ASTM F2363-04

(Specification)Standard Specification for United States Coast Guard Type II or IMO MARPOL 73/78 Annex IV Marine Sanitation Devices (Flow Through Treatment)

Standard Specification for United States Coast Guard Type II or IMO MARPOL 73/78 Annex IV Marine Sanitation Devices (Flow Through Treatment)

SCOPE

1.1 This specification covers the design, manufacture, performance, operation, functioning, and testing of USCG Type II Marine Sanitation Device or IMO MARPOL 73/78 Annex IV flow through treatment device intended to process sewage and graywater generated during the ship's normal service. This specification is intended for use by purchasers, designers, and manufacturers of shipboard environmental pollution control equipment to determine the requirements for equipment purchase, equipment use, and design considerations.

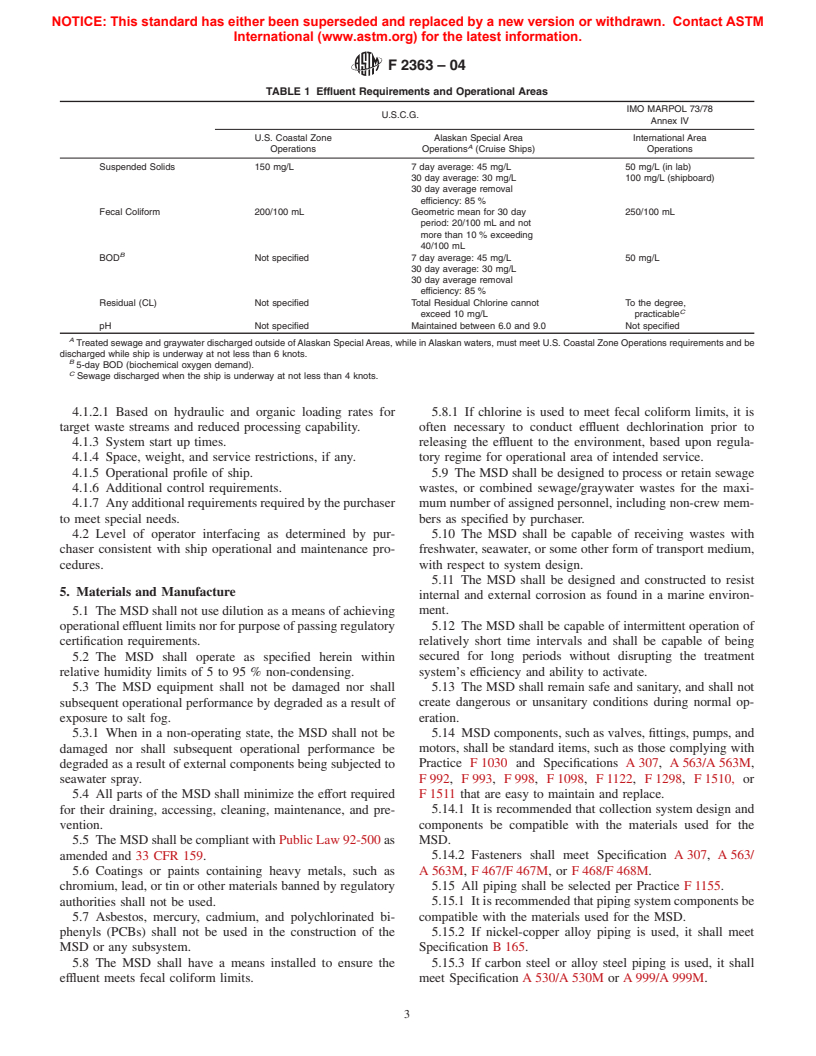

1.2 The device shall be capable of meeting the effluent requirements detailed in Table 1 with respect to ship's operational area.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

An American National Standard

Designation: F 2363 – 04

Standard Specification for

United States Coast Guard Type II or IMO MARPOL 73/78

Annex IV Marine Sanitation Devices (Flow Through

Treatment)

This standard is issued under the fixed designation F 2363; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope F 1030 Practice for Selection of Valve Operators

F 1098 Specification for Envelope Dimensions for Butterfly

1.1 This specification covers the design, manufacture, per-

Valves-NPS 2 to 24

formance, operation, functioning, and testing of USCGType II

F 1122 Specification for Quick Disconnect Couplings

Marine Sanitation Device or IMO MARPOL 73/78 Annex IV

F 1155 Practice for Selection and Application of Piping

flow through treatment device intended to process sewage and

Systems Materials

graywater generated during the ship’s normal service. This

F 1166 Practice for Human Engineering Design for Marine

specification is intended for use by purchasers, designers, and

Systems, Equipment and Facilities

manufacturers of shipboard environmental pollution control

F 1298 Specification for Flexible, Expansion-Type Ball

equipment to determine the requirements for equipment pur-

Joints for Marine Applications

chase, equipment use, and design considerations.

