ASTM E542-00

(Practice)Standard Practice for Calibration of Laboratory Volumetric Apparatus

Standard Practice for Calibration of Laboratory Volumetric Apparatus

SCOPE

1.1 This practice covers procedures for use in the calibration of volumetric ware, in accordance with E694 such as is in common use in chemical and clinical laboratories. It is based on the gravimetric determination of the quantity of water either contained or delivered, and the conversion of this value to true volume at the standard temperature of 20oC by means of suitable equations and standard tables. Calibration using mercury is excluded. Calibration may be performed using alternative gravimetric methodology, provided that it is demonstrated and documented that the results obtained are equivalent to those obtained using the methodology described herein.

1.2 This practice is intended to encompass capacity ware between the limits of 0.1 cm3 and 2000 cm3. Typical products falling within the purview of this practice are burets graduated" to deliver", graduated cylinders, volumetric flasks, specific gravity flasks, measuring and dilution pipets, and transfer and capacity pipets.

1.3 The procedures are not recommended for calibration of apparatus with capacities below 0.1 cm3, such as microglassware.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 542 – 00

Standard Practice for

Calibration of Laboratory Volumetric Apparatus

This standard is issued under the fixed designation E 542; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope manipulating the apparatus, weighing, and converting the

weight to the appropriate standard volume.

1.1 This practice covers procedures for use in the calibration

of volumetric ware, in accordance with E694 such as is in

4. Significance and Use

common use in chemical and clinical laboratories. It is based

4.1 The primary purpose of this practice is to provide

on the gravimetric determination of the quantity of water either

uniform procedures that may be used to accurately calibrate a

contained or delivered, and the conversion of this value to true

wide variety of volumetric ware. The techniques are simple in

volume at the standard temperature of 20°C by means of

concept and can provide reliable results, provided the proce-

suitable equations and standard tables. Calibration using mer-

dures are followed faithfully. Accordingly, the practice should

cury is excluded. Calibration may be performed using alterna-

provide a means for checking the original calibration of

tive gravimetric methodology, provided that it is demonstrated

glassware and similar apparatus and for periodic rechecks as

and documented that the results obtained are equivalent to

the need should arise.

those obtained using the methodology described herein.

4.2 Borosilicate volumetric glassware will hold its calibra-

1.2 This practice is intended to encompass capacity ware

3 3

tion indefinitely provided that it is not exposed to hydrofluoric

between the limits of 0.1 cm and 2000 cm . Typical products

acid, hot phosphoric acid, or strong, hot alkalis, and that it is

falling within the purview of this practice are burets graduated“

not heated above 150°C when dry. A frosting of the glass

to deliver”, graduated cylinders, volumetric flasks, specific

surface (viewed when dry) indicates that chemical attack has

gravity flasks, measuring and dilution pipets, and transfer and

occured, and recalibration may be in order. As a precaution,

capacity pipets.

however, it is recommended that the glassware be recalibrated

1.3 The procedures are not recommended for calibration of

3 after ten years of service regardless of its appearance.

apparatus with capacities below 0.1 cm , such as microglass-

4.3 Soda-lime volumetric glassware will become frosted

ware.

with time because of attack from moisture in the atmosphere as

1.4 This standard does not purport to address all of the

well as from the chemicals mentioned above. In addition, it

safety concerns, if any, associated with its use. It is the

should not be heated above 90°C when dry. It is recommended,

responsibility of the user of this standard to establish appro-

therefore, that it be recalibrated after five years of service

priate safety and health practices and determine the applica-

unless frosting (viewed when dry) is observed sooner.

bility of regulatory limitations prior to use.

5. Units of Measurement

2. Referenced Documents

5.1 Capacity—The basic SI unit for volume is the cubic

2.1 ASTM Standards:

metre, m . Due to its large size, it is rarely used in volumetric

E 1 Specification for ASTM Thermometers

calibration. Rather, the cubic centimetre, cm , is used and will

SI 10 Standard for Use of the International System of Units

be employed in this practice. The unit, millilitre, mL, may be

(SI) (the Modernized Metric System)

3 considered as equivalent to the cubic centimetre.

