ASTM D5182-19

(Test Method)Standard Test Method for Evaluating the Scuffing Load Capacity of Oils (FZG Visual Method)

Standard Test Method for Evaluating the Scuffing Load Capacity of Oils (FZG Visual Method)

SIGNIFICANCE AND USE

5.1 The transmission of power in many automotive and industrial applications is accomplished through the use of geared systems. At higher operating speeds it is well known that the lubricant/additive system can be a significant factor in preventing scuffing (adhesive wear) damage to gears. This test method is used to screen the scuffing load capacity of oils used to lubricate spur and helical (parallel axis) gear units.

5.2 The test method is limited by the capabilities of the equipment (test rig and gears), and the performance observed may not directly relate to scuffing performance observed with spiral bevel on hypoid gearing. It is also limited to discriminating between oils with mild EP additives or less. Lubricants containing higher levels of additives, that is, those meeting the requirements of API GL4 or GL5, generally exceed the maximum load capacity of the test rig and, therefore, cannot be distinguished for their scuffing capabilities by this test method.

SCOPE

1.1 This test method, the Forschungstelle für Záhnräder und Getriebebau (Research Site for Gears and Transmissions) Visual Method, commonly referred to as the FZG Visual Method, is intended to measure the scuffing load capacity of oils used to lubricate hardened steel gears. Scoring, a form of abrasive wear, is also included as a failure criteria in this test method. It is primarily used to assess the resistance to scuffing of mild additive treated oils such as industrial gear oils, transmission fluids, and hydraulic fluids. High EP type oils, for example, those oils meeting the requirements of API GL-4 and GL-5, generally exceed the capacity of the test rig and, therefore, cannot be differentiated with this test method.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific safety information, see Section 7, Section 8, 9.2, 9.3.1, and Annex A1.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5182 − 19

Standard Test Method for

Evaluating the Scuffing Load Capacity of Oils (FZG Visual

1

Method)

This standard is issued under the fixed designation D5182; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This test method, the Forschungstelle für Záhnräder und

D235 Specification for Mineral Spirits (Petroleum Spirits)

Getriebebau (Research Site for Gears and Transmissions)

(Hydrocarbon Dry Cleaning Solvent)

Visual Method, commonly referred to as the FZG Visual

G40 Terminology Relating to Wear and Erosion

Method, is intended to measure the scuffing load capacity of

3

2.2 DIN Standard:

oils used to lubricate hardened steel gears. Scoring, a form of

DIN 51 354 Teil 1 FZG Zahnrad Verspannungs Prüf

abrasive wear, is also included as a failure criteria in this test

maschine—Allgemeine Arbeitsgrundlagen

method. It is primarily used to assess the resistance to scuffing

of mild additive treated oils such as industrial gear oils,

3. Terminology

transmission fluids, and hydraulic fluids. High EPtype oils, for

3.1 Definitions:

example, those oils meeting the requirements ofAPI GL-4 and

3.1.1 See also Terminology G40.

GL-5, generally exceed the capacity of the test rig and,

3.1.2 abrasive wear, n—wear due to hard particles or hard

therefore, cannot be differentiated with this test method.

protuberances forced against and moving along a solid surface.

1.2 The values stated in SI units are to be regarded as

3.1.3 adhesive wear (scuffıng), n—wear due to localized

standard. No other units of measurement are included in this

bonding between contacting solid surfaces leading to material

standard. transfer between the two surfaces or loss from either surface.

3.1.4 scoring, n—asevereformofwearcharacterizedbythe

1.3 This standard does not purport to address all of the

formationofextensivegroovesandscratchesinthedirectionof

safety concerns, if any, associated with its use. It is the

sliding.

responsibility of the user of this standard to establish appro-

3.1.5 scratches, n—the result of mechanical removal or

priate safety, health, and environmental practices and deter-

displacement, or both, of material from a surface by the action

mine the applicability of regulatory limitations prior to use.

of abrasive particles or protuberances sliding across the sur-

For specific safety information, see Section 7, Section 8, 9.2,

faces.

9.3.1, and Annex A1.

1.4 This international standard was developed in accor- 3.2 Definitions of Terms Specific to This Standard:

dance with internationally recognized principles on standard- 3.2.1 polishing, n—amildformofabrasivewearresultingin

minor loss of material and typically characterized by a smooth

ization established in the Decision on Principles for the

finish and removal of all or part of the initial grinding marks.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

4. Summary of Test Method

Barriers to Trade (TBT) Committee.

