ASTM F2095-07

(Test Method)Standard Test Methods for Pressure Decay Leak Test for Flexible Packages With and Without Restraining Plates

Standard Test Methods for Pressure Decay Leak Test for Flexible Packages With and Without Restraining Plates

SIGNIFICANCE AND USE

These test methods provide a rapid, simple to apply method to detect small leaks in flexible package seals or walls at the leak rate level of greater than 1 × 10−4 sccs, thus providing a measure of package integrity. Porous barrier film packages made non-porous with an impermeable film forming coating may demonstrate lateral leakage through the barrier material. Verification of leakage differences from background leakage must be included in validation methods. The use of calibrated hole sizes or orifices may be appropriate to determine leakage sensitivity or barrier integrity for these materials.

While theoretical leak rate sensitivity can be established by calculation, the test measurement is in pressure units and the measuring instrument must be calibrated, certified, and verified with these units.

The pressure decay method of leak testing is a physical measure of package integrity. When testing medical packaging which must conform to ISO 11607–1: 2006 standards, it may necessary to verify the results of the pressure decay test method with other sterile package integrity test methods.

Test Method A allows packages to be pressurized without restraint. In Test Method A the pouch, tray, or other type package will contain a volume of air defined by its mechanical configuration and its ability to resist internal pressure applied. This test method requires that the package reach a stable volume configuration (stop stretching) to make a measurement.

