ASTM E1158-98

(Guide)Standard Guide for Material Selection and Fabrication of Reference Blocks for the Pulsed Longitudinal Wave Ultrasonic Examination of Metal and Metal Alloy Production Material

Standard Guide for Material Selection and Fabrication of Reference Blocks for the Pulsed Longitudinal Wave Ultrasonic Examination of Metal and Metal Alloy Production Material

SCOPE

1.1 This guide covers general procedures for the material selection and fabrication of reference blocks made of metal or metal alloys and intended to be used for the pulsed longitudinal wave ultrasonic examination of the same or similar production materials.

1.2 This guide covers the fabrication of reference blocks for use with either the immersion or the direct-contact method of ultrasonic examination.

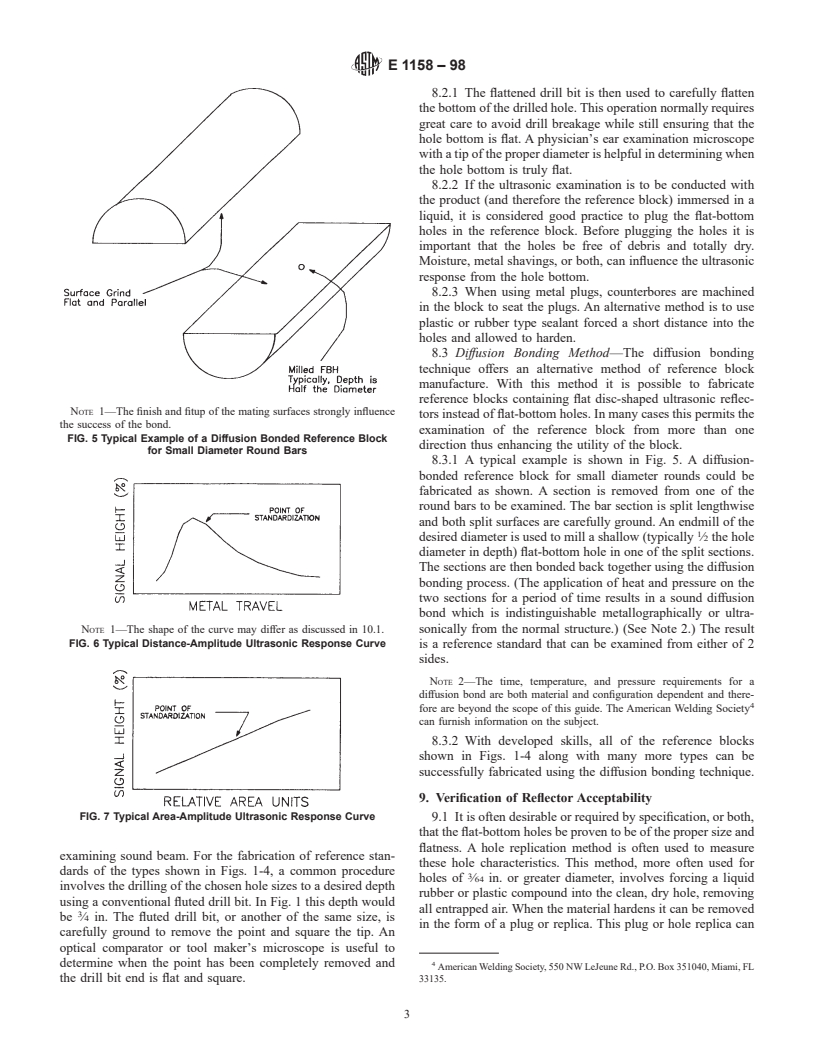

1.3 Reference blocks fabricated in accordance with this guide can be used to determine proper ultrasonic examination system operation. Area-amplitude and distance-amplitude curves can also be determined with these reference blocks.

1.4 This guide does not specify calibration reflector sizes or product rejection limits. It does describe typical industry fabrication practices and commonly applied tolerances where they lend clarity to the guide. In all cases of conflict between this guide and customer specifications, the customer specification shall prevail.

1.5 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 1158 – 98

Standard Guide for

Material Selection and Fabrication of Reference Blocks for

the Pulsed Longitudinal Wave Ultrasonic Examination of

Metal and Metal Alloy Production Material

This standard is issued under the fixed designation E 1158; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 428 Practice for Fabrication and Control of Steel Refer-

ence Blocks Used in Ultrasonic Inspection

1.1 This guide covers general procedures for the material

E 1316 Terminology for Nondestructive Examinations

selection and fabrication of reference blocks made of metal or

metal alloys and intended to be used for the pulsed longitudinal

3. Terminology

wave ultrasonic examination of the same or similar production

3.1 Definitions—For definitions of terms used in this guide,

materials.

see Terminology E 1316.

