ASTM D7465/D7465M-15

(Specification)Standard Specification for Ethylene Propylene Diene Terpolymer (EPDM) Sheet Used In Geomembrane Applications

Standard Specification for Ethylene Propylene Diene Terpolymer (EPDM) Sheet Used In Geomembrane Applications

SCOPE

1.1 This specification covers flexible sheet made from ethylene propylene diene terpolymer (EPDM) geomembrane intended for use in geotechnical and geoenvironmental applications. The tests and property limits used to characterize the sheet are values to ensure minimum quality for the intended use. The vulcanized rubber sheet may be non-reinforced, fabric or scrim reinforced.

1.2 In place geomembrane design criteria, such as field seaming strength, and material compatibility, among others, are factors that must be considered but are beyond the scope of this specification.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7465/D7465M −15

StandardSpecification for

Ethylene Propylene Diene Terpolymer (EPDM) Sheet Used In

1

Geomembrane Applications

This standard is issued under the fixed designation D7465/D7465M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope Cracking (Withdrawn 2007)

D573Test Method for Rubber—Deterioration in an Air

1.1 This specification covers flexible sheet made from

Oven

ethylene propylene diene terpolymer (EPDM) geomembrane

D624Test Method for Tear Strength of Conventional Vul-

intended for use in geotechnical and geoenvironmental appli-

canized Rubber and Thermoplastic Elastomers

cations. The tests and property limits used to characterize the

D751Test Methods for Coated Fabrics

sheet are values to ensure minimum quality for the intended

D1149Test Methods for Rubber Deterioration—Cracking in

use.Thevulcanizedrubbersheetmaybenon-reinforced,fabric

an Ozone Controlled Environment

or scrim reinforced.

D1204Test Method for Linear Dimensional Changes of

1.2 In place geomembrane design criteria, such as field Nonrigid Thermoplastic Sheeting or Film at Elevated

seaming strength, and material compatibility, among others, Temperature

arefactorsthatmustbeconsideredbutarebeyondthescopeof D1418 Practice for Rubber and Rubber Latices—

this specification. Nomenclature

D2137TestMethodsforRubberProperty—BrittlenessPoint

1.3 The values stated in either SI units or inch-pound units

of Flexible Polymers and Coated Fabrics

are to be regarded separately as standard. The values stated in

D4439Terminology for Geosynthetics

each system may not be exact equivalents; therefore, each

D4833/D4833MTest Method for Index Puncture Resistance

system shall be used independently of the other. Combining

of Geomembranes and Related Products

values from the two systems may result in non-conformance

D5884Test Method for Determining Tearing Strength of

with the standard.

Internally Reinforced Geomembranes

1.4 This standard does not purport to address all of the

D7004/D7004MTest Method for Grab Tensile Properties of

safety concerns, if any, associated with its use. It is the

Reinforced Geomembranes

responsibility of the user of this standard to establish appro- D7635/D7635MTestMethodforMeasurementofThickness

priate safety and health practices and determine the applica-

of Coatings Over Fabric Reinforcement

bility of regulatory limitations prior to use. G151PracticeforExposingNonmetallicMaterialsinAccel-

erated Test Devices that Use Laboratory Light Sources

2. Referenced Documents G155Practice for Operating XenonArc LightApparatus for

Exposure of Non-Metallic Materials

2

2.1 ASTM Standards:

D412TestMethodsforVulcanizedRubberandThermoplas-

3. Terminology

tic Elastomers—Tension

3.1 Definitions:

D471Test Method for Rubber Property—Effect of Liquids

D518 Test Method for Rubber Deterioration—Surface 3.1.1 Fordefinitionsofothergeosynthetictermsusedinthis

guide, refer to Terminology D4439.

3.1.2 composite, n—factory laminated non-woven geotex-

tile and EPDM.

1

This specification is under the jurisdiction of ASTM Committee D35 on

GeosyntheticsandisthedirectresponsibilityofSubcommitteeD35.10onGeomem-

3.1.3 EPDM, n—terpolymer of ethylene, propylene, and

branes.

diene with the residual unsaturated portion of the diene in the

Current edition approved May 1, 2015. Published May 2015. Originally

side chain. D1418

approved in 2008. Last previous edition approved in 2008 as D7465–08. DOI:

