ASTM A1095-15(2019)

(Specification)Standard Specification for High-Silicon Molybdenum Ferritic Iron Castings

Standard Specification for High-Silicon Molybdenum Ferritic Iron Castings

ABSTRACT

This specification covers general requirements and corresponding test methods for castings made of high-silicon molybdenum ferritic iron (SiMo). The requirements are prescribed for castings with microstructures of spheroidal graphite (SG) SiMo iron, compacted graphite (CG) SiMo iron, and mixed graphite or medium-nodularity graphite (MG) SiMo iron. MG iron microstructure is comprised of a mixture of spheroidal and compacted graphite shapes.

This specification covers: ordering information (including grade of silicon-molybdenum ferritic iron required, chemical composition requirements, microstructure and mechanical requirements, and special preparation for delivery); material, structural performance, and manufacturing practice; mechanical and chemical composition; workmanship, finish, and appearance; inspection and quality; certification; product marking; and packaging and package marking.

SCOPE

1.1 This specification covers castings made of high-silicon molybdenum ferritic iron, commonly known as SiMo. This specification includes castings with microstructures of spheroidal graphite (SG) SiMo iron, compacted graphite (CG) SiMo iron, and mixed graphite or medium-nodularity graphite (MG) SiMo iron. MG iron microstructure comprises a mixture of spheroidal and compacted graphite shapes. This standard specifies the condition, chemical composition, microstructure, and other technical requirements of three grades of ferritic cast irons, specified as SG SiMo, MG SiMo, and CG SiMo.

1.2 No precise quantitative relationship can be stated between the properties of iron in the various locations of the same casting or between the properties of castings and those of a test specimen cast from the same iron.

1.3 The values stated in SI units are to be regarded as standard. All chemical compositions are in mass percentage. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:A1095 −15 (Reapproved 2019)

Standard Specification for

High-Silicon Molybdenum Ferritic Iron Castings

This standard is issued under the fixed designation A1095; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Graphite in Iron Castings

A395/A395M Specification for Ferritic Ductile Iron

1.1 This specification covers castings made of high-silicon

Pressure-Retaining Castings for Use at ElevatedTempera-

molybdenum ferritic iron, commonly known as SiMo. This

tures

specification includes castings with microstructures of spheroi-

A476/A476M Specification for Ductile Iron Castings for

dal graphite (SG) SiMo iron, compacted graphite (CG) SiMo

Paper Mill Dryer Rolls

iron, and mixed graphite or medium-nodularity graphite (MG)

A536 Specification for Ductile Iron Castings

SiMo iron. MG iron microstructure comprises a mixture of

A834 Specification for Common Requirements for Iron

spheroidal and compacted graphite shapes. This standard

Castings for General Industrial Use

specifies the condition, chemical composition, microstructure,

A842 Specification for Compacted Graphite Iron Castings

and other technical requirements of three grades of ferritic cast

A897/A897M Specification for Austempered Ductile Iron

irons, specified as SG SiMo, MG SiMo, and CG SiMo.

Castings

1.2 No precise quantitative relationship can be stated be-

D1976 Test Method for Elements in Water by Inductively-

tweenthepropertiesofironinthevariouslocationsofthesame

Coupled Plasma Atomic Emission Spectroscopy

casting or between the properties of castings and those of a test

D5381 Guide for X-Ray Fluorescence (XRF) Spectroscopy

specimen cast from the same iron.

of Pigments and Extenders

1.3 The values stated in SI units are to be regarded as E8/E8M Test Methods for Tension Testing of Metallic Ma-

terials

standard. All chemical compositions are in mass percentage.

No other units of measurement are included in this standard. E10 Test Method for Brinell Hardness of Metallic Materials

E21 TestMethodsforElevatedTemperatureTensionTestsof

1.4 This standard does not purport to address all of the

Metallic Materials

safety concerns, if any, associated with its use. It is the

E228 Test Method for Linear Thermal Expansion of Solid

responsibility of the user of this standard to establish appro-

Materials With a Push-Rod Dilatometer

priate safety, health, and environmental practices and deter-

E351 Test Methods for ChemicalAnalysis of Cast Iron—All

mine the applicability of regulatory limitations prior to use.

Types

1.5 This international standard was developed in accor-

E1184 Practice for Determination of Elements by Graphite

dance with internationally recognized principles on standard-

Furnace Atomic Absorption Spectrometry

ization established in the Decision on Principles for the

E1999 Test Method for Analysis of Cast Iron by Spark

Development of International Standards, Guides and Recom-

Atomic Emission Spectrometry

mendations issued by the World Trade Organization Technical

2.2 SAE (Society of Automotive Engineers) International

Barriers to Trade (TBT) Committee.

Standards:

2. Referenced Documents J434 Automotive Ductile (Nodular) Iron Castings

J1887 Automotive Compacted Graphite Iron Castings

2.1 ASTM Standards:

J2582 Automotive Ductile Iron Castings for High Tempera-

A247 Test Method for Evaluating the Microstructure of

ture Applications

2.3 Federal Standard:

FED-STD-123 Marking for Shipment (Civil Agencies)

This specification is under the jurisdiction of ASTM Committee A04 on Iron

Castings and is the direct responsibility of Subcommittee A04.02 on Malleable and

2.4 American National Standard:

Ductile Iron Castings.

MIL-STD-129 Military Marking for Shipment and Storage

Current edition approved Nov. 1, 2019. Published November 2019. Originally

2.5 Other Publications:

approved in 2015. Last previous edition approved in 2015 as A1095 – 15. DOI:

10.1520/A1095-15R19.

AFS (American Foundry Society), Foundrymen’s Guide to

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Ductile Iron Microstructures, 1984

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

AFS, Iron Castings Engineering Handbook, 2004

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. ASM Specialty Handbook, Cast Irons, 1999

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A1095−15 (2019)

ASM Specialty Handbook, Heat-Resistant Materials, 1999 5.3 Controlling the carbon equivalent is important to

ASM Handbook, Casting, Volume 15, 1998 achieve uniform graphite distribution and to minimize solidi-

ficationshrinkageandgraphiteflotation.Thecarbonequivalent

3. Ordering Information

control range shall be established by the manufacturer to

produce castings that meet the chemical composition ranges in

3.1 Orders for materials to this specification shall include

Table 1, the microstructure requirements in Section 6, and the

the following information:

mechanical properties in Table 2.