1.2 This guide covers the fabrication of reference blocks for

use with either the immersion or the direct-contact method of

4. Summary of Guide

ultrasonic examination.

4.1 This guide describes a method of selecting suitable

1.3 Reference blocks fabricated in accordance with this

reference block material from current or previous production

guide can be used to determine proper ultrasonic examination

and the subsequent fabrication and checking of the resulting

system operation. Area-amplitude and distance-amplitude

ultrasonic reference blocks.

curves can also be determined with these reference blocks.

1.4 This guide does not specify calibration reflector sizes or

5. Significance and Use

product rejection limits. It does describe typical industry

5.1 This guide is intended to illustrate the fabrication of

fabrication practices and commonly applied tolerances where

ultrasonic reference blocks that are representative of the

they lend clarity to the guide. In all cases of conflict between

production material to be examined. Care in material selection

this guide and customer specifications, the customer specifica-

and fabrication can result in the manufacture of reference

tion shall prevail.

blocks that are ultrasonically similar to the production material

1.5 This standard does not purport to address the safety

thus eliminating the reference block as an examination vari-

concerns, if any, associated with its use. It is the responsibility

able.

of the user of this standard to establish appropriate safety and

health practices and to determine the applicability of regula-

6. Material Selection

tory limitations prior to use.

6.1 It is good practice to use a sample removed from the

production lot of material as the reference block material.

2. Referenced Documents

When this is not possible the following guidelines should be

2.1 ASTM Standards:

followed.

E 127 Practice for Fabricating and Checking Aluminum

, 6.2 The reference block material should be of the same

2 3

Alloy Ultrasonic Standard Reference Blocks

general shape and dimensions, surface finish, chemical com-

position, and microstructure as the production material to be

examined.

This guide is under the jurisdiction of ASTM Committee E-7 on Nondestructive

Testing and is the direct responsibility of Subcommittee E07.06 on Ultrasonic

6.3 To ensure that the material chosen is suitable for use as

Method.

reference block material and is free of potentially interfering

Current edition approved Dec. 10, 1998. Published February 1999. Originally

e1 reflectors, ultrasonically examine the reference block material

published as E 1158–90. Last previous edition E 1158–90(1994) .

Annual Book of ASTM Standards, Vol 03.03. at the anticipated examining frequency and at a sensitivity that

The reference blocks in Practice E 127 are used to check the performance of

produces an acoustic noise level of 20 % screen height. The

ultrasonic testing equipment and for standardization and control of ultrasonic tests

entire block should be scanned from the surface which will be

of aluminum alloy products. The ultrasonic response of the blocks in Practice E 127

used for calibration. Any discrete indication that exceeds 40 %

is evaluated against a standard target. The blocks described in this standard are used

for the examination of production material and may be used to establish accept-

reject criteria.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1158–98

screen height should be cause to remove the material from

consideration as an ultrasonic reference block.

