ASTM D2843-99(2004)

(Test Method)Standard Test Method for Density of Smoke from the Burning or Decomposition of Plastics

Standard Test Method for Density of Smoke from the Burning or Decomposition of Plastics

SCOPE

1.1 This fire-test-response test method covers a laboratory procedure for measuring and observing the relative amounts of smoke obscuration produced by the burning or decomposition of plastics. It is intended to be used for measuring the smoke-producing characteristics of plastics under controlled conditions of combustion or decomposition. Correlation with other fire conditions is not implied. The measurements are made in terms of the loss of light transmission through a collected volume of smoke produced under controlled, standardized conditions. The apparatus is constructed so that the flame and smoke can be observed during the test.

1.2 Caution-During the course of combustion, gases or vapors, or both, are evolved that may be hazardous to personnel. Adequate precautions should be taken to protect the operator.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information purposes only.

1.4 This standard should be used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled laboratory conditions and should not be used to describe or appraise the fire-hazard or fire-risk of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire-hazard assessment or a fire risk assessment which takes into account all of the factors which are pertinent to an assessment of the fire hazard or fire-risk of a particular end use.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 1.2 and Note 7. Note 1-There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2843–99 (Reapproved 2004)

Standard Test Method for

Density of Smoke from the Burning or Decomposition of

Plastics

This standard is issued under the fixed designation D 2843; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* bility of regulatory limitations prior to use. Specific warning

statements are given in 1.2 and 9.11.

1.1 This fire-test-response test method covers a laboratory

procedure for measuring and observing the relative amounts of

NOTE 1—There is no similar or equivalent ISO standard.

smoke obscuration produced by the burning or decomposition

2. Referenced Documents

of plastics. It is intended to be used for measuring the

smoke-producing characteristics of plastics under controlled

2.1 ASTM Standards:

conditions of combustion or decomposition. Correlation with

D 618 Practice for Conditioning Plastics for Testing

other fire conditions is not implied. The measurements are

D 883 Terminology Relating to Plastics

made in terms of the loss of light transmission through a

D 1600 Terminology for Abbreviated Terms Relating to

collected volume of smoke produced under controlled, stan-

Plastics

dardized conditions. The apparatus is constructed so that the

E 84 Test Method for Surface Burning Characteristics of

flame and smoke can be observed during the test.

Building Materials

1.2 Warning—During the course of combustion, gases or

E 176 Terminology for Fire Standards

vapors, or both, are evolved that may be hazardous to person-

E 662 Test Method for Specific Optical Density of Smoke

nel. Adequate precautions should be taken to protect the

Generated by Solid Materials

operator.

E 691 Practice for Conducting an Interlaboratory Study to

1.3 The values stated in SI units are to be regarded as the

Determine the Precision of a Test Method

standard. The values given in brackets are for information

E 906 Test Method for Heat and Visible Smoke Release

purposes only.

Rates for Materials and Products

1.4 This standard should be used to measure and describe

E 1354 Test Method for Heat and Visible Smoke Release

the response of materials, products, or assemblies to heat and

Rates for Materials and Products Using an Oxygen Con-

flame under controlled laboratory conditions and should not be

sumption Colorimeter

used to describe or appraise the fire-hazard or fire-risk of

3. Terminology

materials, products, or assemblies under actual fire conditions.

However, results of this test may be used as elements of a

3.1 Definitions—Theterminologyusedinthistestmethodis

fire-hazard assessment or a fire risk assessment which takes in accordance with Terminologies D 883 and D 1600 (terms

into account all of the factors which are pertinent to an

relating to plastics) and Terminology E 176 (terms relating to

assessment of the fire hazard or fire-risk of a particular end fire).

use.

