ASTM B49-98e2

(Specification)Standard Specification for Copper Rod Drawing Stock for Electrical Purposes

Standard Specification for Copper Rod Drawing Stock for Electrical Purposes

SCOPE

1.1 This specification covers the requirements for rod drawing stock in diameters from 1/4 to 13/8 in. (6.4 to 35 mm) produced from electrolytic tough-pitch or oxygen-free coppers and are suitable for further fabrication into electrical conductors.

1.2 The values stated in inch-pound units are the standard. The values given in parentheses are for information only.

1.3 The following safety hazards caveat pertains only to Section 13. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e2

Designation: B 49 – 98

Standard Specification for

Copper Rod Drawing Stock for Electrical Purposes

This standard is issued under the fixed designation B 49; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—In Table 1, the footnote to 99.90 % was editorially corrected to E from D.

e NOTE—In Appendix X1 in Note X1.5 under Test Procedures, the value 20 mm/s was editorially corrected to 20 cm/s in

October 2000.

1. Scope * B 846 Terminology for Copper and Copper Alloys

E 8 Test Methods for Tension Testing of Metallic Materials

1.1 This specification covers the requirements for rod draw-

1 3 E 18 Test Methods for Rockwell Hardness and Rockwell

ing stock in diameters from ⁄4 to 1 ⁄8 in. (6.4 to 35 mm)

Superficial Hardness of Metallic Materials

produced from electrolytic tough-pitch or oxygen-free coppers

E 29 Practice for Using Significant Digits in Test Data to

and are suitable for further fabrication into electrical conduc-

Determine Conformance with Specifications

tors.

E 53 Test Methods for Determination of Copper in Unal-

1.2 The values stated in inch-pound units are the standard.

loyed Copper by Gravimetry

The values given in parentheses are for information only.

E 478 Test Methods for Chemical Analysis of Copper

1.3 The following safety hazards caveat pertains only to

Alloys

Section 13. This standard does not purport to address all of the

2.3 Other Document:

safety concerns, if any, associated with its use. It is the

NBS Handbook 100 Copper Wire Tables

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3. Terminology

bility of regulatory limitations prior to use.

3.1 For definitions of general terms relating to copper and

2. Referenced Documents copper alloys refer to Terminology B 846.

2.1 The following documents in the current issue of the

4. Ordering Information

Annual Book of ASTM Standards form a part of this specifi-

4.1 Orders for rod under this specification shall include the

cation to the extent referenced herein and define materials

following information:

suitable for use in rod manufacture:

4.1.1 ASTM designation and year of issue,

2.2 ASTM Standards:

4.1.2 Quantity of each size,

B 5 Specification for High Conductivity Tough-Pitch Cop-

2 4.1.3 Type and requirements of copper (Sections 5-10),

per Refinery Shapes

2 4.1.4 Finish (Sections 9 and 10),

B 115 Specification for Electrolytic Cathode Copper

4.1.5 Package with or without joints (see 5.3),

B 170 Specification for Oxygen-Free Electrolytic Copper—

2 4.1.6 Rod diameter (see 9.2),

Refinery Shapes

4.1.7 Inspection (Section 15),

B 193 Test Method for Resistivity of Electrical Conductor

4.1.8 Package size (see 19.1), and

Materials

2 4.1.9 Special package marking as agreed upon between the

B 224 Classification of Coppers

manufacturer and the purchaser (Section 19).

B 577 Test Methods for Detection of Cuprous Oxide (Hy-

2 4.2 The following requirements are optional and should be

drogen Embrittlement Susceptibility) in Copper

specified in the contract or purchase order when required.

4.2.1 Certification (Section 17) and

This specification is under the jurisdiction of ASTM Committee B-5 on Copper

and Copper Alloys, and is the direct responsibility of Subcommittee B05.07 on

Refined Copper. Annual Book of ASTM Standards, Vol 03.01.

Current edition approved March 10, 1998. Published January 1999. Originally Annual Book of ASTM Standards, Vol 14.02.

published as B 49 – 23 T. Last previous edition B 49 – 92. Annual Book of ASTM Standards, Vol 03.05.