F 1323 Specification for Shipboard Incinerators

1.2 The device shall be capable of meeting the effluent

F 1510 Specification for Rotary Positive Displacement

requirements detailed in Table 1 with respect to ship’s opera-

Pumps, Commercial Ships Use

tional area.

F 1511 Specification for Mechanical Seals for Shipboard

2. Referenced Documents

Pump Applications

F 2044 Specification for Liquid Level Indicating Equip-

2.1 ASTM Standards:

ment, Electrical

A 307 Specification for Carbon Steel Bolts and Studs, 60

2.2 ANSI Standards:

000 PSI Tensile Strength

B16.1 Cast Iron Pipe Flanges and Flange Fittings

A 530/A 530M Specification for General Requirements for

B16.5 Steel Pipe Flanges, Flanged Valves and Fittings 150,

Specialized Carbon and Alloy Steel Pipe

300, 400, 600, 900, 1500 and 2500 lb

A 563/A 563M Specification for Carbon and Alloy Steel

B16.11 Forged Steel Fittings, SocketWelding andThreaded

Nuts

B16.24 Bronze Flanges and Flanged Fittings 150, 300 lb

A 999/A 999M Specification for General Requirements for

2.3 Code of Federal Regulations:

Alloy and Stainless Steel Pipe

33 CFR 159 Department of Homeland Security, U.S. Coast

B 165 Specification for Nickel-Copper Alloy (UNS

Guard (USCG), Marine Sanitation Devices

N04400) Seamless Pipe and Tube

40 CFR Part 136 Guidelines Establishing Test Procedures

F 467/F 467M Specification for Nonferrous Nuts for Gen-

for the Analysis of Pollutants

eral Use

40 CFR 140 Environmental Protection Agency, Marine

F 468/F 468M Specification for Nonferrous Bolts, Hex Cap

Sanitation Device Standard, January 29, 1976

Screws and Studs for General Use

46 CFR Part 111 Department of Homeland Security, U.S.

F 992 Specification for Valve Label Plates

Coast Guard (USCG), Electrical Systems

F 993 Specification for Valve Locking Devices

46 CFR Part 147 Department of Homeland Security, U.S.

F 998 Specification for Centrifugal Pump, Shipboard Use

Coast Guard (USCG), Hazardous Ships’ Stores

49 CFR 171 Department ofTransportation (DoT), Research

and Special Programs Administration (RSPA), General

This specification is under the jurisdiction of ASTM Committee F25 on Ships

Information, Regulations and Definitions

and Marine Technology and is the direct responsibility of Subcommittee F25.06 on

Marine Environmental Protection.

Current edition approved July 1, 2004. Published August 2004.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036.

Standards volume information, refer to the standard’s Document Summary page on AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

the ASTM website. 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

F2363–04

2.4 Other Documents: Does not include industrial wastes, infectious wastes, human

ANSI/NFPA No. 70 National Electrical Code body wastes, and animal wastes.

IEEE 45-2002 Recommended Practice for Electric Installa-

3.1.9 holding tank—generally designed to collect and store

tions on Shipboard treated or untreated waste until it can be legally discharged or

Instrument Society of America (RP 12.2)

pumped to a dockside facility.

International Convention for the Prevention of Pollution 3.1.10 hydraulic loading—the volume of sewage or gray-

from Ships (1973) as modified by the Protocols of 1978

water, or both, applied to the surface of the filtering media per

(MARPOL 73/78) and 1997 and associated Annexes, time period.

Including Annex IV and Annex VI

3.1.11 manufacturer—company that designs, assembles, or

Resolution MEPC.2(IV) Recommendation on International

imports the various parts of the system (except where specified

Effluent Standards and Guidelines for Performance Tests

otherwise).

for Sewage Treatment Plants

3.1.12 marine sanitation device (MSD)—any equipment

MARPOL 73/78 Annex IVAnnex B Guidelines for Perfor-

designed to receive, retain, treat, or discharge sewage, and any

mance Tests for Sewage Treatment Plants with Respect to

process to treat such sewage.

