ASTM E384-99

(Test Method)Standard Test Method for Microindentation Hardness of Materials

Standard Test Method for Microindentation Hardness of Materials

SCOPE

1.1 This test method covers determination of the microindentation hardness of materials, the verification of microindentation hardness testing machines, and the calibration of standardized test blocks.

1.2 This test method covers microindentation tests made with Knoop and Vickers indenters under test forces in the range from 1 to 1000 gf (9.8 10-3 to 9.8 N).

1.3 This test method includes an analysis of the possible sources of errors that can occur during microindentation testing and how these factors affect the accuracy, repeatability, and reproducibility of test results.

Note 1—While Committee E04 is primarily concerned with metals, the test procedures described are applicable to other materials.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 384 – 99

Standard Test Method for

Microindentation Hardness of Materials

This standard is issued under the fixed designation E 384; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope E 766 Practice for Calibrating the Magnification of a Scan-

ning Electron Microscope

1.1 This test method covers determination of the microin-

dentation hardness of materials, the verification of microinden-

3. Terminology

tation hardness testing machines, and the calibration of stan-

3.1 Definitions—For definitions of terms used in this test

dardized test blocks.

method, see Terminology E 7.

1.2 This test method covers microindentation tests made

3.2 Definitions of Terms Specific to This Standard:

with Knoop and Vickers indenters under test forces in the range

–3

3.2.1 calibrating, v—determining the values of the signifi-

from 1 to 1000 gf (9.8 3 10 to 9.8 N).

cant parameters by comparison with values indicated by a

1.3 This test method includes an analysis of the possible

reference instrument or by a set of reference standards.

sources of errors that can occur during microindentation testing

3.2.2 Knoop hardness number, HK, n—an expression of

and how these factors affect the accuracy, repeatability, and

hardness obtained by dividing the force applied to the Knoop

reproducibility of test results.

indenter by the projected area of the permanent impression

NOTE 1—While Committee E-4 is primarily concerned with metals, the

made by the indenter.

test procedures described are applicable to other materials.

