ASTM E1409-97

(Test Method)Standard Test Method for Determination of Oxygen in Titanium and Titanium Alloys by the Inert Gas Fusion Technique

Standard Test Method for Determination of Oxygen in Titanium and Titanium Alloys by the Inert Gas Fusion Technique

SCOPE

1.1 This test method covers the determination of oxygen in titanium and titanium alloys in concentrations from 0.04 and 0.3%.

1.2 The values stated in both inch-pound and SI units are to be regarded separately as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Note 2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 1409 – 97

Standard Test Method for

Determination of Oxygen in Titanium and Titanium Alloys by

the Inert Gas Fusion Technique

This standard is issued under the fixed designation E 1409; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of oxygen in

titanium and titanium alloys in concentrations from 0.04 and

0.3 %.

1.2 The values stated in both inch-pound and SI units are to

be regarded separately as the standard. The values given in

parentheses are for information only.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. Specific precau-

tionary statements are given in Note 2.

2. Referenced Documents

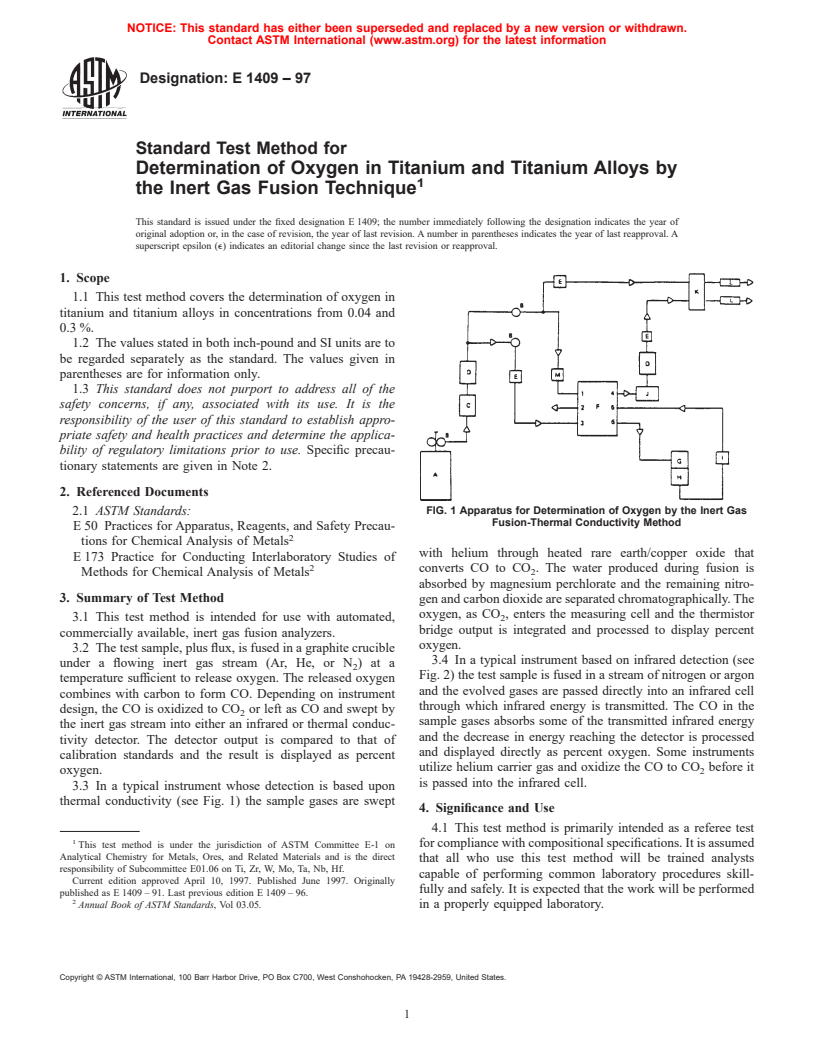

FIG. 1 Apparatus for Determination of Oxygen by the Inert Gas

2.1 ASTM Standards:

Fusion-Thermal Conductivity Method

E 50 Practices for Apparatus, Reagents, and Safety Precau-

tions for Chemical Analysis of Metals

with helium through heated rare earth/copper oxide that

E 173 Practice for Conducting Interlaboratory Studies of

converts CO to CO . The water produced during fusion is

Methods for Chemical Analysis of Metals

absorbed by magnesium perchlorate and the remaining nitro-

3. Summary of Test Method

gen and carbon dioxide are separated chromatographically. The

oxygen, as CO , enters the measuring cell and the thermistor

3.1 This test method is intended for use with automated, 2

bridge output is integrated and processed to display percent

commercially available, inert gas fusion analyzers.

oxygen.

3.2 The test sample, plus flux, is fused in a graphite crucible

3.4 In a typical instrument based on infrared detection (see

under a flowing inert gas stream (Ar, He, or N)ata

Fig. 2) the test sample is fused in a stream of nitrogen or argon

temperature sufficient to release oxygen. The released oxygen

and the evolved gases are passed directly into an infrared cell

combines with carbon to form CO. Depending on instrument

through which infrared energy is transmitted. The CO in the

design, the CO is oxidized to CO or left as CO and swept by

sample gases absorbs some of the transmitted infrared energy

the inert gas stream into either an infrared or thermal conduc-

and the decrease in energy reaching the detector is processed

tivity detector. The detector output is compared to that of

and displayed directly as percent oxygen. Some instruments

calibration standards and the result is displayed as percent

utilize helium carrier gas and oxidize the CO to CO before it

oxygen. 2

is passed into the infrared cell.

