ASTM A1095-15

(Specification)Standard Specification for High-Silicon Molybdenum Ferritic Iron Castings

Standard Specification for High-Silicon Molybdenum Ferritic Iron Castings

ABSTRACT

This specification covers general requirements and corresponding test methods for castings made of high-silicon molybdenum ferritic iron (SiMo). The requirements are prescribed for castings with microstructures of spheroidal graphite (SG) SiMo iron, compacted graphite (CG) SiMo iron, and mixed graphite or medium-nodularity graphite (MG) SiMo iron. MG iron microstructure is comprised of a mixture of spheroidal and compacted graphite shapes.

This specification covers: ordering information (including grade of silicon-molybdenum ferritic iron required, chemical composition requirements, microstructure and mechanical requirements, and special preparation for delivery); material, structural performance, and manufacturing practice; mechanical and chemical composition; workmanship, finish, and appearance; inspection and quality; certification; product marking; and packaging and package marking.

SCOPE

1.1 This specification covers castings made of high-silicon molybdenum ferritic iron, commonly known as SiMo. This specification includes castings with microstructures of spheroidal graphite (SG) SiMo iron, compacted graphite (CG) SiMo iron, and mixed graphite or medium-nodularity graphite (MG) SiMo iron. MG iron microstructure comprises a mixture of spheroidal and compacted graphite shapes. This standard specifies the condition, chemical composition, microstructure, and other technical requirements of three grades of ferritic cast irons, specified as SG SiMo, MG SiMo, and CG SiMo.

1.2 No precise quantitative relationship can be stated between the properties of iron in the various locations of the same casting or between the properties of castings and those of a test specimen cast from the same iron.

1.3 The values stated in SI units are to be regarded as standard. All chemical compositions are in mass percentage. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A1095 −15

Standard Specification for

1

High-Silicon Molybdenum Ferritic Iron Castings

This standard is issued under the fixed designation A1095; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope A834 Specification for Common Requirements for Iron

Castings for General Industrial Use

1.1 This specification covers castings made of high-silicon

A842 Specification for Compacted Graphite Iron Castings

molybdenum ferritic iron, commonly known as SiMo. This

A897/A897M Specification for Austempered Ductile Iron

specification includes castings with microstructures of spheroi-

Castings

dal graphite (SG) SiMo iron, compacted graphite (CG) SiMo

D1976 Test Method for Elements in Water by Inductively-

iron, and mixed graphite or medium-nodularity graphite (MG)

Coupled Argon Plasma Atomic Emission Spectroscopy

SiMo iron. MG iron microstructure comprises a mixture of

D5381 Guide for X-Ray Fluorescence (XRF) Spectroscopy

spheroidal and compacted graphite shapes. This standard

of Pigments and Extenders

specifies the condition, chemical composition, microstructure,

E8/E8M Test Methods for Tension Testing of Metallic Ma-

and other technical requirements of three grades of ferritic cast

terials

irons, specified as SG SiMo, MG SiMo, and CG SiMo.

E10 Test Method for Brinell Hardness of Metallic Materials

1.2 No precise quantitative relationship can be stated be-

E21 TestMethodsforElevatedTemperatureTensionTestsof

tweenthepropertiesofironinthevariouslocationsofthesame

Metallic Materials

casting or between the properties of castings and those of a test

E228 Test Method for Linear Thermal Expansion of Solid

specimen cast from the same iron.

Materials With a Push-Rod Dilatometer

1.3 The values stated in SI units are to be regarded as E351 Test Methods for ChemicalAnalysis of Cast Iron—All

Types

standard. All chemical compositions are in mass percentage.

No other units of measurement are included in this standard. E1184 Practice for Determination of Elements by Graphite

Furnace Atomic Absorption Spectrometry

1.4 This standard does not purport to address all of the

E1999 Test Method for Analysis of Cast Iron by Spark

safety concerns, if any, associated with its use. It is the

Atomic Emission Spectrometry

responsibility of the user of this standard to establish appro-

2.2 SAE (Society of Automotive Engineers) International

priate safety and health practices and determine the applica-

Standards:

bility of regulatory limitations prior to use.