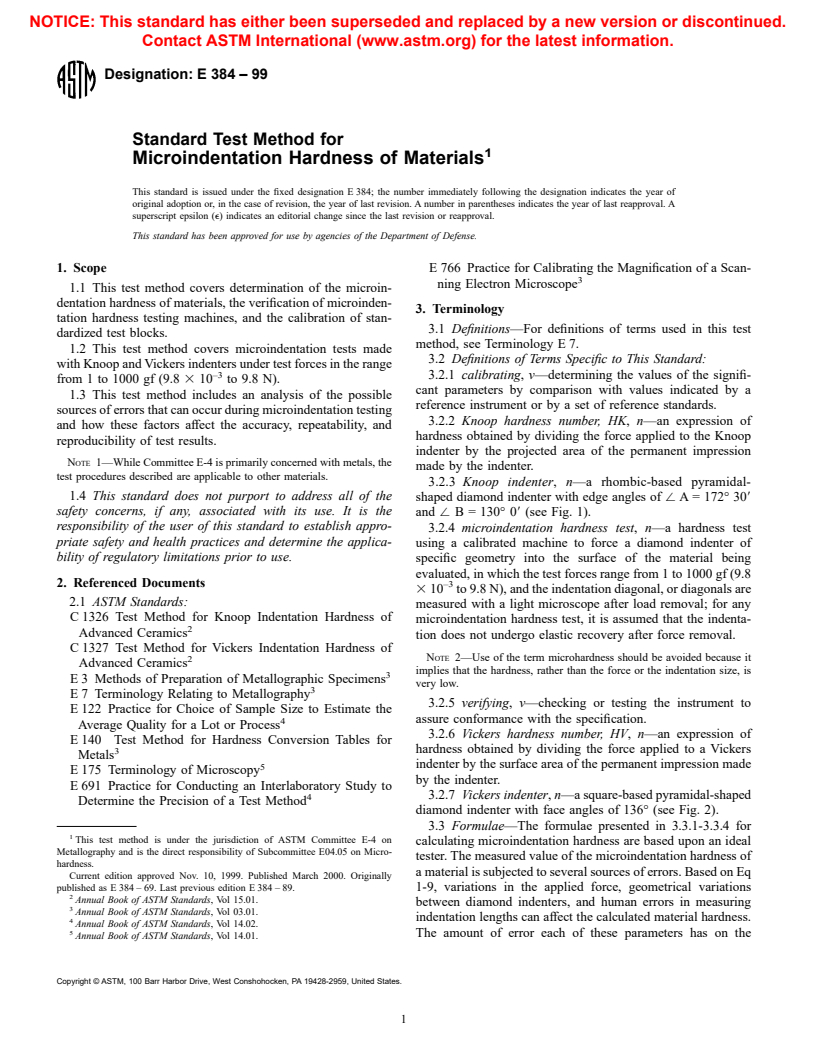

3.2.3 Knoop indenter, n—a rhombic-based pyramidal-

1.4 This standard does not purport to address all of the

shaped diamond indenter with edge angles of / A = 172° 308

safety concerns, if any, associated with its use. It is the

and / B = 130° 08 (see Fig. 1).

responsibility of the user of this standard to establish appro-

3.2.4 microindentation hardness test, n—a hardness test

priate safety and health practices and determine the applica-

using a calibrated machine to force a diamond indenter of

bility of regulatory limitations prior to use.

specific geometry into the surface of the material being

evaluated, in which the test forces range from 1 to 1000 gf (9.8

2. Referenced Documents –3

3 10 to 9.8 N), and the indentation diagonal, or diagonals are

2.1 ASTM Standards:

measured with a light microscope after load removal; for any

C 1326 Test Method for Knoop Indentation Hardness of

microindentation hardness test, it is assumed that the indenta-

Advanced Ceramics

tion does not undergo elastic recovery after force removal.

C 1327 Test Method for Vickers Indentation Hardness of

NOTE 2—Use of the term microhardness should be avoided because it

Advanced Ceramics

implies that the hardness, rather than the force or the indentation size, is

E 3 Methods of Preparation of Metallographic Specimens

very low.

E 7 Terminology Relating to Metallography

3.2.5 verifying, v—checking or testing the instrument to

E 122 Practice for Choice of Sample Size to Estimate the

assure conformance with the specification.

Average Quality for a Lot or Process

3.2.6 Vickers hardness number, HV, n—an expression of

E 140 Test Method for Hardness Conversion Tables for

hardness obtained by dividing the force applied to a Vickers

Metals

indenter by the surface area of the permanent impression made

E 175 Terminology of Microscopy

by the indenter.

