ASTM D6617-00

(Practice)Standard Practice for Laboratory Bias Detection Using Single Test Result from Standard Material

Standard Practice for Laboratory Bias Detection Using Single Test Result from Standard Material

SCOPE

1.1 This practice covers a methodology for establishing an acceptable tolerance zone for the difference between the result obtained from a single implementation of a test method on a CS and its ARV, based on user-specified Type I error, the user-established test method precision, the standard error of the ARV, and a presumed hypothesis that the laboratory is performing the test method without bias.Note 1

Throughout this practice, the term user refers to the user of this practice; and the term laboratory (see 1.1) refers to the organization or entity that is performing the test method.

1.2 For the tolerance zone established in 1.1, a methodology is presented to estimate the probability that the single test result will fall outside the zone, in the event that there is a bias (positive or negative) of a user-specified magnitude that is deemed to be of practical concern (that is, the presumed hypothesis is not true).

1.3 This practice is intended for ASTM Committee D02 test methods that produce results on a continuous numerical scale.

1.4 This practice assumes that the normal (Gaussian) model is adequate for the description and prediction of measurement system behavior when it is in a state of statistical control.

Note 2--While this practice does not cover scenarios in which multiple results are obtained on the same CS under site precision or repeatability conditions, the statistical concepts presented are applicable. Users wishing to apply these concepts for the scenarios described are advised to consult a statistician and to reference the CS methodology described in Practice D6299.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

American National Standard

Designation:D6617–00

Standard Practice for

Laboratory Bias Detection Using Single Test Result from

Standard Material

This standard is issued under the fixed designation D 6617; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Due to the inherent imprecision in all test methods, a laboratory cannot expect to obtain the

numerically exact accepted reference value (ARV) of a check standard (CS) material every time one

is tested. Results that are reasonably close to theARV should provide assurance that the laboratory is

performing the test method either without bias, or with a bias that is of no practical concern, hence

requiring no intervention. Results differing from the ARV by more than a certain amount, however,

should lead the laboratory to take corrective action.

1. Scope 2. Referenced Documents

1.1 This practice covers a methodology for establishing an 2.1 ASTM Standards:

acceptable tolerance zone for the difference between the result D 2699 Test Method for Research Octane Number of

obtained from a single implementation of a test method on a Spark-Ignition Engine Fuel

CS and its ARV, based on user-specified Type I error, the D 6299 Practice for Applying Statistical Quality Assurance

user-establishedtestmethodprecision,thestandarderrorofthe Techniques to Evaluate Analytical Measurement System

ARV, and a presumed hypothesis that the laboratory is per- Performance

forming the test method without bias. E 178 Practice for Dealing with Outlying Observations

NOTE 1—Throughout this practice, the term user refers to the user of

3. Terminology

this practice; and the term laboratory (see 1.1) refers to the organization or

3.1 Definitions for accepted reference value (ARV), accu-

entity that is performing the test method.

racy, bias, check standard (CS), in statistical control, site

1.2 For the tolerance zone established in 1.1, a methodology

precision, site precision standard deviation (s ), site preci-

SITE

ispresentedtoestimatetheprobabilitythatthesingletestresult

sion conditions, repeatability conditions, and reproducibility

will fall outside the zone, in the event that there is a bias

conditions can be found in Practice D 6299.

(positive or negative) of a user-specified magnitude that is

3.2 Definitions of Terms Specific to This Standard:

deemed to be of practical concern (that is, the presumed

3.2.1 acceptable tolerance zone, n—a numerical zone

hypothesis is not true).

bounded inclusively by zero 6 k e (k is a value based on a

1.3 This practice is intended forASTM Committee D02 test

user-specifiedTypeIerror; eisdefinedin3.2.7)suchthatifthe

methods that produce results on a continuous numerical scale.

differencebetweentheresultobtainedfromasingleimplemen-

1.4 This practice assumes that the normal (Gaussian) model

tation of a test method for a CS and its ARV falls inside this

is adequate for the description and prediction of measurement

zone, the presumed hypothesis that the laboratory or testing

system behavior when it is in a state of statistical control.

organization is performing the test method without bias is

NOTE 2—Whilethispracticedoesnotcoverscenariosinwhichmultiple

accepted, and the difference is attributed to normal random

results are obtained on the same CS under site precision or repeatability

variation of the test method. Conversely, if the difference falls

conditions,thestatisticalconceptspresentedareapplicable.Userswishing

outside this zone, the presumed hypothesis is rejected.