3.3 In a typical instrument whose detection is based upon

thermal conductivity (see Fig. 1) the sample gases are swept

4. Significance and Use

4.1 This test method is primarily intended as a referee test

for compliance with compositional specifications. It is assumed

This test method is under the jurisdiction of ASTM Committee E-1 on

Analytical Chemistry for Metals, Ores, and Related Materials and is the direct

that all who use this test method will be trained analysts

responsibility of Subcommittee E01.06 on Ti, Zr, W, Mo, Ta, Nb, Hf.

capable of performing common laboratory procedures skill-

Current edition approved April 10, 1997. Published June 1997. Originally

fully and safely. It is expected that the work will be performed

published as E 1409 – 91. Last previous edition E 1409 – 96.

Annual Book of ASTM Standards, Vol 03.05. in a properly equipped laboratory.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1409–97

7.3 Inert Gas—Use the purity and type (Ar, N ,orHe)

specified by the instrument manufacturer.

7.4 Magnesium Perchlorate, Anhydrous —Used in the in-

strument to absorb water. Use the purity specified by the

instrument manufacturer.

7.5 Nickel Flux Cleaning Solution—Prepare a fresh solution

of nickel cleaning solution by combining 75 mL of acetic acid,

25 mL of HNO and 2 mL of HCl.

7.6 Rare Earth/Copper Oxide—Reagent used in some in-

struments to oxidize CO to CO for thermal conductivity

detection. Use the purity specified by the instrument manufac-

turer.

7.7 Sodium Hydroxide on Clay —Reagent used in some

instruments to absorb CO . Use a purity specified by the

instrument manufacturer.

7.8 Titanium Sample Pickle Solution—Prepare a fresh solu-

FIG. 2 Apparatus for Determination of Oxygen by the Inert Gas

tion of 3 parts 30 % H O and 1 part 48 % HF. HNO may be

2 2 3

Fusion-Infrared Absorption Method

substituted for 30 % H O (see Notes 2 and 3).

2 2

NOTE 2—Warning: HF causes serious burns that may not be immedi-

5. Interferences

ately painful; refer to the paragraph about HF in the Safety Precautions

Section of Practices E 50.

5.1 The elements usually present in titanium and its alloys

do not interfere but there is some evidence to suggest that low NOTE 3—In 1996, alternative sample preparation procedures were

investigated by two laboratories, both active members of subcommittee

purity flux can cause some adsorption of the released oxygen.

E01.06, which has jurisdiction over E1409. The first alternative allows

direct substitution of nitric acid for hydrogen peroxide when preparing

6. Apparatus

titanium pickle solution and subsequent etching of the test specimen as

6.1 Instrument—The general features of the instruments are

specified in 10.2. The second entails removing surfaces of the sample

shown in Figs. 1 and 2.

specimen by filing with a file, thus eliminating the need to use any

6.2 Graphite Crucibles—The crucibles must be made of leaching procedure. The results of the interlaboratory study comparing

these two preparation techniques is summarized in Table 1.

high-purity graphite and be of the dimensions recommended by

the instrument manufacturer.

8. Preparation of Apparatus

6.3 Flux—Wire baskets must be made of high-purity nickel

and the dimensions must meet the requirements of the auto- 8.1 Assemble the apparatus as recommended by the manu-

matic sample drop, if present, on the instrument. (See Note 1.) facturer. Make the required power, gas, and water connections.

Turn on the instrument and allow sufficient time to stabilize the

NOTE 1—In some instruments, nitrogen and oxygen are run sequen-

equipment.

tially and platinum is the required flux for nitrogen. High-purity platinum

8.2 Change the chemical traps and filters as required. Test

can be substituted for nickel in the same ratio of flux to sample.

the furnace and analyzer to ensure the absence of leaks. Make

6.4 Tweezers—Six inches (152 millimetres), solvent and

a minimum of two test runs using a sample as directed in 12.3

acid-resistant plastic (used during the sample preparation

and 12.4 to condition the newly changed filters before attempt-

process).

ing to calibrate the system or to determine the value of the

blank.

7. Reagents

7.1 Acetone—Residue after evaporation must be<

0.0005 %.

7.2 Graphite Powder—High-purity graphite powder speci-

Known commercially as Anhydrone.

fied by the instrument manufacturer. Known commercially as Ascarite II.

TABLE 1 Results of Interlaboratory Study

Lab Sample ID Sample Desc. Filed, % Oxygen HF-HNO Etched, % Oxygen

Comparison of Filed versus HF-HNO Etched Sample Prep Procedures

Lab 1 030 Ti-5A1-2.5Sn 0.160 0.164

Lab 2 0.161 6 0.002, n = 3 0.165 6 0.003, n = 3

Lab 1 035 CP-Ti 0.163 0.163

Lab 2 0.154 6 0.001, n = 3 0.156 6 0.001, n = 3

Lab 1 040 Ti-6A1-4V 0.164 0.160

Lab 2 0.156 6 0.003, n = 3 0.155 6 0.002, n = 3

Comparison of HF-H O Etched versus HF-HNO Etched Sample Prep Procedures

2 2 3

HF-H O Etched, % Oxygen HF-HNO Etched, % Oxygen

2 2 3

Lab 2 CP-Ti 0.1412 6 0.0025, n = 10 0.1422 6 0.0016, n = 10

Ti-6A1-4V 0.1425 6 0.0026, n = 10 0.1418 6 0.0021, n = 10

E1409–97

9. Flux Preparation indicated. Using the last three analyses, adjust the instrument

signal to provide a reading within the range of the certified

9.1 Immerse the flux in nickel flux cleaning solution (see

value of the standard. (Outgassing is accomplished automati-

7.5) for 50 to 60 s, then rinse in running water for 2 to 3 min.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.