3.1.1 ASTM designation and year of issue,

3.1.2 Grade of silicon-molybdenum ferritic iron required,

5.4 Chromium can improve heat resistance of SiMo iron

3.1.3 Chemical composition requirements (see Section 5),

castings. Annealing heat treatments should be utilized if Cr

3.1.4 Microstructure and mechanical requirements (see Sec-

content exceeds 0.10 %.

tions 6 and 7),

5.5 The total concentrations of alloy elements including

3.1.5 Drawing and test coupon criteria (see Section 8),

Mo, Mn, Ni, Cu, W, V, Nb, and Cr shall not exceed 2.5 %.

3.1.6 Special requirements, if desired (see Sections9–11),

5.6 The lower limit of phosphorus for SG SiMo iron is

3.1.7 Certification, if so designated by purchaser (see Sec-

specified to eliminate the brittleness at medium temperature of

tion 12), and

approximately 425 °C.

3.1.8 Special preparation for delivery, if required (see Sec-

tion 14).

6. Microstructure

4. Materials and Manufacture

6.1 The matrix requirements for the three grades of SiMo

irons are the same: predominantly ferritic, a maximum 5 %

4.1 The manufacturer shall produce high-silicon molybde-

primary carbides, and adjacent to the cell boundaries, a

num iron castings with a microstructure consisting of a

maximum 30 % Mo-rich precipitates.

predominantly ferritic matrix in the as-cast condition. Small

amounts of flake graphite in the surface reaction zone are

6.2 All the three grades of SiMo iron castings for which

allowed only when agreed between the manufacturer and

chemical composition is specified in Table 1 shall be substan-

purchaser.

tially free of flake, exploded, chunky, crab, spiky, and floata-

tiongraphite.Flakegraphiteispermittedinthesurfacereaction

4.2 High-silicon ferritic SiMo iron castings are typically

zonetoamaximumdepthof0.30mmforsections≤10mmand

supplied in the as-cast condition. If heat treatment is agreed

to a maximum depth of 0.60 mm for sections >10 mm.

between the manufacturer and purchaser, castings can be either

fully or subcritically annealed. The recommended heat treat-

6.3 For SG SiMo iron, the graphite in the microstructure

ment practice is provided in Appendix X3.

shall consist of a minimum 80 % Type I and Type II graphite

according to Test Method A247.

5. Chemical Composition

6.4 For CG SiMo iron, the graphite in the microstructure

5.1 Chemical requirements for each grade are specified in

shall consist of a minimum 60 % Type IV graphite; the

Table 1. Chemical composition shall be determined from

remaining graphite shall be a combined maximum 40 % Type

chilled disk samples or samples representative of the castings

I, Type II, and Type III graphite according to Test Method

and in accordance with the applicable sections ofTest Methods

A247 and Specification A842.

D1976, E351, and E1999, Practice E1184, and Guide D5381.

6.5 For MG SiMo iron, the graphite in the microstructure

5.2 When agreed between the manufacturer and purchaser,

shallconsistofaminimum40%ofTypeIandTypeIIgraphite

chemistry control ranges may be tighter than those specified in

accordingtoTestMethodA247andarangeof30to60%Type

Table 1.

IV graphite according to Test Method A247 and Specification

A842.

TABLE 1 Chemical Composition Requirements

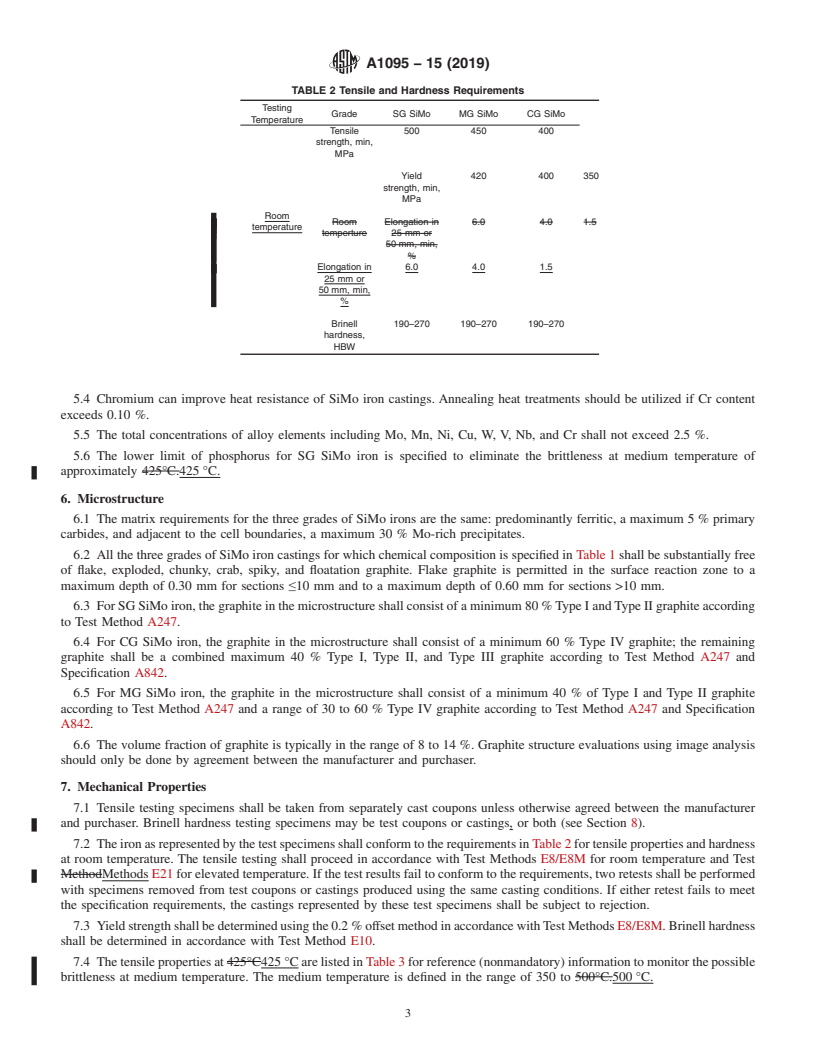

TABLE 2 Tensile and Hardness Requirements

Type

SG SiMo MG SiMo CG SiMo

Testing

Grade SG SiMo MG SiMo CG SiMo

Element Composition (mass %)

