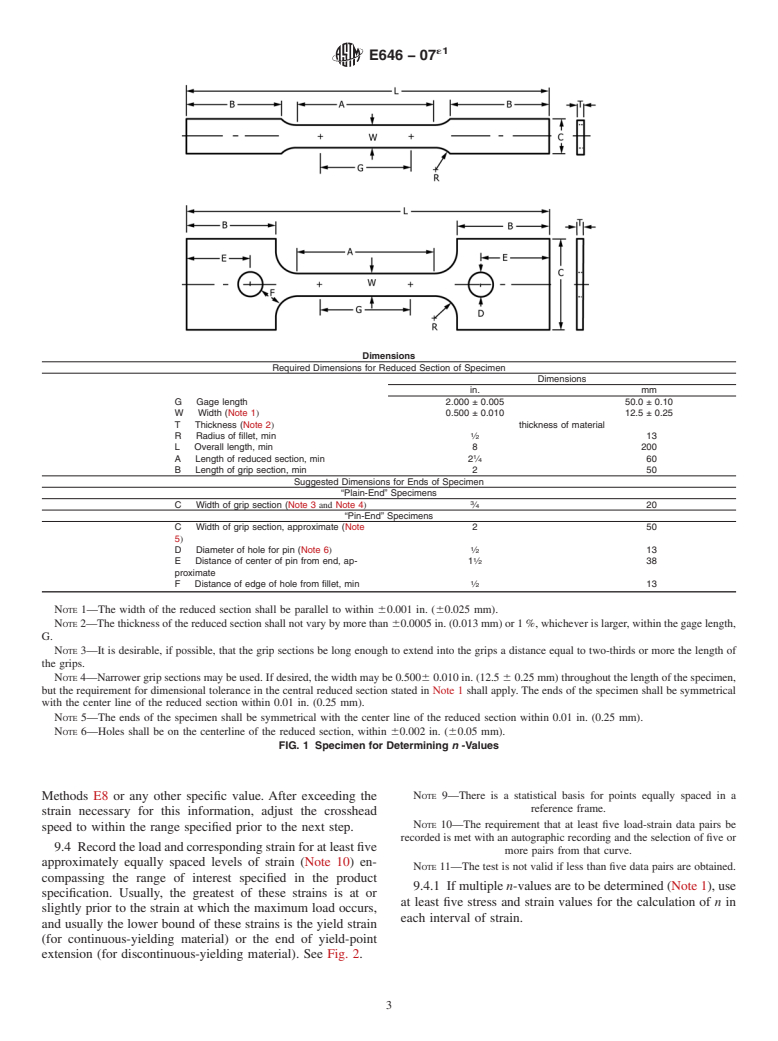

---------------------- Page: 1 ----------------------

´1

E646 − 07

−2

3.1.3 engineering stress (S) [FL ]—the normal stress, ex- 5.4 This test method is suitable for determining the tensile

pressed in units of applied force, F, per unit of original stress-strain response of metallic sheet materials in the plastic

cross-sectional area, A ; that is,S=F⁄A . region prior to the onset of necking.

0 0

3.1.4 necking—the onset of nonuniform or localized plastic

5.5 The n-value may vary with the displacement rate or

deformation, resulting in a localized reduction of cross-

strain rate used, depending on the metal and test temperature.

sectional area.

6. Apparatus

3.1.5 strain-hardening (n)—an increase in hardness and

6.1 Testing Machines—Machines used for tension testing

strength caused by plastic deformation.

−2 shall conform to the requirements of Practices E4. The loads

3.1.6 strength coeffıcient (K) [FL ]—an experimental

usedtodeterminestressshallbewithintheloadingrangeofthe

con

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.