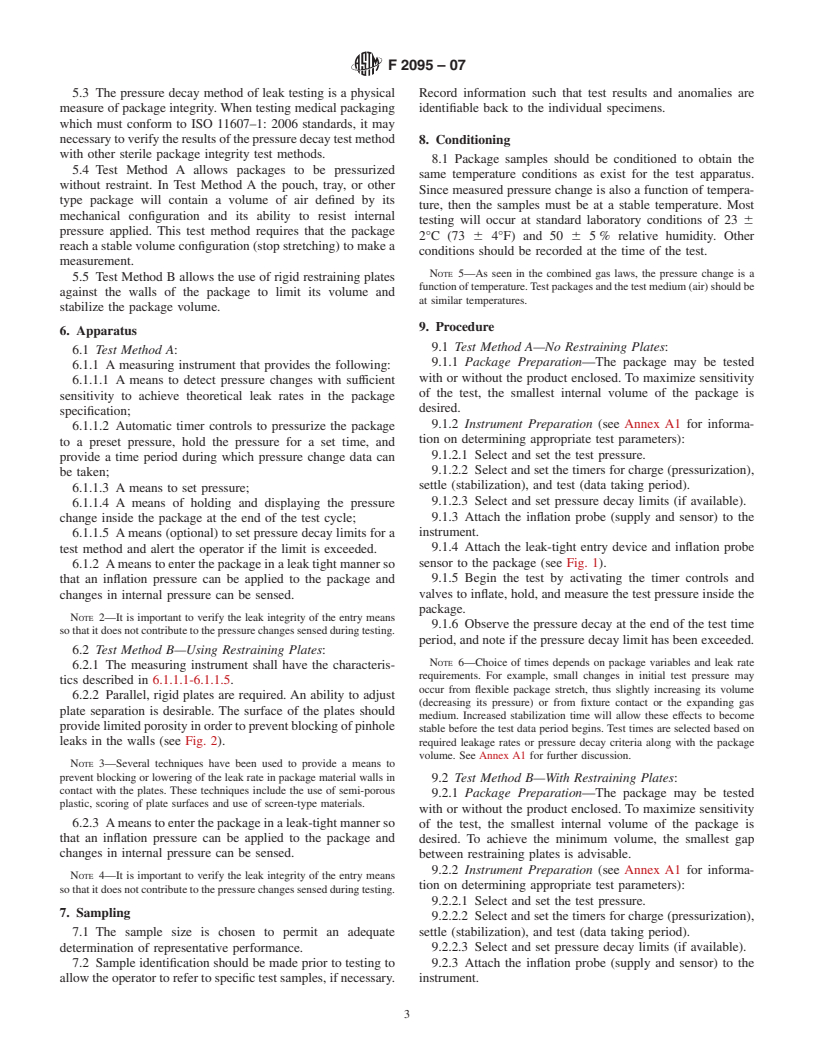

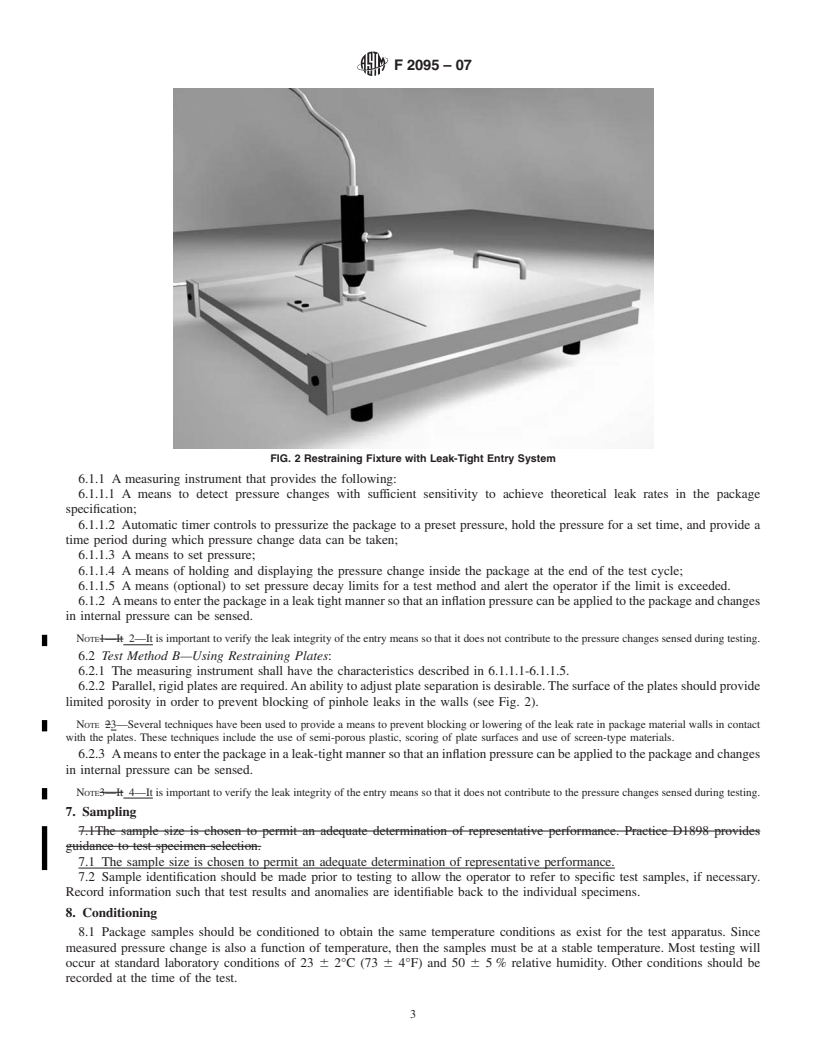

Test Method B allows the use of rigid restraining plates against the walls of the package to limit its volume and stabilize the package volume.

SCOPE

1.1 These test methods cover the measurement of leaks in nonporous film, foil, or laminate flexible pouches and foil-sealed trays, which may be empty or enclose solid product. If product is enclosed, seals or surfaces cannot be in contact with water, oils, or other liquid.

1.2 These test methods will detect leaks at a rate of 1 104 sccs (standard cubic centimetres per second) or greater, in flexible packages. The limitation of leak rate is dependent on package volume as tested.

1.3 The following test methods are included:

1.3.1 Test Method A Pressure Decay Leak Test for Flexible Packages Without Restraining Plates

1.3.2 Test Method B Pressure Decay Leak Test for Flexible Packages With Restraining Plates

1.4 These test methods are destructive in that they require entry into the package to supply an internal pressure of gas, typically air or nitrogen, although other gases may be used. The entry connection into the flexible package must be leak-tight.

1.5 For porous packages, see .

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2095–07

Standard Test Methods for

Pressure Decay Leak Test for Flexible Packages With and

1

Without Restraining Plates

This standard is issued under the fixed designation F2095; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 These test methods cover the measurement of leaks in

F17 Terminology Relating to Flexible Barrier Packaging

nonporous film, foil, or laminate flexible pouches and foil-

2.2 Other Document:

sealed trays, which may be empty or enclose solid product. If

ANSI/AAMI/ISO11607–1:2006 Packaging for Terminally

product is enclosed, seals or surfaces cannot be in contact with

Sterilized Medical Devices—Part 1: Requirements for

water, oils, or other liquid.

−4

Materials, Sterile Barrier Systems, and Packaging Sys-

1.2 Thesetestmethodswilldetectleaksatarateof1 310

3

tems

sccs (standard cubic centimetres per second) or greater, in

flexible packages. The limitation of leak rate is dependent on

3. Terminology

package volume as tested.

3.1 Definitions of Terms Specific to This Standard:

1.3 The following test methods are included:

3.1.1 integrity—the unimpaired physical condition of the

1.3.1 Test Method A—Pressure Decay Leak Test for Flex-

package. This implies that there are no leaks in the seals or

ible Packages Without Restraining Plates

body materials.

1.3.2 Test Method B—Pressure Decay Leak Test for Flex-

3.1.2 leak—See TerminologyF17.

ible Packages With Restraining Plates

3.1.3 nonporous—types of materials that are not purposely

1.4 These test methods are destructive in that they require

designed to transfer gases through their matrix.

entry into the package to supply an internal pressure of gas,

3.1.4 restraining plates—plates of rigid material, for ex-

typicallyairornitrogen,althoughothergasesmaybeused.The

ample,aluminum,thatareusedtorestrictthemovementofthe

entry connection into the flexible package must be leak-tight.

package during inflation.

1.5 For porous packages, see 9.3.

3.1.5 seal—See TerminologyF17.