Temperature

Carbon 2.90–3.70 2.80–3.60 2.70–3.50 Tensile 500 450 400

Silicon 3.50–4.80 3.50–4.80 3.50–4.80

strength, min,

Molybdenum 0.40–1.50 0.40–1.50 0.40–1.50 MPa

Titanium 0.05 max 0.10 max 0.25 max

Magnesium 0.06 max 0.05 max 0.04 max Yield strength, 420 400 350

Manganese 0.50 max 0.50 max 0.50 max

min, MPa

Nickel 0.50 max 0.50 max 0.50 max

Room

Copper 0.30 max 0.30 max 0.30 max

Elongation in 6.0 4.0 1.5

temperature

Tungsten 0.30 max 0.30 max 0.30 max 25 mm or

Vanadium 0.10 max 0.10 max 0.10 max 50 mm, min,

Niobium 0.30 max 0.30 max 0.30 max %

Chromium 0.50 max 0.50 max 0.50 max

Phosphorus 0.02–0.05 0.05 max 0.05 max Brinell 190–270 190–270 190–270

Sulfur 0.02 max 0.02 max 0.02 max hardness,

Iron balance balance balance HBW

A1095−15 (2019)

6.6 The volume fraction of graphite is typically in the range 8.3 Separately cast test coupons shall be Y-blocks, keel

of 8 to 14 %. Graphite structure evaluations using image blocks, or modified keel blocks in accordance with Specifica-

analysis should only be done by agreement between the tions A395/A395M, A476/A476M, A536, A842, and A897/

manufacturer and purchaser. A897M.

8.3.1 The bottom Y-block thickness shall be 13 mm for

7. Mechanical Properties

casting thickness <13 mm, 25 mm for casting thickness 13 to

38 mm, and 75 mm for casting thickness >38 mm.

7.1 Tensile testing specimens shall be taken from separately

8.3.2 Leg thickness of keel blocks shall be 25 mm for

cast coupons unless otherwise agreed between the manufac-

casting thickness 13 to 38 mm. For other casting thickness, the

turer and purchaser. Brinell hardness testing specimens may be

keel block thickness shall be changed according to 8.3.1.

test coupons or castings, or both (see Section 8).

8.3.3 Modified keel blocks of 25 mm bar diameter can be

7.2 The iron as represented by the test specimens shall

substituted for the 25-mm Y-block or the 25-mm keel block.

conform to the requirements in Table 2 for tensile properties

8.3.4 The coupon molds shall have a thickness equal or

and hardness at room temperature. The tensile testing shall

greater than the coupon thickness. The coupons shall be left in

proceed in accordance with Test Methods E8/E8M for room

the mold until they have cooled to a black color (≤500 °C).

temperature andTest Methods E21 for elevated temperature. If

8.3.5 If the test bars show obvious defects, additional bars

the test results fail to conform to the requirements, two retests

shall be cut from other test blocks representing the same iron.

shall be performed with specimens removed from test coupons

8.4 When castings made in accordance with this specifica-

or castings produced using the same casting conditions. If

tion are produced by spheroidization directly in the mold, the

either retest fails to meet the specification requirements, the

manufacturermayuseeitherseparatelycasttestcouponsortest

castings represented by these test specimens shall be subject to

specimens cut from castings. When separately cast test cou-

rejection.

pons are used, selection shall be according to 8.1. If test bars

7.3 Yieldstrengthshallbedeterminedusingthe0.2 %offset

are to be cut from castings, test bar location shall be agreed

method in accordance with Test Methods E8/E8M. Brinell

between the manufacturer and purchaser and shall be indicated

hardness shall be determined in accordance with Test Method

on the casting drawing or model.

E10.