E 691 Practice for Conducting an Interlaboratory Study to

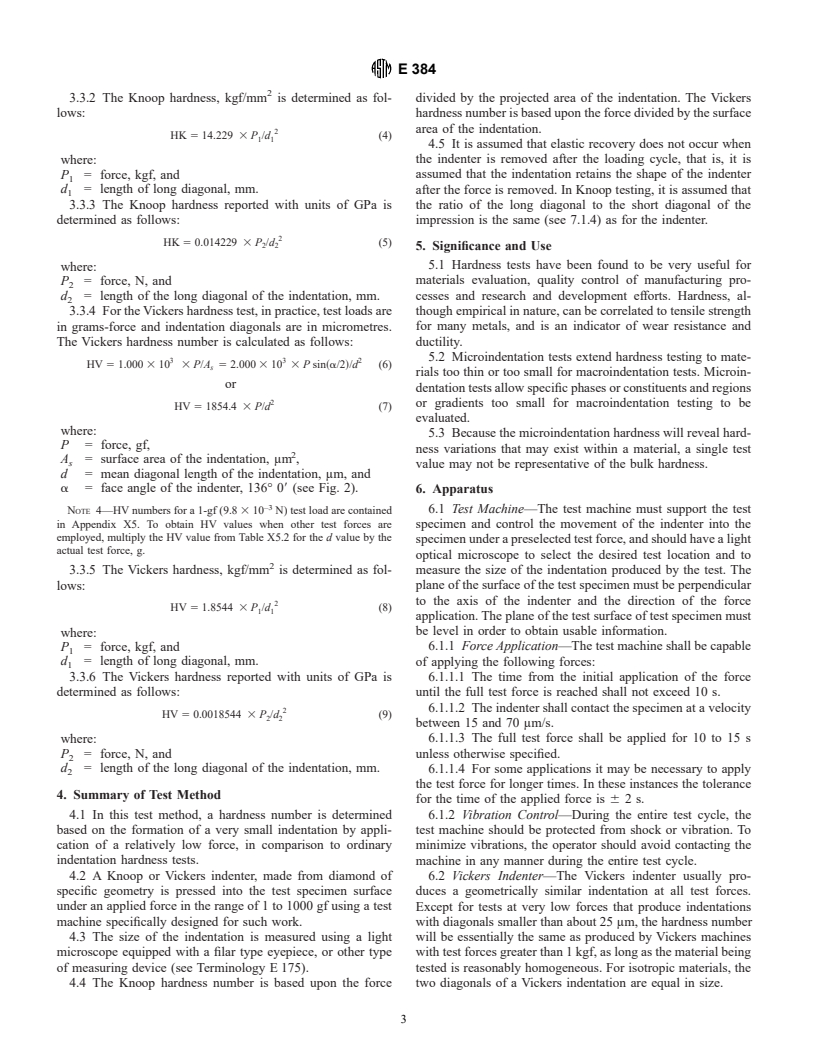

3.2.7 Vickers indenter, n—a square-based pyramidal-shaped

Determine the Precision of a Test Method

diamond indenter with face angles of 136° (see Fig. 2).

3.3 Formulae—The formulae presented in 3.3.1-3.3.4 for

This test method is under the jurisdiction of ASTM Committee E-4 on

calculating microindentation hardness are based upon an ideal

Metallography and is the direct responsibility of Subcommittee E04.05 on Micro-

tester. The measured value of the microindentation hardness of

hardness.

a material is subjected to several sources of errors. Based on Eq

Current edition approved Nov. 10, 1999. Published March 2000. Originally

published as E 384 – 69. Last previous edition E 384 – 89. 1-9, variations in the applied force, geometrical variations

Annual Book of ASTM Standards, Vol 15.01.

between diamond indenters, and human errors in measuring

Annual Book of ASTM Standards, Vol 03.01.

indentation lengths can affect the calculated material hardness.

Annual Book of ASTM Standards, Vol 14.02.

The amount of error each of these parameters has on the

Annual Book of ASTM Standards, Vol 14.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 384

FIG. 1 Knoop Indenter

FIG. 2 Vickers Indenter

calculated value of a microindentation measurement is dis-

where:

cussed in Section 10.

P = force, gf,

3.3.1 For Knoop hardness tests, in practice, test loads are in d = length of long diagonal, μm,

grams-force and indentation diagonals are in micrometres. The A = projected area of indentation, μm ,

p

/ A = included longitudinal edge angle, 172° 308,

Knoop hardness number is calculated using the following:

/ B = included transverse edge angle, 130° 08 (see Fig. 1),

3 3 2

HK 5 1.000 3 10 3 ~P/A ! 5 1.000 3 10 3 P/~c 3 d ! (1)

p p

and

or

c = indenter constant relating projected area of the

p

indentation to the square of the length of the long

HK 5 14229 3 P/d (2)

diagonal, ideally 0.07028.

–3

/ B

NOTE 3—HK values for a 1-gf (9.8 3 10 N) test are contained in

tan

S D

Appendix X5. To obtain HK values when other test forces are employed,

c 5 (3)

p

/ A

multiply the HK value from Table X5.1 for the d value by the actual test

2 tan

S D

2 force, g.