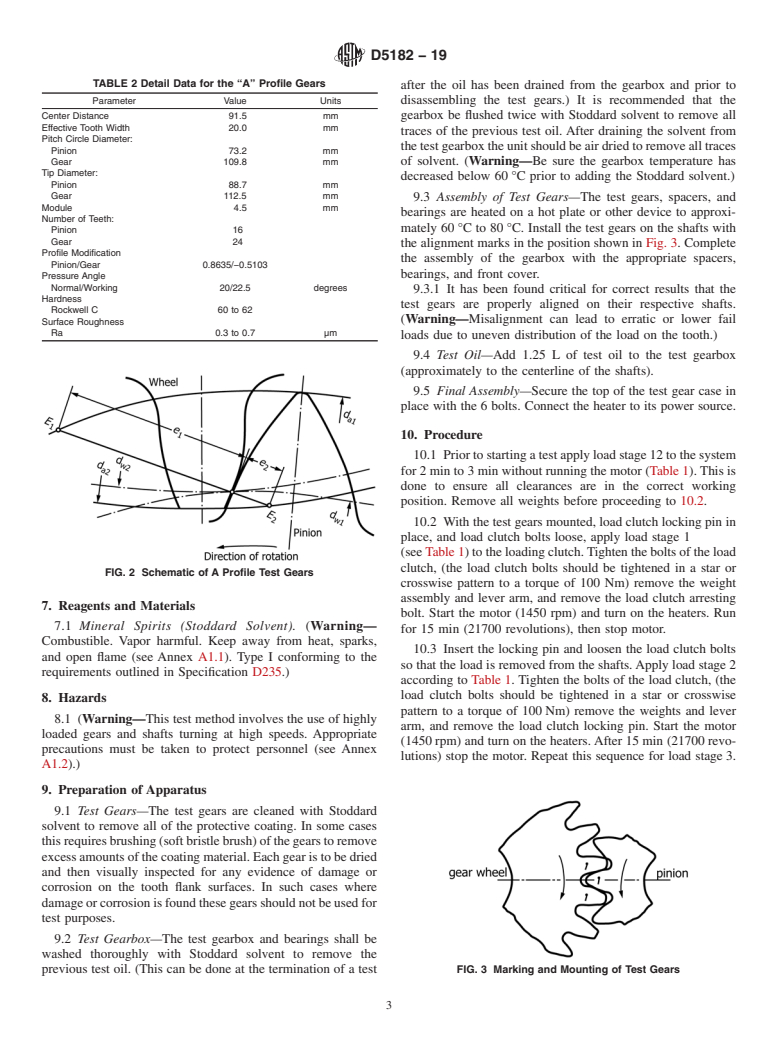

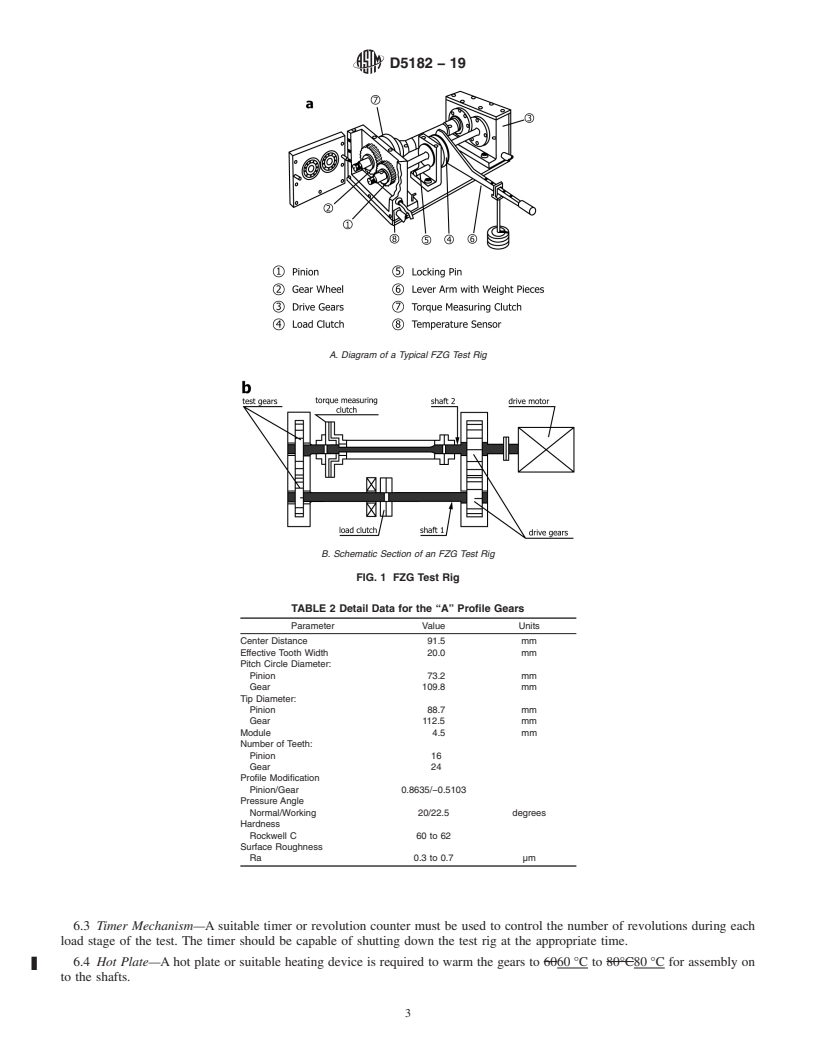

4.1 An FZG Gear Test Machine is operated at constant

speed (1450 rpm) for a fixed period (21700 revolutions—

approximately 15 min) at successively increasing loads until

the failure criteria is reached; the initial oil temperature is

90 °C beginning at load stage four (see Table 1). The test gears

1

This test method is under the jurisdiction of ASTM Committee D02 on

2

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Subcommittee D02.L0.11 on Tribological Properties of Industrial Fluids and contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Lubricates. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Dec. 1, 2019. Published December 2019. Originally the ASTM website.

3

approved in 1991. Last previous edition approved in 2014 as D5182 – 97 (2014). Available from Beuth Verlag GmbH (DIN-- DIN Deutsches Institut fur

DOI: 10.1520/D5182-19. Normung e.V.), Burggrafenstrasse 6, 10787, Berlin, Germany.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5182 − 19

TABLE 1 Standard Load Stages for FZG Scuffing Test

Tota

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5182 − 97 (Reapproved 2014) D5182 − 19

Standard Test Method for

Evaluating the Scuffing Load Capacity of Oils (FZG Visual

1

Method)

This standard is issued under the fixed designation D5182; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This test method, the Forschungstelle für Záhnräder und Getriebebau (Research Site for Gears and Transmissions) Visual

Method, commonly referred to as the FZG Visual Method, is intended to measure the scuffing load capacity of oils used to lubricate

hardened steel gears. Scoring, a form of abrasive wear, is also included as a failure criteria in this test method. It is primarily used

to assess the resistance to scuffing of mild additive treated oils such as industrial gear oils, transmission fluids, and hydraulic fluids.

High EP type oils, for example, those oils meeting the requirements of API GL-4 and GL-5, generally exceed the capacity of the