2 7

Annual Book of ASTM Standards, Vol 02.01. Available from the National Technical Information Service, 5285 Port Royal

Annual Book of ASTM Standards, Vol 02.03. Rd., Springfield, VA 22161.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B49

4.2.2 Test Report (Section 18). 6.3 Silver-bearing tough-pitch copper corresponds to the

designation STP (silver-bearing tough-pitch) as shown in

5. Material and Manufacture

Classification B 224 and to coppers having UNS numbers

C11300, C11400, C11500, and C11600.

5.1 The rod shall be fabricated from copper of such quality

and purity that the finished product shall have the properties 6.4 Oxygen Content—Oxygen-free copper as described

herein is defined as a copper containing not in excess of

and characteristics prescribed in this specification.

0.0010 % (10 ppm) oxygen and produced without the use of

NOTE 1—The following specifications define materials suitable for use:

metallic or other deoxidizers.

Specification B 5, or Specification B 115, or Specification B 170.

5.2 Copper of special qualities, forms, or types, as agreed

7. Physical Property Requirements

upon between the manufacturer and the purchaser and that will

7.1 Electrical Resistivity—Resistivity of the copper in the

conform to the requirements prescribed in this specification

annealed condition (See Note X1.1) shall not exceed the

may also be used.

following values at 20°C:

5.3 The rod coils shall be furnished in continuous lengths

Type of Copper Resistivity, max, at 20°C

with or without joints, as ordered.

Annealed, V · g/m

UNS C10100 only 0.15176 (101.00 % IACS min)

A

TABLE 1 Chemical Composition

All others 0.15328 (100.00 % IACS min)

UNS Number C11040 C10100 C10200 C11000

B C D

Copper Type ETP OFE OF ETP

E E F F

Copper, min 99.90 % 99.99 % 99.95 % 99.90 %

8. Mechanical Property Requirements

incl silver incl silver

ppm ppm ppm ppm

8.1 Tensile Tests—Rod finished by hot working or annealing

Tellurium, max 2 2 . . . . . .

Selenium, max 2 3 . . . . . .

shall have a minimum elongation of 30 % in 10 in. (250 mm).

Bismuth, max 1.0 1.0 . . . . . .

(Note X1.2 and Test Methods E 8.)

Group total, max 3 . . . . . . . . .

Antimony, max 4 4 . . . . . . 8.2 Torsion Tests—If torsion tests are requested, refer to

Arsenic, max 5 5 . . . . . .

Note X1.3.

Tin, max 5 2 . . . . . .

8.3 Embrittlement (Bend) Test:

Lead, max 5 5 . . . . . .

Iron, max 10 10 . . . . . .

8.3.1 A test to reflect propensity towards hydrogen em-

Nickel, max 10 10 . . . . . .

brittlement shall be performed only on oxygen-free copper.

Sulfur, max 15 15 . . . . . .

Silver, max 25 25 . . . . . .

8.3.2 The specimen shall be tested in accordance with 13.6

Oxygen 100–650 5 max 10 max . . .

G and Specification B 170.

Maximum allowable 65 . . .

total

8.3.3 The specimen, prepared and tested from the OFE

Cadmium, max . . . 1 . . . . . .

(oxygen-free electronic) copper (UNS-C10100) listed in Table

Phosphorus, max . . . 3 . . . . . .

1, shall withstand without breaking into two pieces, a minimum

Zinc, max . . . 1 . . . . . .

Manganese, max . . . 0.5 . . . . . .

of ten (10) reverse bends.

8.3.4 The specimen, prepared and tested from the OF

A

See 13.1.2.

B (oxygen-free) copper (UNS-C10200) listed in Table 1, shall

From B 115 Grade 1 copper or equivalent.

C

From B 170 Grade 1 copper or equivalent.

withstand, without breaking into two pieces, a minimum of

D

From B 170 Grade 2 copper or equivalent.

eight (8) reverse bends.

E

By difference. See 13.1.2 and 13.1.3.

F

See 13.1.1. 8.4 Annealability—Annealability is not a requirement of

G

Not including oxygen.

this specification. However, a discussion will be found in Notes

X1.4-X1.6.

6. Chemical Composition

9. Other Requirements

6.1 Each rod type shall conform to the chemical composi-

9.1 Surface Oxide—The surface oxide film thickness shall

tion requirements prescribed in Table 1 for the type of copper

be determined in accordance with 13.5.

ordered (Section 4).