9. Additional Tests

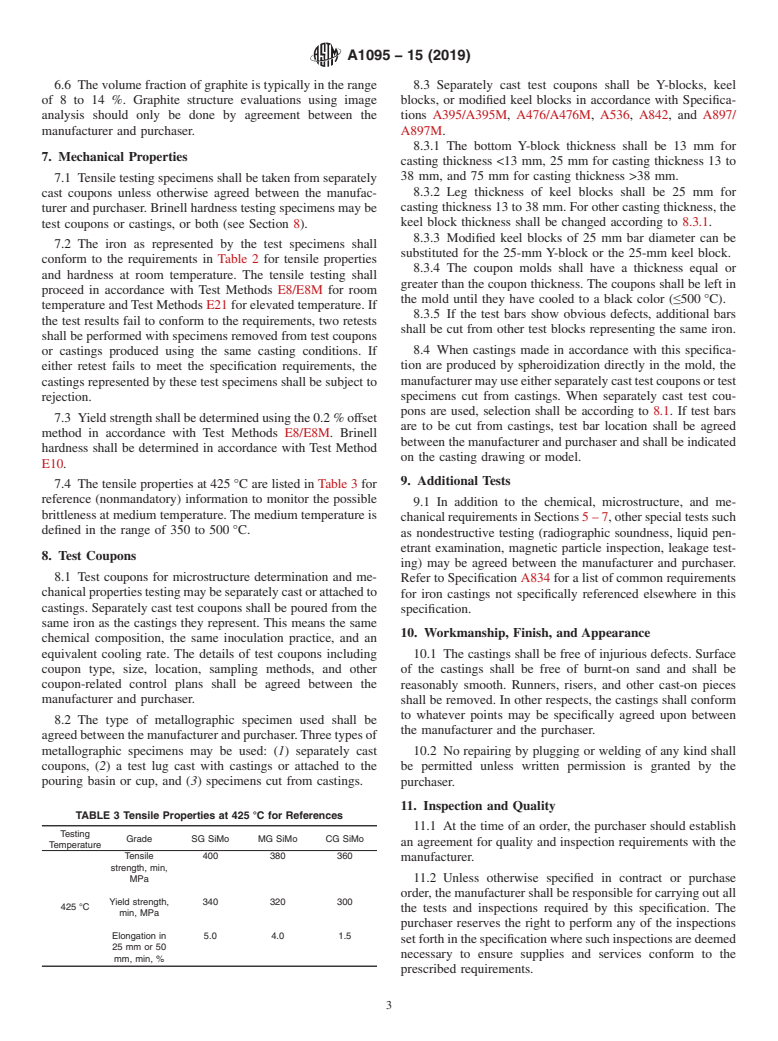

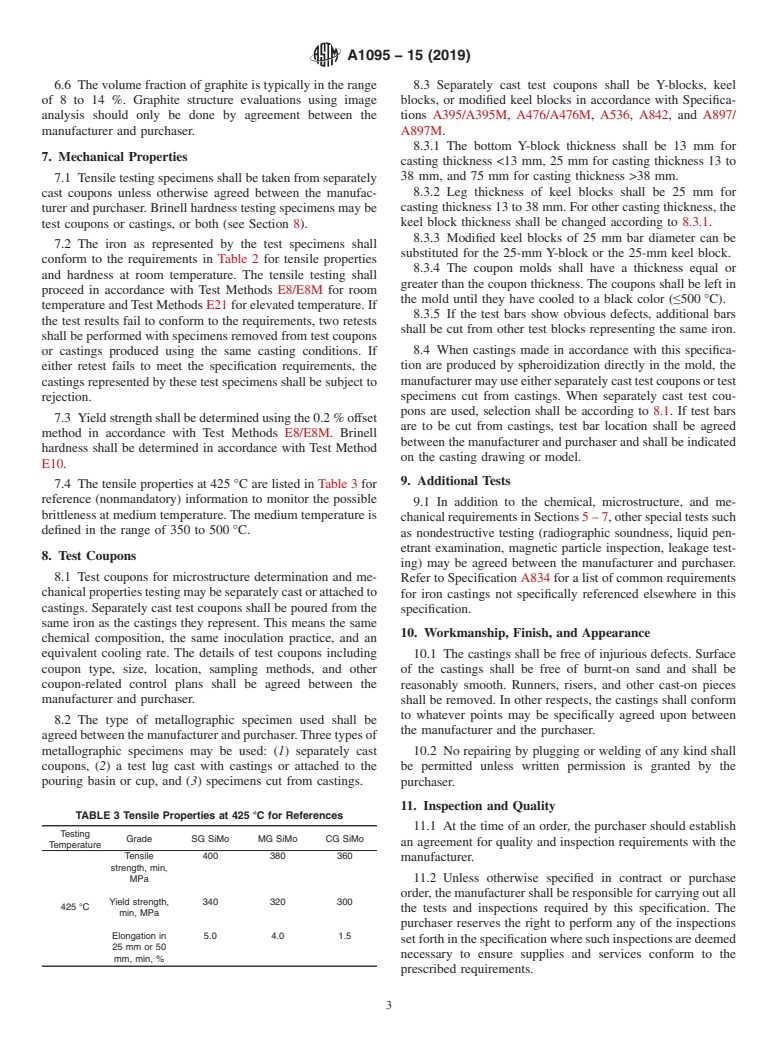

7.4 The tensile properties at 425 °C are listed in Table 3 for

reference (nonmandatory) information to monitor the possible

9.1 In addition to the chemical, microstructure, and me-

brittleness at medium temperature. The medium temperature is

chanicalrequirementsinSections5–7,otherspecialtestssuch

defined in the range of 350 to 500 °C.

as nondestructive testing (radiographic soundness, liquid pen-

etrant examination, magnetic particle inspection, leakage test-

8. Test Coupons

ing) may be agreed between the manufacturer and purchaser.

8.1 Test coupons for microstructure determination and me-

Refer to Specification A834 for a list of common requirements

chanicalpropertiestestingmaybeseparatelycastorattachedto

for iron castings not specifically referenced elsewhere in this

castings. Separately cast test coupons shall be poured from the

specification.

same iron as the castings they represent. This means the same

10. Workmanship, Finish, and Appearance

chemical composition, the same inoculation practice, and an

equivalent cooling rate. The details of test coupons including

10.1 The castings shall be free of injurious defects. Surface

coupon type, size, location, sampling methods, and other of the castings shall be free of burnt-on sand and shall be

coupon-related control plans shall be agreed between the reasonably smooth. Runners, risers, and other cast-on pieces

manufacturer and purchaser. shall be removed. In other respects, the castings shall conform

to whatever points may be specifically agreed upon between

8.2 The type of metallographic specimen used shall be

the manufacturer and the purchaser.

agreedbetweenthemanufacturerandpurchaser.Threetypesof

metallographic specimens may be used: (1) separately cast 10.2 No repairing by plugging or welding of any kind shall

coupons, (2) a test lug cast with castings or attached to the be permitted unless written permission is granted by the

pouring basin or cup, and (3) specimens cut from castings. purchaser.

11. Inspection and Quality

TABLE 3 Tensile Properties at 425°C for References

11.1 At the time of an order, the purchaser should establish

Testing

Grade SG SiMo MG SiMo CG SiMo

an agreement for quality and inspection requirements with the

Temperature

Tensile 400 380 360

manufacturer.

strength, min,

11.2 Unless otherwise specified in contract or purchase

MPa

order, the manufacturer shall be responsible for carrying out all

Yield strength, 340 320 300

425 °C

the tests and inspections required by this specification. The

min, MPa

purchaser reserves the right to

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A1095 − 15 (Reapproved 2019)

Standard Specification for

High-Silicon Molybdenum Ferritic Iron Castings

This standard is issued under the fixed designation A1095; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Graphite in Iron Castings

A395/A395M Specification for Ferritic Ductile Iron

1.1 This specification covers castings made of high-silicon

Pressure-Retaining Castings for Use at Elevated Tempera-

molybdenum ferritic iron, commonly known as SiMo. This

tures

specification includes castings with microstructures of spheroi-

A476/A476M Specification for Ductile Iron Castings for

dal graphite (SG) SiMo iron, compacted graphite (CG) SiMo

Paper Mill Dryer Rolls

iron, and mixed graphite or medium-nodularity graphite (MG)

A536 Specification for Ductile Iron Castings

SiMo iron. MG iron microstructure comprises a mixture of

A834 Specification for Common Requirements for Iron

spheroidal and compacted graphite shapes. This standard

Castings for General Industrial Use

specifies the condition, chemical composition, microstructure,

A842 Specification for Compacted Graphite Iron Castings

and other technical requirements of three grades of ferritic cast

A897/A897M Specification for Austempered Ductile Iron

irons, specified as SG SiMo, MG SiMo, and CG SiMo.

