ASTM E384-99e1

(Test Method)Standard Test Method for Microindentation Hardness of Materials

Standard Test Method for Microindentation Hardness of Materials

SCOPE

1.1 This test method covers determination of the microindentation hardness of materials, the verification of microindentation hardness testing machines, and the calibration of standardized test blocks.

1.2 This test method covers microindentation tests made with Knoop and Vickers indenters under test forces in the range from 1 to 1000 gf (9.8 10-3 to 9.8 N).

1.3 This test method includes an analysis of the possible sources of errors that can occur during microindentation testing and how these factors affect the accuracy, repeatability, and reproducibility of test results.

Note 1—While Committee E04 is primarily concerned with metals, the test procedures described are applicable to other materials.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: E 384 – 99

Standard Test Method for

1

Microindentation Hardness of Materials

This standard is issued under the fixed designation E 384; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

e NOTE—Values for 138 Diagonal of Impression µm, in Table X5.1, were editorially corrected in February 2002.

5

1. Scope E 175 Terminology of Microscopy

E 691 Practice for Conducting an Interlaboratory Study to

1.1 This test method covers determination of the microin-

4

Determine the Precision of a Test Method

dentation hardness of materials, the verification of microinden-

E 766 Practice for Calibrating the Magnification of a Scan-

tation hardness testing machines, and the calibration of stan-

3

ning Electron Microscope

dardized test blocks.

1.2 This test method covers microindentation tests made

3. Terminology

withKnoopandVickersindentersundertestforcesintherange

–3

3.1 Definitions—For definitions of terms used in this test

from 1 to 1000 gf (9.8 3 10 to 9.8 N).

method, see Terminology E 7.

1.3 This test method includes an analysis of the possible

3.2 Definitions of Terms Specific to This Standard:

sourcesoferrorsthatcanoccurduringmicroindentationtesting

3.2.1 calibrating, v—determining the values of the signifi-

and how these factors affect the accuracy, repeatability, and

cant parameters by comparison with values indicated by a

reproducibility of test results.

reference instrument or by a set of reference standards.

NOTE 1—WhileCommitteeE04isprimarilyconcernedwithmetals,the

3.2.2 Knoop hardness number, HK, n—an expression of

test procedures described are applicable to other materials.

hardness obtained by dividing the force applied to the Knoop

1.4 This standard does not purport to address all of the

indenter by the projected area of the permanent impression

safety concerns, if any, associated with its use. It is the

made by the indenter.

responsibility of the user of this standard to establish appro-

3.2.3 Knoop indenter, n—a rhombic-based pyramidal-

priate safety and health practices and determine the applica-

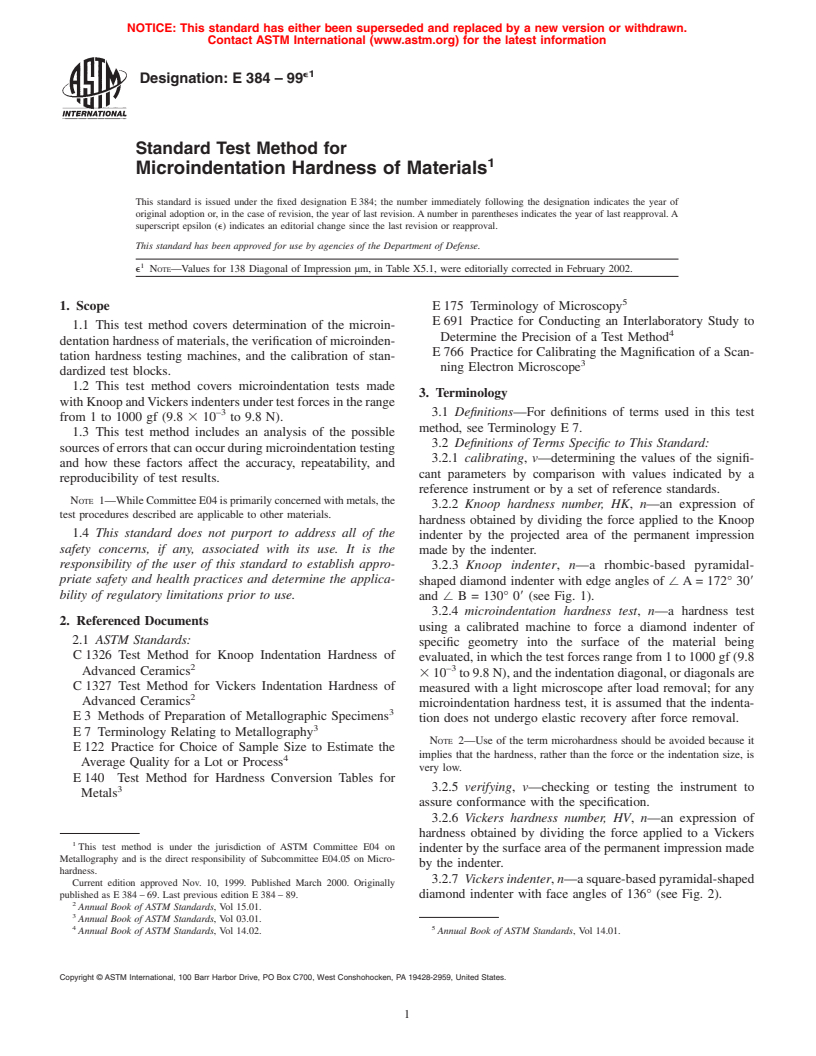

shaped diamond indenter with edge angles of/ A = 172° 308

bility of regulatory limitations prior to use.

and/ B = 130° 08 (see Fig. 1).