1.6 This standard does not purport to address all of the

3.1.6 standard cubic centimetre per second (sccs)—theflow

safety concerns, if any, associated with its use. It is the

rate of a gas (air) at standard conditions of 20°C (68°F) and

responsibility of the user of this standard to establish appro-

101.3 kPa (14.7 psig) (1 atmosphere or 760 mm Hg).

priate safety and health practices and determine the applica-

3.1.6.1 Discussion—Conditions may be varied depending

bility of regulatory limitations prior to use.

on the source of data.Always check the definition being used.

2. Referenced Documents

4. Summary of Test Method

2

2.1 ASTM Standards:

4.1 Detection of leak paths in flexible packages that have

D4332 Practice for Conditioning Containers, Packages, or

nonporous material surfaces and seals can be accomplished by

Packaging Components for Testing

pressurization of the package to a fixed pressure, shutting off

E177 Practice for Use of the Terms Precision and Bias in

the pressure and connecting a pressure transducer. Observed

ASTM Test Methods

changes in pressure indicate the presence of leakage paths in

the package seals or pinholes in the surfaces.This leak may be

1

represented in decay pressure units or calculated leak rate

These test methods are under the jurisdiction of ASTM Committee F02 on

FlexibleBarrierPackagingandarethedirectresponsibilityofSubcommitteeF02.40

units. To accomplish this technique, a leak-tight measuring

on Package Integrity.

path must be available between the package interior volume

Current edition approved Oct. 1, 2007. Published November 2007. Originally

and the pressure transducer (see Fig. 1).

approved in 2001. Last previous edition approved in 2001 as F2095–01.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F2095–07

FIG. 1 Leak-Tight Entry System

−4

NOTE 1—The coating used on porous barrier films will mask defects

at the leak rate level of greater than 1 3 10 sccs, thus

(pin-holes) in/through the porous material but not defects in the seals.

providin

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:F2095–01 Designation:F2095–07

Standard Test Methods for

Pressure Decay Leak Test for Nonporous Flexible Packages

1

With and Without Restraining Plates

This standard is issued under the fixed designation F2095; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 These test methods cover the measurement of leaks in nonporous film, foil, or laminate flexible pouches and foil-sealed

trays, which may be empty or enclose solid product. If product is enclosed, seals or surfaces cannot be in contact with water, oils,

or other liquid.

−4

1.2 Thesetestmethodswilldetectleaksatarateof1 310 sccs(standardcubiccentimetrespersecond)orgreater,inflexible

packages. The limitation of leak rate is dependent on package volume as tested.

1.3 The following test methods are included:

1.3.1 Test Method A— Pressure Decay Leak Test for Nonporous Flexible Packages Without Restraining Plates

1.3.2 Test Method B— Pressure Decay Leak Test for Nonporous Flexible Packages With Restraining Plates

1.4 Thesetestmethodsaredestructiveinthattheyrequireentryintothepackagetosupplyaninternalpressureofgas,typically

air or nitrogen, although other gases may be used. The entry connection into the flexible package must be leak-tight.

1.5

1.5 For porous packages, see 9.3.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

2

D1898 Practice for Sampling of Plastics ASTM Standards:

D4332 Practice for Conditioning Containers, Packages, or Packaging Components for Testing

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

F17Terminology Relating to Flexible Barrier Packaging

F1327Terminology Relating to Barrier Materials for Medical Packaging Terminology Relating to Flexible Barrier Packaging

2.2 Other Document:

ANSI/AAMI/ISO 11607Packaging for Terminally Sterilized Medical DevicesANSI/AAMI/ISO11607–1:2006 Packaging for

3

TerminallySterilizedMedicalDevices—Part1:RequirementsforMaterials,SterileBarrierSystems,andPackagingSystems

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 integrity—the unimpaired physical condition of the package. This implies that there are no leaks in the seals or body

materials.

3.1.2 leak—See Terminology F1327—See Terminology F17.

3.1.3 nonporous—types of materials that are not purposely designed to transfer gases through their matrix.

1

ThesetestmethodsareunderthejurisdictionofASTMCommitteeF02onFlexibleBarrierMaterialsandarethedirectresponsibilityofSubcommitteeF02.40onPackage

Integrity.

Current edition approved April 10, 2001. Published June 2001.

1

These test methods are under the jurisdiction of ASTM Committee F02 on Flexible Barrier Packaging and are the direct responsibility of Subcommittee F02.40 on

Package Integrity.

Current edition approved Oct. 1, 2007. Published November 2007. Originally approved in 2001. Last previous edition approved in 2001 as F2095–01.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F2095–07

3.1.4 restraining plates—platesofrigidmaterial,forexample,aluminum,thatareusedtorestrictthemovementofthepackage

during inflation.

3.1.5 seal—See Terminology F17.

3.1.6 standard cubic centimetre per second (sccs)—the flow rate of a gas (air) at standard conditions of 20°C (68°F) and 101.3

kPa (14.7 psig) (1 atmosphere or 760 mm Hg).

3.1.6.1 Discussion—Conditions may be varied depending on the source of data. Always check the definition being used.

4. Summary of Test Method

4.1 Detection of leak paths in flexible packages that have n

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.