E 384

3.3.2 The Knoop hardness, kgf/mm is determined as fol- divided by the projected area of the indentation. The Vickers

lows: hardness number is based upon the force divided by the surface

area of the indentation.

HK 5 14.229 3 P /d (4)

1 1

4.5 It is assumed that elastic recovery does not occur when

the indenter is removed after the loading cycle, that is, it is

where:

assumed that the indentation retains the shape of the indenter

P = force, kgf, and

d = length of long diagonal, mm.

after the force is removed. In Knoop testing, it is assumed that

3.3.3 The Knoop hardness reported with units of GPa is the ratio of the long diagonal to the short diagonal of the

determined as follows:

impression is the same (see 7.1.4) as for the indenter.

HK 5 0.014229 3 P /d (5)

2 2

5. Significance and Use

5.1 Hardness tests have been found to be very useful for

where:

materials evaluation, quality control of manufacturing pro-

P = force, N, and

d = length of the long diagonal of the indentation, mm. cesses and research and development efforts. Hardness, al-

3.3.4 For the Vickers hardness test, in practice, test loads are though empirical in nature, can be correlated to tensile strength

in grams-force and indentation diagonals are in micrometres. for many metals, and is an indicator of wear resistance and

The Vickers hardness number is calculated as follows: ductility.

5.2 Microindentation tests extend hardness testing to mate-

3 3 2

HV 5 1.000 3 10 3 P/A 5 2.000 3 10 3 P sin~a/2!/d (6)

s

rials too thin or too small for macroindentation tests. Microin-

or

dentation tests allow specific phases or constituents and regions

or gradients too small for macroindentation testing to be

HV 5 1854.4 3 P/d (7)

evaluated.

where:

5.3 Because the microindentation hardness will reveal hard-

P = force, gf,

ness variations that may exist within a material, a single test

A = surface area of the indentation, μm ,

s

value may not be representative of the bulk hardness.

d = mean diagonal length of the indentation, μm, and

a = face angle of the indenter, 136° 08 (see Fig. 2).

6. Apparatus

–3

6.1 Test Machine—The test machine must support the test

NOTE 4—HV numbers for a 1-gf (9.8 3 10 N) test load are contained

in Appendix X5. To obtain HV values when other test forces are

specimen and control the movement of the indenter into the

employed, multiply the HV value from Table X5.2 for the d value by the

specimen under a preselected test force, and should have a light

actual test force, g.

optical microscope to select the desired test location and to

3.3.5 The Vickers hardness, kgf/mm is determined as fol- measure the size of the indentation produced by the test. The

plane of the surface of the test specimen must be perpendicular

lows:

to the axis of the indenter and the direction of the force

HV 5 1.8544 3 P /d (8)

1 1

application. The plane of the test surface of test specimen must

be level in order to obtain usable information.

where:

6.1.1 Force Application—The test machine shall be capable

P = force, kgf, and

d = length of long diagonal, mm.

of applying the following forces:

3.3.6 The Vickers hardness reported with units of GPa is 6.1.1.1 The time from the initial application of the force

determined as follows: until the full test force is reached shall not exceed 10 s.

6.1.1.2 The indenter shall contact the specimen at a velocity

HV 5 0.0018544 3 P /d (9)

2 2

between 15 and 70 μm/s.

6.1.1.3 The full test force shall be applied for 10 to 15 s

where:

P = force, N, and unless otherwise specified.

d = length of the long diagonal of the indentation, mm.

6.1.1.4 For some applications it may be necessary to apply

the test force for longer times. In these instances the tolerance

4. Summary of Test Method

for the time of the applied force is 6 2s.

4.1 In this test method, a hardness number is determined

6.1.2 Vibration Control—During the entire test cycle, the

based on the formation of a very small indentation by appli- test machine should be protected from shock or vibration. To

cation of a relatively low force, in comparison to ordinary

minimize vibrations, the operator should avoid contacting the

indentation hardness tests. machine in any manner during the entire test cycle.

