ASTM D3170/D3170M-14(2022)

(Test Method)Standard Test Method for Chipping Resistance of Coatings

Standard Test Method for Chipping Resistance of Coatings

SIGNIFICANCE AND USE

4.1 Owners consider chipping of coatings, particularly on the leading faces and edges of automobile surfaces, unacceptable. In formulating a coating or coating system to meet service requirements, the resistance to chipping damage by flying objects such as gravel is one of the properties of importance since it can vary considerably as other properties are adjusted. Since resistance to chipping decreases at lower temperatures partly as the result of decreased flexibility, the test may be more directly related to service conditions by performing it at a low temperature. This test method is designed to produce a controlled amount of impact by the media on the coated panel in order to enhance reproducibility.

SCOPE

1.1 This test method covers the determination of the resistance of coatings to chipping damage by stones or other flying objects.

Note 1: This test method is similar to SAE J-400.

1.2 All dimensions are nominal unless otherwise specified.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3170/D3170M − 14 (Reapproved 2022)

Standard Test Method for

Chipping Resistance of Coatings

This standard is issued under the fixed designation D3170/D3170M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope D1005 Test Method for Measurement of Dry-Film Thick-

ness of Organic Coatings Using Micrometers

1.1 This test method covers the determination of the resis-

D1186 Test Methods for Nondestructive Measurement of

tance of coatings to chipping damage by stones or other flying

Dry Film Thickness of Nonmagnetic Coatings Applied to

objects.

a Ferrous Base (Withdrawn 2006)

NOTE 1—This test method is similar to SAE J-400.

D1400 TestMethodforNondestructiveMeasurementofDry

1.2 All dimensions are nominal unless otherwise specified. Film Thickness of Nonconductive Coatings Applied to a

Nonferrous Metal Base (Withdrawn 2006)

1.3 The values stated in either SI units or inch-pound units

D1733 Method for Preparation of Aluminum Alloy Panels

are to be regarded separately as standard. The values stated in

for Testing Paint, Varnish, Lacquer, and Related Products

each system are not necessarily exact equivalents; therefore, to

(Withdrawn 1979)

ensure conformance with the standard, each system shall be

D2201 Practice for Preparation of Zinc-Coated and Zinc-

used independently of the other, and values from the two

Alloy-Coated Steel Panels for Testing Paint and Related

systems shall not be combined.

Coating Products

1.4 This standard does not purport to address all of the

2.2 Other Documents:

safety concerns, if any, associated with its use. It is the 4

Test for Chip Resistance of Surface Coatings (J-400)

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

3. Summary of Test Method

mine the applicability of regulatory limitations prior to use.

3.1 Standardized road gravel is projected by means of a

1.5 This international standard was developed in accor-

controlled air blast at the coated specimens. All testing is

dance with internationally recognized principles on standard-

conducted under controlled temperature conditions, generally

ization established in the Decision on Principles for the

either at ambient (room) temperature or at -29 6 3 °C [-20 6

Development of International Standards, Guides and Recom-

5 °F]. After the gravel impact, tape is applied to remove any

mendations issued by the World Trade Organization Technical

loose coating chips and the degree of chipping is determined.

Barriers to Trade (TBT) Committee.

4. Significance and Use

2. Referenced Documents

4.1 Owners consider chipping of coatings, particularly on

2.1 ASTM Standards:

the leading faces and edges of automobile surfaces, unaccept-

D609 Practice for Preparation of Cold-Rolled Steel Panels

able.Informulatingacoatingorcoatingsystemtomeetservice

for Testing Paint, Varnish, Conversion Coatings, and

requirements, the resistance to chipping damage by flying

Related Coating Products

objects such as gravel is one of the properties of importance

D823 Practices for Producing Films of Uniform Thickness

since it can vary considerably as other properties are adjusted.

of Paint, Coatings and Related Products on Test Panels

Since resistance to chipping decreases at lower temperatures

partly as the result of decreased flexibility, the test may be

more directly related to service conditions by performing it at

This test method is under the jurisdiction of ASTM Committee D01 on Paint

a low temperature. This test method is designed to produce a

and Related Coatings, Materials, andApplications and is the direct responsibility of

controlled amount of impact by the media on the coated panel

Subcommittee D01.55 on Factory Applied Coatings on Preformed Products.

in order to enhance reproducibility.