6.4 Reference block material that meets the guidelines of

6.3 should then be examined at a sensitivity that produces

multiple reflections from the back surface (between 3 and 5

reflections in most metals and metal alloys). The production

material should be examined at the same sensitivity level to

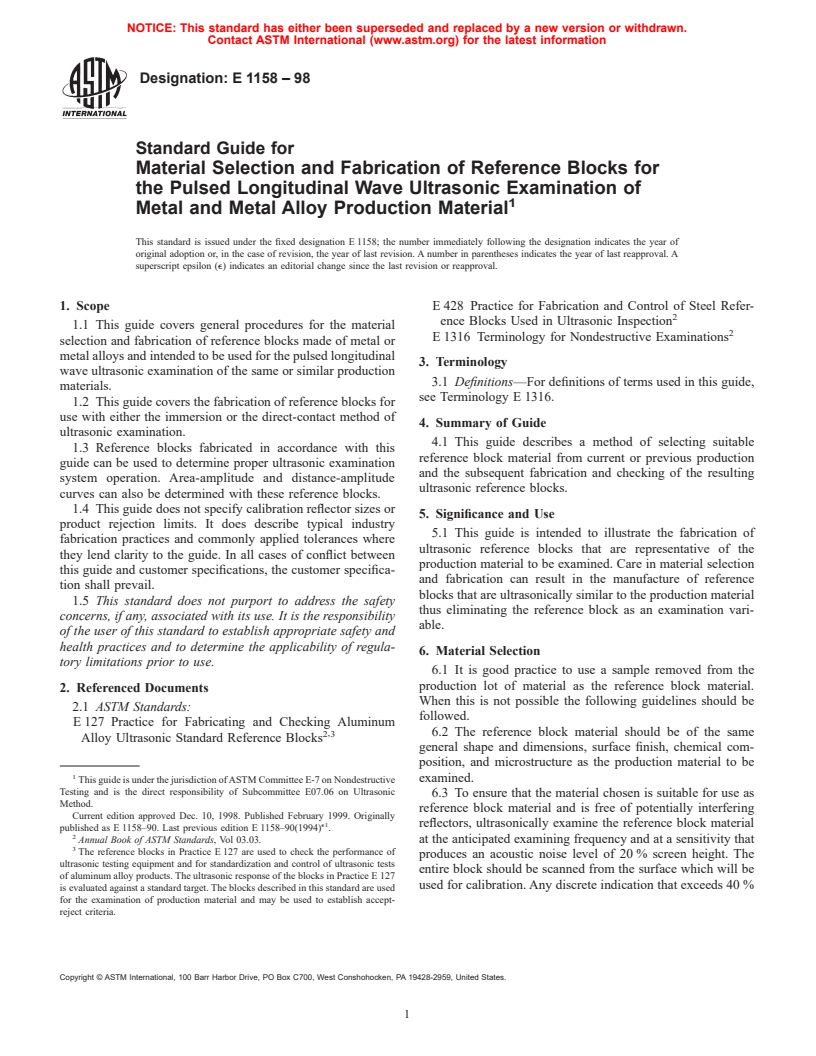

NOTE 1—Holes are of different diameters.

determine that the same number of back reflections are

FIG. 2 Typical Area-Amplitude Reference Block for use in

obtained. This procedure may have to be repeated several times

Ultrasonic Examination of Round Bars as in Fig. 1

and an average number of back reflections determined in the

case of some materials (see Note 1).

NOTE 1—In some highly attenuative materials more than one or two

back reflections may not be attainable. In these cases, selection of the

reference block material may be based on similar acoustic noise levels

from both the production material and that chosen for a reference block.

7. Reference Block Configuration

7.1 There are many different types of reference blocks used

NOTE 1—All holes are the same diameter.

in industry depending upon the size and shape of the material

FIG. 3 Typical Distance-Amplitude Reference Block for the

to be examined. Some of the more common types are described

Ultrasonic Examination of Large Square or Rectangular Bars

in 7.2 through 7.7, and shown in Figs. 1-7. Greater than 1 in.

7.2 Fig. 1 shows the typical reference standards used for

ultrasonic examination when the product to be examined

consists of large round bar stock, between 1 and 10 in. in

diameter. With such products it is often necessary to correct for

the loss of signal with increasing examination distance

(distance-amplitude-correction, or DAC). Therefore, a stepped

NOTE 1—Holes are of different diameters.

block, as shown in Fig. 1 is commonly used. This type of block

FIG. 4 Typical Area-Amplitude Reference Block for the Ultrasonic

is typically referred to as a distance-amplitude-block. It con-

Examination of Square or Rectangular Bars

tains a number of holes of the same size at various distances

from the scan surface. A typical flat-bottom hole size found in

5 area-amplitude block for this product is the same as for the

many such blocks is ⁄64 in. or larger depending upon the

larger diameter material as shown in Fig. 2, but on a smaller

ultrasonic attenuation, or the internal structure of the product,

2 5

scale. The hole sizes typically range from between ⁄64 and ⁄64

or both. For even larger diameter bars the distance amplitude

in. for many metal and metal alloy products.

correction reference standard may contain even larger flat

1 7.5 When the product to be examined consists of large

bottom holes, possibly ⁄4 in. or greater.

square or rectangular bar stock, the distance-amplitude refer-

7.3 To determine the linearity of the examination and to

ence block is often of the type shown in Fig. 3. The typical

establish the quality level of the large-diameter product, (7.2),

area-amplitude reference block is shown in Fig. 4. The refer-

an area-amplitude reference block as shown in Fig. 2 is

ence block hole sizes are typically the same as those used for

common. An area-amplitude-block contains holes of different

similar thickness round bars.

crossectional areas placed at the same distance from the scan

2 8 7.6 The smaller sizes of square or rectangular bar stock, 1

surface. Typical hole sizes range from between ⁄64 and ⁄64 in.

in. and under in the direction of examination, often do not

with even larger flat-bottom holes used in reference blocks

require the use of a distance-amplitude reference block. The

intended for use for the largest bars.

area-amplitude block may be similar to that sh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.