ASTM D6481-99(2004)

(Test Method)Standard Test Method for Determination of Phosphorus, Sulfur, Calcium, and Zinc in Lubrication Oils by Energy Dispersive X-ray Fluorescence Spectroscopy

Standard Test Method for Determination of Phosphorus, Sulfur, Calcium, and Zinc in Lubrication Oils by Energy Dispersive X-ray Fluorescence Spectroscopy

SIGNIFICANCE AND USE

Some oils are formulated with organo-metallic additives, which act, for example, as detergents, antioxidants, and antiwear agents. Some of these additives contain one or more of these elements: calcium, phosphorus, sulfur, and zinc. This test method provides a means of determining the concentrations of these elements, which in turn provides an indication of the additive content of these oils.

This test method is primarily intended to be used at a manufacturing location for monitoring of additive elements in lubricating oils. It can also be used in central and research laboratories.

SCOPE

1.1 This test method covers the quantitative determination of additive elements in unused lubricating oils, as shown in .

1.2 This test method is limited to the use of energy dispersive X-ray fluorescence (EDXRF) spectrometers employing an X-ray tube for excitation in conjunction with the ability to separate the signals of adjacent elements.

1.3 This test method uses interelement correction factors calculated from empirical calibration data.

1.4 This test method is not suitable for the determination of magnesium and copper at the concentrations present in lubricating oils.

1.5 This test method excludes lubricating oils that contain chlorine or barium as an additive element.

1.6 This test method can be used by persons who are not skilled in X-ray spectrometry. It is intended to be used as a routine test method for production control analysis.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D6481–99 (Reapproved 2004)

Standard Test Method for

Determination of Phosphorus, Sulfur, Calcium, and Zinc in

Lubrication Oils by Energy Dispersive X-ray Fluorescence

1

Spectroscopy

This standard is issued under the fixed designation D6481; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