4. Summary of Test Method

1.5 This standard does not purport to address all of the

safety problems, if any, associated with its use. It is the 4.1 Thetestspecimenisexposedtoflameforthedurationof

responsibility of the user of this standard to establish appro- the test, and the smoke is substantially trapped in the chamber

priate safety and health practices and determine the applica- in which combustion occurs. A 25 by 25 by 6-mm [1 by 1 by

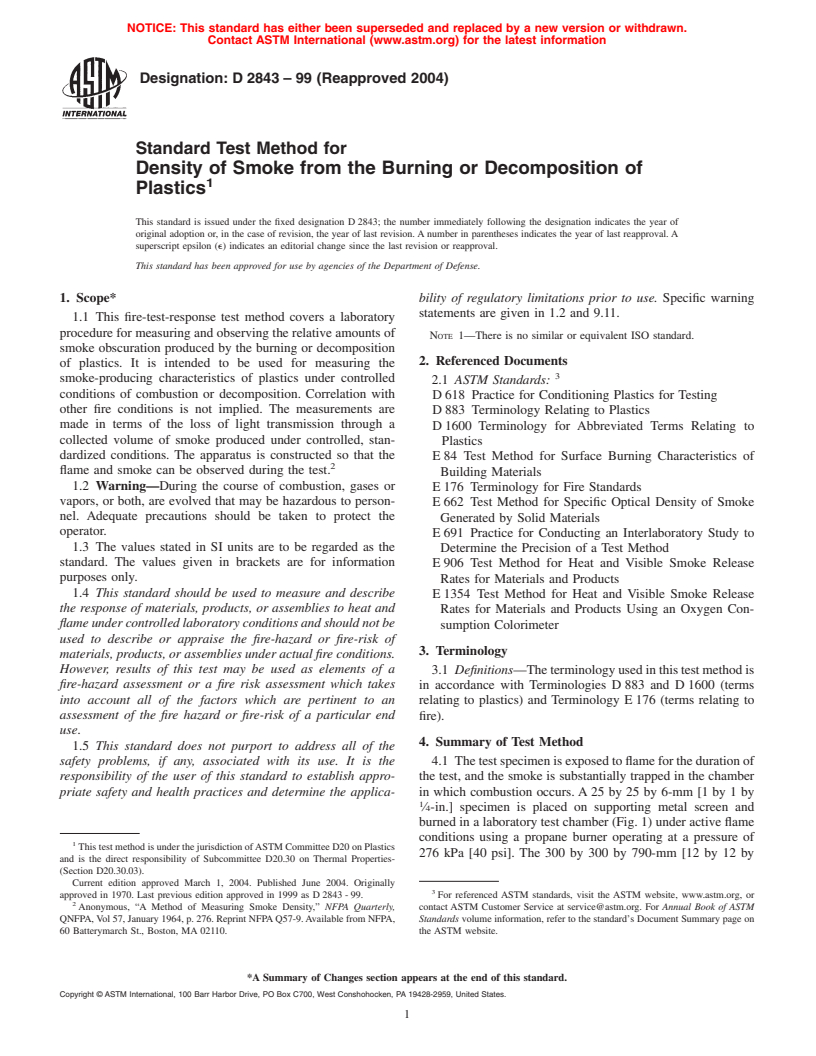

⁄4-in.] specimen is placed on supporting metal screen and

burned in a laboratory test chamber (Fig. 1) under active flame

conditions using a propane burner operating at a pressure of

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

276 kPa [40 psi]. The 300 by 300 by 790-mm [12 by 12 by

and is the direct responsibility of Subcommittee D20.30 on Thermal Properties-

(Section D20.30.03).

Current edition approved March 1, 2004. Published June 2004. Originally

approved in 1970. Last previous edition approved in 1999 as D 2843 - 99. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Anonymous, “A Method of Measuring Smoke Density,” NFPA Quarterly, contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

QNFPA, Vol 57, January 1964, p. 276. Reprint NFPAQ57-9.Available from NFPA, Standards volume information, refer to the standard’s Document Summary page on

60 Batterymarch St., Boston, MA 02110. the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D2843–99 (2004)

1. Specimen Holder

A Stainless steel screen

B Asbestos sheet

C Adjusting knob

D Quench pan

2. Ignition

A Burner 4. Photometer

B Propane tank A Visual system (exit sign)

C Gas shut-off valve B Measuring system

D Pressure regulator adjustment 1 Light source and adjusting transformer

E Pressure indicator 2 Photronic cell and grid (to block stray light)

F Burner-positioning knob 3 Meter (indicating percent of light absorbed)

