ASTM D4514-00

(Specification)Standard Specification for Friction Tape

Standard Specification for Friction Tape

SCOPE

1.1 This specification covers friction tapes that are commonly used for protecting, and binding in place, insulation applied to joints of electrical wires and cables, and for other mechanical purposes.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 4514 – 00

Standard Specification for

Friction Tape

This standard is issued under the fixed designation D 4514; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope with the best manufacturing practices. The threads shall run in

2 lines as straight as possible without weaving, to reduce to a

1.1 This specification covers friction tapes that are com-

minimum the raveling of the cloth when cut into tape.

monly used for protecting, and binding in place, insulation

4.3 The frictioning compound shall be a tacky adhesive

applied to joints of electrical wires and cables, and for other

insulatingcompoundthatwillnothaveadeterioratingeffecton

mechanical purposes.

copper or other metals or on the fabric.

1.2 The values stated in inch-pound units are to be regarded

4.4 The fabric shall be thoroughly impregnated and evenly

as the standard. The values in parentheses are for information

covered on both sides with the frictioning compound. The

only.

compound shall adhere firmly to the fabric and shall not pull

2. Referenced Documents away from the fabric and leave bare spots when adjacent layers

of tape are separated.

2.1 ASTM Standards:

D 69 Test Methods for Friction Tapes

5. General Requirements

D 1711 Terminology Relating to Electrical Insulation

5.1 FrictiontapesshallmeettherequirementsgiveninTable

D 3636 Practice for Sampling and Judging Quality of Solid

1 when tested in accordance with Test Methods D 69.

