ASTM D3650-93(2011)

(Test Method)Standard Test Method for Comparison of Waterborne Petroleum Oils By Fluorescence Analysis (Withdrawn 2018)

Standard Test Method for Comparison of Waterborne Petroleum Oils By Fluorescence Analysis (Withdrawn 2018)

SIGNIFICANCE AND USE

This test method is useful for rapid identification of waterborne petroleum oil samples as well as oil samples obtained from fuel or storage tanks, or from sand, vegetation, or other substrates. This test method is applicable to weathered and unweathered neat oil samples.

The unknown oil is identified through the comparison of the fluorescence spectrum of the oil with the spectra (obtained at similar instrumental settings on the same instrument) of possible source samples. A match of the entire spectrum between the unknown and possible source sample indicates a common source.

SCOPE

1.1 This test method covers the comparison of waterborne petroleum oils with oils from possible sources by means of fluorescence spectroscopy (1). Useful references for this test method include: (2) and (3) for fluorescence analysis in general and (4), (5), and (6) for oil spill identification including fluorescence.

1.2 This test method is applicable to crude or refined petroleum products, for any sample of neat oil, waterborne oil, or sample of oil-soaked material. Unless the samples are collected soon after the spill occurs, it is not recommended that volatile fuels such as gasoline, kerosine, and No. 1 fuel oils be analyzed by this test method, because their fluorescence signatures change rapidly with weathering. Some No. 2 fuel oils and light crude oils may only be identifiable up to 2 days weathering, or less, depending on the severity of weathering. In general, samples weathered up to 1 week may be identified, although longer periods of weathering may be tolerated for heavy residual oils, oil weathered under Arctic conditions, or oil that has been protected from weathering by collecting in a thick layer.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers the comparison of waterborne petroleum oils with oils from possible sources by means of fluorescence spectroscopy.

Formerly under the jurisdiction of Committee D19 on Water, this test method was withdrawn in November 2018. This standard was withdrawn without replacement due to its limited use by the industry.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3650 −93 (Reapproved 2011)

Standard Test Method for

Comparison of Waterborne Petroleum Oils By

Fluorescence Analysis

This standard is issued under the fixed designation D3650; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method covers the comparison of waterborne

D1129 Terminology Relating to Water

petroleum oils with oils from possible sources by means of

D1193 Specification for Reagent Water

fluorescence spectroscopy (1). Useful references for this test

D3325 Practice for Preservation of Waterborne Oil Samples

methodinclude: (2)and (3)forfluorescenceanalysisingeneral

D3326 Practice for Preparation of Samples for Identification

and (4), (5), and (6) for oil spill identification including

of Waterborne Oils

fluorescence.

D3415 Practice for Identification of Waterborne Oils

1.2 This test method is applicable to crude or refined

D4489 Practices for Sampling of Waterborne Oils

petroleum products, for any sample of neat oil, waterborne oil,

E131 Terminology Relating to Molecular Spectroscopy

or sample of oil-soaked material. Unless the samples are

E275 Practice for Describing and Measuring Performance of

collectedsoonafterthespilloccurs,itisnotrecommendedthat

Ultraviolet and Visible Spectrophotometers

volatile fuels such as gasoline, kerosine, and No. 1 fuel oils be

E520 Practice for Describing Photomultiplier Detectors in

analyzed by this test method, because their fluorescence

Emission and Absorption Spectrometry

signatures change rapidly with weathering. Some No. 2 fuel

oils and light crude oils may only be identifiable up to 2 days

3. Terminology

weathering,orless,dependingontheseverityofweathering.In

3.1 Definitions—For definitions of terms used in this test

general, samples weathered up to 1 week may be identified,

method refer to Terminology D1129, Practice D3415, and

although longer periods of weathering may be tolerated for

Terminology E131.

heavy residual oils, oil weathered under Arctic conditions, or

4. Summary of Test Method

oil that has been protected from weathering by collecting in a

thick layer.

4.1 This test method consists of fluorescence analyses of

dilute solutions of oil in spectroquality cyclohexane. In most

1.3 The values stated in SI units are to be regarded as

cases the emission spectra, with excitation at 254 nm, over the

standard. No other units of measurement are included in this

spectral range from 280 to 500 nm, are adequate for matching.

standard.