3. Cabinet (shown without door) 4 Temperature compensation

A Hinges (door gasketed three sides) 5 Photocell temperature monitor

B Vents (25-mm [1-in.] high opening four sides) 6 Range change

C Blower (damper on mounting side) 5. Timer

D Control (blower on when damper is open) A Indicator, 0 to 5 min (friction reset)

FIG. 1 Schematic Diagram of Smoke Chamber

D2843–99 (2004)

31-in.] test chamber is instrumented with a light source, 6. Apparatus

photoelectric cell, and meter to measure light absorption

6.1 The smoke chamber shall be constructed essentially as

horizontally across the 300-mm [12-in.] light beam path. The 5

shown in Fig. 1.

chamber is closed during the 4-min test period except for the

6.1.1 Chamber:

25-m [1-in.] high ventilation openings around the bottom.

6.1.1.1 The chamber shall consist of a 14-gage (B & S) 300

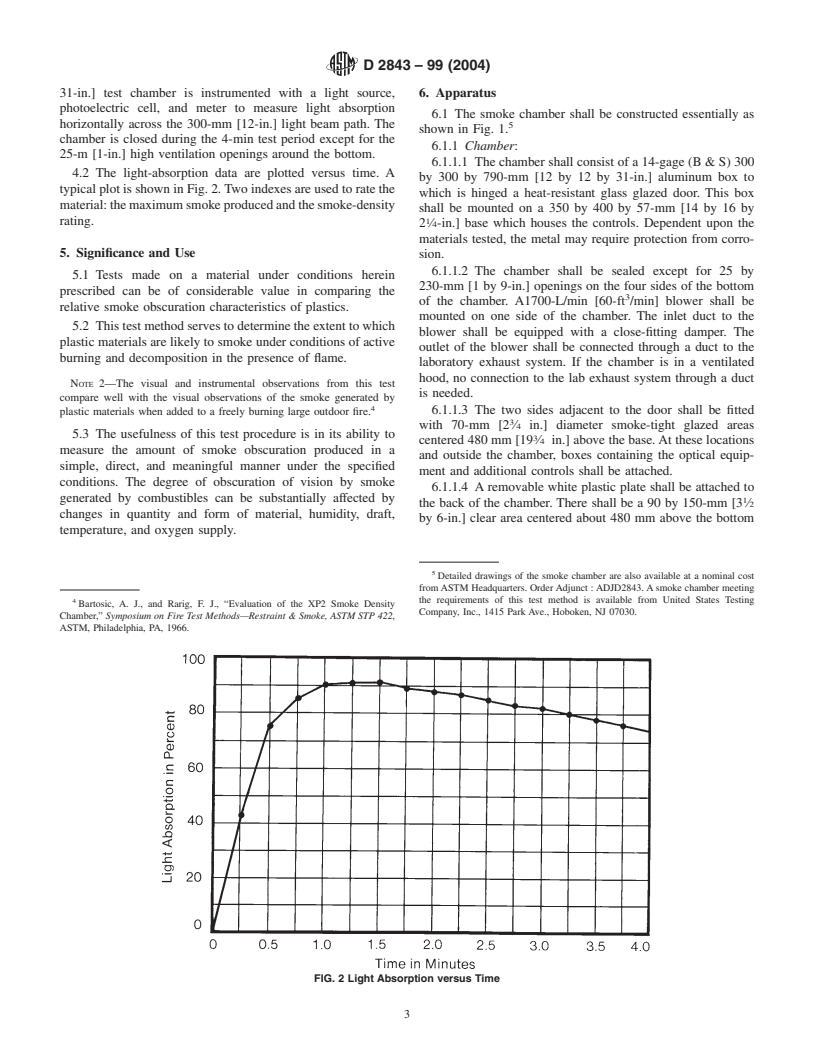

4.2 The light-absorption data are plotted versus time. A

by 300 by 790-mm [12 by 12 by 31-in.] aluminum box to

typical plot is shown in Fig. 2.Two indexes are used to rate the

which is hinged a heat-resistant glass glazed door. This box

material:themaximumsmokeproducedandthesmoke-density

shall be mounted on a 350 by 400 by 57-mm [14 by 16 by

rating.

