ASTM C231-97e1

(Test Method)Standard Test Method for Air Content of Freshly Mixed Concrete by the Pressure Method

Standard Test Method for Air Content of Freshly Mixed Concrete by the Pressure Method

SCOPE

1.1 This test method covers determination of the air content of freshly mixed concrete from observation of the change in volume of concrete with a change in pressure.

1.2 This test method is intended for use with concretes and mortars made with relatively dense aggregates for which the aggregate correction factor can be satisfactorily determined by the technique described in Section 6. It is not applicable to concretes made with lightweight aggregates, air-cooled blast-furnace slag, or aggregates of high porosity. In these cases, Test Method C173 should be used. This test method is also not applicable to nonplastic concrete such as is commonly used in the manufacture of pipe and concrete masonry units.

1.3 The text of this standard references notes and footnotes that provide explanatory information. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of this standard.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See Note A1.7 for a specific caution statement.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

e1

Designation:C231–97

Standard Test Method for

Air Content of Freshly Mixed Concrete

by the Pressure Method

This standard is issued under the fixed designation C231; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—Section 1.4 was updated editorially in April 1999.

1. Scope Concrete by the Volumetric Method

C192 PracticeforMakingandCuringConcreteTestSpeci-

1.1 This test method covers determination of the air content

mens in the Laboratory

of freshly mixed concrete from observation of the change in

C670 Practice for Preparing Precision and Bias Statements

volume of concrete with a change in pressure.

for Test Methods of Construction Materials

1.2 This test method is intended for use with concretes and

E177 Practice for Use of the Terms Precision and Bias in

mortars made with relatively dense aggregates for which the

ASTM Test Methods

aggregate correction factor can be satisfactorily determined by

the technique described in Section 6. It is not applicable to

3. Significance and Use

concretes made with lightweight aggregates, air-cooled blast-

3.1 This test method covers the determination of the air

furnaceslag,oraggregatesofhighporosity.Inthesecases,Test

content of freshly mixed concrete. The test determines the air

Method C173 should be used. This test method is also not

contentoffreshlymixedconcreteexclusiveofanyairthatmay

applicable to nonplastic concrete such as is commonly used in

be inside voids within aggregate particles. For this reason, it is

the manufacture of pipe and concrete masonry units.

applicable to concrete made with relatively dense aggregate

1.3 The text of this standard references notes and footnotes

particlesandrequiresdeterminationoftheaggregatecorrection

that provide explanatory information. These notes and foot-

factor (see 6.1 and 9.1).

notes (excluding those in tables and figures) shall not be

3.2 This test method and Test Method C138 and C173

considered as requirements of this standard.

provide pressure, gravimetric, and volumetric procedures,

1.4 The values stated in inch-pound units are to be regarded

respectively, for determining the air content of freshly mixed

as the standard. The values given in parentheses are for

concrete. The pressure procedure of this test method gives

information only.

substantially the same air contents as the other two test

1.5 This standard does not purport to address all of the

methods for concretes made with dense aggregates.

safety concerns, if any, associated with its use. It is the

3.3 The air content of hardened concrete may be either

responsibility of the user of this standard to establish appro-

higher or lower than that determined by this test method. This

priate safety and health practices and determine the applica-

depends upon the methods and amount of consolidation effort

bility of regulatory limitations prior to use. See NoteA1.7 for

applied to the concrete from which the hardened concrete

a specific caution statement.

specimenistaken;uniformityandstabilityoftheairbubblesin

2. Referenced Documents the fresh and hardened concrete; accuracy of the microscopic

examination, if used; time of comparison; environmental

2.1 ASTM Standards:

exposure; stage in the delivery, placement and consolidation

C138 Test Method for Unit Weight,Yield, andAir Content

processes at which the air content of the unhardened concrete

(Gravimetric) of Concrete

is determined, that is, before or after the concrete goes through

C172 Practice for Sampling Freshly Mixed Concrete

a pump; and other factors.

