ASTM D6723-02

(Test Method)Standard Test Method for Determining the Fracture Properties of Asphalt Binder in Direct Tension (DT) (Withdrawn 2011)

Standard Test Method for Determining the Fracture Properties of Asphalt Binder in Direct Tension (DT) (Withdrawn 2011)

SIGNIFICANCE AND USE

Stress at failure is used in a mechanistic pavement cracking model to compute critical cracking temperature. The procedure to compute critical cracking temperature is described in Practice D 6521. The critical cracking temperature is then used in specifying the low temperature grade of asphalt binder in accordance with Specification D 6373.

The test method is designed to measure the strength of the asphalt binder at the critical cracking temperature. The asphalt binder has limited ability to resist stress without cracking. In the asphalt binder Specification D 6373, failure stress is used to determine the critical cracking temperature.

For evaluating an asphalt binder for conformance to Specification D 6373, the elongation rate of the gage section is 1.0 mm/min and the test temperature is selected from Table number 1 of Specification D 6373 according to the grade of asphalt binder. Other rates of elongation and test temperatures may be used to test asphalt binders.

SCOPE

1.1 This test method covers the determination of the failure strain and failure stress of asphalt binders by means of a direct tension test. It can be used with unaged material or with material aged using Test Method D 2872 (RTFOT), Practice D 6521 (PAV), or AASHTO T240 (RTFOT) and AASHTO PP1 (PAV). The test apparatus is designed for testing within the temperature range from +6 to -36°C.

1.2 This test method is limited to asphalt binders containing particulate material having dimensions less than 250 μm.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

Formerly under the jurisdiction of Committee D04 on Road and Paving Materials, this Test Method was withdrawn in 2011 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6723–02

Standard Test Method for

Determining the Fracture Properties of Asphalt Binder in

1

Direct Tension (DT)

This standard is issued under the fixed designation D6723; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E77 Test Method for Inspection and Verification of Ther-

mometers

1.1 This test method covers the determination of the failure

E83 Practice for Verification and Classification of Exten-

strain and failure stress of asphalt binders by means of a direct

someter Systems

tension test. It can be used with unaged material or with

E220 Test Method for Calibration of Thermocouples By

material aged using Test Method D2872 (RTFOT), Practice

Comparison Techniques

D6521(PAV),orAASHTOT 240(RTFOT)andAASHTOPP1

E691 Practice for Conducting an Interlaboratory Study to

(PAV). The test apparatus is designed for testing within the

Determine the Precision of a Test Method

temperature range from +6 to -36°C.

2.2 Deutche Industrie Norm (DIN) Standard:

1.2 This test method is limited to asphalt binders containing

3

43760 Standard for Calibrating Thermocouples

particulate material having dimensions less than 250 µm.

2.3 AASHTO Standards:

1.3 The values stated in SI units are to be regarded as the

4

T 240

standard.

4

PPI (PAV)

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Terminology

responsibility of the user of this standard to establish appro-

3.1 Definitions—For definitions of general terms used in

priate safety and health practices and determine the applica-

this standard, refer to Terminology D8.

bility of regulatory limitations prior to use.

3.2 Definitions of Terms Specific to This Standard:

2. Referenced Documents 3.2.1 brittle, adj—type of failure in a direct tension test

2

wherethestress-straincurveisessentiallylinearuptothepoint

2.1 ASTM Standards:

of failure and the failure is by sudden rupture of the test

C670 Practice for Preparing Precision and Bias Statements

specimen without appreciable reduction in cross-section of the

for Test Methods for Construction Materials

specimen.

D8 Terminology Relating to Materials for Roads and Pave-

3.2.2 brittle-ductile, adj—type of failure in a direct tension

ments

test where the stress-strain curve is curvilinear and the failure

D140 Practice for Sampling Bituminous Materials

is by sudden rupture of the test specimen. Limited reduction in

D2872 Test Method for Effect of Heat andAir on a Moving

cross-section of the specimen occurs before rupture.

Film of Asphalt (Rolling Thin-Film Oven Test)

3.2.3 ductile, adj—type of failure in a direct tension test

D6373 Specification for Performance Graded Asphalt

where the specimen does not rupture but fails by flow at large

Binder

strains.