to apply these concepts for the scenarios described are advised to consult

3.2.2 consensus check standard (CCS), n—aspecialtypeof

a statistician and to reference the CS methodology described in Practice

CS in which the ARV is assigned as the arithmetic average of

D 6299.

at least 16 non-outlying (see Practice E 178 or equivalent) test

This practice is under the jurisdiction of ASTM Committee D02 on Petroleum

Products and Lubricants and is the direct responsibility of Subcommittee CS94 on Annual Book of ASTM Standards, Vol 05.01.

Quality Assurance and Statistics. Annual Book of ASTM Standards, Vol 05.03.

Current edition approved Dec. 10, 2000. Published February 2001. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

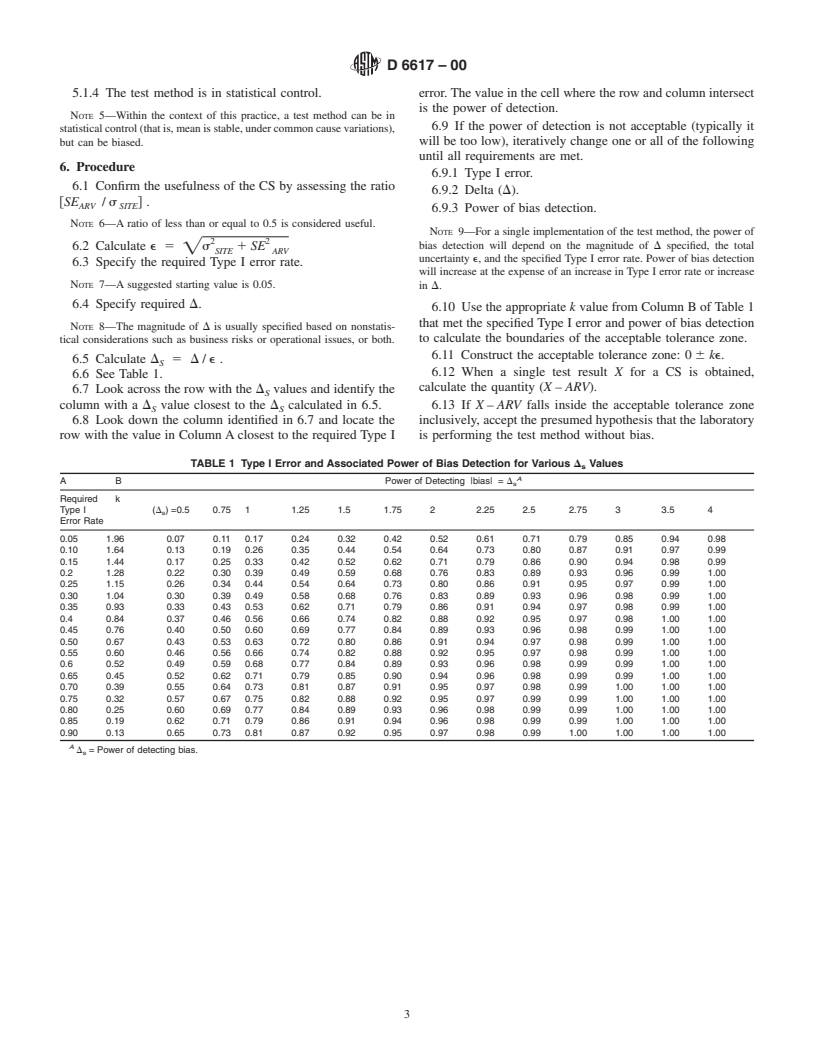

D6617–00

results obtained under reproducibility conditions, and the method is being performed without bias; or it can be equiva-

results pass the Anderson-Darling normality test in Practice lently stated as: H : bias = 0.