Current edition approved July 1, 2022. Published July 2022. Originally approved

in 1973. Last previous edition approved in 2014 as D3170 – 14. DOI: 10.1520/

D3170_D3170M-14R22.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

Standards volume information, refer to the standard’s Document Summary page on Available from Society of Automotive Engineers (SAE), 400 Commonwealth

the ASTM website. Dr., Warrendale, PA 15096-0001, http://www.sae.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3170/D3170M − 14 (2022)

FIG. 1 Gravel Projecting Machine

5. Apparatus 9.5-mm [ ⁄8-in.] space screen. Note that mesh screen is not a

substitute for a space screen. It is important to remove the

5.1 Gravel-Projecting Machine (Gravelometer), con-

small pieces of gravel before reusing the gravel. Other media

structed according to the design specifications shown in Fig.

5,6

may be used as agreed by contractual parties.

1. There are two types of Gravelometers: the old cabinet

8,6

style and the newer, modular style with an electronic feed 5.3 Tape, 51 to 102 mm [2.0 to 4.0 in.] wide. Other tape

mechanism. may be used as agreed upon by the contractual parties.

5.4 Temperature-Conditioning Equipment (alternatives):

NOTE 2—It is recommended that the operation/maintenance checklist

shown in Appendix X1 should be completed at least once per month for

5.4.1 A cold room or freezer of sufficient size in which the

gravelometers that are operated on a weekly basis, and once every 6

gravel-projecting machine and test specimens can be main-

months for gravelometers that are operated less frequently. Note that

tained at the specified temperature of testing.

values in the checklist are specific to the standard gravel testing protocol.

5.4.2 A freezer or cooler in which the test panels can be

Different specifications may be necessary for other media types.

cooled 5 °C [10 °F] below the specified test temperature.

7,6

5.2 Gravel—Water-eroded alluvial road gravel passing

5.4.3 Ambient—Room maintained at a temperature between

through a 16-mm [ ⁄8-in.] space screen but retained on a

20 °C [68 °F] and 30 °C [86 °F].

5 5.5 Transparent Grid—A chip counting aid constructed of

The sole source of a suitable apparatus meeting these specifications known to

the committee at this time is Q-Panel Co., 26200 First St., Westlake, OH 44135. transparent plastic approximately 3.2 mm thick by 127 mm

If you are aware of alternative suppliers, please provide this information to

ASTM International Headquarters. Your comments will receive careful consider-

ation at a meeting of the responsible technical committee, which you may attend.

7 8

The sole source of supply of gravel meeting these specifications known to the The sole source of supply of No. 898 filament strapping tape known to the

committee at this time is Q-Panel Co., 26200 First St., Westlake, OH 44135. committee at this time is the 3M Co., St. Paul MN 55101.

D3170/D3170M − 14 (2022)