test rig and, therefore, cannot be differentiated with this test method.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. For specific safety information, see Section 7, Section 8, 9.2, 9.3.1, and Annex

A1.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D235 Specification for Mineral Spirits (Petroleum Spirits) (Hydrocarbon Dry Cleaning Solvent)

G40 Terminology Relating to Wear and Erosion

3

2.2 DIN Standard:

DIN 51 354 Teil 1 FZG Zahnrad Verspannungs Prüf maschine—Allgemeine Arbeitsgrundlagen

3. Terminology

3.1 Definitions:

3.1.1 See also Terminology G40.

3.1.2 abrasive wear—wear, n—wear due to hard particles or hard protuberances forced against and moving along a solid

surface.

3.1.3 adhesive wear (scuffıng)—(scuffıng), n—wear due to localized bonding between contacting solid surfaces leading to

material transfer between the two surfaces or loss from either surface.

3.1.4 scoring—scoring, n—a severe form of wear characterized by the formation of extensive grooves and scratches in the

direction of sliding.

3.1.5 scratches—scratches, n—the result of mechanical removal or displacement, or both, of material from a surface by the

action of abrasive particles or protuberances sliding across the surfaces.

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.L0.11 on TribiologicalTribological Properties of Industrial Fluids and Lubricates.

Current edition approved Jan. 1, 2014Dec. 1, 2019. Published February 2014December 2019. Originally approved in 1991. Last previous edition approved in 20082014

as D5182–97(2008).D5182 – 97 (2014). DOI: 10.1520/D5182-97R14.10.1520/D5182-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Beuth Verlag GmbH (DIN-- DIN Deutsches Institut fur Normung e.V.), Burggrafenstrasse 6, 10787, Berlin, Germany.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5182 − 19

3.2 Definitions of Terms Specific to This Standard:

3.2.1 polishing—polishing, n—a mild form of abrasive wear resulting in minor loss of material and typically characterized by

a smooth finish and removal of all or part of the initial grinding marks.

4. Summary of Test Method

4.1 An FZG Gear Test Machine is operated at const

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.