Effluent Standards

3.1.13 organic loading—the concentration of pollutants ap-

Public Law 92-500 Federal Water Pollution Control Act,

plied to the surface of the filtering media per time period.

October 18, 1972, as amended by Public Law 95-217,

3.1.14 recognized facility—recognized facility means any

Clean Water Act, December 27, 1977, as amended

laboratory or facility listed by the Coast Guard as a recognized

Public Law 106-554 Title XIV CertainAlaskan Cruise Ship

facility under 33 CFR 159.

Operations, of the Miscellaneous Appropriations Act of

3.1.15 sewage—wastes of human origin from water closets,

urinals, and medical facilities transported by the ship soil drain

SNAME T&R Bulletin No. 3-37 Design Guide for Ship-

system. It also includes animal wastes from spaces containing

board Airborne Noise Control

living animals. When graywater is combined with sewage, the

Underwriters Laboratories STD 698 Industrial Control

waste stream is characterized as sewage.

Equipment for Use in Hazardous Locations

3.1.16 USCG Type II MSD—a flow through device capable

ofproducinganeffluentwithafecalcoliformbacterialcountof

3. Terminology

not more than 200 per 100 mL and with a total suspended

3.1 Definitions of Terms Specific to This Standard: solids concentration of not more than 150 mg/L.

3.1.1 collection, holding, and transfer tank (CHT)—tank 3.1.17 vacuum collection—the method for collection of

used to collect by gravity sewage or graywater, or both, prior sewage used in VCHT systems.

to legal discharge or pumping to shore facility.

3.1.18 vacuum collection, holding, and transfer tank

3.1.2 deodorant—substance which masks or destroys offen- (VCHT)—tank utilizing vacuum suction to hold sewage and/or

sive odors.

graywater for legal discharge or pumping ashore.

3.1.3 discharge—includes spilling, leaking, pumping, pour-

ing, emitting, emptying, and dumping.

4. Ordering Information

3.1.4 effluent—discharge from a properly functioning MSD.

4.1 Orders shall include the following information:

3.1.5 failure—any malfunction that causes an MSD to shut

4.1.1 Sizing Requirements:

down or that, if not corrected, would preclude sewage process-

4.1.1.1 Design sizing requirements shall include consider-

ing or prevent the MSD from meeting the applicable perfor-

ation of collection method (gravity or vacuum) utilized for

mance requirements.

Marine Sanitation Device.

3.1.6 fecal coliform bacteria—organisms, associated with

4.1.1.2 Hydraulic loading for both graywater and sewage

the intestines of warm-blooded animals, that commonly are

generation rates.

used to indicate the presence of fecal material and the potential

(1) If capacity is provided in litres per day per person or

presence of organisms capable of causing human disease.

gallons per day per person, the maximum number of personnel

3.1.7 gravity collection—the method of collection for sew-

(crew and passenger) must also be supplied.

age and graywater used in CHT systems.

(a) When specifying growth margin, it is important to

3.1.8 graywater—discarded water from deck drains, lava-

consider the potential for increases in crew size or number of

tories,showers,dishwashers,laundries,anddrinkingfountains.

passengers, or both, over the life of the ship.

4.1.1.3 Organic loading for both graywater and sewage

generation rates.

Available from Institute of Electrical and Electronics Engineers, Inc. (IEEE), 4.1.1.4 Thermal loading and expected temperature variation

445 Hoes Ln., P.O. Box 1331, Piscataway, NJ 08854-1331

if processing combined sewage and graywater waste streams.

Available from Instrumentation, Systems, and Automation Society, 67 Alex-

(1) Take into account the management of potential influent

ander Dr., Research Triangle Park, NC 27709.

temperature variation in applications where the MSD treats a

Available from International Maritime Organization (IMO), 4 Albert Embank-

ment, London SE1 7SR, U.K.

combined sewage and graywater waste stream. Consideration

AvailablefromSocietyofNavalArchitectsandMarineEngineers,601Pavonia

might include the addition of a temperature/flow equalization

Ave., Jersey City, NJ 07306.

9 tank or other means to adjust temperature to meet 6.9.1.

Available from Underwriters Laboratories (UL), Corporate Progress, 333

Pfingsten Rd., Northbrook, IL 60062. 4.1.2 Processing Rate Requirements:

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

F2363–04

TABLE 1 Effluent Requirements and Operational Areas

IMO MARPOL 73/78

U.S.C.G.

