ASTM D3230-99(2004)

(Test Method)Standard Test Method for Salts in Crude Oil (Electrometric Method)

Standard Test Method for Salts in Crude Oil (Electrometric Method)

SCOPE

1.1 This test method covers the determination of the approximate chloride (salts) concentration in crude oil. The range of concentration covered is 0 to 500 mg/kg or 0 to 150 lb/1000 bbl as chloride concentration/volume of crude oil.

1.2 This test method measures conductivity in the crude oil due to the presence of common chlorides, such as sodium, calcium, and magnesium. Other conductive materials may also be present in the crude oil.

1.3 The values stated in SI units are regarded as standard. Acceptable concentration units are g/m3 or PTB (lb/1000 bbl).

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 7.3, 7.4, and 7.11.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D3230–99 (Reapproved 2004)

Standard Test Method for

Salts in Crude Oil (Electrometric Method)

This standard is issued under the fixed designation D 3230; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 salts in crude oil—commonly, chlorides of sodium,

calcium, and magnesium dissolved in crude oil. Other inor-

1.1 This test method covers the determination of the ap-

ganic chlorides may also be present.

proximate chloride (salts) concentration in crude oil.The range

of concentration covered is 0 to 500 mg/kg or 0 to 150 lb/1000

4. Summary of Test Method

bbl as chloride concentration/volume of crude oil.

4.1 Thistestmethodmeasurestheconductivityofasolution

1.2 This test method measures conductivity in the crude oil

of crude oil in a mixed alcohol solvent when subjected to an

due to the presence of common chlorides, such as sodium,

electrical stress.This test method measures conductivity due to

calcium, and magnesium. Other conductive materials may also

the presence of inorganic chlorides, and other conductive

be present in the crude oil.

material, in the crude oil. A homogenized test specimen is

1.3 The values stated in SI units are regarded as standard.

3 dissolved in a mixed alcohol solvent and placed in a test cell

Acceptable concentration units are g/m or PTB (lb/1000 bbl).

consisting of a beaker and a set of electrodes. A voltage is

1.4 This standard does not purport to address all of the

impressed on the electrodes, and the resulting current flow is

safety concerns, if any, associated with its use. It is the

measured. The chloride (salt) content is obtained by reference

responsibility of the user of this standard to establish appro-

to a calibration curve of current versus chloride concentration

priate safety and health practices and determine the applica-

of known mixtures. Calibration curves are based on standards

bility of regulatory limitations prior to use. For specific

prepared to approximate the type and concentration of chlo-

warning statements, see 7.3, 7.4, and 7.11.

rides in the crude oils being tested.

2. Referenced Documents

5. Significance and Use

2.1 ASTM Standards:

5.1 This test method is used to determine the approximate

D 91 Test Method for Precipitation Number of Lubricating

chloride content of crude oils, a knowledge of which is

Oils

important in deciding whether or not the crude oil needs

D 381 Test Method for Existent Gum in Fuels by Jet

desalting. The efficiency of the process desalter can also be

Evaporation

evaluated.

D 1193 Specification for Reagent Water

5.2 Excessivechlorideleftinthecrudeoilfrequentlyresults

D 4928 Test Method for Water in Crude Oils by Coulom-

in higher corrosion rates in refining units and also has

etric Karl Fischer Titration

detrimental effects on catalysts used in these units.

D 5002 Test Method for Density and Relative Density of

5.3 This test method provides a rapid and convenient means

Crude Oils by Digital Density Analyzer

of determining the approximate content of chlorides in crude

3. Terminology oil and is useful to crude oil processors.

3.1 Definitions of Terms Specific to This Standard:

6. Apparatus

3.1.1 PTB—lb/1000 bbl.

6.1 The apparatus (seeAnnexA1) shall consist of a control

unit capable of producing and displaying several voltage levels

for applying stress to a set of electrodes suspended in a test

This test method is under the jurisdiction of ASTM Committee D02 on

beaker containing a test solution. The apparatus shall be

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

capable of measuring and displaying the current (mA) con-

D02.03 on Elemental Analysis.

ducted through the test solution between the electrodes at each

Current edition approved May 1, 2004. Published June 2004. Originally

voltage level.

approved in 1973. Last previous edition approved in 1999 as D 3230–99.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

NOTE 1—Some apparatus are capable of measuring voltage and current

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

internally and, after comparison to internal calibration curves, of display-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. ing the resultant concentration.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3230–99 (2004)

present in a number of common crude oils. When the relative proportions

6.2 Test Beaker—See Annex A1.

ofcalcium,magnesium,andsodiumchloridesareknownforagivencrude

6.3 Pipet, 10 mL (total delivery)—The type of pipet that is

oil, such proportions should be used for most the accurate results.

rinsed to ensure the entire volume of the material is contained

7.10 Salts, Mixed Solution (Dilute Solution)—Transfer 10

in the intended volume.