C173 Test Method for Air Content of Freshly Mixed

4. Apparatus

4.1 Air Meters—There are available satisfactory apparatus

ThistestmethodisunderthejurisdictionofASTMCommitteeC-9onConcrete

of two basic operational designs employing the principle of

and Concrete Aggregates, and is the direct responsibility of Subcommittee C09.60

on Fresh Concrete Testing.

Current edition approved Jan. 10, 1997. Published March 1997. Originally

published as C231–49 T. Last previous edition C231–97.

2 3

Annual Book of ASTM Standards, Vol 04.02. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

C231

Boyle’s law. For purposes of reference herein these are

designated Meter Type A and Meter Type B.

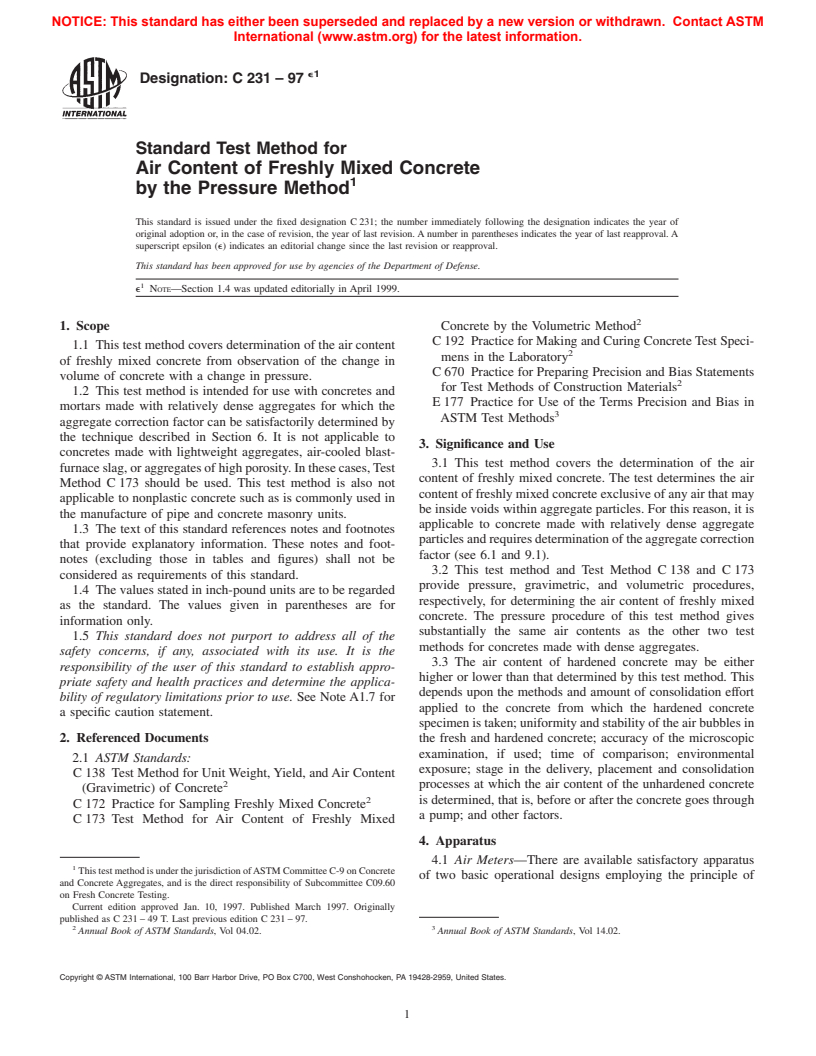

4.1.1 MeterTypeA—Anairmeterconsistingofameasuring

bowl and cover assembly (see Fig. 1) conforming to the

requirements of 4.2 and 4.3. The operational principle of this

meter consists of introducing water to a predetermined height

above a sample of concrete of known volume, and the

application of a predetermined air pressure over the water.The

determination consists of the reduction in volume of the air in

theconcretesamplebyobservingtheamountthewaterlevelis

lowered under the applied pressure, the latter amount being

FIG. 2 Schematic Diagram—Type-B Meter

calibrated in terms of percent of air in the concrete sample.