D 6299, or other statistical normality test at the 95 % confi- 3.2.9 type II error, n—in applying the methodology of this

dence level. practice, this refers to the long run probability of accepting

(that is, not rejecting) the presumed hypothesis that the method

3.2.2.1 Discussion—These may be production materials

is performed without bias, when in fact the presumed hypoth-

with unspecified composition, but are compositionally repre-

esis is not true, and the test method is biased by a magnitude of

sentative of material routinely tested by the test method, or

at least D, hence, committing an error in decision.

materialswithspecifiedcompositionsthatarereproducible,but

3.2.9.1 Discussion—Type II error, commonly known as

may not be representative of routinely tested materials.

beta (b) error in classical statistical hypothesis testing, refers to

3.2.3 delta (D), n—asignlessquantity,tobespecifiedbythe

the probability of failure to reject the null hypothesis when it is

user as the minimum magnitude of bias (either positive or

not true, based on statistics generated from relevant data. To

negative) that is of practical concern.

quantify Type II error, the user is required to declare a specific

3.2.4 power of bias detection, n—in applying the method-

alternate hypothesis that is believed to be true. In applying this

ology of this practice, this refers to the long run probability of

practice, the alternate hypothesis will take the form: “The test

being able to correctly detect a bias of a magnitude of at least

method is biased by at least D”, where D is a priori decided by

D; given the acceptance tolerance zone set under the presumed

the user as the minimum amount of bias in either direction

hypothesis, and is defined as (1 – Type II error), for a user-

(positive or negative) that is of practical concern. The alternate

specified D.

hypothesis can be equivalently stated as: H : |bias|$ D.

3.2.4.1 Discussion—The quantity (1 – Type II error), com-

monly known as the power of the test in classical statistical

4. Significance and Use

hypothesis testing, refers to the probability of correctly reject-

4.1 Laboratoriesperformingpetroleumtestmethodscanuse

ing the null hypothesis, given that the alternate hypothesis is

this practice to set an acceptable tolerance zone for infrequent

true. In applying this SP, the power refers to the probability of

testing of CS or CCS material, based on e, and a desired Type

detecting a positive or negative bias of at least D.

I error, for the purpose of ascertaining if the test method is

3.2.5 standardized delta (D ), n—D, expressed in units of

S

being performed without bias.

total uncertainty (e) per the equation:

4.2 This practice can be used to estimate the power of

~D !5D / e (1)

S

correctly detecting bias of different magnitudes, using the

3.2.6 standard error of ARV (SE ), n—a statistic quanti- acceptable tolerance zone set in 4.1, and hence, gain insight

ARV

fying the uncertainty associated with the ARV in which the into the limitation of the true bias detection capability associ-

latter is used as an estimate for the true value of the property ated with this acceptable tolerance zone. With this insight,

of interest. For a CCS, this is defined as: trade-offs can be made between desired Type I error versus

desired bias detection capability to suit specific business needs.

s / N (2)

=

CCS

4.3 The CS testing activities described in this practice are

where: intended to augment and not replace the regular statistical

N = total number of non-outlying results used to estab- monitoringoftestmethodperformanceasdescribedinPractice

lish the ARV, collected under reproducibility con-

D 6299.

ditions, and

5. General Requirement

s = the standard deviation of all the non-outlying

CCS

results.

5.1 Application of the methodology in this practice requires

3.2.6.1 Discussion—Assuming a normal model, a 95 %

the following:

confidence interval that would contain the true value of the

5.1.1 The standard material has an ARV and associated

property of interest can be constructed as follows:

standard error (SE ).

ARV

ARV – 1.96 SE to ARV 1 1.96 SE (3)

ARV ARV

NOTE 3—For a given power of detection, the magnitude of the

associated bias detectable is directly proportional to e5

3.2.7 total uncertainty (e), n—combined quantity of test

2 2

SE 1s . Therefore, efforts should be made to keep the ratio

=

ARV SITE

method s and SE as follows:

SITE ARV

(SE / s ) to as low a value as practical. A ratio of 0.5 or less is

ARV SITE

2 2

considered useful.

e5=s 1 SE (4)

SITE ARV

5.1.2 The user has a s for the test method that is

3.2.8 type I error, n—in applying the methodology of this

SITE

reasonably suited for the standard material.

practice, this refers to the theoretical long run probability of

rejecting the presumed hypothesis that the test method is

NOTE 4—It is recognized that there will be situations in which the CS

performed without bias when in fact the hypothesis is true,

may not be compositionally similar to or have property level similar to, or

hence, committing an error in decision. both, the materials regularly tested. For those situations, the site precision

standard deviation (s ) estimated using regularly tested material at a

3.2.8.1 Discussion—Type I error, commonly known as SITE

property level cl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.