6.4 Cylinders, 100 mL, stoppered. mL of the concentrated mixed chlorides solution into a

1000-mL volumetric flask, and dilute to the mark with mixed

6.5 Other volumetric and graduated pipets and volumetric

flasks. alcohol solvent.

7.11 Xylene, reagent grade, minimum purity. (Warning—

7. Reagents and Materials

Flammable. Vapor harmful.)

7.1 Purity of Reagents—Reagent grade chemicals shall be

8. Sampling

used in all tests. Unless otherwise indicated, it is intended that

8.1 Obtain a sample and test specimen in accordance with

all reagents shall conform to the specifications of theAmerican

Test Method D 4928. Ensure that the sample is completely

Chemical Society, where such specifications are available.

homogenized with a suitable mixer. See Annex A1 of Test

Other grades may be used, provided it is first ascertained that

Method D 4928 for suitable apparatus and proving.

the reagent is of sufficiently high purity to permit its use

8.2 Samples of very viscous materials may be warmed until

without lessening the accuracy of the determination.

they are reasonably fluid before they are sampled; however, no

7.2 Purity of Water—Unless otherwise indicated, references

sample shall be heated more than is necessary to lower the

to water shall be understood to mean reagent water as defined

viscosity to a manageable level.

by Type II in Specification D 1193.

8.3 Samplesofcrudeoilcontainwaterandsedimentandare

7.3 Mixed Alcohol Solvent—Mix 63 volumes of 1-butanol

inhomogeneous by nature.The presence of water and sediment

and 37 volumes of absolute methyl alcohol (anhydrous). To

will influence the conductivity of the sample. The utmost care

each litre of this mixture, add 3 mL of water. (Warning—

shall be taken in obtaining homogenized representative

Flammable. Liquid causes eye burns. Vapor harmful. May be

samples.

fatal or cause blindness if swallowed or inhaled.)

NOTE 2—The mixed alcohol solvent is suitable for use if its conduc-

9. Preparation of Apparatus

tivity is less than 0.25 mA at 125 V ac. High conductivity can be due to

9.1 Support the apparatus on a level, steady surface, such as

excess water in the solvent and can indicate that the methyl alcohol used

a table.

is not anhydrous.

9.2 Prepare the apparatus for operation in accordance with

7.4 ASTM Precipitation Naphtha, conforming to the re-

the manufacturer’s instructions for calibrating, checking, and

quirements of Test Method D 91. (Warning—Extremely

operating the equipment. (Warning—The voltage applied to

Flammable. Harmful if inhaled. Vapors may cause flash fire.)

the electrodes can be as great as 250 V ac, and hazardous.)

7.5 Calcium Chloride (CaCl ) Solution (10 g/L)—Transfer

9.3 Thoroughly clean and dry all parts of the test beaker, the

1.006 0.01 g of CaCl , or the equivalent weight of a hydrated

electrodes, and its accessories before starting the test, being

salt, into a 100-mL volumetric flask and dissolve in 25 mL of

sure to remove any solvent that had been used to clean the

water. Dilute to the mark with mixed alcohol solvent.

apparatus.

7.6 Magnesium Chloride (MgCl ) Solution (10 g/L)—

Transfer 1.00 6 0.01 g of MgCl , or the equivalent weight of

10. Calibration

a hydrated salt, into 100-mL volumetric flask and dissolve in

10.1 The conductivity of solutions is affected by the tem-

25 mLof water. Dilute to the mark with mixed alcohol solvent.

perature of the specimen when measurements are made. The

7.7 Sodium Chloride (NaCl) Solution (10 g/L)—Transfer

temperature of the test specimen at the time of measurement

1.00 6 0.01 g of NaCl into a 100-mL volumetric flask and

shall be within 3°C of the temperature at which the calibration

dissolve in 25 mL of water. Dilute to the mark with mixed

curves were made.

alcohol solvent.

10.2 Establish a blank measurement by following the pro-

7.8 Oil, Refined Neutral—Any refined chloride-free oil of

cedure in 10.3 and 10.4, omitting the mixed salts solution.

approximately 20 mm /sec (cSt) viscosity at 40°C and free of

Whentheindicatedelectrodecurrentisgreaterthan0.25mAat

additive.

