ASTM D5182-97(2014)

(Test Method)Standard Test Method for Evaluating the Scuffing Load Capacity of Oils (FZG Visual Method)

Standard Test Method for Evaluating the Scuffing Load Capacity of Oils (FZG Visual Method)

SIGNIFICANCE AND USE

5.1 The transmission of power in many automotive and industrial applications is accomplished through the use of geared systems. At higher operating speeds it is well known that the lubricant/additive system can be a significant factor in preventing scuffing (adhesive wear) damage to gears. This test method is used to screen the scuffing load capacity of oils used to lubricate spur and helical (parallel axis) gear units.

5.2 The test method is limited by the capabilities of the equipment (test rig and gears), and the performance observed may not directly relate to scuffing performance observed with spiral bevel on hypoid gearing. It is also limited to discriminating between oils with mild EP additives or less. Lubricants containing higher levels of additives, that is, those meeting the requirements of API GL4 or GL5, generally exceed the maximum load capacity of the test rig and, therefore, cannot be distinguished for their scuffing capabilities by this test method.

SCOPE

1.1 This test method, the Forschungstelle für Záhnräder und Getriebebau (Research Site for Gears and Transmissions) Visual Method, commonly referred to as the FZG Visual Method, is intended to measure the scuffing load capacity of oils used to lubricate hardened steel gears. Scoring, a form of abrasive wear, is also included as a failure criteria in this test method. It is primarily used to assess the resistance to scuffing of mild additive treated oils such as industrial gear oils, transmission fluids, and hydraulic fluids. High EP type oils, for example, those oils meeting the requirements of API GL-4 and GL-5, generally exceed the capacity of the test rig and, therefore, cannot be differentiated with this test method.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific safety information, see Section 7, Section 8, 9.2, 9.3.1, and Annex A1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5182 − 97 (Reapproved 2014)

Standard Test Method for

Evaluating the Scuffing Load Capacity of Oils (FZG Visual

Method)

This standard is issued under the fixed designation D5182; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 DIN Standard:

DIN 51 354 Teil 1 FZG Zahnrad Verspannungs Prüf

1.1 This test method, the Forschungstelle für Záhnräder und

maschine—Allgemeine Arbeitsgrundlagen

Getriebebau (Research Site for Gears and Transmissions)

Visual Method, commonly referred to as the FZG Visual

3. Terminology

Method, is intended to measure the scuffing load capacity of

3.1 Definitions:

oils used to lubricate hardened steel gears. Scoring, a form of

3.1.1 See also Terminology G40.

abrasive wear, is also included as a failure criteria in this test

3.1.2 abrasive wear—wear due to hard particles or hard

method. It is primarily used to assess the resistance to scuffing

protuberances forced against and moving along a solid surface.

of mild additive treated oils such as industrial gear oils,

3.1.3 adhesive wear (scuffıng)—wear due to localized bond-

transmission fluids, and hydraulic fluids. High EPtype oils, for

ing between contacting solid surfaces leading to material

example, those oils meeting the requirements ofAPI GL-4 and

transfer between the two surfaces or loss from either surface.

GL-5, generally exceed the capacity of the test rig and,

3.1.4 scoring—a severe form of wear characterized by the

therefore, cannot be differentiated with this test method.

formationofextensivegroovesandscratchesinthedirectionof

1.2 The values stated in SI units are to be regarded as

sliding.

standard. No other units of measurement are included in this

3.1.5 scratches—the result of mechanical removal or

standard.

displacement, or both, of material from a surface by the action

1.3 This standard does not purport to address all of the of abrasive particles or protuberances sliding across the sur-

faces.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.2 Definitions of Terms Specific to This Standard:

priate safety and health practices and determine the applica-

3.2.1 polishing—a mild form of abrasive wear resulting in

bility of regulatory limitations prior to use. For specific safety

minor loss of material and typically characterized by a smooth

information, see Section 7, Section 8, 9.2, 9.3.1, and Annex

finish and removal of all or part of the initial grinding marks.

A1.

4. Summary of Test Method

2. Referenced Documents

4.1 An FZG Gear Test Machine is operated at constant

speed (1450 rpm) for a fixed period (21700 revolutions—

2.1 ASTM Standards:

approximately 15 min) at successively increasing loads until

D235 Specification for Mineral Spirits (Petroleum Spirits)

the failure criteria is reached; the initial oil temperature is 90°C

(Hydrocarbon Dry Cleaning Solvent)

beginning at load stage four (see Table 1). The test gears are

G40 Terminology Relating to Wear and Erosion

examined initially and after the prescribed duration at each

load stage for cumulative damage (scuffing) to the gear tooth

flanks.