Castings

1.2 No precise quantitative relationship can be stated be-

D1976 Test Method for Elements in Water by Inductively-

tween the properties of iron in the various locations of the same

Coupled Plasma Atomic Emission Spectroscopy

casting or between the properties of castings and those of a test

D5381 Guide for X-Ray Fluorescence (XRF) Spectroscopy

specimen cast from the same iron.

of Pigments and Extenders

E8/E8M Test Methods for Tension Testing of Metallic Ma-

1.3 The values stated in SI units are to be regarded as

standard. All chemical compositions are in mass percentage. terials

E10 Test Method for Brinell Hardness of Metallic Materials

No other units of measurement are included in this standard.

E21 Test Methods for Elevated Temperature Tension Tests of

1.4 This standard does not purport to address all of the

Metallic Materials

safety concerns, if any, associated with its use. It is the

E228 Test Method for Linear Thermal Expansion of Solid

responsibility of the user of this standard to establish appro-

Materials With a Push-Rod Dilatometer

priate safety, health, and environmental practices and deter-

E351 Test Methods for Chemical Analysis of Cast Iron—All

mine the applicability of regulatory limitations prior to use.

Types

1.5 This international standard was developed in accor-

E1184 Practice for Determination of Elements by Graphite

dance with internationally recognized principles on standard-

Furnace Atomic Absorption Spectrometry

ization established in the Decision on Principles for the

E1999 Test Method for Analysis of Cast Iron by Spark

Development of International Standards, Guides and Recom-

Atomic Emission Spectrometry

mendations issued by the World Trade Organization Technical

2.2 SAE (Society of Automotive Engineers) International

Barriers to Trade (TBT) Committee.

Standards:

J434 Automotive Ductile (Nodular) Iron Castings

2. Referenced Documents

2 J1887 Automotive Compacted Graphite Iron Castings

2.1 ASTM Standards:

J2582 Automotive Ductile Iron Castings for High Tempera-

A247 Test Method for Evaluating the Microstructure of

ture Applications

2.3 Federal Standard:

FED-STD-123 Marking for Shipment (Civil Agencies)

This specification is under the jurisdiction of ASTM Committee A04 on Iron

Castings and is the direct responsibility of Subcommittee A04.02 on Malleable and

2.4 American National Standard:

Ductile Iron Castings.

MIL-STD-129 Military Marking for Shipment and Storage

Current edition approved Nov. 1, 2019. Published November 2019. Originally

2.5 Other Publications:

approved in 2015. Last previous edition approved in 2015 as A1095 – 15. DOI:

10.1520/A1095-15R19.

AFS (American Foundry Society), Foundrymen’s Guide to

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Ductile Iron Microstructures, 1984

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

AFS, Iron Castings Engineering Handbook, 2004

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. ASM Specialty Handbook, Cast Irons, 1999

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A1095 − 15 (2019)

ASM Specialty Handbook, Heat-Resistant Materials, 1999 5.3 Controlling the carbon equivalent is important to

ASM Handbook, Casting, Volume 15, 1998 achieve uniform graphite distribution and to minimize solidi-

fication shrinkage and graphite flotation. The carbon equivalent

3. Ordering Information

control range shall be established by the manufacturer to

produce castings that meet the chemical composition ranges in

3.1 Orders for materials to this specification shall include

Table 1, the microstructure requirements in Section 6, and the

the following information:

mechanical properties in Table 2.

3.1.1 ASTM designation and year of issue,

3.1.2 Grade of silicon-molybdenum ferritic iron required,

5.4 Chromium can improve heat resistance of SiMo iron

3.1.3 Chemical composition requirements (see Section 5),

castings. Annealing heat treatments should be utilized if Cr

3.1.4 Microstructure and mechanical requirements (see Sec-

content exceeds 0.10 %.

tions 6 and 7),

5.5 The total concentrations of alloy elements including

3.1.5 Drawing and test coupon criteria (see Section 8),

Mo, Mn, Ni, Cu, W, V, Nb, and Cr shall not exceed 2.5 %.

3.1.6 Special requirements, if desired (see Sections 9 – 11),

5.6 The lower limit of phosphorus for SG SiMo iron is

3.1.7 Certification, if so designated by purchaser (see Sec-

specified to eliminate the brittleness at medium temperature of

tion 12), and

approximately 425 °C.

3.1.8 Special preparation for delivery, if required (see Sec-

tion 14).

6. Microstructure

4. Materials and Manufacture

6.1 The matrix requirements for the three grades of SiMo

irons are the same: predominantly ferritic, a maximum 5 %

4.1 The manufacturer shall produce high-silicon molybde-

primary carbides, and adjacent to the cell boundaries, a

num iron castings with a microstructure consisting of a

maximum 30 % Mo-rich precipitates.

predominantly ferritic matrix in the as-cast condition. Small

amounts of flake graphite in the surface reaction zone are

6.2 All the three grades of SiMo iron castings for which

allowed only when agreed between the manufacturer and

chemical composition is specified in Table 1 shall be substan-

purchaser.

tially free of flake, exploded, chunky, crab, spiky, and floata-

tion graphite. Flake graphite is permitted in the surface reaction

4.2 High-silicon ferritic SiMo iron castings are typically

zone to a maximum depth of 0.30 mm for sections ≤10 mm and

supplied in the as-cast condition. If heat treatment is agreed

to a maximum depth of 0.60 mm for sections >10 mm.

between the manufacturer and purchaser, castings can be either

fully or subcritically annealed. The recommended heat treat-

6.3 For SG SiMo iron, the graphite in the microstructure

ment practice is provided in Appendix X3.

shall consist of a minimum 80 % Type I and Type II graphite

according to Test Method A247.

5. Chemical Composition

6.4 For CG SiMo iron, the graphite in the microstructure

5.1 Chemical requirements for each grade are specified in

shall consist of a minimum 60 % Type IV graphite; the

Table 1. Chemical composition shall be determined from

remaining graphite shall be a combined maximum 40 % Type

chilled disk samples or samples representative of the castings

I, Type II, and Type III graphite according to Test Method

and in accordance with the applicable sections of Test Methods

A247 and Specification A842.

D1976, E351, and E1999, Practice E1184, and Guide D5381.

6.5 For MG SiMo iron, the graphite in the microstructure

5.2 When agreed between the manufacturer and purchaser,

shall consist of a minimum 40 % of Type I and Type II graphite

chemistry control ranges may be tighter than those specified in

according to Test Method A247 and a range of 30 to 60 % Type

Table 1.

IV graphite according to Test Method A247 and Specification

A842.