10.1520/D7465_D7465M-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

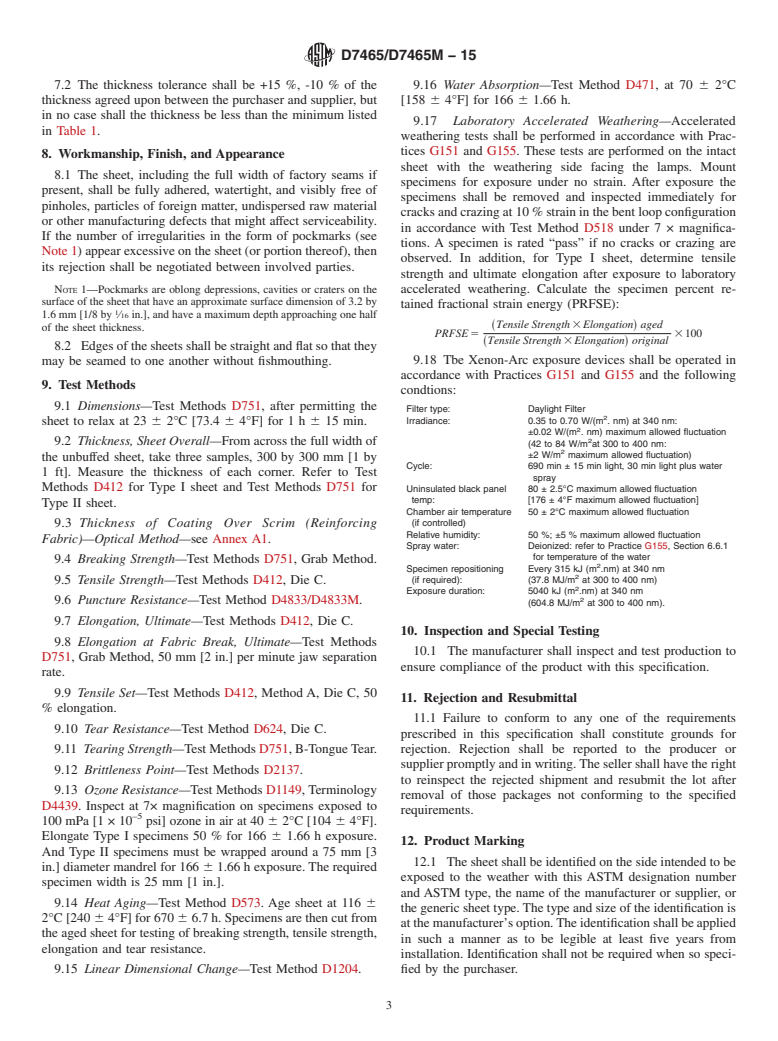

D7465/D7465M−15

4. Classification 6. Physical Properties and Requirements

4.1 Types describe the sheet construction:

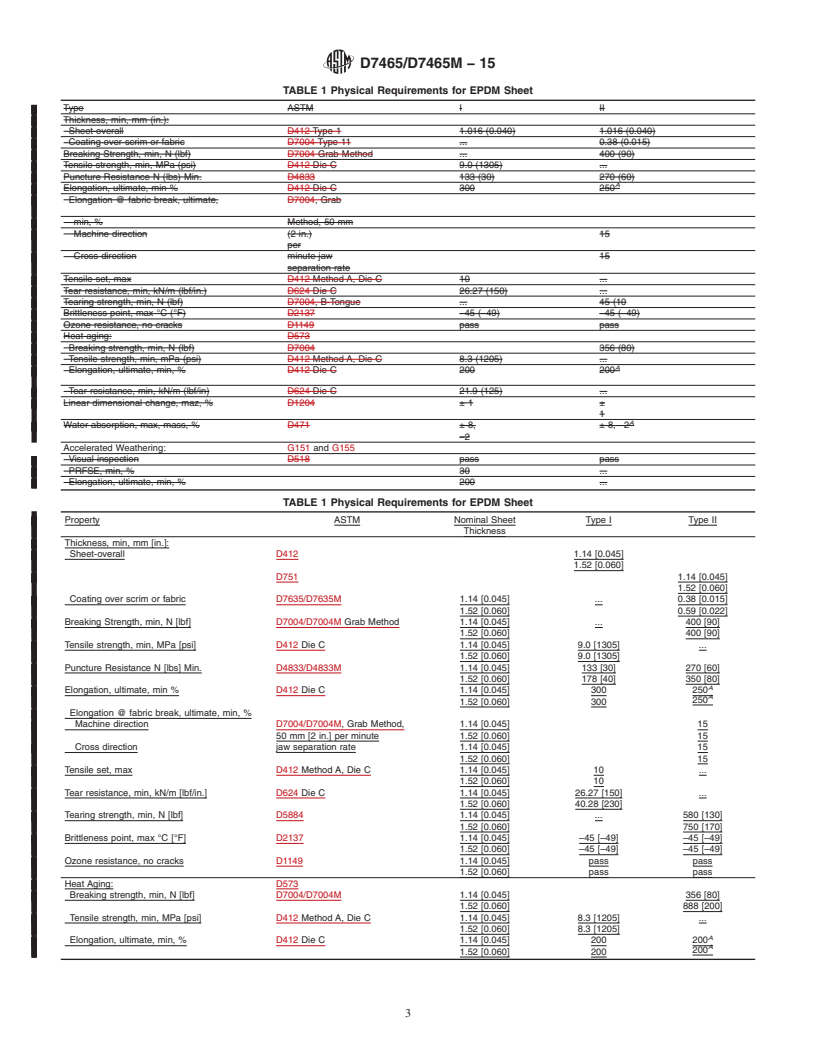

6.1 The sheet shall conform to the physical requirements

4.1.1 Type I—Non-reinforced.

prescribed in Table 1.

4.1.2 Type II—Scrim (or fabric) internally reinforced.

6.2 The tolerance for time conditions (aging, weathering,

and so forth) is 615 min or 61 % of the period; whichever is

5. Materials and Manufacture

greater, unless otherwise specified.

5.1 ThesheetshallbeformulatedfromEPDMpolymersand

6.3 Tolerances for temperature shall be 62°C [64°F].

other compounding ingredients. EPDM shall be the principal

polymerused

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7465 − 08 D7465/D7465M − 15

Standard Specification for

Ethylene Propylene Diene Terpolymer (EPDM) Sheet Used In

1

Geomembrane Applications

This standard is issued under the fixed designation D7465;D7465/D7465M; the number immediately following the designation indicates

the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers flexible sheet made from ethylene propylene diene terpolymer (EPDM) geomembrane intended for

use in geotechnical and geoenvironmental applications. The tests and property limits used to characterize the sheet are values to

ensure minimum quality for the intended use. The vulcanized rubber sheet may be non-reinforced, fabric or scrim reinforced.

reinforced.

1.2 In place geomembrane design criteria, such as field seaming strength, and material compatibility, among others, are factors

that must be considered but are beyond the scope of this specification.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as the standard. The values stated in

parentheses are for information only. each system may not be exact equivalents; therefore, each system shall be used independently

of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D412 Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension

D471 Test Method for Rubber Property—Effect of Liquids

3

