ASTM D8210-19a

(Test Method)Standard Test Method for Automatic Determination of Low-Temperature Viscosity of Automatic Transmission Fluids, Hydraulic Fluids, and Lubricants Using a Rotational Viscometer

Standard Test Method for Automatic Determination of Low-Temperature Viscosity of Automatic Transmission Fluids, Hydraulic Fluids, and Lubricants Using a Rotational Viscometer

SIGNIFICANCE AND USE

5.1 The low-temperature, low-shear-rate viscosity of automatic transmission fluids, gear oils, torque and tractor fluids, power steering fluids, and hydraulic oils are of considerable importance to the proper operation of many mechanical devices. Low-temperature viscosity limits of these fluids are often specified to ensure their suitability for use and are cited in many specifications.

5.2 The manual test method, Test Method D2983, was developed to determine whether an automatic transmission fluid (ATF) would meet low-temperature performance criterion originally defined using a particular model viscometer.4 The viscosity range covered in the original ATF performance correlation studies was from less than 1000 mPa·s to more than 60 000 mPa·s. The success of the ATF correlation and the development of this test method has over time been applied to other fluids and lubricants such as gear oils, hydraulic fluids, and so forth.

5.3 The viscosity determined by this test method using option A was found to be statistically indistinguishable from Test Method D2983 – 16 measurements based on the ILS data to establish this test method’s precision.

5.4 Due to the shorter time at test temperature, results from the abbreviated thermal conditioning (Option B) may differ from results obtained with the 14 h soak at test temperature (Option A). For the samples used in developing this test method, results obtained with the abbreviated procedure (Option B) tended to be less than 14 h soak (Option A). This difference seemed to be larger for products that contained high wax base stock.

SCOPE

1.1 This test method automates the determination of low temperature, low-shear-rate viscosity of driveline and hydraulic fluids, such as automatic transmission fluids, gear oils, hydraulic fluids, and other lubricants. It utilizes a thermoelectrically temperature-controlled sample chamber along with a programmable rotational viscometer. This test method covers a viscosity range of 300 mPa·s to 900 000 mPa·s measured at temperatures from –40 °C to –10 °C.

1.2 The precision data were determined at –40 °C and –26 °C for a viscosity range of 6380 mPa·s to 255 840 mPa·s.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard except those noted below.

1.3.1 Exception—The test method uses the SI unit, milliPascal-second (mPa·s), as the unit of viscosity. (1 cP = 1 mPa·s).

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D8210 − 19a

Standard Test Method for

Automatic Determination of Low-Temperature Viscosity of

Automatic Transmission Fluids, Hydraulic Fluids, and

1

Lubricants Using a Rotational Viscometer

This standard is issued under the fixed designation D8210; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This test method automates the determination of low

D341 Practice for Viscosity-Temperature Charts for Liquid

temperature, low-shear-rate viscosity of driveline and hydrau-

Petroleum Products

lic fluids, such as automatic transmission fluids, gear oils,

D2162 Practice for Basic Calibration of Master Viscometers

hydraulic fluids, and other lubricants. It utilizes a thermoelec-

and Viscosity Oil Standards

trically temperature-controlled sample chamber along with a

D2983 Test Method for Low-Temperature Viscosity of Au-

programmable rotational viscometer.This test method covers a

tomaticTransmission Fluids, Hydraulic Fluids, and Lubri-

viscosity range of 300 mPa·s to 900 000 mPa·s measured at

cants using a Rotational Viscometer

temperatures from –40 °C to –10 °C.

D5293 Test Method for Apparent Viscosity of Engine Oils

1.2 The precision data were determined at –40 °C and and Base Stocks Between –10 °C and –35 °C Using

–26 °C for a viscosity range of 6380 mPa·s to 255 840 mPa·s. Cold-Cranking Simulator

D6708 Practice for StatisticalAssessment and Improvement

1.3 The values stated in SI units are to be regarded as

of Expected Agreement Between Two Test Methods that

standard. No other units of measurement are included in this

Purport to Measure the Same Property of a Material

standard except those noted below.

D7962 Practice for Determination of Minimum Immersion

1.3.1 Exception—The test method uses the SI unit,

Depth and Assessment of Temperature Sensor Measure-

milliPascal-second (mPa·s), as the unit of viscosity. (1 cP =

ment Drift

1 mPa·s).

E644 Test Methods for Testing Industrial Resistance Ther-

mometers

1.4 This standard does not purport to address all of the

E2877 Guide for Digital Contact Thermometers

safety concerns, if any, associated with its use. It is the

3

2.2 ISO Standard:

responsibility of the user of this standard to establish appro-

ISO/IEC 17025 General requirements for the competence of

priate safety, health, and environmental practices and deter-

testing and calibration laboratories

mine the applicability of regulatory limitations prior to use.

ISO 17034 General requirement for the competence of

1.5 This international standard was developed in accor-

reference material producers

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

3. Terminology

Development of International Standards, Guides and Recom-

3.1 Definitions:

mendations issued by the World Trade Organization Technical

3.1.1 digital contact thermometer (DCT), n—an electronic

Barriers to Trade (TBT) Committee.

device consisting of a digital display and associated tempera-

ture sensing probe.

3.1.1.1 Discussion—This device consists of a temperature

sensor connected to a measuring instrument; this instrument

1 2

This test method is under the jurisdiction of ASTM Committee D02 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Subcommittee D02.07 on Flow Properties. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved July 1, 2019. Published August 2019. Originally the ASTM website.