TABLE 1 Chemical Composition Requirements

TABLE 2 Tensile and Hardness Requirements

Type

SG SiMo MG SiMo CG SiMo

Testing

Grade SG SiMo MG SiMo CG SiMo

Element Composition (mass %)

Temperature

Carbon 2.90–3.70 2.80–3.60 2.70–3.50

Tensile 500 450 400

Silicon 3.50–4.80 3.50–4.80 3.50–4.80 strength, min,

Molybdenum 0.40–1.50 0.40–1.50 0.40–1.50

MPa

Titanium 0.05 max 0.10 max 0.25 max

Magnesium 0.06 max 0.05 max 0.04 max

Yield strength, 420 400 350

Manganese 0.50 max 0.50 max 0.50 max min, MPa

Nickel 0.50 max 0.50 max 0.50 max

Room

Copper 0.30 max 0.30 max 0.30 max Elongation in 6.0 4.0 1.5

temperature

Tungsten 0.30 max 0.30 max 0.30 max 25 mm or

Vanadium 0.10 max 0.10 max 0.10 max 50 mm, min,

Niobium 0.30 max 0.30 max 0.30 max %

Chromium 0.50 max 0.50 max 0.50 max

Phosphorus 0.02–0.05 0.05 max 0.05 max Brinell 190–270 190–270 190–270

Sulfur 0.02 max 0.02 max 0.02 max hardness,

Iron balance balance balance HBW

A1095 − 15 (2019)

6.6 The volume fraction of graphite is typically in the range 8.3 Separately cast test coupons shall be Y-blocks, keel

of 8 to 14 %. Graphite structure evaluations using image blocks, or modified keel blocks in accordance with Specifica-

analysis should only be done by agreement between the tions A395/A395M, A476/A476M, A536, A842, and A897/

manufacturer and purchaser. A897M.

8.3.1 The bottom Y-block thickness shall be 13 mm for

7. Mechanical Properties

casting thickness <13 mm, 25 mm for casting thickness 13 to

38 mm, and 75 mm for casting thickness >38 mm.

7.1 Tensile testing specimens shall be taken from separately

8.3.2 Leg thickness of keel blocks shall be 25 mm for

cast coupons unless otherwise agreed between the manufac-

casting thickness 13 to 38 mm. For other casting thickness, the

turer and purchaser. Brinell hardness testing specimens may be

keel block thickness shall be changed according to 8.3.1.

test coupons or castings, or both (see Section 8).

8.3.3 Modified keel blocks of 25 mm bar diameter can be

7.2 The iron as represented by the test specimens shall

substituted for the 25-mm Y-block or the 25-mm keel block.

conform to the requirements in Table 2 for tensile properties

8.3.4 The coupon molds shall have a thickness equal or

and hardness at room temperature. The tensile testing shall

greater than the coupon thickness. The coupons shall be left in

proceed in accordance with Test Methods E8/E8M for room

the mold until they have cooled to a black color (≤500 °C).

temperature and Test Methods E21 for elevated temperature. If

8.3.5 If the test bars show obvious defects, additional bars

the test results fail to conform to the requirements, two retests

shall be cut from other test blocks representing the same iron.

shall be performed with specimens removed from test coupons

8.4 When castings made in accordance with this specifica-

or castings produced using the same casting conditions. If

tion are produced by spheroidization directly in the mold, the

either retest fails to meet the specification requirements, the

manufacturer may use either separately cast test coupons or test

castings represented by these test specimens shall be subject to

specimens cut from castings. When separately cast test cou-

rejection.

pons are used, selection shall be according to 8.1. If test bars

7.3 Yield strength shall be determined using the 0.2 % offset

are to be cut from castings, test bar location shall be agreed

method in accordance with Test Methods E8/E8M. Brinell

between the manufacturer and purchaser and shall be indicated

hardness shall be determined in accordance with Test Method

on the casting drawing or model.

E10.

9. Additional Tests

7.4 The tensile properties at 425 °C are listed in Table 3 for

reference (nonmandatory) information to monitor the possible

9.1 In addition to the chemical, microstructure, and me-

brittleness at medium temperature. The medium temperature is

chanical requirements in Sections 5 – 7, other special tests such

defined in the range of 350 to 500 °C.

as nondestructive testing (radiographic soundness, liquid pen-

etrant examination, magnetic particle inspection, leakage test-

8. Test Coupons

ing) may be agreed between the manufacturer and purchaser.

8.1 Test coupons for microstructure determination and me-

Refer to Specification A834 for a list of common requirements

chanical properties testing may be separately cast or attached to

for iron castings not specifically referenced elsewhere in this

castings. Separately cast test coupons shall be poured from the

specification.

same iron as the castings they represent. This means the same

10. Workmanship, Finish, and Appearance

chemical composition, the same inoculation practice, and an

equivalent cooling rate. The details of test coupons including 10.1 The castings shall be free of injurious defects. Surface

coupon type, size, location, sampling methods, and other of the castings shall be free of burnt-on sand and shall be

coupon-related control plans shall be agreed between the reasonably smooth. Runners, risers, and other cast-on pieces

manufacturer and purchaser. shall be removed. In other respects, the castings shall conform

to whatever points may be specifically agreed upon between

8.2 The type of metallographic specimen used shall be

the manufacturer and the purchaser.

agreed between the manufacturer and purchaser. Three types of

metallographic specimens may be used: (1) separately cast 10.2 No repairing by plugging or welding of any kind shall

coupons, (2) a test lug cast with castings or attached to the be permitted unless written permission is granted by the

pouring basin or cup, and (3) specimens cut from castings.

purchaser.

11. Inspection and Quality

TABLE 3 Tensile Properties at 425 °C for References

11.1 At the time of an order, the purchaser should establish

Testing

Grade SG SiMo MG SiMo CG SiMo

an agreement for quality and inspection requirements with the

Temperature

Tensile 400 380 360

manufacturer.

strength, min,

MPa 11.2 Unless otherwise specified in contract or purchase

order, the manufacturer shall be responsible for carrying out all

Yield strength, 340 320 300

425 °C

the tests and inspections required by this specification. The

min, MPa

purchaser reserves th

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A1095 − 15 A1095 − 15 (Reapproved 2019)

Standard Specification for

High-Silicon Molybdenum Ferritic Iron Castings

This standard is issued under the fixed designation A1095; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers castings made of high-silicon molybdenum ferritic iron, commonly known as SiMo. This

specification includes castings with microstructures of spheroidal graphite (SG) SiMo iron, compacted graphite (CG) SiMo iron,

and mixed graphite or medium-nodularity graphite (MG) SiMo iron. MG iron microstructure comprises a mixture of spheroidal

and compacted graphite shapes. This standard specifies the condition, chemical composition, microstructure, and other technical

requirements of three grades of ferritic cast irons, specified as SG SiMo, MG SiMo, and CG SiMo.

