ASTM B953-13

(Practice)Standard Practice for Sampling Magnesium and Magnesium Alloys for Spectrochemical Analysis

Standard Practice for Sampling Magnesium and Magnesium Alloys for Spectrochemical Analysis

SIGNIFICANCE AND USE

4.1 This practice, used in conjunction with the following quantitative atomic emission spectrochemical test method, B954, is suitable for use in manufacturing control, material or product acceptance, certification, and research and development.

SCOPE

1.1 This practice describes the sampling of magnesium and magnesium-base alloys to obtain a chill-cast sample suitable for quantitative atomic emission spectrochemical analysis. The disk in the region to be excited is representative of the melt and gives a repeatability of results that approach that of the reference materials used.

1.2 This practice describes the procedure for representative sampling of molten metal.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 5.1.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B953 − 13

Standard Practice for

Sampling Magnesium and Magnesium Alloys for

1

Spectrochemical Analysis

This standard is issued under the fixed designation B953; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* produce a chill-cast disk. The disk is machined to a specific

depth that represents the average melt composition and pro-

1.1 This practice describes the sampling of magnesium and

duces an acceptable surface for excitation.

magnesium-base alloys to obtain a chill-cast sample suitable

for quantitative atomic emission spectrochemical analysis. The 3.2 Fabricated, cast, or wrought products may be excited

disk in the region to be excited is representative of the melt and directly without remelting; however, accuracy of results may

gives a repeatability of results that approach that of the suffer in highly alloyed samples due to the potential for

reference materials used. elemental segregation.

1.2 This practice describes the procedure for representative

4. Significance and Use

sampling of molten metal.

4.1 This practice, used in conjunction with the following

1.3 The values stated in SI units are to be regarded as the

quantitative atomic emission spectrochemical test method,

standard. The values given in parentheses are for information

B954, is suitable for use in manufacturing control, material or

only.

product acceptance, certification, and research and develop-

1.4 This standard does not purport to address all of the

ment.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 5. Apparatus

priate safety and health practices and determine the applica-

5.1 Ladle, capable of holding a minimum of 400 g (7.7 oz)

bility of regulatory limitations prior to use. Specific precau-

of molten metal, with a handle of sufficient length to reach into

tionary statements are given in 5.1.

a furnace, trough, or crucible sufficiently deep to obtain a

sample representative of the melt being cast. The ladle may be

2. Referenced Documents

lightly coated with a tightly adhering ladle wash that will not

2

2.1 ASTM Standards:

contaminate the sample. Boron nitride can be applied at

B954 Test Method for Analysis of Magnesium and Magne-

elevated temperatures to form a tenacious coating. Warning—

sium Alloys by Atomic Emission Spectrometry

Trace moisture in the coating or on the tool may cause

B881 Terminology Relating toAluminum- and Magnesium-

dangerous spattering. Preheat all sampling tools and molds

Alloy Products

prior to use.

E135 Terminology Relating to Analytical Chemistry for

5.2 Sample Molds, capable of producing homogeneous

Metals, Ores, and Related Materials

chill-cast disks having smooth surfaces, free of surface pockets

E1257 Guide for Evaluating Grinding Materials Used for

and porosity. These castings should have a spectrochemical

Surface Preparation in Spectrochemical Analysis

response similar to the reference materials used in preparing

3. Summary of Practice

the analytical curves and must have a repeatability from

3.1 Molten metal representative of the furnace melt is excitation-to-excitation of no more than 2% relative on major

poured directly into a specified mold (described in 5.2.1)to

alloying elements. They must be representative of the melt in

the region excited. Several types of molds have been found

1

These practices are under the jurisdiction of ASTM Committee B07 on Light

acceptable:

Metals and Alloys and are the direct responsibility of Subcommittee B07.04 on

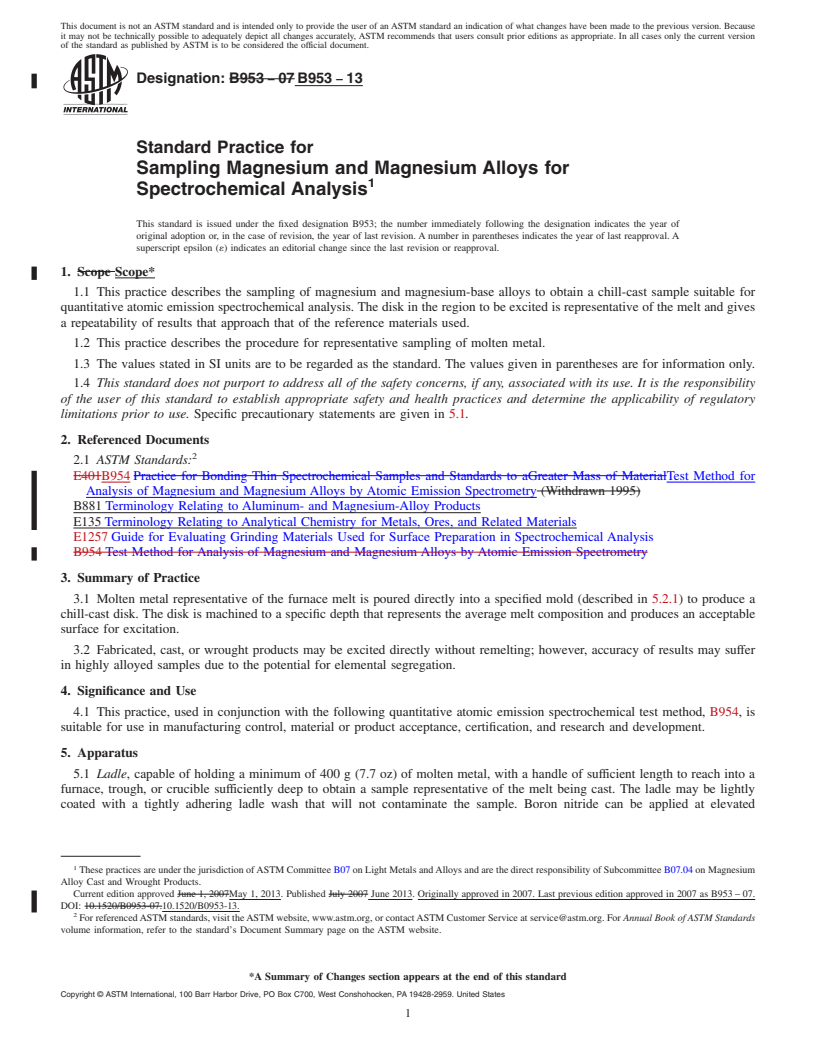

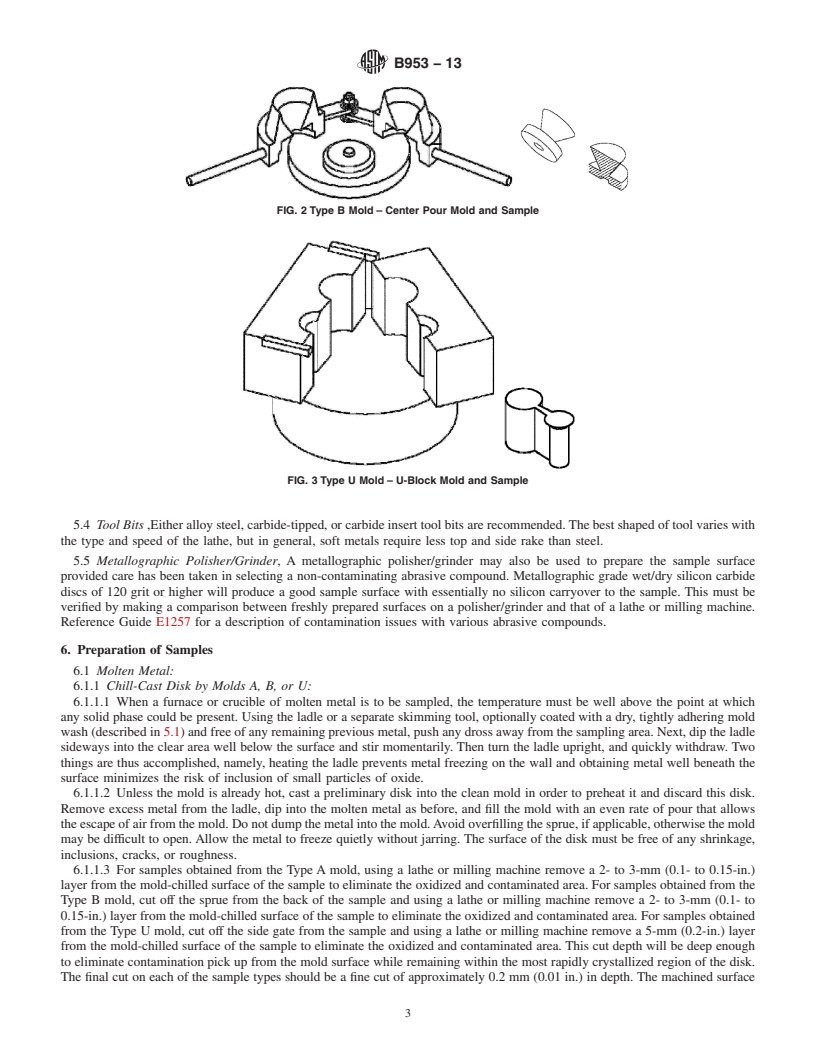

5.2.1 Type A, open cavity mold, is shown in Fig. 1. The

Magnesium Alloy Cast and Wrought Products.

advantage of this mold is its simple design and ability to

Current edition approved May 1, 2013. Published June 2013. Originally

produce a sample disk that can be excited around the entire

approved in 2007. Last previous edition approved in 2007 as B953 – 07. DOI:

10.1520/B0953-13.

annular area. Mold dimensions can be modified to produce a

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

disk size ranging from approximately 44 to 64 mm (1.75 to 2.5

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in.) in diameter by 10 to 15 mm (0.4 to 0.6 in.) in thickness.A

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. circular central recess 10 to 20 mm (0.4 to 0.8 in.) in diameter

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

-------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B953 − 07 B953 − 13

Standard Practice for

Sampling Magnesium and Magnesium Alloys for

1

Spectrochemical Analysis

This standard is issued under the fixed designation B953; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This practice describes the sampling of magnesium and magnesium-base alloys to obtain a chill-cast sample suitable for

quantitative atomic emission spectrochemical analysis. The disk in the region to be excited is representative of the melt and gives

a repeatability of results that approach that of the reference materials used.

1.2 This practice describes the procedure for representative sampling of molten metal.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific precautionary statements are given in 5.1.

2. Referenced Documents

2

2.1 ASTM Standards:

E401B954 Practice for Bonding Thin Spectrochemical Samples and Standards to aGreater Mass of MaterialTest Method for

Analysis of Magnesium and Magnesium Alloys by Atomic Emission Spectrometry (Withdrawn 1995)

B881 Terminology Relating to Aluminum- and Magnesium-Alloy Products

E135 Terminology Relating to Analytical Chemistry for Metals, Ores, and Related Materials

E1257 Guide for Evaluating Grinding Materials Used for Surface Preparation in Spectrochemical Analysis