4.2 Identification of the sample is made by direct visual

1.4 This standard does not purport to address all of the

comparison of the sample’s spectrum with the spectra from

safety concerns, if any, associated with its use. It is the

possible source samples.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

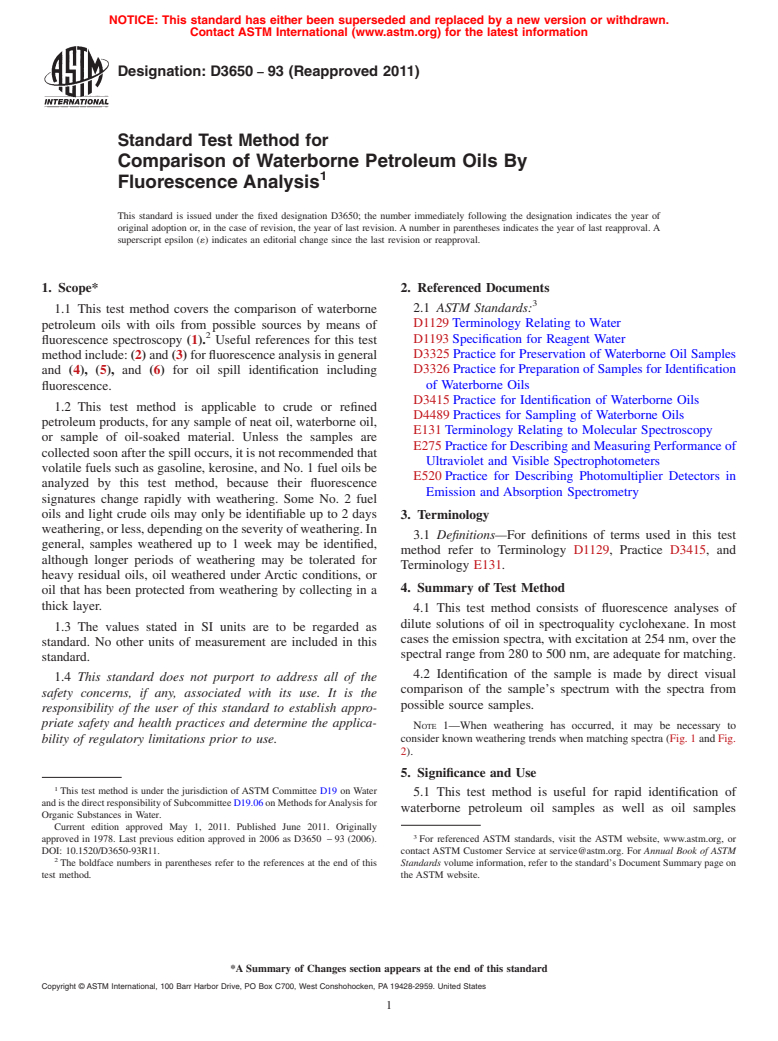

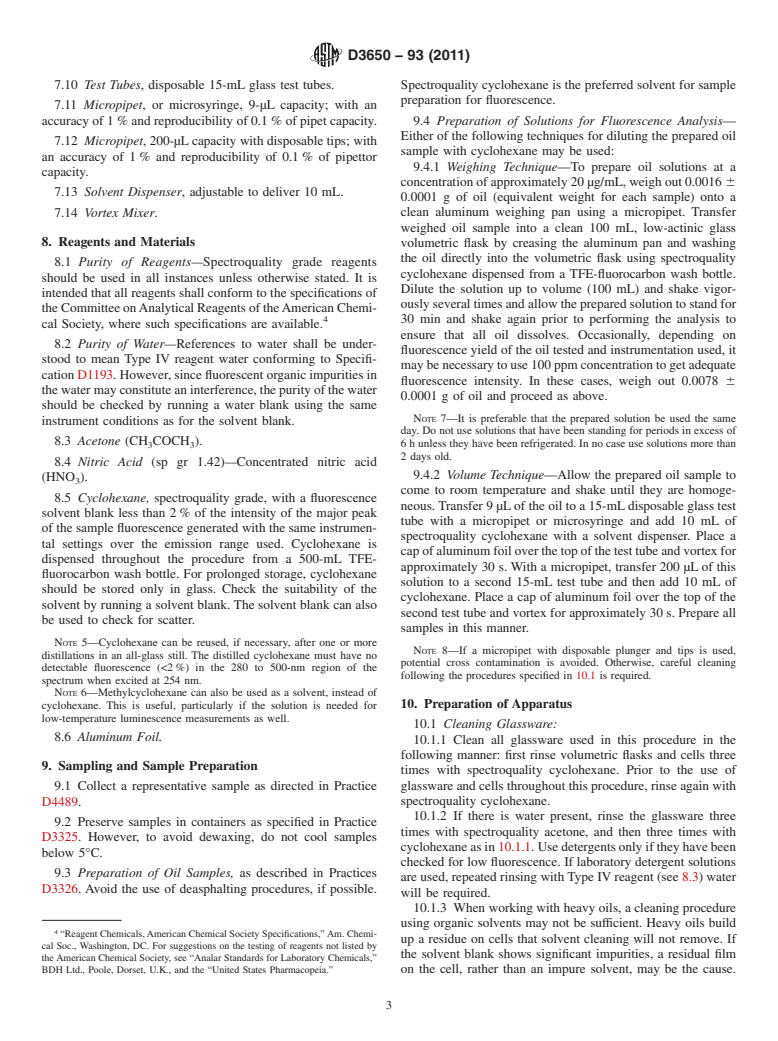

NOTE 1—When weathering has occurred, it may be necessary to

bility of regulatory limitations prior to use. consider known weathering trends when matching spectra (Fig. 1 and Fig.

2).

5. Significance and Use

This test method is under the jurisdiction of ASTM Committee D19 on Water

5.1 This test method is useful for rapid identification of

andisthedirectresponsibilityofSubcommitteeD19.06onMethodsforAnalysisfor

waterborne petroleum oil samples as well as oil samples

Organic Substances in Water.

Current edition approved May 1, 2011. Published June 2011. Originally

approved in 1978. Last previous edition approved in 2006 as D3650 – 93 (2006). For referenced ASTM standards, visit the ASTM website, www.astm.org, or

DOI: 10.1520/D3650-93R11. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

The boldface numbers in parentheses refer to the references at the end of this Standards volume information, refer to the standard’s Document Summary page on

test method. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3650−93 (2011)

6.3 Possible interferences from Raman or RayleighTyndall

scattering are not observed in the emission scan ranges

selected.

7. Apparatus

7.1 Fluorescence Spectrophotometer (or Spectro-

fluorometer)—An instrument recording in the spectral range of