9.1.1 Total thickness of the copper oxide film on cleaned

6.2 By agreement between the manufacturer and the pur-

copper rod or annealed shaved rod or cold-finished rod shall

chaser, the addition of silver up to an average of 30 troy oz per

−7

not exceed 1000 Å (10 m).

short ton of copper (0.10 %) will be considered within the

9.1.2 The residual oxide film thickness on as-shaved rod

specification, copper including silver in the chemical analysis,

does not need to be specified.

with no individual silver analysis to exceed 35 troy oz per short

9.1.3 A surface oxide requirement is not necessary for rod

ton (0.12 %). In the case of oxygen-free silver-bearing coppers,

ordered uncleaned.

the designation OFS (oxygen-free, silver-bearing) will be used

as shown in Classification B 224 and will include the UNS 9.2 Diameter—The diameter of the rod at any point shall

numbers C10400, C10500, and C10700 as defined by the not vary from that specified by more than the amounts

agreed silver content. prescribed in Table 2.

B49

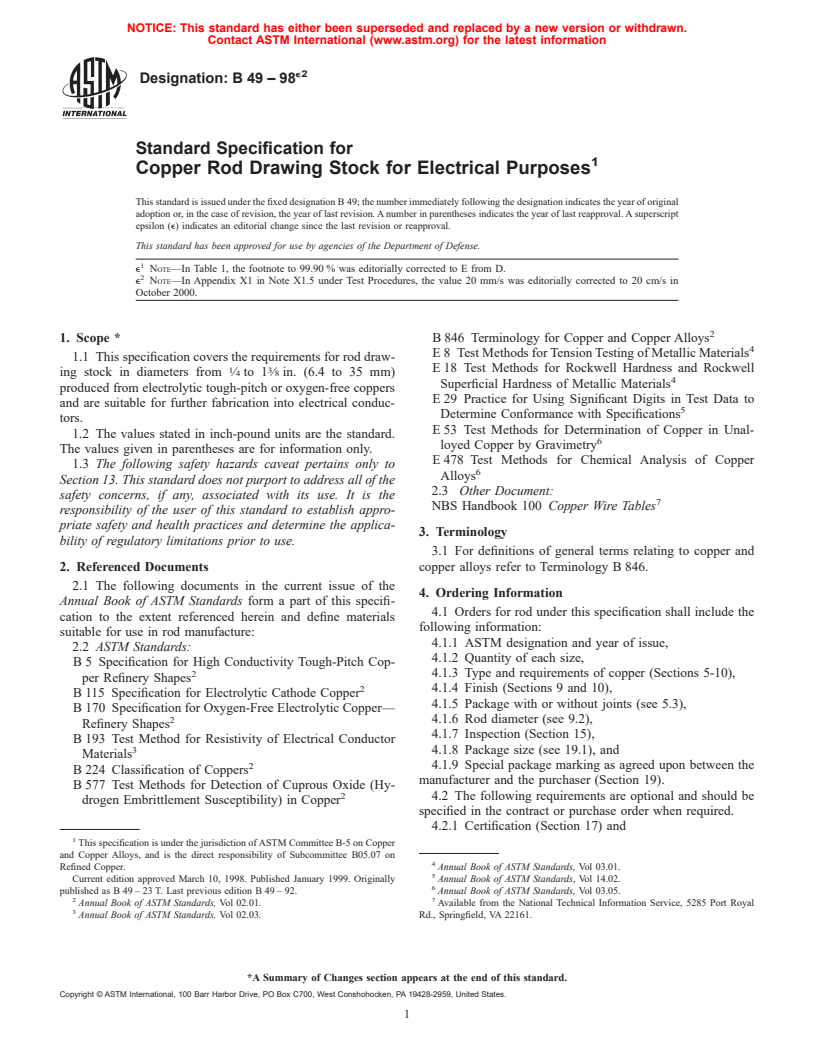

TABLE 2 Permissible Variations in Diameter

13. Test Methods

Permissible Variation, in.