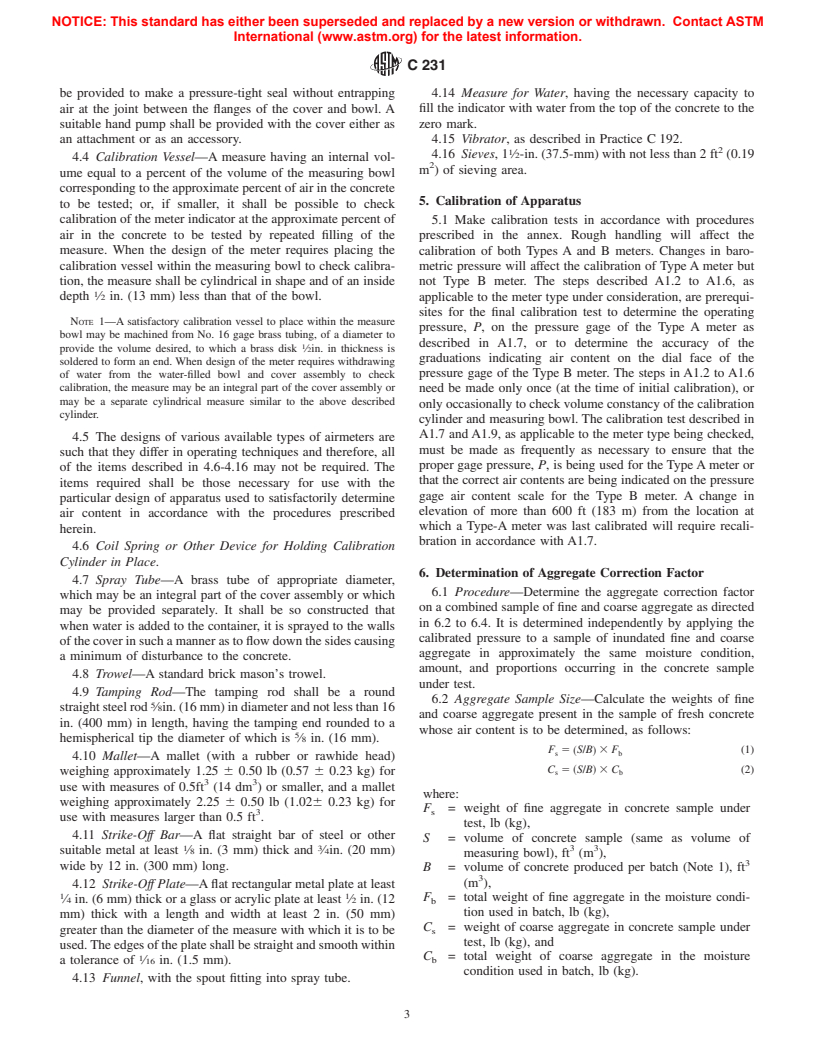

4.1.2 MeterTypeB—Anairmeterconsistingofameasuring

bowl and cover assembly (see Fig. 2) conforming to the

requirements of 4.2 and 4.3. The operational principle of this 4.3.1 Thecoverassemblyshallbemadeofsteel,hardmetal,

meter consists of equalizing a known volume of air at a known orotherhardmaterialnotreadilyattackedbythecementpaste.

pressure in a sealed air chamber with the unknown volume of It shall be flanged or otherwise constructed to provide for a

air in the concrete sample, the dial on the pressure gage being pressure-tight fit between bowl and cover assembly and shall

calibrated in terms of percent air for the observed pressure at have machined smooth interior surfaces contoured to provide

which equalization takes place. Working pressures of 7.5 to an air space above the level of the top of the measuring bowl.