220 nm to at least 600 nm for both excitation and emission

responses and capable of meeting the specifications stated in

Table 1.

7.2 Excitation Source—A high-pressure xenon lamp (a

150-W xenon lamp has proven acceptable). Other continuum

sources, such as deuterium or high-pressure xenon-mercury,

FIG. 1 Fluorescence Spectra for a Typical No. 2 Fuel Oil (Un-

which have sufficient intensity in the ultraviolet region, could

weathered and Weathered One Day)

be used as excitation sources.

NOTE 4—Line sources such as a low-pressure mercury lamp may also

be used for excitation at 254 nm, if the flexibility of using arbitrary

excitation wavelengths or excitation spectra is not desired and if source

intensity is adequate.

7.3 Fluorescence Cells—Standard cells, made from

fluorescence-free fused silica with a pathlength of 10 mm and

a height of 45 mm.

7.4 Recorder or Computer—Strip chart or X-Y recorder,

with a response time less than 1 s for full-scale deflection, or a

computer capable of digitizing the data at a rate of 1 data point

per nanometre.

7.5 Cell-Filling Device—Disposable Pasteur capillary pipet.

7.6 Volumetric Flasks—Low-actinic glass, ground-glass

FIG. 2 Fluorescence Spectra for a Typical No. 6 Fuel Oil (Un-

stoppered volumetric flasks (100-mL).

weathered and Weathered One Day)

7.7 Micropipet, 10 to 50-µL capacity.

obtained from fuel or storage tanks, or from sand, vegetation,

7.8 AnalyticalBalance,withaprecisionofatleast 60.1mg.

or other substrates.This test method is applicable to weathered

7.9 Weighing Pans, 5 to 7-mm diameter, 18 mm deep, made

and unweathered neat oil samples.

of aluminum or equivalent.

