ASTM C511-13

(Specification)Standard Specification for Mixing Rooms, Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in the Testing of Hydraulic Cements and Concretes

Standard Specification for Mixing Rooms, Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in the Testing of Hydraulic Cements and Concretes

ABSTRACT

This specification includes the requirements for mixing rooms where paste and mortar specimens are prepared and for moist cabinets, moist rooms, and water storage tanks where paste, mortar, and concrete specimens are stored; intended for use in the testing of hydraulic cements and concretes. The system shall be equipped with a temperature recorder and a reference temperature measuring device that are to be placed practically near to each other. The air and mixing water temperatures and the relative humidity in the cement mixing room shall be maintained at specific values. Moist cabinets and moist rooms shall be constructed of durable materials with tight-fitting doors or windows for all openings. Air in moist cabinet or moist room shall be saturated with moisture in order to provide specified storage conditions and air temperature shall be controlled with provisions made for heating, cooling, or both. The specified relative humidity in these systems shall be maintained by the use of one or more fog sprays, water sprays, or curtains of water on the inner walls. Water storage tanks shall be constructed of non-corroding materials with provisions for automatic control of water temperature. The water in a storage tank shall be saturated with calcium hydroxide to prevent leaching.

SCOPE

1.1 This specification includes requirements for mixing rooms where paste and mortar specimens are prepared; and for moist cabinets, moist rooms, and water storage tanks where paste, mortar, and concrete specimens are stored.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard. Values in SI units shall be obtained by measurement in SI units or by appropriate conversion, using the Rules for Conversion and rounding given in Standard IEEE/ASTM SI 10, of measurements made in other units.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C511 −13

Standard Specification for

Mixing Rooms, Moist Cabinets, Moist Rooms, and Water

Storage Tanks Used in the Testing of Hydraulic Cements

1

and Concretes

This standard is issued under the fixed designation C511; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3.1.2 moist cabinet, n—a compartmented storage facility of

moderate dimensions with controlled temperature and relative

1.1 This specification includes requirements for mixing

humidity.

rooms where paste and mortar specimens are prepared; and for

3.1.3 moist room, n—a “walk-in” storage facility with

moist cabinets, moist rooms, and water storage tanks where

controlled temperature and relative humidity, commonly called

paste, mortar, and concrete specimens are stored.

a fog room when the prescribed relative humidity is achieved

1.2 The values stated in SI units are to be regarded as

by the atomization of water.

standard. No other units of measurement are included in this

standard. Values in SI units shall be obtained by measurement

4. Requirements for Cement Mixing Rooms

in SI units or by appropriate conversion, using the Rules for

4.1 The temperature of the air in the vicinity of the mixing

Conversion and rounding given in Standard IEEE/ASTM SI

slab, molds, and base plates shall be maintained at 23.0 6 4.0

10, of measurements made in other units.

°C and at a relative humidity of not less than 50 %.

1.3 This standard does not purport to address all of the

4.2 The temperature of the mixing water used to prepare

safety concerns, if any, associated with its use. It is the

cement paste and mortar specimens shall be 23.0 6 2.0 °C.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5. Temperature Measuring Devices

bility of regulatory limitations prior to use.

5.1 Reference Temperature Measuring Device—used to

2. Referenced Documents

verify the temperature recorder, must be accurate and readable

2

to 0.5 ºC. A copy of the certificate or report which verifies the

2.1 ASTM Standards:

accuracy shall be available in the laboratory.

C51 Terminology Relating to Lime and Limestone (as used

by the Industry)

NOTE 1—The ice-point method described in Test Method E77 may be

E77 Test Method for Inspection and Verification of Ther-

used to ensure that no damage to the reference thermometer has occurred

during shipping.

mometers

IEEE/ASTM SI 10 Standard for Use of the International

5.2 Temperature Recorder—shall record temperatures every

System of Units (SI): The Modern Metric System

15 min or less and shall be accurate and readable to 1 ºC. The

data from the recorder shall be evaluated at a minimum of once

3. Terminology

each week. A record of this evaluation documenting the date

3.1 Definitions:

checked, a confirmation that the data is within the required

3.1.1 mixing room, n—a room with controlled temperature

temperature range, and the name of the individual performing

and relative humidity where cement paste and mortar speci-

this evaluation shall be maintained in the laboratory. (Note 2)

mens are prepared.

NOTE 2—This requirement may be satisfied by an initialed and dated

temperature recorder chart. Brief changes in the temperature due to door

1 openings should be ignored.

This specification is under the jurisdiction of ASTM Committee C01 on

Cement and is the direct responsibility of Subcommittee C01.95 on Coordination of

5.2.1 The temperature recorder shall be verified at least

Standards.

every six months or whenever there is a question of accuracy.

Current edition approved Dec. 1, 2013. Published January 2014. Originally

5.2.1.1 For moist cabinets and rooms, position the reference

approved in 1968. Last previous edition approved in 2009 as C511–09. DOI:

10.1520/C0511-13.

temperature measuring device in a readable position in air as

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

near as practical to the temperature recorder probe. Keep the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

door closed for at least 5 min prior to taking readings. Record

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. the temperature readings of both the temperature recorder and