E 694 Specification for Volumetric Ware

5.2 Standard Temperature—Volumetric ware is almost uni-

3. Summary of Practice versally calibrated at 20°C. The procedures described provide

for such a calibration. When it is necessary to work at higher

3.1 This practice is based upon a determination of the

ambient temperatures, such as is the case in tropical countries,

volume of water either contained in or delivered by the vessel.

calibration may be required at the International Standards

Procedures are given for cleaning, setting the meniscus,

Organization (ISO) recommended temperature of 27°C. Equa-

tions are given to correct the calibrated volume to other

This practice is under the jurisdiction of ASTM Committee E41 on Laboratory

temperatures as this may be required or desired.

Apparatus, and is the direct responsibility of Subcommittee E41.01 on Apparatus.

Current edition approved Nov. 10, 2000. Published November 2000. Originally

6. Apparatus

published as E 542 – 79. Last previous edition E 542 – 94(1999).

Annual Book of ASTM Standards, Vol 14.03.

6.1 Balance, having sufficient capacity to weigh the loaded

Annual Book of ASTM Standards, Vol 14.04.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 542

vessel. The sensitivity of the balance will be a limiting factor 7.3.1 Reading the Meniscus—For all apparatus calibrated

in the accuracy of the measurements. Either a single-pan, by this procedure, the reading is made on the lowest point of

direct-reading balance or an equal-arm balance of adequate the meniscus. In order that the lowest point may be observed,

sensitivity and capacity may be used. In either case the weights it is necessary to place a shade of some dark material

must be calibrated with adequate accuracy. Ordinarily, weights immediately below and behind the meniscus, which renders the

with NBS Class S-1 tolerances are required. The balance must profile of the meniscus dark and clearly visible against a light

have physical dimensions to accept the size of the vessels background. A convenient device for this purpose is a collar-

which need to be weighed. shaped section of thick black rubber tubing, cut open at one

6.2 Thermometer, for measuring the temperature of the side and of such size as to clasp the tube firmly. Alternatively,

water. The accuracy of this calibration will depend upon the black paper may be used. “Short line” graduated vessels where

accuracy requirement of the volumetric calibration (see Section the lines are less than one half of the circumference may be

14 for tolerances). read more accurately by placing a mirror against the rear of the

6.3 Barometer, capable of providing atmospheric pressure vessel to reflect the front line.

measurements, consistent with the tolerances given in Section 7.3.2 Setting the Meniscus—Setting of the meniscus shall

14. Alternatively, the existing barometric pressure may be be performed by one of the two methods detailed below.

obtained from the local weather service. Wherever practical the meniscus should descend to the position

6.4 Distilled or Deionized Water, suitable for general labo- of setting.

ratory purposes. 7.3.2.1 The position of the lowest point of the meniscus

with reference to the graduation line is horizontally tangent to

7. General Considerations

the plane of the upper edge of the graduation line. The position

7.1 This section describes manipulative techniques required

of the meniscus is obtained by having the eye in the same plane

to obtain accurate and reproducible volumetric measurements.

of the upper edge of the graduation line.

7.2 Cleaning Procedures:

7.3.2.2 The position of the lowest point of the meniscus

7.2.1 It is important that volumetric ware be thoroughly

with reference to the graduation line is such that it is in the

cleaned before being tested or used. Glass apparatus must be

plane of the middle of the graduation line. This position of the

sufficiently clean to permit uniform wetting of the surface.

meniscus is obtained by making the setting in the center of the

When clean, the walls will be uniformly wetted and the water

ellipse formed by the graduation line on the front and the back

will adhere to the glass surface in a continuous film. The clean

of the tube as observed by having the eye slightly below the

walls of some plastic apparatus, however, will not be wetted.

plane of the graduation line. The setting is accurate if, as the

(Follow the instructions of the manufacturer. Do not use

eye is raised and the ellipse narrows, the lowest point of the

materials which will attack, discolor, or swell the plasticware.)