B954 Test Method for Analysis of Magnesium and Magnesium Alloys by Atomic Emission Spectrometry

3. Summary of Practice

3.1 Molten metal representative of the furnace melt is poured directly into a specified mold (described in 5.2.1) to produce a

chill-cast disk. The disk is machined to a specific depth that represents the average melt composition and produces an acceptable

surface for excitation.

3.2 Fabricated, cast, or wrought products may be excited directly without remelting; however, accuracy of results may suffer

in highly alloyed samples due to the potential for elemental segregation.

4. Significance and Use

4.1 This practice, used in conjunction with the following quantitative atomic emission spectrochemical test method, B954, is

suitable for use in manufacturing control, material or product acceptance, certification, and research and development.

5. Apparatus

5.1 Ladle, capable of holding a minimum of 400 g (7.7 oz) of molten metal, with a handle of sufficient length to reach into a

furnace, trough, or crucible sufficiently deep to obtain a sample representative of the melt being cast. The ladle may be lightly

coated with a tightly adhering ladle wash that will not contaminate the sample. Boron nitride can be applied at elevated

1

These practices are under the jurisdiction of ASTM Committee B07 on Light Metals and Alloys and are the direct responsibility of Subcommittee B07.04 on Magnesium

Alloy Cast and Wrought Products.

Current edition approved June 1, 2007May 1, 2013. Published July 2007 June 2013. Originally approved in 2007. Last previous edition approved in 2007 as B953 – 07.

DOI: 10.1520/B0953-07.10.1520/B0953-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B953 − 13

temperatures to form a tenacious coating. Warning—Trace moisture in the coating or on the tool may cause dangerous spattering.

Preheat all sampling tools and molds prior to use.

5.2 Sample Molds, capable of producing homogeneous chill-cast disks having smooth surfaces, free of surface pockets and

porosity. These castings should have a spectrochemical response similar to the reference materials used in preparing the analytical

curves and must have a repeatability from excitation-to-excitation of no

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.