ASTM C1135-00(2005)

(Test Method)Standard Test Method for Determining Tensile Adhesion Properties of Structural Sealants

Standard Test Method for Determining Tensile Adhesion Properties of Structural Sealants

SIGNIFICANCE AND USE

Frequently, glass or other glazing or panel materials are structurally adhered with a sealant to a metal framing system. The sealants used for these applications are designed to provide a structural link between the glazing or panel and the framing system.

Although this test method is conducted at one prescribed environmental condition, other environmental conditions and duration cycles can be employed.

SCOPE

1.1 This test method covers a laboratory procedure for quantitatively measuring the tensile adhesion properties of structural sealants, hereinafter referred to as the "sealant".

1.2 The values stated in SI (metric) units are to be regarded as the standard. The inch-pound values given in parentheses are provided for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.Note 1

Two ISO standards are known that develop similar information to C 1135; ISO 8339 and ISO 8340.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1135–00(Reapproved2005)

Standard Test Method for

Determining Tensile Adhesion Properties of Structural

Sealants

This standard is issued under the fixed designation C1135; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Thesealantsusedfortheseapplicationsaredesignedtoprovide

a structural link between the glazing or panel and the framing

1.1 This test method covers a laboratory procedure for

system.

quantitatively measuring the tensile adhesion properties of

4.2 Althoughthistestmethodisconductedatoneprescribed

structural sealants, hereinafter referred to as the “sealant”.

environmental condition, other environmental conditions and

1.2 The values stated in SI (metric) units are to be regarded

duration cycles can be employed.

asthestandard.Theinch-poundvaluesgiveninparenthesesare

provided for information only.

5. Apparatus and Materials

1.3 This standard does not purport to address all of the

5.1 Tensile Testing Machine, capable of producing a tensile

safety concerns, if any, associated with its use. It is the

load on the specimen at the rate of 50.8 6 5.1 mm (2.0 6 0.20

responsibility of the user of this standard to establish appro-

in.) per minute.

priate safety and health practices and determine the applica-

5.1.1 Fixed Member—A fixed or essentially stationary

bility of regulatory limitations prior to use.

member carrying one grip.

NOTE 1—Two ISO standards are known that develop similar informa-

5.1.2 Movable Member—A movable member carrying a

tion to C1135; ISO 8339 and ISO 8340.

second grip.

5.1.3 Grips—The grips should be suitable to firmly grasp

2. Referenced Documents

the test fixture that holds the test specimen and should be

2.1 ASTM Standards:

designed to eliminate eccentric specimen loading. Specimen

C717 Terminology of Building Seals and Sealants

loading should be perpendicular to the substrate/sealant inter-

2.2 ISO Standards:

faces. For alignment purposes, each grip shall have a swivel or

ISO 8339 Determination of Tensile Properties

universal joint at the end nearest to the specimen.

ISO8340 DeterminationofTensilePropertiesatMaintained

5.1.4 Grip Fixture—A fixture capable of being held by the

Extension

grips and furnishing a tensile force to the sealant specimen.

5.2 Spatulas, for use in applying sealant.

3. Terminology

5.3 Caulking Gun, for extruding sealant from cartridges

3.1 Definitions—Refer to Terminology C717 for definitions

when applicable.

of the following terms used in this test method: cohesive

5.4 Substrate Panels—Two substrates of the same finish are

failure,primer,sealant,spacer,structuralsealant,andsubstrate.

required for each test specimen.

4. Significance and Use

NOTE 2—This test method is based on identical substrates of

6.3 3 25.4 3 76.2 mm (0.25 3 1.0 3 3.0 in.) clear float glass. Other

4.1 Frequently, glass or other glazing or panel materials are

substrates may be tested; however, consideration needs to be given to

structurally adhered with a sealant to a metal framing system.

maintaining adequate rigidity of the substrates during testing.

5.5 Spacer—One piece spacer made from polytetrafluoreth-

ThistestmethodisunderthejurisdictionofASTMCommitteeC24onBuilding

ylene(PTFE)orasuitablerigidmaterialshallbeusedtowhich

Seals and Sealants and is the direct responsibility of Subcommittee C24.30 on

the test sealant will not bond.

Adhesion.

Current edition approved Sept. 1, 2005. Published October 2005. Originally 5.6 Substrate Cleaning Materials.

approved in 1990. Last previous edition approved in 2000 as C1135 – 00. DOI:

5.7 Primer (if needed).

10.1520/C1135-00R05.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6. Test Specimen

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

6.1 Assembly:

the ASTM website.