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

5. Significance and Use

Subcommittee D02.L0.11 on Tribiological Properties of Industrial Fluids and

Lubricates.

5.1 The transmission of power in many automotive and

Current edition approved Jan. 1, 2014. Published February 2014. Originally

industrial applications is accomplished through the use of

approved in 1991. Last previous edition approved in 2008 as D5182–97(2008).

geared systems. At higher operating speeds it is well known

DOI: 10.1520/D5182-97R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from Beuth Verlag GmbH (DIN-- DIN Deutsches Institut fur

the ASTM website. Normung e.V.), Burggrafenstrasse 6, 10787, Berlin, Germany.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5182 − 97 (2014)

TABLE 1 Standard Load Stages for FZG Scuffing Test

Total

Torque Tooth Hertzian

Load Work Load Clutch

on Normal Contact

A

Stage Trans- Loaded with

Pinion Force Pressure

mitted

(N·m) (N) (N/mm ) (kW·h)

1 3.3 99 146 0.19 H1

2 13.7 407 295 0.97 H2

3 35.3 1044 474 2.96 H2+K

4 60.8 1799 621 6.43 H2+K+W1

5 94.1 2786 773 11.8 H2+K+W1+W2

6 135.5 4007 929 19.5 H2+.+W3

7 183.4 5435 1080 29.9 H2+.+W4

8 239.3 7080 1232 43.5 H2+.+W5

9 302.0 8949 1386 60.8 H2+.+W6

10 372.6 11029 1539 82.0 H2+.+W7

11 450.1 13342 1691 107.0 H2+.+W8

12 534.5 15826 1841 138.1 H2+.+W9

A

where:

H1 = load lever H1 (light),

H2 = load lever H2 (heavy),

K = support rod for weights, and

A. Diagram of a Typical FZG Test Rig

W1 to W9 = weights for loading (supplied with test rig).

that the lubricant/additive system can be a significant factor in

preventing scuffing (adhesive wear) damage to gears. This test

method is used to screen the scuffing load capacity of oils used

to lubricate spur and helical (parallel axis) gear units.

5.2 The test method is limited by the capabilities of the

equipment (test rig and gears), and the performance observed

may not directly relate to scuffing performance observed with

spiral bevel on hypoid gearing. It is also limited to discrimi-

nating between oils with mild EP additives or less. Lubricants

B. Schematic Section of an FZG Test Rig

containing higher levels of additives, that is, those meeting the

requirements of API GL4 or GL5, generally exceed the

FIG. 1 FZG Test Rig

maximum load capacity of the test rig and, therefore, cannot be

distinguished for their scuffing capabilities by this test method.

information supplied in Table 2. A schematic of the profile is

6. Apparatus

shown in Fig. 2. Both sides of the test gear flanks can be used

6.1 FZG Gear Test Rig:

for testing purposes since only one side is loaded during the

6.1.1 A more complete description of the test rig and

evaluation. It should be noted that these gears have been

operating instructions may be found in the instruction manuals

available from the manufacturers/suppliers identified in

A2.1.2.

TABLE 2 Detail Data for the “A” Profile Gears

6.1.2 The FZG gear test rig utilizes a recirculating power

Parameter Value Units

loop principle, also known as a four-square configuration, to

Center Distance 91.5 mm

provide a fixed torque (load) to a pair of precision test gears.A

Effective Tooth Width 20.0 mm

Pitch Circle Diameter:

schematic of the test rig is shown in Fig. 1A and Fig. 1B. The

Pinion 73.2 mm

drive gearbox and the test gearbox are connected through two

Gear 109.8 mm

torsional shafts. Shaft 1 contains a load coupling used to apply

Tip Diameter:

Pinion 88.7 mm

the torque through the use of known weights hung on the

Gear 112.5 mm

loading arm.

Module 4.5 mm

6.1.3 The test gearbox contains heating and cooling ele-

Number of Teeth:

Pinion 16

ments to maintain and control the temperature of the oil. A

Gear 24

temperature sensor located in the side of the test gearbox is

Profile Modification

used to control the heating/cooling system as required by the

Pinion/Gear 0.8635/−0.5103

Pressure Angle

test operating conditions.