13.1 Chemical Analysis:

Nominal Diameter, in. (mm)

(mm)

13.1.1 In case of dispute, determine copper content of the

⁄4 (6.4) +0.020 (+0.51)

coppers other than UNS-C10100 and UNS-C11040 in Table 1

−0.010 (−0.25)

1 3

Over ⁄4 (6.4) to ⁄4in. (19 mm) incl. 60.015 (60.38) in accordance with Test Method E 53.

Over ⁄4 (19) to 1.0 in. (25 mm) incl. 60.020 (60.51)

13.1.2 Analytical method for determining impurity levels of

Over 1.0 (25) to 1 ⁄8 in. (35 mm) incl. 60.030 (60.76)

coppers listed in Table 1 shall be in accordance with Specifi-

cation B 115.

A

13.1.3 Calculate copper content of UNS-C10100 and UNS-

TABLE 3 Equivalent Resistivity Values

C11040 types by subtracting from 100 % the total impurity

Conductivity at 68°F (20°C), % IACS 100.00 101.00

concentration determined. The impurity total for UNS-C10100

V · lb/mile 875.20 866.53

V · g/m 0.153 28 0.151 76

is defined as the sum of sulfur, silver, lead, tin, bismuth,

V · c mil/ft 10.371 10.268

arsenic, antimony, iron, nickel, zinc, phosphorus, selenium,

V ·mm /m 0.017 241 0 0.017 070

tellurium, manganese, cadmium, and oxygen present in the

μV · in. 0.678 79 0.672 07

μV · cm 1.7241 1.7070

sample. The impurity total for UNS-C11040 is defined as the

A

The equivalent resistivity values for 100 % IACS (soft copper) were each sum of sulfur, silver, lead, tin, bismuth, arsenic, antimony, iron,

computed from the fundamental IEC value (1/58 V ·mm /m) using conversion

nickel, selenium, tellurium, and oxygen present in the sample.

factors each accurate to at least seven significant figures.

13.1.4 The test methods annex of Specification B 170

should be referenced for the oxygen-free coppers. Test Method

10. Workmanship, Finish and Appearance E 478 should be referenced for the determination of silver-

bearing alloys permitted under this specification.

10.1 The rod shall be free of defects, but blemishes of a

13.1.5 Oxygen content is determined on cleaned copper

nature that do not interfere with the intended application are

samples using a suitable laboratory apparatus or a commercial

acceptable.

instrument designed specifically for this purpose. An ASTM

11. Sampling method has not been developed.

13.2 Elongation—Determine the elongation as the perma-

11.1 This procedure shall be used in case of dispute between

nent increase in length, caused by breaking of the rod in

the manufacturer and the purchaser.

tension, measured between gage marks placed originally 10 in.

11.2 One sample shall be taken from each 200 000-lb

(250 mm) apart upon the test specimen (Note X1.2). The

(90 000-kg) lot for resistivity, elongation, surface oxide, em-

fracture shall be between gage marks and not closer than 1 in.

brittlement (bend) test, and chemical analysis.

(25 mm) to either gage mark.

11.3 When a cast refinery shape has been chemically

13.3 Electrical Resistivity:

analyzed and converted into rod without remelting, further

13.3.1 At the option of the manufacturer, electrical resistiv-

chemical analysis shall not be required.

ity may be determined in accordance with 13.3.2 or 13.3.3.

12. Number of Tests and Retests However, in case of dispute, 13.3.2 shall apply.

13.3.2 Make resistance measurements (Note X1.3) on speci-

12.1 Tests:

mens of the rod after cleaning and processing down to a

12.1.1 Chemical Analysis—Chemical composition shall be

diameter of approximately 0.080 in. (2.0 mm) and annealing at

determined as per the element mean of the results from at least

approximately 932°F (500°C) for 30 min. Other equivalent

two replicate analyses of the sample(s).

annealing methods may be used. Test specimens processed to

12.1.2 Other Tests:

a diameter other than 0.080 in. may be used if agreed upon

12.1.2.1 Electrical Resistivity, Elongation, and Surface

between the manufacturer and the purchaser.

Oxide—Results shall be reported as the average obtained from

at least two test specimens, each taken from a separate test

piece where possible.

12.1.2.2 Hydrogen Embrittlement Test and Microscopical

Examination—All specimens tested must meet the require-

ments of the specification.

12.2 Retests:

12.2.1 When requested by the manufacturer or supplier, a

retest shall be permitted when results of tests obtained by the

purchaser fail to conform to the requirements of the product

specification.