J434 Automotive Ductile (Nodular) Iron Castings

J1887 Automotive Compacted Graphite Iron Castings

2. Referenced Documents

J2582 Automotive Ductile Iron Castings for High Tempera-

2

2.1 ASTM Standards:

ture Applications

A247 Test Method for Evaluating the Microstructure of

2.3 Federal Standard:

Graphite in Iron Castings

FED-STD-123 Marking for Shipment (Civil Agencies)

A395 Specification for Ferritic Ductile Iron Pressure-

2.4 American National Standard:

Retaining Castings for Use at Elevated Temperatures

MIL-STD-129 Military Marking for Shipment and Storage

A476/A476M Specification for Ductile Iron Castings for

2.5 Other Publications:

Paper Mill Dryer Rolls

AFS (American Foundry Society), Foundrymen’s Guide to

A536 Specification for Ductile Iron Castings

Ductile Iron Microstructures, 1984

AFS, Iron Castings Engineering Handbook, 2004

ASM Specialty Handbook, Cast Irons, 1999

1

This test method is under the jurisdiction of ASTM Committee A04 on Iron

ASM Specialty Handbook, Heat-Resistant Materials, 1999

Castings and is the direct responsibility of Subcommittee A04.02 on Malleable and

ASM Handbook, Casting, Volume 15, 1998

Ductile Iron Castings.

Current edition approved Nov. 1, 2015. Published December 2015. DOI:

3. Ordering Information

10.1520/A1095-15

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.1 Orders for materials to this specification shall include

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

the following information:

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 3.1.1 ASTM designation and year of issue,

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A1095−15

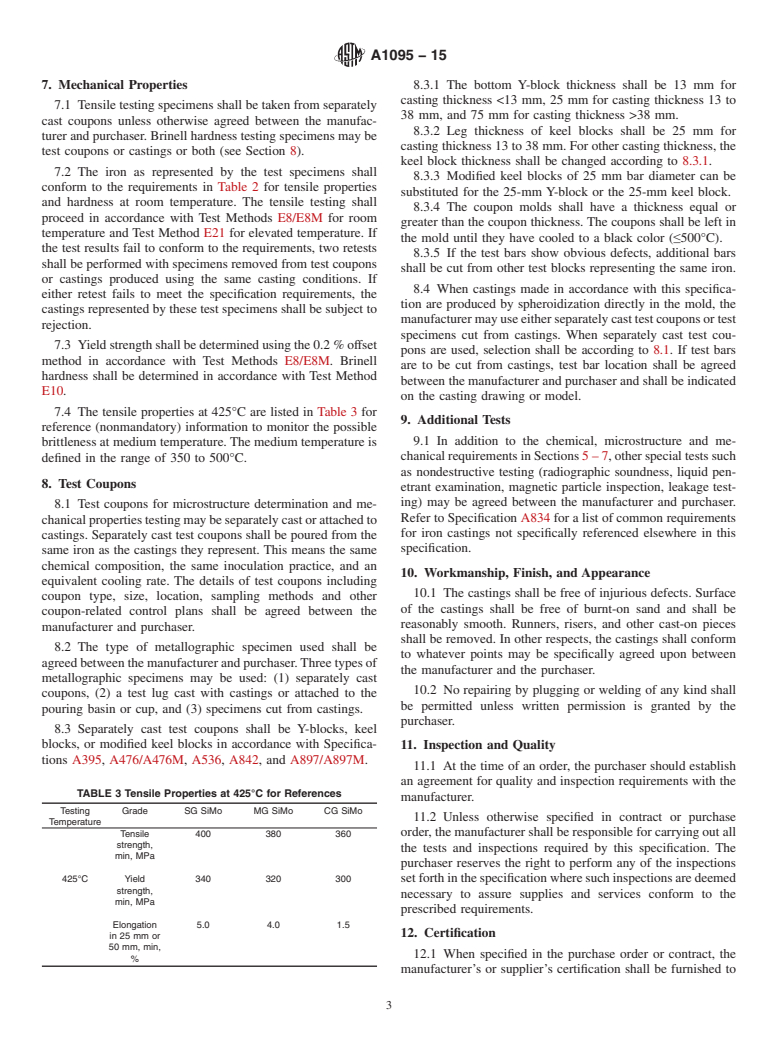

TABLE 2 Tensile and Hardness Requirements

3.1.2 Grade of silicon-molybdenum ferritic iron required,

3.1.3 Chemical composition requirements (see Section 5), Testing Grade SG SiMo MG SiMo CG SiMo

Temperature

3.1.4 Microstructure and mechanical requirements (see Sec-

Tensile 500 450 400

tion

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.