30.0 psi (51 to 207 kPa) have been used satisfactorily. The cover shall be sufficiently rigid to limit the expansion

4.2 Measuring Bowl—The measuring bowl shall be essen- factor of the apparatus assembly as prescribed in 4.2.

tially cylindrical in shape, made of steel, hard metal, or other 4.3.2 The cover assembly shall be fitted with a means of

hard material not readily attacked by the cement paste, having direct reading of the air content. The cover for the Type A

aminimumdiameterequalto0.75to1.25timestheheight,and meter shall be fitted with a standpipe, made of a transparent

3 3

a capacity of at least 0.20 ft (0.006 m ). It shall be flanged or graduated tube or a metal tube of uniform bore with a glass

otherwise constructed to provide for a pressure tight fit water gage attached. In the Type B meter, the dial of the

between bowl and cover assembly. The interior surfaces of the pressure gage shall be calibrated to indicate the percent of air.

bowl and surfaces of rims, flanges, and other component fitted Graduations shall be provided for a range in air content of at

parts shall be machined smooth. The measuring bowl and least 8% readable to 0.1% as determined by the proper air

coverassemblyshallbesufficientlyrigidtolimittheexpansion pressure calibration test.

factor, D, of the apparatus assembly (AnnexA1.5) to not more 4.3.3 The cover assembly shall be fitted with air valves, air

than 0.1% of air content on the indicator scale when under bleeder valves, and petcocks for bleeding off or through which

normal operating pressure. water may be introduced as necessary for the particular meter

4.3 Cover Assembly: design.Suitablemeansforclampingthecovertothebowlshall

FIG. 1 Illustration of the Pressure Method for Air Content—Type-A Meter

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

C231

be provided to make a pressure-tight seal without entrapping 4.14 Measure for Water, having the necessary capacity to

air at the joint between the flanges of the cover and bowl. A fill the indicator with water from the top of the concrete to the

suitable hand pump shall be provided with the cover either as zero mark.

an attachment or as an accessory. 4.15 Vibrator, as described in Practice C192.

4.16 Sieves,1 ⁄2-in. (37.5-mm) with not less than 2 ft (0.19

4.4 Calibration Vessel—A measure having an internal vol-

m ) of sieving area.

ume equal to a percent of the volume of the measuring bowl

correspondingtotheapproximatepercentofairintheconcrete

5. Calibration of Apparatus

to be tested; or, if smaller, it shall be possible to check

calibration of the meter indicator at the approximate percent of

5.1 Make calibration tests in accordance with procedures

air in the concrete to be tested by repeated filling of the

prescribed in the annex. Rough handling will affect the

measure. When the design of the meter requires placing the

calibration of both Types A and B meters. Changes in baro-

calibration vessel within the measuring bowl to check calibra- metric pressure will affect the calibration of TypeAmeter but

tion, the measure shall be cylindrical in shape and of an inside

not Type B meter. The steps described A1.2 to A1.6, as

depth ⁄2 in. (13 mm) less than that of the bowl. applicable to the meter type under consideration, are prerequi-

sites for the final calibration test to determine the operating

NOTE 1—A satisfactory calibration vessel to place within the measure

pressure, P, on the pressure gage of the Type A meter as

bowl may be machined from No. 16 gage brass tubing, of a diameter to

described in A1.7, or to determine the accuracy of the

provide the volume desired, to which a brass disk ⁄2in. in thickness is

graduations indicating air content on the dial face of the

soldered to form an end. When design of the meter requires withdrawing

pressure gage of the Type B meter. The steps in A1.2 to A1.6

of water from the water-filled bowl and cover assembly to check

calibration, the measure may be an integral part of the cover assembly or

need be made only once (at the time of initial calibration), or

may be a separate cylindrical measure similar to the above described

onlyoccasionallytocheckvolumeconstancyofthecalibration

cylinder.

cylinder and measuring bowl. The calibration test described in

A1.7 andA1.9, as applicable to the meter type being checked,

4.5 The designs of various available types of airmeters are

must be made as frequently as necessary to ensure that the

such that they differ in operating techniques and therefore, all

proper gage pressure, P, is being used for the TypeAmeter or

of the items described in 4.6-4.16 may not be required. The

that the correct air contents are being indicated on the pressure

items required shall be those necessary for use with the

gage air content scale for the Type B meter. A change in

particular design of apparatus used to satisfactorily determine

elevation of more than 600 ft (183 m) from the location at

air content in accordance with the procedures prescribed

which a Type-A meter was last calibrated will require recali-

herein.

bration in accordance with A1.7.