Annex IV

U.S. Coastal Zone Alaskan Special Area International Area

A

Operations Operations (Cruise Ships) Operations

Suspended Solids 150 mg/L 7 day average: 45 mg/L 50 mg/L (in lab)

30 day average: 30 mg/L 100 mg/L (shipboard)

30 day average removal

efficiency: 85 %

Fecal Coliform 200/100 mL Geometric mean for 30 day 250/100 mL

period: 20/100 mL and not

more than 10 % exceeding

40/100 mL

B

BOD Not specified 7 day average: 45 mg/L 50 mg/L

30 day average: 30 mg/L

30 day average removal

efficiency: 85 %

Residual (CL) Not specified Total Residual Chlorine cannot To the degree,

C

exceed 10 mg/L practicable

pH Not specified Maintained between 6.0 and 9.0 Not specified

A

Treated sewage and graywater discharged outside ofAlaskan SpecialAreas, while inAlaskan waters, must meet U.S. Coastal Zone Operations requirements and be

discharged while ship is underway at not less than 6 knots.

B

5-day BOD (biochemical oxygen demand).

C

Sewage discharged when the ship is underway at not less than 4 knots.

4.1.2.1 Based on hydraulic and organic loading rates for 5.8.1 If chlorine is used to meet fecal coliform limits, it is

target waste streams and reduced processing capability. often necessary to conduct effluent dechlorination prior to

4.1.3 System start up times. releasing the effluent to the environment, based upon regula-

4.1.4 Space, weight, and service restrictions, if any. tory regime for operational area of intended service.

4.1.5 Operational profile of ship. 5.9 The MSD shall be designed to process or retain sewage

4.1.6 Additional control requirements. wastes, or combined sewage/graywater wastes for the maxi-

4.1.7 Anyadditionalrequirementsrequiredbythepurchaser mum number of assigned personnel, including non-crew mem-

to meet special needs. bers as specified by purchaser.

4.2 Level of operator interfacing as determined by pur- 5.10 The MSD shall be capable of receiving wastes with

chaser consistent with ship operational and maintenance pro- freshwater, seawater, or some other form of transport medium,

cedures. with respect to system design.

5.11 The MSD shall be designed and constructed to resist

5. Materials and Manufacture

internal and external corrosion as found in a marine environ-

ment.

5.1 The MSD shall not use dilution as a means of achieving

operationaleffluentlimitsnorforpurposeofpassingregulatory 5.12 The MSD shall be capable of intermittent operation of

relatively short time intervals and shall be capable of being

certification requirements.

5.2 The MSD shall operate as specified herein within secured for long periods without disrupting the treatment

system’s efficiency and ability to activate.

relative humidity limits of 5 to 95 % non-condensing.

5.3 The MSD equipment shall not be damaged nor shall 5.13 The MSD shall remain safe and sanitary, and shall not

subsequent operational performance by degraded as a result of create dangerous or unsanitary conditions during normal op-

exposure to salt fog. eration.

5.3.1 When in a non-operating state, the MSD shall not be 5.14 MSD components, such as valves, fittings, pumps, and

damaged nor shall subsequent operational performance be motors, shall be standard items, such as those complying with

degraded as a result of external components being subjected to Practice F 1030 and Specifications A 307, A 563/A 563M,

seawater spray. F 992, F 993, F 998, F 1098, F 1122, F 1298, F 1510, or

5.4 All parts of the MSD shall minimize the effort required F 1511 that are easy to maintain and replace.

for their draining, accessing, cleaning, maintenance, and pre- 5.14.1 It is recommended that collection system design and

vention. components be compatible with the materials used for the

MSD.

5.5 TheMSDshallbecompliantwithPublicLaw92-500as

amended and 33 CFR 159. 5.14.2 Fasteners shall meet Specification A 307, A 563/

A 563M, F 467/F 467M,or F 468/F 468M.

5.6 Coatings or paints containing heavy metals, such as

chromium, lead, or tin or other materials banned by regulatory 5.15 All piping shall be selected per Practice F 1155.

5.15.1 Itisrecommendedthatpipingsystemcomponentsbe

authorities shall not be used.

5.7 Asbestos, mercury, cadmium, and polychlorinated bi- compatible with the materials used for the MSD.

phenyls (PCBs) shall not b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.