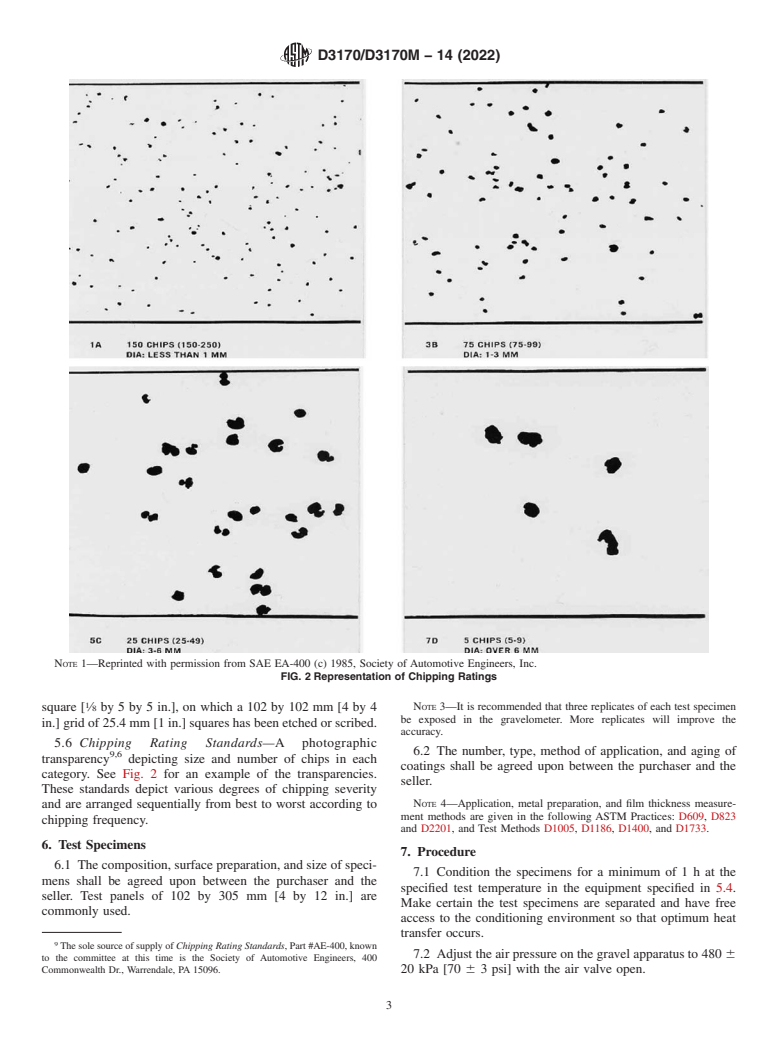

NOTE 1—Reprinted with permission from SAE EA-400 (c) 1985, Society of Automotive Engineers, Inc.

FIG. 2 Representation of Chipping Ratings

NOTE 3—It is recommended that three replicates of each test specimen

square [ ⁄8 by 5 by 5 in.], on which a 102 by 102 mm [4 by 4

be exposed in the gravelometer. More replicates will improve the

in.] grid of 25.4 mm [1 in.] squares has been etched or scribed.

accuracy.

5.6 Chipping Rating Standards—A photographic

6.2 The number, type, method of application, and aging of

9,6

transparency depicting size and number of chips in each

coatings shall be agreed upon between the purchaser and the

category. See Fig. 2 for an example of the transparencies.

seller.

These standards depict various degrees of chipping severity

NOTE 4—Application, metal preparation, and film thickness measure-

and are arranged sequentially from best to worst according to

ment methods are given in the following ASTM Practices: D609, D823

chipping frequency.

and D2201, and Test Methods D1005, D1186, D1400, and D1733.

6. Test Specimens

7. Procedure

6.1 The composition, surface preparation, and size of speci-

7.1 Condition the specimens for a minimum of1hatthe

mens shall be agreed upon between the purchaser and the

specified test temperature in the equipment specified in 5.4.

seller. Test panels of 102 by 305 mm [4 by 12 in.] are

Make certain the test specimens are separated and have free

commonly used.

access to the conditioning environment so that optimum heat

transfer occurs.

The sole source of supply ofChippingRatingStandards, Part #AE-400, known

7.2 Adjust the air pressure on the gravel apparatus to 480 6

to the committee at this time is the Society of Automotive Engineers, 400

Commonwealth Dr., Warrendale, PA 15096. 20 kPa [70 6 3 psi] with the air valve open.

D3170/D3170M − 14 (2022)

NOTE 5—For cabinet type gravelometers, keep the lid to the gravel

7.4.4 When the test has been completed, remove the test

chamber closed during this operation as a safety precaution. Other air

panel from the specimen holder by pulling back on the

pressures can be used as agreed upon by the contractual parties.

Specimen Mounting Clamp and removing the test specimen.

7.3 Cabinet Style Gravelometer: 7.4.5 Remove the gravel from the return receptacle and

screen before reuse.

7.3.1 After adjusting the air pressure, shut off the air valve,

openthelidtothegravelchamberandcollect473mL(1.00US

7.5 Allow the test specimens to return to room temperature

Liquid Pint) of graded gravel (approximately 250 to 300

and dry with a soft cloth to remove any condensation.

stones) in a suitable container. Collect the gravel by scraping

7.6 Use the tape referenced in 5.3 to remove all loose or

across the screen to allow fines to fall through.

damaged paint.