3.2.4 microindentation hardness test, n—a hardness test

2. Referenced Documents

using a calibrated machine to force a diamond indenter of

2.1 ASTM Standards:

specific geometry into the surface of the material being

C 1326 Test Method for Knoop Indentation Hardness of

evaluated, in which the test forces range from 1 to 1000 gf (9.8

2

–3

Advanced Ceramics

310 to9.8N),andtheindentationdiagonal,ordiagonalsare

C 1327 Test Method for Vickers Indentation Hardness of

measured with a light microscope after load removal; for any

2

Advanced Ceramics

microindentation hardness test, it is assumed that the indenta-

3

E 3 Methods of Preparation of Metallographic Specimens

tion does not undergo elastic recovery after force removal.

3

E 7 Terminology Relating to Metallography

NOTE 2—Use of the term microhardness should be avoided because it

E 122 Practice for Choice of Sample Size to Estimate the

implies that the hardness, rather than the force or the indentation size, is

4

Average Quality for a Lot or Process

very low.

E 140 Test Method for Hardness Conversion Tables for

3 3.2.5 verifying, v—checking or testing the instrument to

Metals

assure conformance with the specification.

3.2.6 Vickers hardness number, HV, n—an expression of

hardness obtained by dividing the force applied to a Vickers

1

This test method is under the jurisdiction of ASTM Committee E04 on

indenter by the surface area of the permanent impression made

Metallography and is the direct responsibility of Subcommittee E04.05 on Micro-

by the indenter.

hardness.

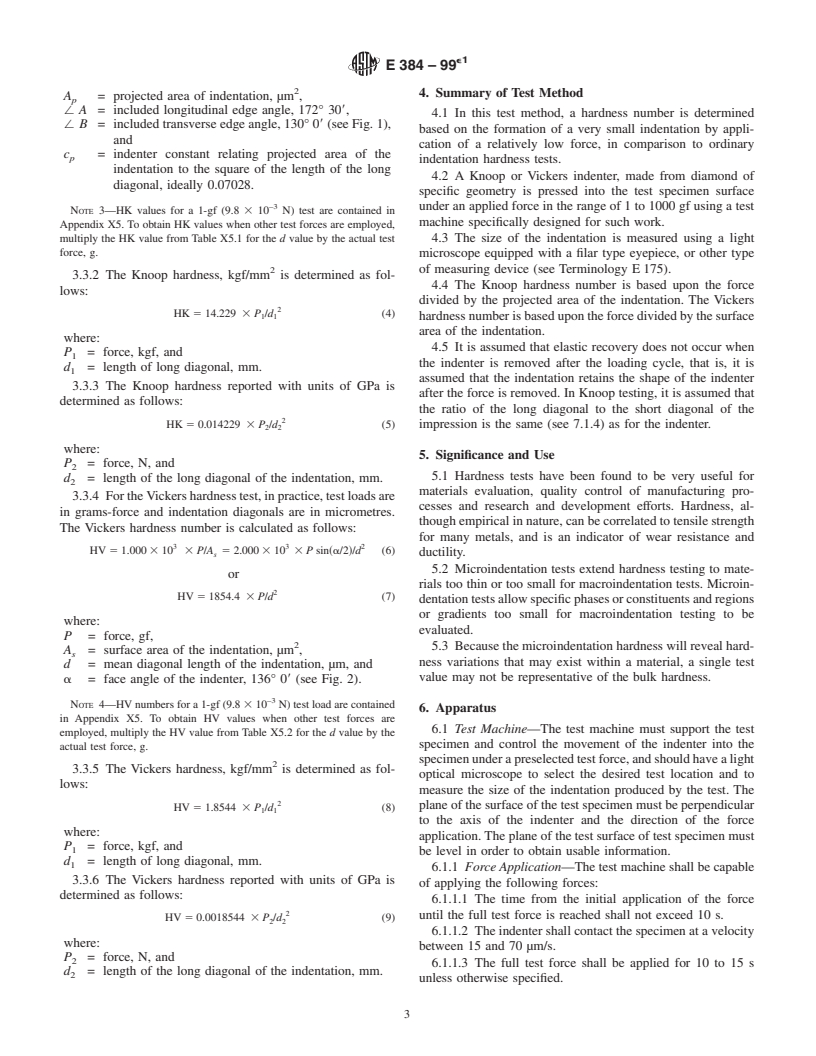

3.2.7 Vickers indenter, n—asquare-basedpyramidal-shaped

Current edition approved Nov. 10, 1999. Published March 2000. Originally

published as E 384 – 69. Last previous edition E 384 – 89. diamond indenter with face angles of 136° (see Fig. 2).

2

Annual Book of ASTM Standards, Vol 15.01.

3

Annual Book of ASTM Standards, Vol 03.01.

4 5

Annual Book of ASTM Standards, Vol 14.02. Annual Book of ASTM Standards, Vol 14.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

e1

E384–99

FIG. 1 Knoop Indenter

FIG. 2 Vickers Indenter

3 3 2

3.3 Formulae—The formulae presented in 3.3.1-3.3.4 for

HK 5 1.000 3 10 3 P/A ! 5 1.000 3 10 3 P/ c 3 d ! (1)

~ ~

p p

calculating m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.