1.2 No precise quantitative relationship can be stated between the properties of iron in the various locations of the same casting

or between the properties of castings and those of a test specimen cast from the same iron.

1.3 The values stated in SI units are to be regarded as standard. All chemical compositions are in mass percentage. No other

units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

A247 Test Method for Evaluating the Microstructure of Graphite in Iron Castings

A395A395/A395M Specification for Ferritic Ductile Iron Pressure-Retaining Castings for Use at Elevated Temperatures

A476/A476M Specification for Ductile Iron Castings for Paper Mill Dryer Rolls

A536 Specification for Ductile Iron Castings

A834 Specification for Common Requirements for Iron Castings for General Industrial Use

A842 Specification for Compacted Graphite Iron Castings

A897/A897M Specification for Austempered Ductile Iron Castings

D1976 Test Method for Elements in Water by Inductively-Coupled Plasma Atomic Emission Spectroscopy

D5381 Guide for X-Ray Fluorescence (XRF) Spectroscopy of Pigments and Extenders

E8/E8M Test Methods for Tension Testing of Metallic Materials

E10 Test Method for Brinell Hardness of Metallic Materials

E21 Test Methods for Elevated Temperature Tension Tests of Metallic Materials

E228 Test Method for Linear Thermal Expansion of Solid Materials With a Push-Rod Dilatometer

E351 Test Methods for Chemical Analysis of Cast Iron—All Types

E1184 Practice for Determination of Elements by Graphite Furnace Atomic Absorption Spectrometry

E1999 Test Method for Analysis of Cast Iron by Spark Atomic Emission Spectrometry

2.2 SAE (Society of Automotive Engineers) International Standards:

J434 Automotive Ductile (Nodular) Iron Castings

J1887 Automotive Compacted Graphite Iron Castings

This test method specification is under the jurisdiction of ASTM Committee A04 on Iron Castings and is the direct responsibility of Subcommittee A04.02 on Malleable

and Ductile Iron Castings.

Current edition approved Nov. 1, 2015Nov. 1, 2019. Published December 2015November 2019. Originally approved in 2015. Last previous edition approved in 2015 as

A1095 – 15. DOI: 10.1520/A1095-1510.1520/A1095-15R19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A1095 − 15 (2019)

J2582 Automotive Ductile Iron Castings for High Temperature Applications

2.3 Federal Standard:

FED-STD-123 Marking for Shipment (Civil Agencies)

2.4 American National Standard:

MIL-STD-129 Military Marking for Shipment and Storage

2.5 Other Publications:

AFS (American Foundry Society), Foundrymen’s Guide to Ductile Iron Microstructures, 1984

AFS, Iron Castings Engineering Handbook, 2004

ASM Specialty Handbook, Cast Irons, 1999

ASM Specialty Handbook, Heat-Resistant Materials, 1999

ASM Handbook, Casting, Volume 15, 1998

3. Ordering Information

3.1 Orders for materials to this specification shall include the following information:

3.1.1 ASTM designation and year of issue,

3.1.2 Grade of silicon-molybdenum ferritic iron required,

3.1.3 Chemical composition requirements (see Section 5),

3.1.4 Microstructure and mechanical requirements (see Sections 6 and 76 and 7),

3.1.5 Drawing and test coupon criteria (see Section 8),

3.1.6 Special requirements, if desired (see Sections 9 and– 11),

3.1.7 Certification, if so designated by purchaser (see Section 12), and

3.1.8 Special preparation for delivery, if required (see Section 14).

4. Materials and Manufacture

4.1 The manufacturer shall produce high-silicon molybdenum iron castings with a microstructure consisting of a predominantly

ferritic matrix in the as-cast condition. Small amounts of flake graphite in the surface reaction zone are allowed only when agreed

between the manufacturer and purchaser.

4.2 High-silicon ferritic SiMo iron castings are typically supplied in the as-cast condition. If heat treatment is agreed between

the manufacturer and purchaser, castings can be either fully or subcritically annealed. The recommended heat treatment practice

is provided in Appendix X3.

5. Chemical Composition

5.1 Chemical requirements for each grade are specified in Table 1. Chemical composition shall be determined from chilled disk

samples or samples representative of the castings and in accordance with the applicable sections of Test Methods D1976, E351,

and E1999, Practice E1184, and Guide D5381.

5.2 When agreed between the manufacturer and purchaser, chemistry control ranges may be tighter than those specified in Table

1.

5.3 Controlling the carbon equivalent is important to achieve uniform graphite distribution and to minimize solidification

shrinkage and graphite flotation. The carbon equivalent control range shall be established by the manufacturer to produce castings

that meet the chemical composition ranges in Table 1, the microstructure requirements in Section 6, and the mechanical properties

in Table 2.

TABLE 1 Chemical Composition Requirements

Type

SG SiMo MG SiMo CG SiMo

Element Composition (mass %)

Carbon 2.90–3.70 2.80–3.60 2.70–3.50

Silicon 3.50–4.80 3.50–4.80 3.50–4.80

Molybdenum 0.40–1.50 0.40–1.50 0.40–1.50

Titanium 0.05 max 0.10 max 0.25 max

Magnesium 0.06 max 0.05 max 0.04 max

Manganese 0.50 max 0.50 max 0.50 max

Nickel 0.50 max 0.50 max 0.50 max

Copper 0.30 max 0.30 max 0.30 max

Tungsten 0.30 max 0.30 max 0.30 max

Vanadium 0.10 max 0.10 max 0.10 max

Niobium 0.30 max 0.30 max 0.30 max

Chromium 0.50 max 0.50 max 0.50 max

Phosphorus 0.02–0.05 0.05 max 0.05 max

Sulfur 0.02 max 0.02 max 0.02 max

Iron balance balance balance

A1095 − 15 (2019)

TABLE 2 Tensile and Hardness Requirements

Testing

Grade SG SiMo MG SiMo CG SiMo

Temperature

Tensile 500 450 400

strength, min,

MPa

Yield 420 400 350

strength, min,

MPa

Room

Room Elongation in 6.0 4.0 1.5

temperature

temperture 25 mm or

50 mm, min,

%

Elongation in 6.0 4.0 1.5

25 mm or

50 mm, min,

%

Brinell 190–270 190–270 190–270

hardness,

HBW

5.4 Chromium can improve heat resistance of SiMo iron castings. Annealing heat treatments should be utilized if Cr content

exceeds 0.10 %.