7.3.2 Place one test specimen at the desired test temperature

7.6.1 Cover the entire test area of the specimen with a

in the panel holder with the coated side facing the front of the

strip(s) of tape.

apparatus and close the lid to the panel chamber.

(1) For 51 to 56 mm [2.0 to 2.2 in.] wide tape, apply the

7.3.3 Open the gravel feed door and pour gravel from the

strips side by side over the evaluation area.

onepintcontainerobtainedfrom7.3.1intothetopofthegravel

(2) For 56 to 102 mm [2.2 to 4.0 in.] wide tape, strip(s)

hopper. Do not allow gravel to fall into the nozzle entrance.

may be applied consecutively with the first strip covering only

7.3.4 Opentheairvalvetoallowtheairtoprojectthegravel partofthetestarea.Thesecondstrip,ifneeded,isappliedafter

at the specimen. removal of the first strip and covers the remaining test area as

well as overlapping part of the test area covered by the first

NOTE 6—The gravel hopper must empty in 7 to 10 s. If gravel remains

strip.

in the hopper after 10 s, stop the test and investigate the cause. The

7.6.2 Apply uniform pressure to ensure that the tape(s) is

operator should not touch the gravel during the test or otherwise

firmly adhered to the specimen. There should not be any air

physically help the gravel into the funnel.

bubbles trapped beneath the tape.

NOTE 7—It is important to know that the vibrator may become frozen

when the chamber is installed in a cold room or freezer. If the vibrator is

NOTE 10—Uniform pressure can be applied by using a pencil eraser or

frozen, discontinue the test until the vibrator has thawed and is operating

tongue depressor. Methods such as plastic squeegee and rubber roller may

correctly.

also be acceptable for applying uniform pressure, but should be agreed

upon by contractual parties before use.

7.3.5 Shut the air valve, open the lid to the specimen

chamber and remove the specimen.

7.6.3 Remove the tape(s) by pulling straight up.

7.6.4 Apply new strips of tape as specified in 7.6.1 and

7.4 Modular Style Gravelometer:

7.6.2, but in the opposite direction.

7.4.1 After adjusting the air pressure, shut off the air valve,

7.6.5 Remove the tape by pulling straight up in the opposite

open the lid to the gravel hopper and pour 473 mL (1.00 US

direction to 7.6.3.

Liquid Pint) of graded gravel (approximately 250 to 300

7.6.6 Continue this procedure using new strips of tape until

stones) into the top of the gravel hopper.

all loose or damaged paint is removed.

7.4.2 Pullbackonthespecimenmountingclamptoopenthe

NOTE 11—Other tapes or loose paint removal methods may be used as

specimen holder on the holder assembly. Place one test

agreed upon by contractual parties.

specimen at the desired test temperature in the panel holder

with the coated side facing the front of the apparatus. Clamp to

8. Chip Rating Systems

close the specimen holder.

8.1 There are two generally accepted methods for determin-

7.4.3 Set the test timer.

ingthedegreeofchippingonthetestpanel.Inthefirstmethod,

theexactnumberofchipsineachsizerangeistabulatedforthe

NOTE 8—There are two ways to operate a test on the Modular style

gravelometer.Atimed test is a test that shuts off the machine after a preset test area. The second method utilizes a visual comparison of

amount of time has passed.Amanual test requires the operator to shut off

the test panel to the Chipping Rating Standards. An example

the machine after the desired amount of time has passed.

of the chipping standards is shown in Fig. 2.

7.4.3.1 Timed Test:

NOTE12—Thefirstmethod,whilethemosttimeconsuming,isthemost

(1) Make sure that the control switch is set to stop.

precise and should be used where definitive accuracy is required or as the

(2) Set the test timer to the desired test time.Atypical test

referee method in case differences arise between laboratories. The second

method, while more of an approximation than the first method, can be

time is 10 s.

used for many routine laboratory evaluations where the accuracy of the

(3) Turn the main power switch on.

first method is not required. The second method also lends itself to field

(4) Turn the control switch to Timed Start.

survey work where the chipped areas can be rated by direct comparison

7.4.3.2 Manual Test: with the Chipping Rating Standards.

NOTE 13—Other rating methods may be employed as agreed upon by

(1) Make sure that the control switch is set to stop.

contractual parties. The evalu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.