meniscus remains midway between the front and rear portions

Lack of cleanliness causes irregularities in capacity by distort-

of the graduation line. By this method it is possible to observe

ing the water surface. The liquids usually used for cleaning

the approach of the meniscus from either above or below the

glassware are sodium dichromatic-sulfuric acid cleaning solu-

line to its proper setting.

tion (commercially available from laboratory supply houses),

NOTE 1—The difference between meniscus positions resulting from the

nitric acid, fuming sulfuric acid, alcohol, and water. The choice

alternative methods of adjustment is the volume equivalent of one half the

of cleaning agent to be used depends on the nature of the

thickness of the graduation line. In the case of articles where the capacity

contaminant. After cleaning with the cleaning solution and

is read as the difference between two meniscus readings (for example on

thoroughly rinsing with tap water, the vessel should be rinsed

a buret), then no error results if the article is manufactured using one

method of adjustment and is later used by the other method.

with distilled water.

Even in the most unfavorable cases of single-mark articles (for example

7.2.2 After cleaning, the vessel should be rinsed with ethyl

large flasks), when working to the highest attainable accuracy, the

alcohol and dried with clean air at room temperature. It is not

difference between the two methods of adjustment is unlikely to exceed

necessary to dry any vessel marked “to deliver.” When

30 % of the Class A (precision apparatus) limit of error and a correction

cleaning small articles such as pipets, it is usually easier to fill

can be calculated where necessary.

them with cleaning solution by suction, using a vacuum line, if

8. Calibration Procedure for Burets

available, or a small rubber bulb, but never by mouth. The

solution should be drawn through the pipet several times until 8.1 Clamp the buret vertically on a support stand; also

the entire inside surface is evenly coated. Rinse thoroughly clamp a plain glass test tube, large enough to hold a thermom-

with tap water and then with distilled water. For cleaning eter, near the buret if the buret is of such a size that it is not

flasks, pour in enough cleaning solution while rotating so that large enough to insert a thermometer in the top for observing

a film of solution will cover the entire interior surface. A break the temperature of the water. Fill the buret from a reservoir or

in the film indicates a contaminated area. For filling a buret storage bottle, in which the water has reached equilibrium with

with cleaning solution, it should be held in a vertical position room temperature, and check to verify that there is neither

and filled by pouring into the top. Open the stopcock to drain. leakage from the tip nor from the stopcock plug. Drain and

Regardless of the type of vessel, always rinse thoroughly, first record the delivery time. Delivery time is determined by the

with tap water and then with distilled water. Plastic volumetric unrestricted outflow of the water from the zero mark to the

ware should be cleaned in an appropriate manner before lowest graduation mark with the stopcock fully open. Refill the