125 V ac, water or another conductive impurity is present and

7.9 Salts, Mixed Solution (Concentrated Solution)—

its source must be found and eliminated before calibration can

Combine10.0mLoftheCaCl solution,20.0mLoftheMgCl

2 2

be completed. Determine a blank measurement each time fresh

solution, and 70.0 mL of the NaCl solution, and mix thor-

xylene or mixed solvent is used.

oughly.

10.3 Into a dry, 100-mL graduated, glass-stoppered mixing

NOTE 3—The 10:20:70 proportions are representative of the chlorides cylinder, add 15 mL of xylene. From a pipet (total delivery),

add 10 mLof neutral oil. Rinse the pipet with xylene until free

of oil. Make up to 50 mL with xylene. Stopper and shake the

cylinder vigorously for approximately 60 s to effect solution.

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

Add a quantity of dilute mixed salts solution, in accordance

listed by the American Chemical Society, see Annual Standards for Laboratory

with Table 1, that is appropriate to the range of salt contents to

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

be measured. Dilute to 100 mL with mixed alcohol solvent.

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

MD. Again shake the cylinder vigorously for approximately 30 s to

D3230–99 (2004)

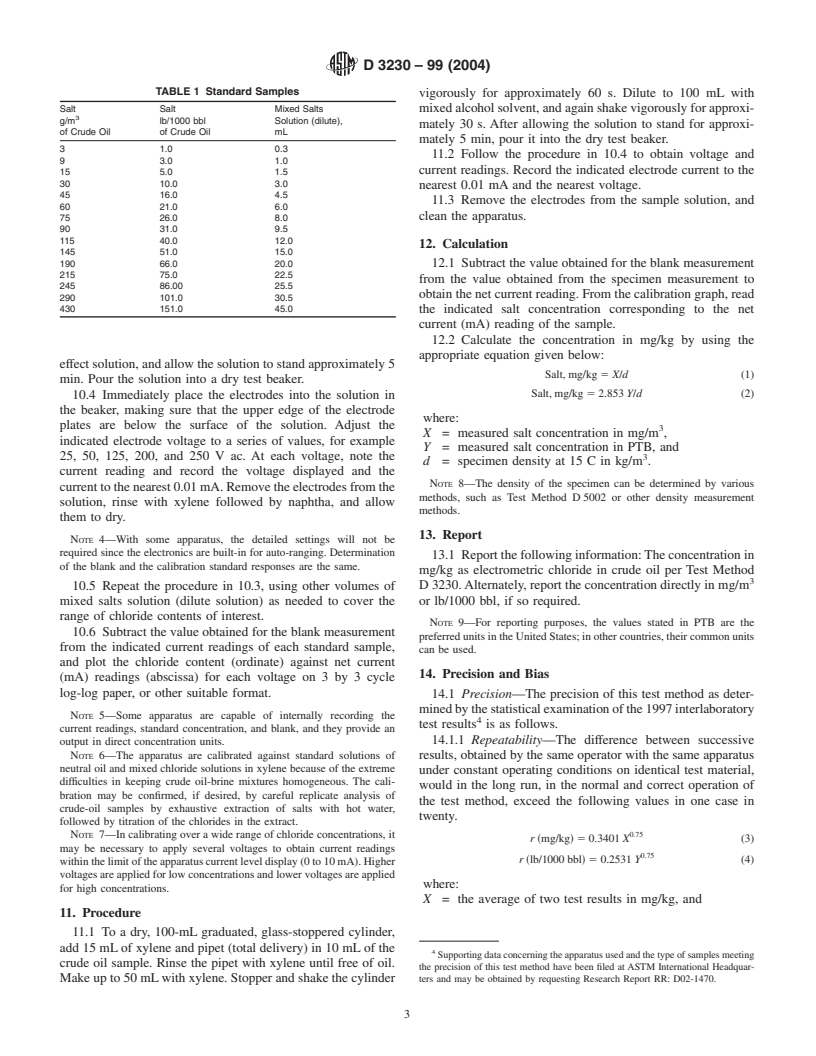

TABLE 1 Standard Samples

vigorously for approximately 60 s. Dilute to 100 mL with

Salt Salt Mixed Salts mixedalcoholsolvent,andagainshakevigorouslyforapproxi-

g/m lb/1000 bbl Solution (dilute),

mately 30 s. After allowing the solution to stand for approxi-

of Crude Oil of Crude Oil mL

mately 5 min, pour it into the dry test beaker.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.