12.2.2 The retest shall be as directed in the product speci-

fication for the initial test except the number of test specimens

shall be twice that normally required for the specified test.

12.2.3 All test specimens shall conform to the product

specification requirement(s) in retest. Failure to conform shall

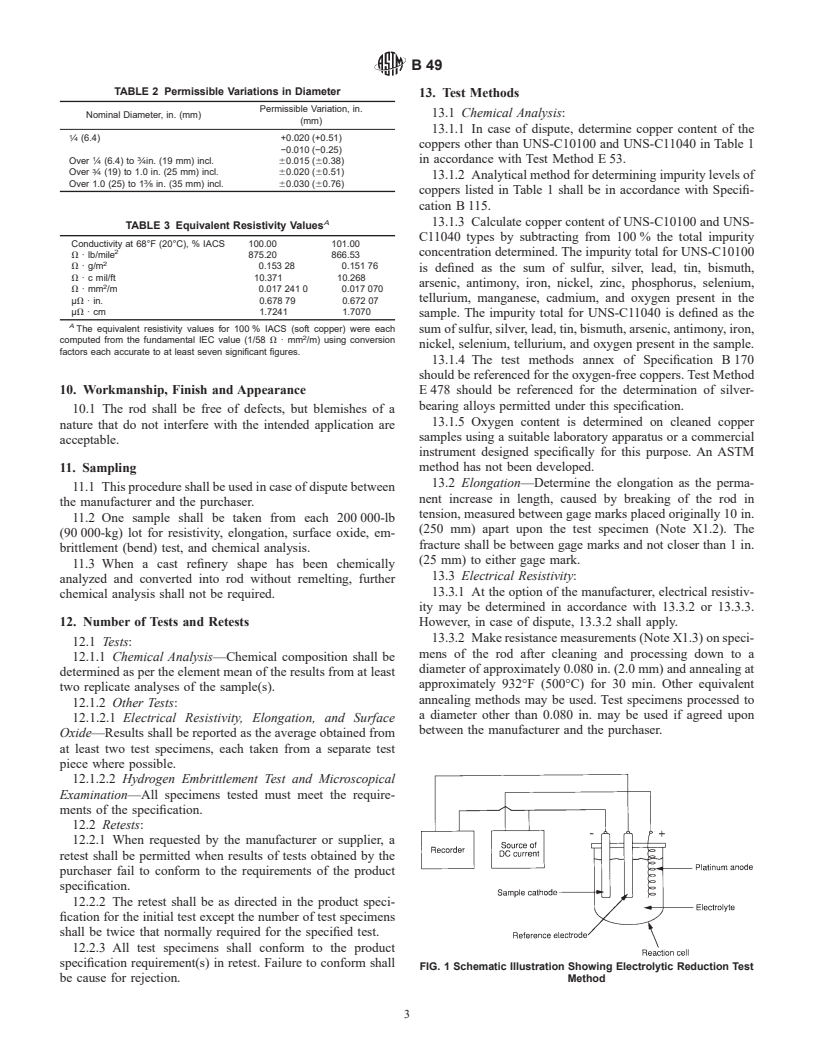

FIG. 1 Schematic Illustration Showing Electrolytic Reduction Test

be cause for rejection. Method

B49

testing, clean each rod sample of oil or grease using acetone or

an equivalent solvent.

13.5.2 Each of the oxides found on copper, namely cuprous

and cupric, are reduced sequentially to copper at different

reduction potentials, and the voltages are to be recorded against

time during the entire test. When the individual reactions

between the oxides and hydrogen ions are complete, gaseous

hydrogen is evolved and may be seen visually at the surface of

the copper rod sample.

13.5.3 A typical curve of voltage versus time is presented in

Fig. 2. Cuprous oxide is reduced initially. When this reaction is

complete, reduction of the cupric oxide occurs at a higher

voltage.

13.5.4 Calculate thickness of each oxide present as follows:

ItM

T 5 (1)

Sd Fn

where:

T = oxide thickness, cm;

I = current, A;

t = time of reaction, s;

M = molecular weight of the oxide, g;

S = surface area of immersed sample, cm ;

3 3

d = oxide density (6.0

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.