2 ⁄4-in.] base which houses the controls. Dependent upon the

materials tested, the metal may require protection from corro-

5. Significance and Use

sion.

6.1.1.2 The chamber shall be sealed except for 25 by

5.1 Tests made on a material under conditions herein

230-mm [1 by 9-in.] openings on the four sides of the bottom

prescribed can be of considerable value in comparing the

of the chamber. A1700-L/min [60-ft /min] blower shall be

relative smoke obscuration characteristics of plastics.

mounted on one side of the chamber. The inlet duct to the

5.2 This test method serves to determine the extent to which

blower shall be equipped with a close-fitting damper. The

plastic materials are likely to smoke under conditions of active

outlet of the blower shall be connected through a duct to the

burning and decomposition in the presence of flame.

laboratory exhaust system. If the chamber is in a ventilated

hood, no connection to the lab exhaust system through a duct

NOTE 2—The visual and instrumental observations from this test

is needed.

compare well with the visual observations of the smoke generated by

6.1.1.3 The two sides adjacent to the door shall be fitted

plastic materials when added to a freely burning large outdoor fire.

with 70-mm [2 ⁄4 in.] diameter smoke-tight glazed areas

5.3 The usefulness of this test procedure is in its ability to

centered 480 mm [19 ⁄4 in.] above the base.At these locations

measure the amount of smoke obscuration produced in a

and outside the chamber, boxes containing the optical equip-

simple, direct, and meaningful manner under the specified

ment and additional controls shall be attached.

conditions. The degree of obscuration of vision by smoke

6.1.1.4 A removable white plastic plate shall be attached to

generated by combustibles can be substantially affected by

the back of the chamber. There shall be a 90 by 150-mm [3 ⁄2

changes in quantity and form of material, humidity, draft,

by 6-in.] clear area centered about 480 mm above the bottom

temperature, and oxygen supply.

Detailed drawings of the smoke chamber are also available at a nominal cost

from ASTM Headquarters. Order Adjunct : ADJD2843. A smoke chamber meeting

4 the requirements of this test method is available from United States Testing

Bartosic, A. J., and Rarig, F. J., “Evaluation of the XP2 Smoke Density

Company, Inc., 1415 Park Ave., Hoboken, NJ 07030.

Chamber,” Symposium on Fire Test Methods—Restraint & Smoke, ASTM STP 422,

ASTM, Philadelphia, PA, 1966.

FIG. 2 Light Absorption versus Time

D2843–99 (2004)

NOTE 4—Since the orifice provides the metering effect proportionate to

of the chamber through which is seen an illuminated white-

the supply pressure, care must be taken that the orifice is the only means

on-red exit sign. The white background permits observation of

of fuel egress.

the flame, smoke, and burning characteristics of the material.

The viewing of the exit sign helps to correlate visibility and

6.1.3.2 The burner shall be capable of being positioned

measured values.

quickly under the specimen so that the axis of the burner falls

6.1.2 Specimen Holder: 3

onalinepassingthroughapoint8mm[ ⁄10 in.]abovethebase

6.1.2.1 The specimen shall be supported on a 64-mm

at one back corner of the chamber extending diagonally across

1 1 1

[2 ⁄2-in.] square of 6 by 6-mm, 0.9-mm gage [ ⁄4 by ⁄4-in.,

the chamber and sloping upward at 45 deg with the base. The

0.035-in. gage] stainless steel wire cloth 220 mm [8 ⁄4 in.]

exit opening of the burner shall be 260 mm [10 ⁄4 in.] from the

above the base and equidistant from all sides of the chamber.

reference point at the rear of the chamber.

Thisscreenshalllieinastainlesssteelbezelsupportedbyarod

6.1.3.3 Aductatleast150mm[6in.]outsideofthechamber

through the right side of the chamber. From the same rod, a

shall provide the air piped to the burner.

similar bezel shall be located 76 mm [3 in.] below, and it shall

6.1.3.4 Propane pressure shall be adjustable and preferably

support a square of asbestos paper which catches any particles

automatically regulated. Propane pressure shall be indicated by

thatmaydripfromthespecimenduringthetest.Byrotatingthe

means of a Bourdon tube gage.

specimen holder rod, the burning specimen can be quenched in

6.1.4 Photometric System:

a shallow pan of water positioned below the specimen holder.