4.2 A Knoop or Vickers indenter, made from diamond of 6.2 Vickers Indenter—The Vickers indenter usually pro-

specific geometry is pressed into the test specimen surface duces a geometrically similar indentation at all test forces.

under an applied force in the range of 1 to 1000 gf using a test Except for tests at very low forces that produce indentations

machine specifically designed for such work. with diagonals smaller than about 25 μm, the hardness number

4.3 The size of the indentation is measured using a light will be essentially the same as produced by Vickers machines

microscope equipped with a filar type eyepiece, or other type with test forces greater than 1 kgf, as long as the material being

of measuring device (see Terminology E 175). tested is reasonably homogeneous. For isotropic materials, the

4.4 The Knoop hardness number is based upon the force two diagonals of a Vickers indentation are equal in size.

E 384

6.2.1 The ideal Vickers indenter is a highly polished, measurement of the diagonals. Conducting tests on non-planar

pointed, square-based pyramidal diamond with face angles of surfaces is not recommended. Results will be affected even in

136° 08. The effect that geometrical variations of these angles the case of the Knoop test where the radius of curvature is in

have on the measured values of Vickers hardness are discussed the direction of the short diagonal.

in Section 10. 7.1.1 In all tests, the indentation perimeter, and the inden-

6.2.2 The four faces of the Vickers indenter shall be equally tation tips in particular, must be clearly defined in the micro-

inclined to the axis of the indenter (within 6 308) and shall scope field of view.

meet at a sharp point. The line of junction between opposite 7.1.2 The specimen surface should not be etched before

faces (offset) shall be not more than 0.5 μm in length as shown making an indentation. Etched surfaces can obscure the edge of

in Fig. 2. the indentation, making an accurate measurement of the size of

6.3 Knoop Indenter—The Knoop indenter does not produce the indentation difficult. However, when determining the mi-

a geometrically similar indentation as a function of test force. croindentation hardness of an isolated phase or constituent, a

Consequently, the Knoop hardness will vary with test force. light etch can be used to delineate the object of interest. The

Due to its rhombic shape, the indentation depth is shallower for quality of the required surface finish can vary with the forces

a Knoop indentation compared to a Vickers indentation under and magnifications used in microindentation hardness testing.

identical test conditions. The two diagonals of a Knoop The lighter the force and the smaller the indentation size, the

indentation are markedly different. Ideally, the long diagonal is more critical is the surface preparation. Some materials are

7.114 times longer than the short diagonal, but this ratio is more sensitive to preparation-induced damage than others.

influenced by elastic recovery. Thus, the Knoop indenter is 7.1.3 Due to the small size of the indentations, special

very useful for evaluating hardness gradients or thin coatings. precautions must be taken during specimen preparation. It is

6.3.1 The Knoop indenter is a highly polished, pointed, well known that improper polishing can alter test results.

rhombic-based, pyramidal diamond. The ideal included longi- Specimen preparation must remove any damage introduced

tudinal edge angles are 172° 308 and 130° 08. The ideal during these steps, either due to excessive heating or cold

indenter constant, c , is 0.07028. The effect that geometrical work, for example.

p

variations of these angles have on the measured values of 7.1.4 Specimen preparation should be performed in accor-

Knoop hardness are discussed in Section 10. dance with Methods E 3.

6.3.2 The four faces of the Knoop indenter shall be equally 7.2 In some instances, it is necessary to mount the specimen

inclined to the axis of the indenter (within 6 308) and shall for convenience in preparation. When mounting is required, the

meet at a sharp point. The line of junction between opposite specimen must be adequately supported by the mounting

faces (offset) shall be not more than 1.0 μm in length for medium so that the specimen does not move during force

indentations greater than 20 μm in length, as shown in Fig. 1. application, that is, avoid the use of polymeric mounti

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.