5.5 The total concentrations of alloy elements including Mo, Mn, Ni, Cu, W, V, Nb, and Cr shall not exceed 2.5 %.

5.6 The lower limit of phosphorus for SG SiMo iron is specified to eliminate the brittleness at medium temperature of

approximately 425°C.425 °C.

6. Microstructure

6.1 The matrix requirements for the three grades of SiMo irons are the same: predominantly ferritic, a maximum 5 % primary

carbides, and adjacent to the cell boundaries, a maximum 30 % Mo-rich precipitates.

6.2 All the three grades of SiMo iron castings for which chemical composition is specified in Table 1 shall be substantially free

of flake, exploded, chunky, crab, spiky, and floatation graphite. Flake graphite is permitted in the surface reaction zone to a

maximum depth of 0.30 mm for sections ≤10 mm and to a maximum depth of 0.60 mm for sections >10 mm.

6.3 For SG SiMo iron, the graphite in the microstructure shall consist of a minimum 80 % Type I and Type II graphite according

to Test Method A247.

6.4 For CG SiMo iron, the graphite in the microstructure shall consist of a minimum 60 % Type IV graphite; the remaining

graphite shall be a combined maximum 40 % Type I, Type II, and Type III graphite according to Test Method A247 and

Specification A842.

6.5 For MG SiMo iron, the graphite in the microstructure shall consist of a minimum 40 % of Type I and Type II graphite

according to Test Method A247 and a range of 30 to 60 % Type IV graphite according to Test Method A247 and Specification

A842.

6.6 The volume fraction of graphite is typically in the range of 8 to 14 %. Graphite structure evaluations using image analysis

should only be done by agreement between the manufacturer and purchaser.

7. Mechanical Properties

7.1 Tensile testing specimens shall be taken from separately cast coupons unless otherwise agreed between the manufacturer

and purchaser. Brinell hardness testing specimens may be test coupons or castings, or both (see Section 8).

7.2 The iron as represented by the test specimens shall conform to the requirements in Table 2 for tensile properties and hardness

at room temperature. The tensile testing shall proceed in accordance with Test Methods E8/E8M for room temperature and Test

MethodMethods E21 for elevated temperature. If the test results fail to conform to the requirements, two retests shall be performed

with specimens removed from test coupons or castings produced using the same casting conditions. If either retest fails to meet

the specification requirements, the castings represented by these test specimens shall be subject to rejection.

7.3 Yield strength shall be determined using the 0.2 % offset method in accordance with Test Methods E8/E8M. Brinell hardness

shall be determined in accordance with Test Method E10.

7.4 The tensile properties at 425°C425 °C are listed in Table 3 for reference (nonmandatory) information to monitor the possible

brittleness at medium temperature. The medium temperature is defined in the range of 350 to 500°C.500 °C.

A1095 − 15 (2019)

TABLE 3 Tensile Properties at 425°C425 °C for References

Testing

Grade SG SiMo MG SiMo CG SiMo

Temperature

Tensile 400 380 360

strength, min,

MPa

425 °C 425°C Yield strength, 340 320 300

min, MPa

Yield strength, 340 320 300

min, MPa

Elongation in 5.0 4.0 1.5

25 mm or 50

mm, min, %

8. Test Coupons

8.1 Test coupons for microstructure determination and mechanical properties testing may be separately cast or attached to

castings. Separately cast test coupons shall be poured from the same iron as the castings they represent. This means the same

chemical composition, the same inoculation practice, and an equivalent cooling rate. The details of test coupons including coupon

type, size, location, sampling methods, and other coupon-related control plans shall be agreed between the manufacturer and

purchaser.

8.2 The type of metallographic specimen used shall be agreed between the manufacturer and purchaser. Three types of

metallographic specimens may be used: (1)(1) separately cast coupons, (2)(2) a test lug cast with castings or attached to the pouring

basin or cup, and (3)(3) specimens cut from castings.

8.3 Separately cast test coupons shall be Y-blocks, keel blocks, or modified keel blocks in accordance with Specifications

A395A395/A395M, A476/A476M, A536, A842, and A897/A897M.

8.3.1 The bottom Y-block thickness shall be 13 mm for casting thickness <13 mm, 25 mm for casting thickness 13 to 38 mm,

and 75 mm for casting thickness >38 mm.

8.3.2 Leg thickness of keel blocks shall be 25 mm for casting thickness 13 to 38 mm. For other casting thickness, the keel block

thickness shall be changed according to 8.3.1.

8.3.3 Modified keel blocks of 25 mm bar diameter can be substituted for the 25-mm Y-block or the 25-mm keel block.

8.3.4 The coupon molds shall have a thickness equal or greater than the coupon thickness. The coupons shall be left in the mold

until they have cooled to a black color (≤500°C).(≤500 °C).

8.3.5 If the test bars show obvious defects, additional bars shall be cut from other test blocks representing the same iron.

8.4 When castings made in accordance with this specification are produced by spheroidization directly in the mold, the

manufacturer may use either separately cast test coupons or test specimens cut from castings. When separately cast test coupons

are used, selection shall be according to 8.1. If test bars are to be cut from castings, test bar location shall be agreed between the

manufacturer and purchaser and shall be indicated on the casting drawing or model.

9. Additional Tests

9.1 In addition to the chemical, microstructure, and mechanical requirements in Sections 5 – 7, other special tests such as

nondestructive testing (radiographic soundness, liquid penetrant examination, magnetic particle inspection, leakage testing) may

be agreed between the manufacturer and purchaser. Refer to Specification A834 for a list of common requirements for iron castings

not specifically referenced elsewhere in this specification.

10. Workmanship, Finish, and Appearance

10.1 The castings shall be free of injurious defects. Surface of the castings shall be free of burnt-on sand and shall be reasonably

smooth. Runners, risers, and other cast-on pieces shall be removed. In other respects, the castings shall conform to whatever points

may be

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.