D6521 Practice for Accelerated Aging of Asphalt Binder

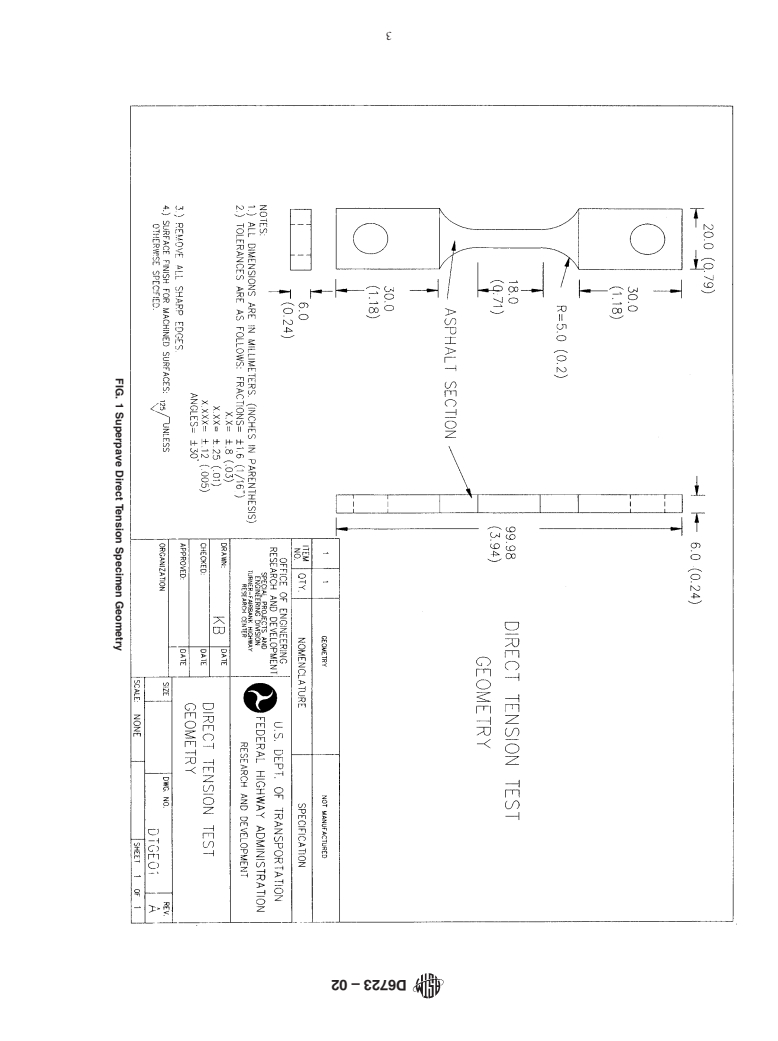

3.2.4 effective gage length, n—for specimens used in this

Using a Pressurized Aging Vessel (PAV)

test, the effective gauge length, L , has been determined to be

e

E1 Specification for ASTM Liquid-in-Glass Thermometers

33.8 mm. This is an effective gauge length that represents the

E4 Practices for Force Verification of Testing Machines

portion of the specimen that contributes to the majority of the

strain.

3.2.5 failure, n—point at which the tensile load reaches a

1

This test method is under the jurisdiction of ASTM Committee D04 on Road

maximumvalueasthetestspecimenispulledataconstantrate

and Paving Materials and is the direct responsibility of Subcommittee D04.44 on

of elongation.

Rheological Tests.

Current edition approved Jan. 10, 2002. Published March 2002. Originally

published as D6723 – 01. Last previous edition D6723 – 01. DOI: 10.1520/D6723-

02.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Deutsches Institut fur Normung e.V. (German Standards Institute), Beuth

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Verlag GmbH, Burggrafenstrasse 6, 10787, Berlin Germany.

4

Standards volume information, refer to the standard’s Document Summary page on Available from the American State Highway and Transportation Officials, 444

the ASTM website. N. Capitol Street, N.W., Washington, DC 20001.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6723–02

3.2.6 failure strain, n—the tensile strain corresponding to 6. Apparatus

the failure stress.

6.1 DirectTensionTestSystem—Adirecttensiontestsystem

3.2.7 failure stress, n—the tensile stress on the test speci-

consisting of (1)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.