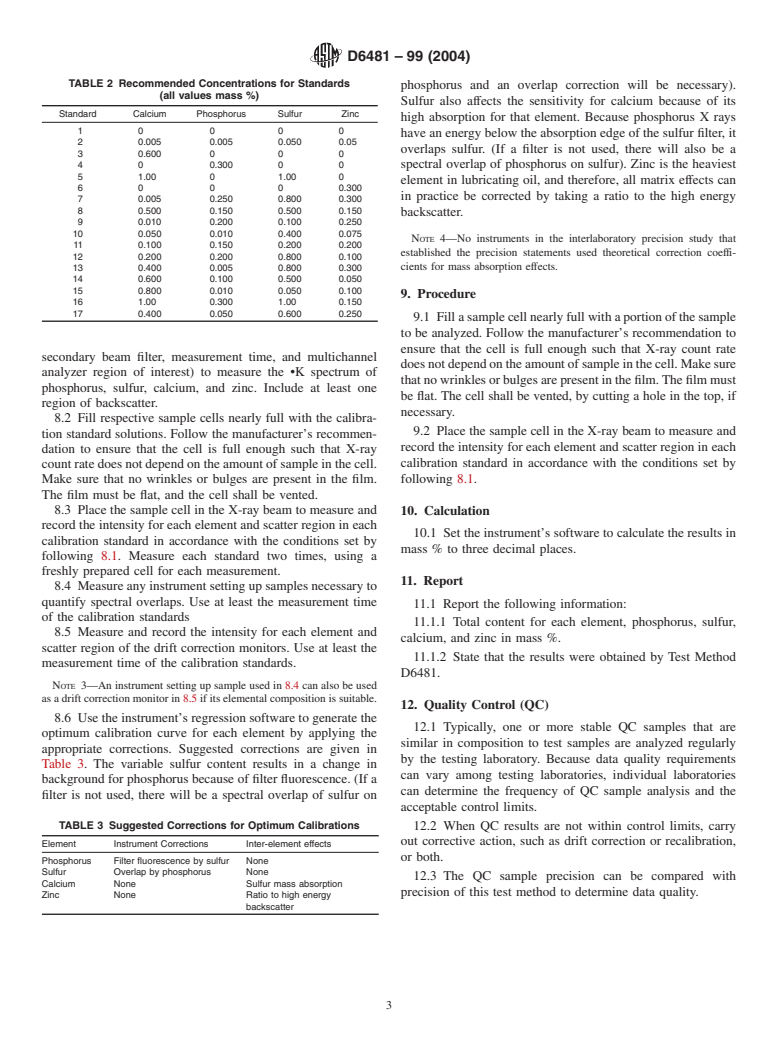

TABLE 1 Elements and Range of Concentrations Determined

1. Scope

Element Concentration Range

1.1 This test method covers the quantitative determination

Phosphorus 0.02 to 0.3 mass %

of additive elements in unused lubricating oils, as shown in

Sulfur 0.05 to 1.0 mass %

Table 1.

Calcium 0.02 to 1.0 mass %

1.2 This test method is limited to the use of energy

Zinc 0.01 to 0.3 mass %

dispersive X-ray fluorescence (EDXRF) spectrometers em-

ploying an X-ray tube for excitation in conjunction with the

ability to separate the signals of adjacent elements.

are determined by comparison of these intensities against a

1.3 This test method uses interelement correction factors

calibration curve using empirical interelement correction fac-

calculated from empirical calibration data.

tors and ratio to backscatter.

1.4 This test method is not suitable for the determination of

2.2 The EDXRF spectrometer is initially calibrated using a

magnesium and copper at the concentrations present in lubri-

setofpreparedstandardstocollectthenecessaryintensitydata.

cating oils.

Each calibration line and any correction coefficient are ob-

1.5 This test method excludes lubricating oils that contain

tained by a regression of this data, using the program supplied

chlorine or barium as an additive element.

with the spectrometer.

1.6 This test method can be used by persons who are not

3. Significance and Use

skilled in X-ray spectrometry. It is intended to be used as a

routine test method for production control analysis.

3.1 Some oils are formulated with organo-metallic addi-

1.7 This standard does not purport to address all of the

tives, which act, for example, as detergents, antioxidants, and

safety concerns, if any, associated with its use. It is the

antiwear agents. Some of these additives contain one or more

responsibility of the user of this standard to establish appro-

of these elements: calcium, phosphorus, sulfur, and zinc. This

priate safety and health practices and determine the applica-

test method provides a means of determining the concentra-

bility of regulatory limitations to use.

tions of these elements, which in turn provides an indication of

the additive content of these oils.

2. Summary of Test Method

3.2 This test method is primarily intended to be used at a

2.1 A specimen is placed in the X-ray beam, and the

manufacturing location for monitoring of additive elements in

appropriate regions of its spectrum are measured to give the

lubricating oils. It can also be used in central and research

fluorescent intensities of phosphorus, sulfur, calcium, and zinc.

laboratories.

Other regions of the spectrum are measured to compensate for

4. Interferences

varying background. If the detector does not completely

resolve all the elements in a single measurement, then to

4.1 The additive elements found in lubricating oils will

improve selectivity, there is a combination of sequential and

affect the measured intensities from the elements of interest to

simultaneous measurements employing primary and secondary

a varying degree. In general, for lubricating oils, the

beam filters. There can be correction of measured intensities

X-radiation emitted by the element of interest can be absorbed

for spectral overlap. Concentrations of the elements of interest

by itself (self-absorption) or by the other elements present in

the sample matrix. Also the X-radiation emitted from one

element can further excite (enhance) another element. These

1

interelement effects are significant at concentrations varying

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

from 0.03 mass %, due to the heavier elements, to 1 mass %,

D02.03 on Elemental Analysis.

forthelighterelements.Enhancementeffectscanbeminimised

Current edition approved May 1, 2004. Published May 2004. Originally

byselectiveexcitation.Themeasuredconcentrationforagiven

approved in 1999. Last previous edition approved in 1999 as D6481 - 99. DOI:

10.1520/D6481-99R04. element can be mathematically corrected for self-absorption

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6481–

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.