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C511−13

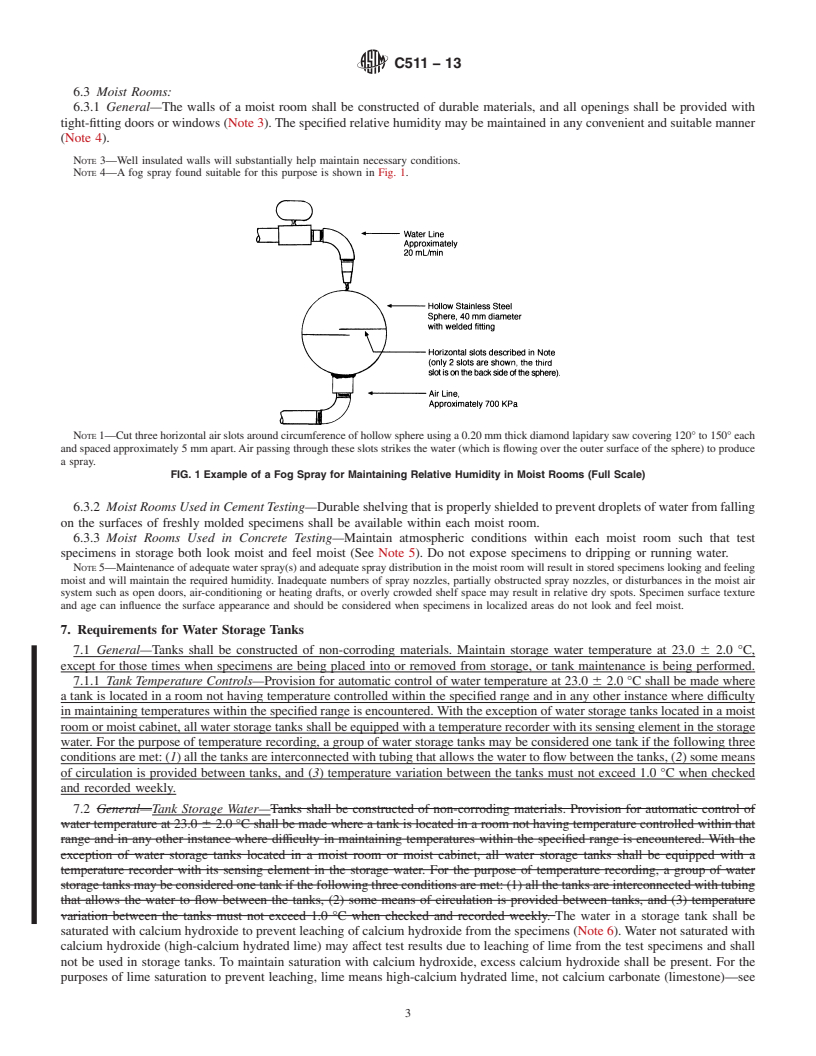

the reference temperature measuring device. When taking 6.3 Moist

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C511 − 09 C511 − 13

Standard Specification for

Mixing Rooms, Moist Cabinets, Moist Rooms, and Water

Storage Tanks Used in the Testing of Hydraulic Cements

1

and Concretes

This standard is issued under the fixed designation C511; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification includes requirements for mixing rooms where paste and mortar specimens are prepared; and for moist

cabinets, moist rooms, and water storage tanks where paste, mortar, and concrete specimens are stored.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

Values in SI units shall be obtained by measurement in SI units or by appropriate conversion, using the Rules for Conversion and

rounding given in Standard IEEE/ASTM SI 10, of measurements made in other units.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C51 Terminology Relating to Lime and Limestone (as used by the Industry)

E77 Test Method for Inspection and Verification of Thermometers

IEEE/ASTM SI 10 Standard for Use of the International System of Units (SI): The Modern Metric System

3. Terminology

3.1 Definitions:

3.1.1 mixing room, n—a room with controlled temperature and relative humidity where cement paste and mortar specimens are

prepared.

3.1.2 moist cabinet, n—a compartmented storage facility of moderate dimensions with controlled temperature and relative

humidity.

3.1.3 moist room, n—a “walk-in” storage facility with controlled temperature and relative humidity, commonly called a fog

room when the prescribed relative humidity is achieved by the atomization of water.

4. Requirements for Cement Mixing Rooms

4.1 The temperature of the air in the vicinity of the mixing slab, molds, and base plates shall be maintained at 23.0 6 4.0 ° C

and at a relative humidity of not less than 50 %.

4.2 The temperature of the mixing water used to prepare cement paste and mortar specimens shall be 23.0 6 2.0 °C.

5. Temperature Measuring Devices

5.1 Reference Temperature Measuring Device—used to verify the temperature recorder, must be accurate and readable to 0.5

ºC. A copy of the certificate or report which verifies the accuracy shall be available in the laboratory.

1

This specification is under the jurisdiction of ASTM Committee C01 on Cement and is the direct responsibility of Subcommittee C01.95 on Coordination of Standards.

Current edition approved June 1, 2009Dec. 1, 2013. Published July 2009January 2014. Originally approved in 1968. Last previous edition approved in 20062009 as

C511–06.–09. DOI: 10.1520/C0511-09.10.1520/C0511-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C511 − 13

NOTE 1—The ice-point method described in Test Method E77 may be used to ensure that no damage to the reference thermometer has occurred during

shipping.

5.2 Temperature Recorder—shall record temperatures every 15 min or less and shall be accurate and readable to 1 º C. The data

from the recorder shall be evaluated at a minimum of once each week. A record of this evaluation documenting the date checked,

a confirmation that the data is within the required temperature range, and the name of the individual performing this evaluation

shall be maintained in the laboratory. (Note 2)

NOTE 2—This requirement may be satisfied by an initialed and dated temperature recorder chart. Brief changes in the temperature due to door openings

should be ignored.

5.2.1 The temperature recorder shall be verified at least every six months or whenever there is a question of accuracy.

5.2.1.1 For moist cabinets and rooms, posit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.