4.6 Coil Spring or Other Device for Holding Calibration

Cylinder in Place.

6. Determination of Aggregate Correction Factor

4.7 Spray Tube—A brass tube of appropriate diameter,

6.1 Procedure—Determine the aggregate correction factor

which may be an integral part of the cover assembly or which

on a combined sample of fine and coarse aggregate as directed

may be provided separately. It shall be so constructed that

in 6.2 to 6.4. It is determined independently by applying the

when water is added to the container, it is sprayed to the walls

calibrated pressure to a sample of inundated fine and coarse

ofthecoverinsuchamannerastoflowdownthesidescausing

aggregate in approximately the same moisture condition,

a minimum of disturbance to the concrete.

amount, and proportions occurring in the concrete sample

4.8 Trowel—A standard brick mason’s trowel.

under test.

4.9 Tamping Rod—The tamping rod shall be a round

6.2 Aggregate Sample Size—Calculate the weights of fine

straightsteelrod ⁄8in.(16mm)indiameterandnotlessthan16

and coarse aggregate present in the sample of fresh concrete

in. (400 mm) in length, having the tamping end rounded to a

whose air content is to be determined, as follows:

hemispherical tip the diameter of which is ⁄8 in. (16 mm).

F 5 ~S/B! 3F (1)

s b

4.10 Mallet—A mallet (with a rubber or rawhide head)

C 5 ~S/B! 3C (2)

weighing approximately 1.25 6 0.50 lb (0.57 6 0.23 kg) for s b

3 3

use with measures of 0.5ft (14 dm ) or smaller, and a mallet

where:

weighing approximately 2.25 6 0.50 lb (1.026 0.23 kg) for

F = weight of fine aggregate in concrete sample under

3 s

use with measures larger than 0.5 ft .

test, lb (kg),

4.11 Strike-Off Bar—A flat straight bar of steel or other

S = volume of concrete sample (same as volume of

1 3 3 3

suitable metal at least ⁄8 in. (3 mm) thick and ⁄4in. (20 mm)

measuring bowl), ft (m ),

wide by 12 in. (300 mm) long.

B = volume of concrete produced per batch (Note 1), ft

4.12 Strike-Off Plate—Aflat rectangular metal plate at least (m ),

1 1

F = total weight of fine aggregate in the moisture condi-

⁄4 in. (6 mm) thick or a glass or acrylic plate at least ⁄2 in. (12 b

tion used in batch, lb (kg),

mm) thick with a length and width at least 2 in. (50 mm)

C = weight of coarse aggregate in concrete sample under

greater than the diameter of the measure with which it is to be s

test, lb (kg), and

used.Theedgesoftheplateshallbestraightandsmoothwithin

1 C = total weight of coarse aggregate in the moisture

b

a tolerance of ⁄16 in. (1.5 mm).

condition used in batch, lb (kg).

4.13 Funnel, with the spout fitting into spray tube.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

C231

NOTE 2—The volume of concrete produced per batch can be deter-

8.1.1 Dampen the interior of the measuring bowl and place

mined in accordance with applicable provisions of Test Method C138.

itonaflat,level,firmsurface.Placearepresentativesampleof

NOTE 3—The term “weight” is temporarily used in this standard

the concrete, prepared as described in Section 7, in the

becauseofestablishedtradeusage.Thewordisusedtomeanboth“force”

measuring b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.