6.1.3 Ignition System:

6.1.4.1 Alight source, a barrier-layer photoelectric cell, and

6.1.3.1 The specimen shall be ignited by a propane flame

a temperature compensated meter shall be used to measure the

from a burner operating at a pressure of 276 kPa [40 psi]. The

proportion of a light beam which penetrates a 300-mm [12-in.]

fuel (Note 3) shall be mixed with air which has been propelled

path through the smoke. The light path shall be arranged

through the burner by the venturi effect of the propane as it

horizontally as shown in Fig. 4.

passes from a 0.13-mm [0.0005-in.] diameter orifice (Note 4),

6.1.4.2 The light source shall be mounted in a box (4B1 in

and the burner shall be assembled as shown in the exploded

Fig. 1) extending from the left side of the chamber at the mean

view of the burner in Fig. 3. The burner must be designed to 3

height of 480 mm [19 ⁄4 in.] above the base. The light source

provide adequate outside air.

shall be a compact filament microscope lamp No. 1493

operated at 5.8Vand a spherical reflector, with power supplied

NOTE 3—Commercial grade 85.0 % minimum, gross heating value

23 000 cal/litre [2590 Btu/ft ] propane meets the requirements. by a voltage-regulating transformer. A60 to 65-mm [2 ⁄2-in.]

FIG. 3 Exploded View of Burner

D2843–99 (2004)

T = Temperature-sensitive winding in or on meter case to increase in resistance in proportion to increase in meter resistance with temperature.

R = Potentiometer with calibrated scale to reduce resistance in proportion to decrease in photocell output with rise in temperature.

C = Potentiometer to calibrate total resistance of shunt to change meter sensitivity exactly by 10:1 ratio.

FIG. 4 Smoke Density Test Chamber Photometer

focal length lens shall focus a spot of light on the photocell in 7. Test Specimen

the right instrument panel.

7.1 The standard specimen shall be 25.4 6 0.3 by 25.4 6

6.1.4.3 Another box containing the photometer (4B2 in Fig. 1

0.3 by 6.2 6 0.3 mm [1 6 0.01 by 1 6 0.01 by ⁄4 6 0.01 in.].

1) shall be attached to the right side of the chamber. The

Thicknesses other than 6.2 mm [ ⁄4 in.] may be used and their

barrier-layer photoelectric cell shall have standard observer

size must be reported with the smoke density values (Note 6).

spectral response. An egg-crate grid in front of the photocell

Material thinner than 6.2 mm [ ⁄4 in.] may be tested, either in

shall be used to protect the cell from stray light. The grid shall

its normal use thickness, or by stacking and forming a

be finished in dull black and have openings at least twice as 1

composite specimen approximately 6.2 mm [ ⁄4 in.] thick.

deep as they are wide. The current produced by the photocell 1

Material thicker than 6.2 mm [ ⁄4 in.] may be tested either in its

isindicatedintermsofpercentlightabsorptiononameter.The

normal use thickness or by machining the material down to a

photocell linearity decreases as the temperature increases; 1

thickness of 6.2 mm [ ⁄4 in.].

compensations shall therefore be made.

NOTE 6—If specimens other than the standard specimen are to be used,

NOTE 5—Photocell manufacturers recommend operating the photocell

cooperating laboratories should agree upon preparation procedures and

at temperatures not exceeding 50°C.

dimensions of the specimen. The results in such cases may vary from the

results obtained with the standard specimen.

6.1.4.4 The meter shall have two ranges. The range change

shall be accomplished by shunting the meter to one tenth of its 7.2 The specimens shall be sanded, machined, or die cut in

sensitivity. When smoke accumulates to absorb 90 percent of a manner that produces a cut surface that is free from

the light beam, a momentary switch shall be depressed return- projecting fibers, chips, and ridges.

ing the meter to its basic sensitivity. By doing this the meter 7.3 The test sample shall consist of three

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.