Electrical Insulating Materials

2.2 Federal Specifications:

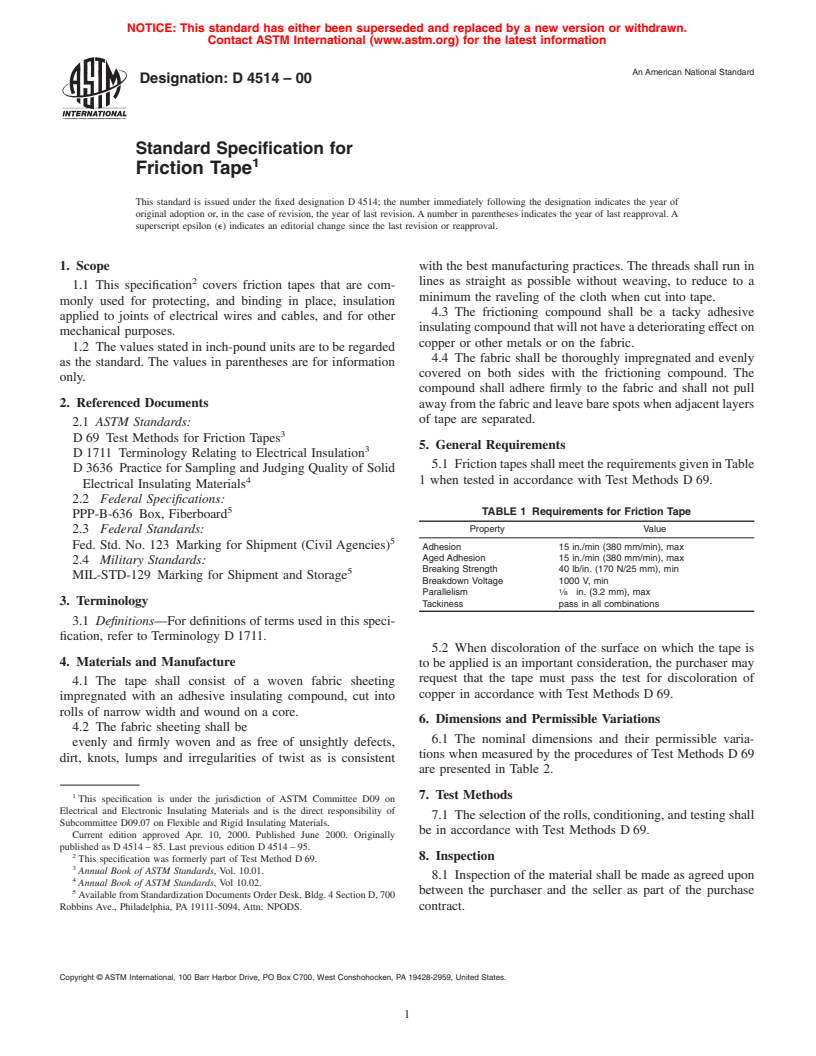

TABLE 1 Requirements for Friction Tape

PPP-B-636 Box, Fiberboard

Property Value

2.3 Federal Standards:

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

Adhesion 15 in./min (380 mm/min), max

Aged Adhesion 15 in./min (380 mm/min), max

2.4 Military Standards:

Breaking Strength 40 lb/in. (170 N/25 mm), min

MIL-STD-129 Marking for Shipment and Storage

Breakdown Voltage 1000 V, min

Parallelism ⁄8 in. (3.2 mm), max

3. Terminology

Tackiness pass in all combinations

3.1 Definitions—For definitions of terms used in this speci-

fication, refer to Terminology D 1711.

5.2 When discoloration of the surface on which the tape is

4. Materials and Manufacture

to be applied is an important consideration, the purchaser may

request that the tape must pass the test for discoloration of

4.1 The tape shall consist of a woven fabric sheeting

copper in accordance with Test Methods D 69.

impregnated with an adhesive insulating compound, cut into

rolls of narrow width and wound on a core.

6. Dimensions and Permissible Variations

4.2 The fabric sheeting shall be

6.1 The nominal dimensions and their permissible varia-

evenly and firmly woven and as free of unsightly defects,

tions when measured by the procedures of Test Methods D 69

dirt, knots, lumps and irregularities of twist as is consistent

are presented in Table 2.

7. Test Methods

This specification is under the jurisdiction of ASTM Committee D09 on

Electrical and Electronic Insulating Materials and is the direct responsibility of

7.1 The selection of the rolls, conditioning, and testing shall

Subcommittee D09.07 on Flexible and Rigid Insulating Materials.

be in accordance with Test Methods D 69.

Current edition approved Apr. 10, 2000. Published June 2000. Originally

published as D 4514 – 85. Last previous edition D 4514 – 95.

8. Inspection

This specification was formerly part of Test Method D 69.

Annual Book of ASTM Standards, Vol. 10.01.

8.1 Inspection of the material shall be made as agreed upon

Annual Book of ASTM Standards, Vol 10.02.

5 between the purchaser and the seller as part of the purchase

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS. contract.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4514–00