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

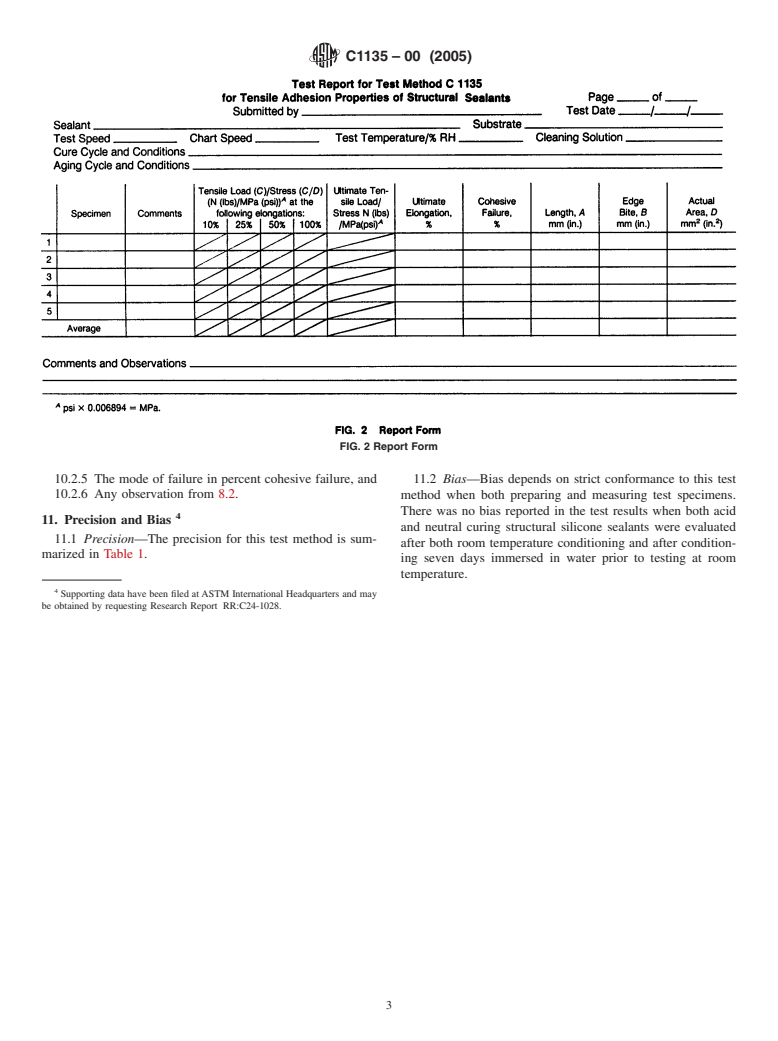

C1135–00 (2005)

6.1.1 Prior to assembly, wipe the substrates with a clean, 7.2 Remove all spacer sections from the specimens. If

dry, lint-free cloth, then thoroughly clean with a solution desired, spacers may be removed prior to the end of the 21 day

appropriate for the substrate material. Prior to evaporation of cure. If removed early, note this in the report.

the cleaning solution, wipe the substrates dry with a clean,

8. Procedure

lint-free cloth.

8.1 Testing:

NOTE 3—The precision and bias statement is based on glass substrates

8.1.1 Pull all specimens on the tensile test machine at

with a recommended cleaning solution of a 50 to 50 ratio isopropanol and

standard conditions at a rate of 50.8 mm (2.0 in.) per minute.

water.

If an analog chart recording device is being used, the chart

6.1.2 Apply recommended primer, if required. Then, con-

speed should be a minimum of 127 mm (5.0 in.) per minute

struct the test specimen assemblies by forming a sealant cavity

(508 mm (20.0 in.) per minute is preferred) to allow for a more

12.7 by 12.7 by 50.8 mm (0.50 by 0.50 by 2.0 in.) between two

accurate reading of force at specific elongations.

substratepanels(seeFig.1)withtheaidofappropriatespacers.

8.1.2 Measure and record to the nearest 0.8 mm (0.03125

6.2 Preparation of Test Assemblies:

in.) the actual minimum length (Dimension A) and minimum

6.2.1 Prepare a set of five test specimen assemblies for each

width (Dimension B), in millimetres (inches) as shown

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.