3

approved in 2018. Last previous edition approved in 2019 as D8210 – 19. DOI: Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

10.1520/D8210-19A. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

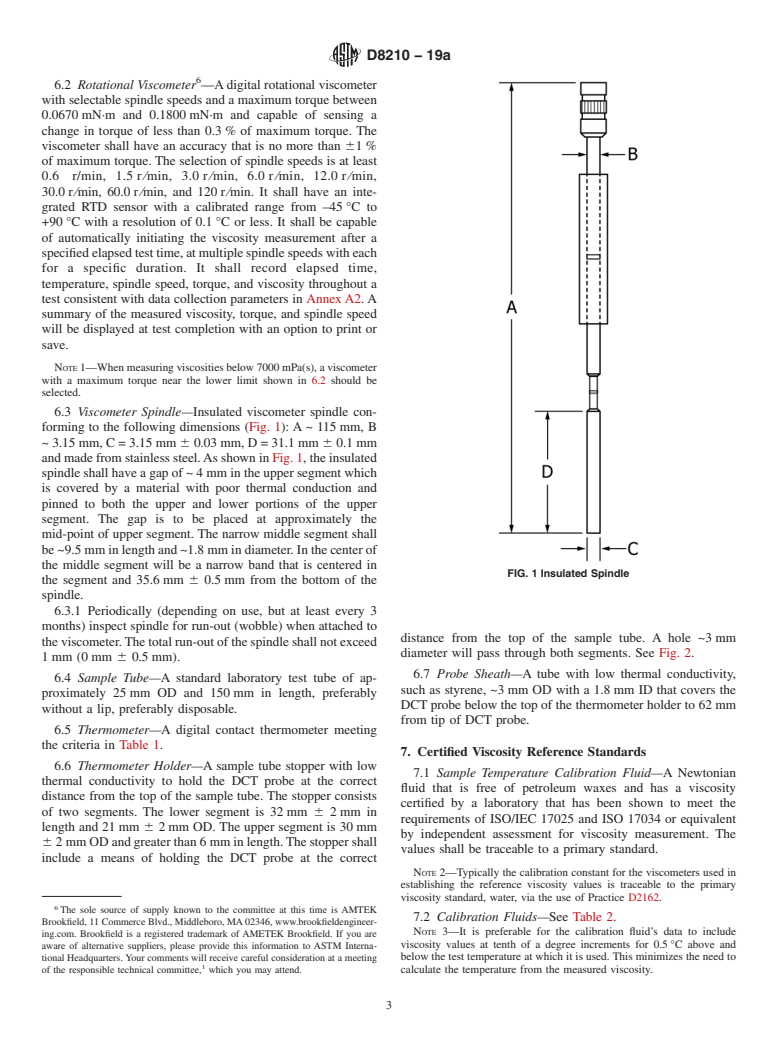

D8210 − 19a

measures the temperature-dependent quantity of the sensor, neededforeitherthefull-lengthtest(OptionA)withoutpreheat

computes the temperature from the measured quantity, and or the abbreviated test (Option B) without preheat.

provides a digital output. This digital output goes to a digital

5. Significance and Use

displayand/orrecordingdevicethatmaybeinternalorexternal

to the device. These devices are referred to as “digital

5.1

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D8210 − 19 D8210 − 19a

Standard Test Method for

Automatic Determination of Low-Temperature Viscosity of

Automatic Transmission Fluids, Hydraulic Fluids, and

1

Lubricants Using a Rotational Viscometer

This standard is issued under the fixed designation D8210; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method automates the determination of low temperature, low-shear-rate viscosity of driveline and hydraulic fluids,

such as automatic transmission fluids, gear oils, hydraulic fluids, and other lubricants. It utilizes a thermoelectrically

temperature-controlled sample chamber along with a programmable rotational viscometer. This test method covers a viscosity

range of 300 mPa·s to 900 000 mPa·s measured at temperatures from –40 °C to –10 °C.

1.2 The precision data were determined at –40 °C and –26 °C for a viscosity range of 6380 mPa·s to 255 840 mPa·s.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard

except those noted below.

1.3.1 Exception—The test method uses the SI unit, milliPascal-second (mPa·s), as the unit of viscosity. (1 cP = 1 mPa·s).

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D341 Practice for Viscosity-Temperature Charts for Liquid Petroleum Products

D2162 Practice for Basic Calibration of Master Viscometers and Viscosity Oil Standards

D2983 Test Method for Low-Temperature Viscosity of Automatic Transmission Fluids, Hydraulic Fluids, and Lubricants using

a Rotational Viscometer

D5293 Test Method for Apparent Viscosity of Engine Oils and Base Stocks Between –10 °C and –35 °C Using Cold-Cranking

Simulator

D6708 Practice for Statistical Assessment and Improvement of Expected Agreement Between Two Test Methods that Purport

to Measure the Same Property of a Material

D7962 Practice for Determination of Minimum Immersion Depth and Assessment of Temperature Sensor Measurement Drift

E644 Test Methods for Testing Industrial Resistance Thermometers

E2877 Guide for Digital Contact Thermometers

3

2.2 ISO Standard:

ISOISO/IEC 17025 General requirements for the competence of testing and calibration laboratories

ISO 17034 General requirement for the competence of reference material producers

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.07 on Flow Properties.

Current edition approved May 1, 2019July 1, 2019. Published May 2019August 2019. Originally approved in 2018. Last previous edition approved in 20182019 as

D8210 – 18.D8210 – 19. DOI: 10.1520/D8210-19.10.1520/D8210-19A.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D8210 − 19a

3. Terminology

3.1 Definitions:

3.1.1 digital contact thermometer (DCT), n—an electronic device consisting of a digital display and associated temperature

sensing probe.

3.1.1.1 Discussion—

This device consists of a temperature sensor connected to a measuring instrument; this instrument measures the temperature-

dependent quantity of the sensor, computes the temperature from the measured qu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.