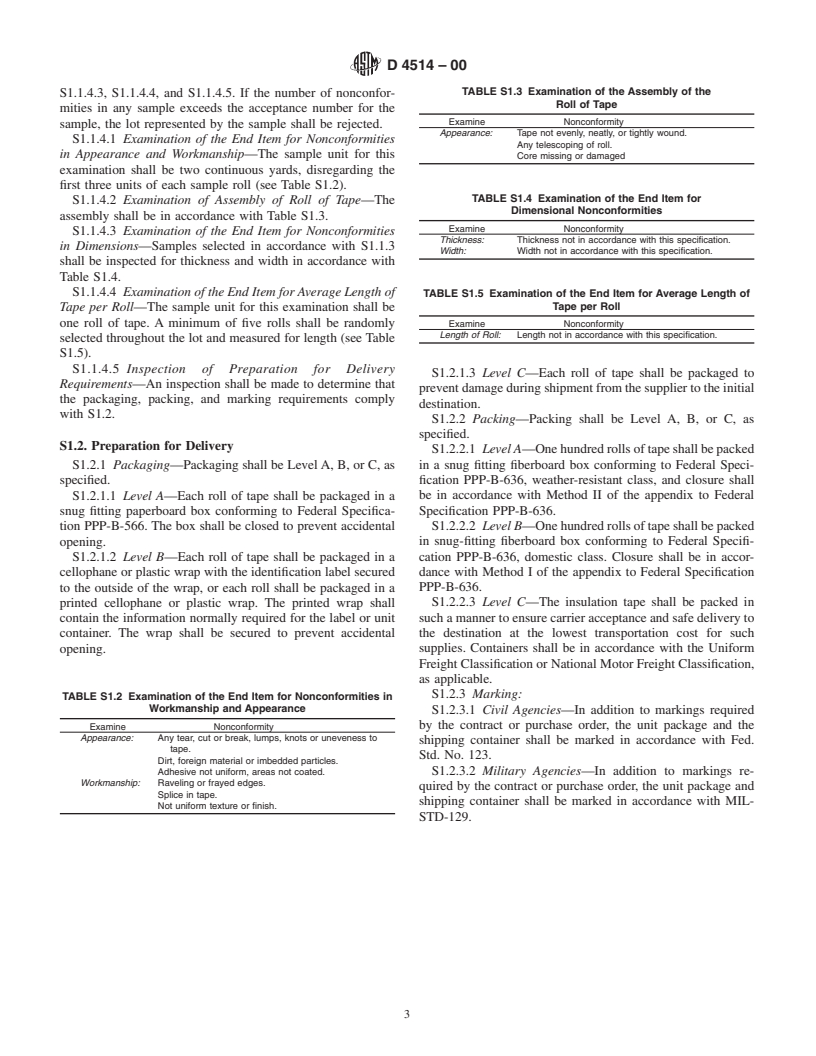

TABLE 2 Dimensions and Permissible Variations

3 1

Nominal width ⁄4 in. (19 mm) 1 in. (25 mm) 1 ⁄2 in. (38 mm) 2 in. (51 mm)

Permissible variation for average ←←← 6 ⁄32 in. (60.8 mm) →→→

Permissible variation for individual ←←← 6 ⁄16 in. (61.6 mm) →→→

Nominal thickness ←←← 0.015 in. (0.38 mm) →→→

Permissible variation for average ←←← 6 0.003 in. (6 0.08 mm) →→→

Permissible variation for individual ←←← 6 0.004 in. (6 0.10 mm) →→→

Nominal length ←←← 82 ft (25 m) →→→

Permissible variation for length ←←← +3ft(+0.9m)–0ft(–0m) →→→

8.2 If it is required, the tape shall be tested and inspected test specified in Test Methods D 69 except that a force of 3

either at the place of manufacture prior to shipment or at the lbf/in. (13.3 N/25 mm) shall be substituted for the 4 lbf/in.

place of delivery within four weeks from the date of delivery.

(17.8 N/25 mm) during unwinding.

10.2 Proper storage of tape requires the use of the original

9. Rejection

boxes and a cool, dark location. Tape shall not be stored near

9.1 The purchaser reserves the right to reject any part of the

steam pipes, radiators, or other sources of heat.

shipment that does not comply with Section 11 of this

specification.

11. Packaging and Package Marking

9.2 The purchaser reserves the right to reject a shipment

from which two or more sample rolls fail to meet the

11.1 Packaging—Each roll of tape shall be enclosed in a

requirements of any individual test or measurement prescribed

paper carton unless otherwise specified. If enclosed in a paper

in this specification, without additional sampling. If only one

carton, either the roll of tape or the carton shall be wrapped in

sample roll fails an individual test or measurement or the

amoisture-proofmaterialandsealed.Thewrappingonthetape

average length of the sample rolls exceeds the prescribed

or carton shall be secure and shall protect the contents fully.

value, a second set of samples shall be taken in accordance

11.2 Package Marking—Each box shall be marked with the

with Test Methods D 69, and all rolls in the second sampling

name of the manufacturer or trademark, and the nominal width

shall be subjected to that test or measurement wherein the

and length of the tape.

failure occurred. The purchaser reserves the right to reject the

shipment if the second sampling fails to conform with the

12. Keywords

applicable requirement.

12.1 adhesion; aged adhesion; aging; breakdown voltage;

10. Aging and Storage

breaking strength; dimensions; friction tape; parallelism; stor-

10.1 The tape shall at any time, within eight months after

age; tackiness

acceptanceifstoredinaccordancewith10.2,meettheadhesion

GOVERNMENT/MILITARY PROCUREMENT

These requirements apply only to Federal/Military procurement, not domestic sales or transfers.

S1.1 QualityAssurance Provisions determining the sample size in accordance with Practice

D 3636, shall be expressed in units of rolls of tape, or

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.