5.2 Theunknownoilisidentifiedthroughthecomparisonof

the fluorescence spectrum of the oil with the spectra (obtained

TABLE 1 Specifications for Fluorescence Spectrophotometers

at similar instrumental settings on the same instrument) of

Wavelength Reproducibility

possible source samples. A match of the entire spectrum

Excitation monochromator better than± 2 nm

between the unknown and possible source sample indicates a

Emission monochromator better than ±2 nm

Gratings (Typical Values)

common source.

Excitation monochromator minimum of 600 lines/mm blazed at

A

300 nm

6. Interferences

Emission monochromator minimum of 600 lines/mm blazed at

A

6.1 The fluorescence spectrum will be distorted if an oil 300 nm or 500 nm

sample has been contaminated by an appreciable amount, for

B

Photomultiplier Tube

example, 1 % of common chemical impurities such as other

C D E

Either S-20 or S-5 Response

oils that are fluorescent on excitation at 254 nm.

NOTE 2—Storage of samples in improper containers (for example, Resolution

Excitation monochromator better than 2 nm

plastics) may result in contamination. This interference can be eliminated

Emission monchromator better than 2 nm

by observing proper procedures for collection and preservation of

samples. Refer to Practice D3325.

Time Constant

NOTE 3—“Spectroquality” cyclohexane may not have a low enough

fluorescence solvent blank. Lots vary in the content of fluorescent

not to exceed one second

impurities, which may increase with storage time even if the bottle is

A

Or designed to have a good efficiency in this spectral region.

unopened.

B

See Practice E520.

C

6.2 Oil residues may build up in fluorescence cells particu- Photomultiplier tubes such as Hamamatsu R-446-UR.

D

Photomultiplier tubes such as RCA 1P28 or Hamamatsu R-106.

larly after prolonged usage with heavy oils. In such a case,

E

Or equivalent having a good spectral response in the spectral region from 280 to

follow the procedure using nitric acid for cleaning glassware

600 nm.

(10.1.3).

D3650−93 (2011)

7.10 Test Tubes, disposable 15-mL glass test tubes. Spectroquality cyclohexane is the preferred solvent for sample

preparation for fluorescence.

7.11 Micropipet, or microsyringe, 9-µL capacity; with an

accuracy of 1 % and reproducibility of 0.1 % of pipet capacity. 9.4 Preparation of Solutions for Fluorescence Analysis—

Either of the following techniques for diluting the prepared oil

7.12 Micropipet, 200-µLcapacity with disposable tips; with

sample with cyclohexane may be used:

an accuracy of 1 % and reproducibility of 0.1 % of pipettor

9.4.1 Weighing Technique—To prepare oil solutions at a

capacity.

concentrationofapproximately20µg/mL,weighout0.0016 6

7.13 Solvent Dispenser, adjustable to deliver 10 mL.

0.0001 g of oil (equivalent weight for each sample) onto a

clean aluminum weighing pan using a micropipet. Transfer

7.14 Vortex Mixer.

weighed oil sample into a clean 100 mL, low-actinic glass

8. Reagents and Materials

volumetric flask by creasing the aluminum pan and washing

the oil directly into the volumetric flask using spectroquality

8.1 Purity of Reagents—Spectroquality grade reagents

cyclohexane dispensed from a TFE-fluorocarbon wash bottle.

should be used in all instances unless otherwise stated. It is

Dilute the solution up to volume (100 mL) and shake vigor-

intended that all reagents shall conform to the specifications of

ouslyseveraltimesandallowthepreparedsolutiontostandfor

theCommitteeonAnalyticalReagentsoftheAmericanChemi-

30 min and shake again prior to performing the analysis to

cal Society, where such specifications are available.

ensure that all oil dissolves. Occasionally, depending on

8.2 Purity of Water—References to water shall be under-

fluorescence yield of the oil tested and instrumentation used, it

stood to mean Type IV reagent water conforming to Specifi-

maybenecessarytouse100ppmconcentrationtogetadequate

cationD1193. However,sincefluorescentorganicimpurities in

fluorescence intensity. In these cases, weigh out 0.0078 6

thewatermayconstituteaninterference,thepurityofthewater

0.0001 g of oil and proceed as above.

should be checked by running a water blank using the same

NOTE 7—It is preferable that the prepared solution be used the same

instrument conditions as for the solvent blank.

day. Do not use solutions that have been standing for periods in excess of

8.3 Acetone (CH COCH ).

6 h unless they have been refrigerated. In no case use solutions more than

3 3

2 days old.