Normal/Working 20/22.5 degrees

6.1.4 The test rig is driven by an electric motor capable of

Hardness

delivering at least 5.5 kW at 1440 rpm.

Rockwell C 60 to 62

Surface Roughness

6.2 Test Gears—The test gearset (pinion and gear) are

Ra 0.3 to 0.7 µm

commonly referred to as type A profile and conform to the

D5182 − 97 (2014)

9.3 Assembly of Test Gears—The test gears, spacers, and

bearings are heated on a hot plate or other device to approxi-

mately 60 to 80°C. Install the test gears on the shafts with the

alignment marks in the position shown in Fig. 3. Complete the

assemblyofthegearboxwiththeappropriatespacers,bearings,

and front cover.

9.3.1 It has been found critical for correct results that the

test gears are properly aligned on their respective shafts.

(Warning—Misalignment can lead to erratic or lower fail

loads due to uneven distribution of the load on the tooth.)

9.4 Test Oil—Add 1.25 L of test oil to the test gearbox

(approximately to the centerline of the shafts).

9.5 Final Assembly—Secure the top of the test gear case in

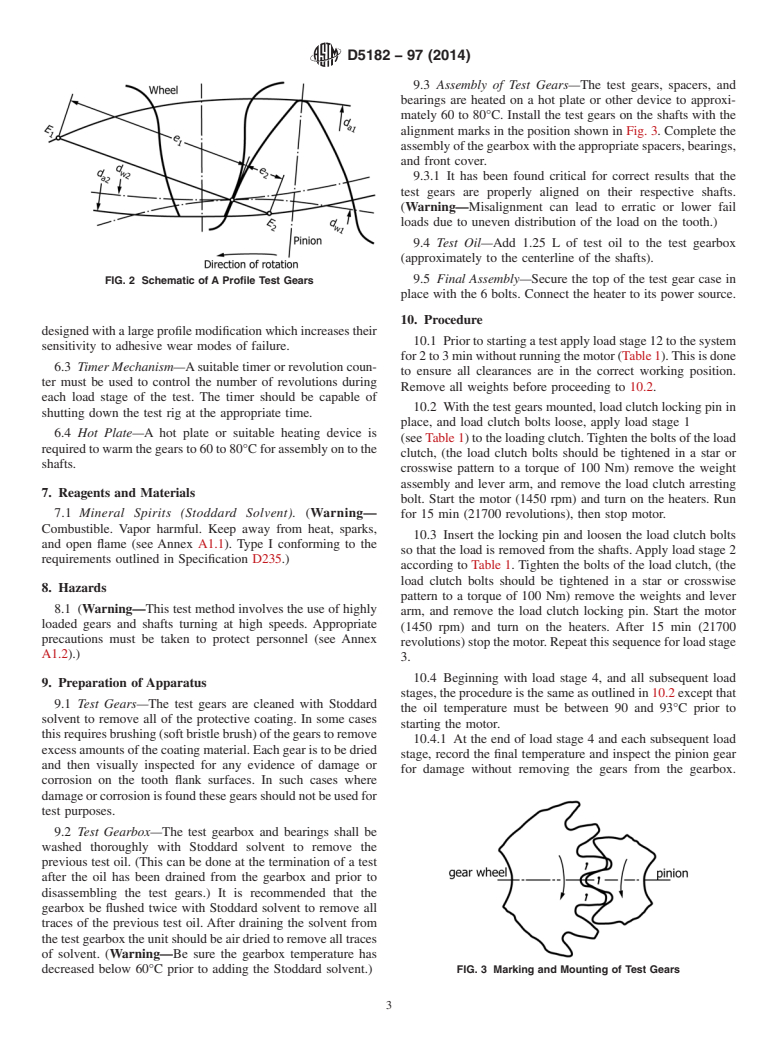

FIG. 2 Schematic of A Profile Test Gears

place with the 6 bolts. Connect the heater to its power source.

10. Procedure

designedwithalargeprofilemodificationwhichincreasestheir

10.1 Prior to starting a test apply load stage 12 to the system

sensitivity to adhesive wear modes of failure.

for2to3minwithoutrunningthemotor(Table1).Thisisdone

6.3 Timer Mechanism—Asuitable timer or revolution coun-

to ensure all clearances are

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.