calibration. buret to approximately 10 mm above the zero mark and fill the

7.3 Reading and Setting a Liquid Meniscus: test tube that holds the thermometer; record the temperature.

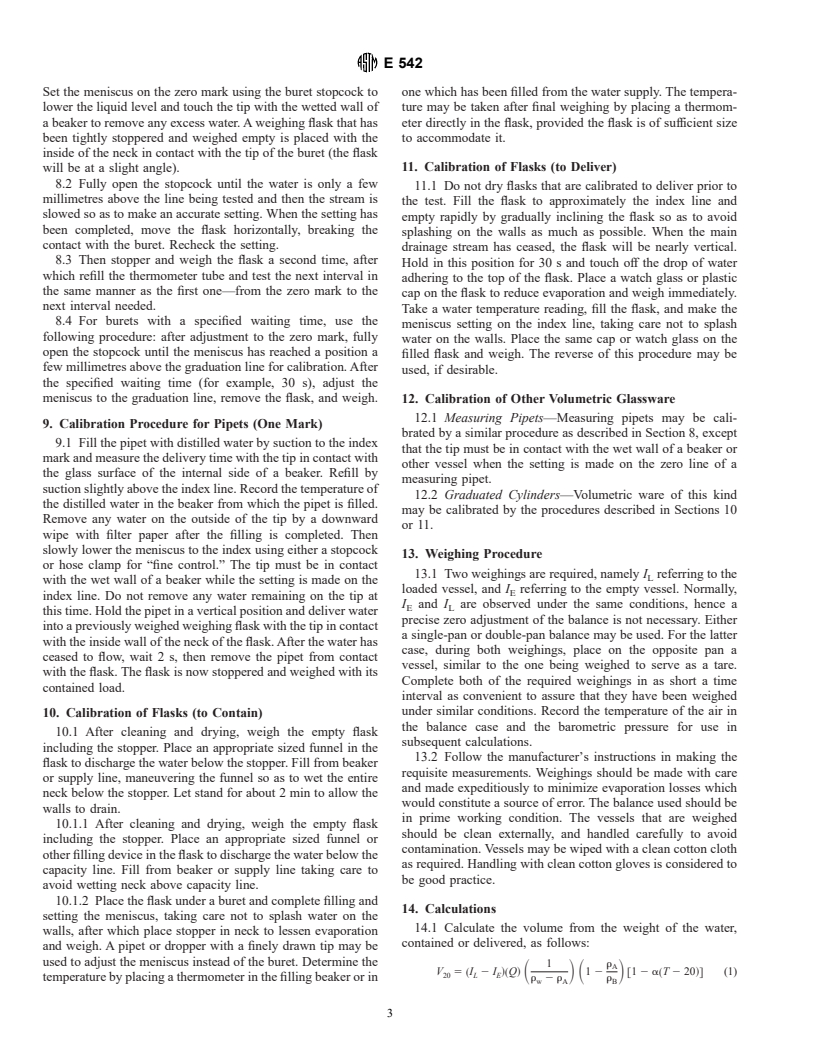

E 542

Set the meniscus on the zero mark using the buret stopcock to one which has been filled from the water supply. The tempera-

lower the liquid level and touch the tip with the wetted wall of ture may be taken after final weighing by placing a thermom-

a beaker to remove any excess water. A weighing flask that has eter directly in the flask, provided the flask is of sufficient size

been tightly stoppered and weighed empty is placed with the to accommodate it.

inside of the neck in contact with the tip of the buret (the flask

11. Calibration of Flasks (to Deliver)

will be at a slight angle).

8.2 Fully open the stopcock until the water is only a few

11.1 Do not dry flasks that are calibrated to deliver prior to

millimetres above the line being tested and then the stream is

the test. Fill the flask to approximately the index line and

slowed so as to make an accurate setting. When the setting has

empty rapidly by gradually inclining the flask so as to avoid

been completed, move the flask horizontally, breaking the

splashing on the walls as much as possible. When the main

contact with the buret. Recheck the setting.

drainage stream has ceased, the flask will be nearly vertical.

8.3 Then stopper and weigh the flask a second time, after

Hold in this position for 30 s and touch off the drop of water

which refill the thermometer tube and test the next interval in

adhering to the top of the flask. Place a watch glass or plastic

the same manner as the first one—from the zero mark to the

cap on the flask to reduce evaporation and weigh immediately.

next interval needed.

Take a water temperature reading, fill the flask, and make the

8.4 For burets with a specified waiting time, use the

meniscus setting on the index line, taking care not to splash

following procedure: after adjustment to the zero mark, fully

water on the walls. Place the same cap or watch glass on the

open the stopcock until the meniscus has reached a position a

filled flask and weigh. The reverse of this procedure may be

few millimetres above the graduation line for calibration. After

used, if desirable.

the specified waiting time (for example, 30 s), adjust the

meniscus to the graduation line, remove the flask, and weigh.

12. Calibration of Other Volumetric Glassware

12.1 Measuring Pipets—Measuring pipets may be cali-

9. Calibration Procedure for Pipets (One Mark)

brated by a similar procedure as described in Section 8, except

9.1 Fill the pipet with distilled water by suction to the index

that the tip must be in contact with the wet wall of a beaker or

mark and measure the delivery time with the tip in contact with

other vessel when the setting is made on the zero line of a

the glass surface of the internal side of a beaker. Refill by

measuring pipet.

suction slightly above the index line

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.