8.4 Nitric Acid (sp gr 1.42)—Concentrated nitric acid

9.4.2 Volume Technique—Allow the prepared oil sample to

(HNO ).

come to room temperature and shake until they are homoge-

8.5 Cyclohexane, spectroquality grade, with a fluorescence

neous.Transfer 9 µLof the oil to a 15-mLdisposable glass test

solvent blank less than 2 % of the intensity of the major peak

tube with a micropipet or microsyringe and add 10 mL of

of the sample fluorescence generated with the same instrumen-

spectroquality cyclohexane with a solvent dispenser. Place a

tal settings over the emission range used. Cyclohexane is

capofaluminumfoiloverthetopofthetesttubeandvortexfor

dispensed throughout the procedure from a 500-mL TFE-

approximately 30 s. With a micropipet, transfer 200 µL of this

fluorocarbon wash bottle. For prolonged storage, cyclohexane

solution to a second 15-mL test tube and then add 10 mL of

should be stored only in glass. Check the suitability of the

cyclohexane. Place a cap of aluminum foil over the top of the

solvent by running a solvent blank. The solvent blank can also

second test tube and vortex for approximately 30 s. Prepare all

be used to check for scatter.

samples in this manner.

NOTE 5—Cyclohexane can be reused, if necessary, after one or more

NOTE 8—If a micropipet with disposable plunger and tips is used,

distillations in an all-glass still. The distilled cyclohexane must have no

potential cross contamination is avoided. Otherwise, careful cleaning

detectable fluorescence (<2 %) in the 280 to 500-nm region of the

following the procedures specified in 10.1 is required.

spectrum when excited at 254 nm.

NOTE 6—Methylcyclohexane can also be used as a solvent, instead of

10. Preparation of Apparatus

cyclohexane. This is useful, particularly if the solution is needed for

low-temperature luminescence measurements as well.

10.1 Cleaning Glassware:

8.6 Aluminum Foil.

10.1.1 Clean all glassware used in this procedure in the

following manner: first rinse volumetric flasks and cells three

9. Sampling and Sample Preparation

times with spectroquality cyclohexane. Prior to the use of

glassware and cells throughout this procedure, rinse again with

9.1 Collect a representative sample as directed in Practice

D4489. spectroquality cyclohexane.

10.1.2 If there is water present, rinse the glassware three

9.2 Preserve samples in containers as specified in Practice

times with spectroquality acetone, and then three times with

D3325. However, to avoid dewaxing, do not cool samples

cyclohexaneasin10.1.1.Usedetergentsonlyiftheyhavebeen

below 5°C.

checked for low fluorescence. If laboratory detergent solutions

9.3 Preparation of Oil Samples, as described in Practices

are used, repeated rinsing with Type IVreagent (see 8.3) water

D3326. Avoid the use of deasphalting procedures, if possible.

will be required.

10.1.3 When working with heavy oils, a cleaning procedure

using organic solvents may not be sufficient. Heavy oils build

“Reagent Chemicals,American Chemical Society Specifications,”Am. Chemi-

up a residue on cells that solvent cleaning will not remove. If

cal Soc., Washington, DC. For suggestions on the testing of reagents not listed by

the solvent blank shows significant impurities, a residual film

theAmerican Chemical Society, see “Analar Standards for Laboratory Chemicals,”

BDH Ltd., Poole, Dorset, U.K., and the “United States Pharmacopeia.” on the cell, rather than an impure solvent, may be the cause.

D3650−93 (2011)

Soak the cells in undiluted nitric acid for 1 h. Observe proper 12. Interpretation of Spectra

safety precautions by using adequate eye and hand protection.

12.1 Overlay the spectrum of the unknown sample with the

RinsethecellsrepeatedlywithTypeIVreagentwater,andthen

spectra of the suspect samples. Note five features when

proceed as in 10.1.2.

comparing the oil spectra: (1) general shape, (2) number of

10.2 Calibration of Spectrophotometer:

peaks,(3)wavelengthscorrespondingtothepeaks,(4)ratiosof

10.2.1 Adjust and calibrate the spectroph

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.