D518 Test Method for Rubber Deterioration—Surface Cracking (Withdrawn 2007)

D573 Test Method for Rubber—Deterioration in an Air Oven

D624 Test Method for Tear Strength of Conventional Vulcanized Rubber and Thermoplastic Elastomers

D751 Test Methods for Coated Fabrics

D1149 Test Methods for Rubber Deterioration—Cracking in an Ozone Controlled Environment

D1204 Test Method for Linear Dimensional Changes of Nonrigid Thermoplastic Sheeting or Film at Elevated Temperature

D1418 Practice for Rubber and Rubber Latices—Nomenclature

D2137 Test Methods for Rubber Property—Brittleness Point of Flexible Polymers and Coated Fabrics

D4439 Terminology for Geosynthetics

D4833D4833/D4833M Test Method for Index Puncture Resistance of Geomembranes and Related Products

D5884 Test Method for Determining Tearing Strength of Internally Reinforced Geomembranes

D7004D7004/D7004M Test Method for Grab Tensile Properties of Reinforced Geomembranes

D7635/D7635M Test Method for Measurement of Thickness of Coatings Over Fabric Reinforcement

G151 Practice for Exposing Nonmetallic Materials in Accelerated Test Devices that Use Laboratory Light Sources

G155 Practice for Operating Xenon Arc Light Apparatus for Exposure of Non-Metallic Materials

3. Terminology

3.1 Definitions:

3.1.1 For definitions of other geosynthetic terms used in this guide, refer to Terminology D4439.

1

This specification is under the jurisdiction of ASTM Committee D35 on Geosynthetics and is the direct responsibility of Subcommittee D35.10 on Geomembranes.

Current edition approved July 1, 2008May 1, 2015. Published October 2008May 2015. Originally approved in 2008. Last previous edition approved in 2008 as D7465–08.

DOI: 10.1520/D7465-08.10.1520/D7465_D7465M-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7465/D7465M − 15

3.1.2 composite, n—factory laminated non-woven geotextile and EPDM.

3.1.3 EPDM, n—terpolymer of ethylene, propylene, and diene with the residual unsaturated portion of the diene in the side

chain. D1418

3.1.3 composite, n—factory laminated non-woven geotextile and EPDM.

4. Classification

4.1 Types describe the sheet construction:

4.1.1 Type I—Non-reinforce

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.