ASTM D4457-02(2008)

(Test Method)Standard Test Method for Determination of Dichloromethane and 1,1,1-Trichloroethane in Paints and Coatings by Direct Injection into a Gas Chromatograph

Standard Test Method for Determination of Dichloromethane and 1,1,1-Trichloroethane in Paints and Coatings by Direct Injection into a Gas Chromatograph

SIGNIFICANCE AND USE

Use of 1,1,1-trichloroethane and dichloromethane, which do not measurably contribute to the atmospheric oxidant level, is a way for industry to meet government or other regulations on volatile organic compounds. This test method is designed to determine the content of these halohydrocarbon solvents in paints and coatings. That content can subsequently be used in calculating the volatile organic compound content of a coating.

SCOPE

1.1 This test method covers the determination of total amount of dichloromethane or 1,1,1-trichloroethane, or both, in paints and coatings. It has been evaluated for cellulose nitrate, alkyd, vinyl, and styrene-butadiene systems. It has not yet been evaluated for other formulations, but is believed to be applicable. The established working range of this test method is from 31 to 65 % for 1,1,1-trichloroethane and 32 to 78 % for dichloromethane. There is no reason to believe it will not work outside of these ranges. The presence of 1-propanol in paints and coatings requires the use of a different internal standard. (See also Practice E 260.)

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 7.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4457 − 02 (Reapproved2008)

Standard Test Method for

Determination of Dichloromethane and 1,1,1-Trichloroethane

in Paints and Coatings by Direct Injection into a Gas

Chromatograph

This standard is issued under the fixed designation D4457; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Summary of Test Method

3.1 Anhydrous 1-propanol (see 10.5) is added as an internal

1.1 This test method covers the determination of total

amountofdichloromethaneor1,1,1-trichloroethane,orboth,in standard to suitable aliquot of the whole paint. The aliquot is

then diluted with dimethylformamide and injected onto a gas

paints and coatings. It has been evaluated for cellulose nitrate,

alkyd,vinyl,andstyrene-butadienesystems.Ithasnotyetbeen chromatographic column containing a porous polymer packing

that separates dichloromethane and 1,1,1-trichloroethane from

evaluated for other formulations, but is believed to be appli-

cable. The established working range of this test method is other volatile compounds.

from 31 to 65 % for 1,1,1-trichloroethane and 32 to 78 % for

4. Significance and Use

dichloromethane.There is no reason to believe it will not work

outside of these ranges. The presence of 1-propanol in paints

4.1 Use of 1,1,1-trichloroethane and dichloromethane,

and coatings requires the use of a different internal standard.

which do not measurably contribute to the atmospheric oxidant

(See also Practice E260.)

level, is a way for industry to meet government or other

regulations on volatile organic compounds. This test method is

1.2 The values stated in inch-pound units are to be regarded

designed to determine the content of these halohydrocarbon

as the standard. The values given in parentheses are for

solvents in paints and coatings. That content can subsequently

information only.

beusedincalculatingthevolatileorganiccompoundcontentof

1.3 This standard does not purport to address all of the

a coating.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Apparatus

priate safety and health practices and determine the applica-

5.1 Chromatograph, any gas-liquid chromatographic instru-

bility of regulatory limitations prior to use. Specific hazard

ment equipped with a thermal conductivity detector and

statements are given in Section 7.

capable of being temperature programmed (see Table 1).

Optionally, a flame ionization detector may be used if the

2. Referenced Documents

sample is diluted so that no more than 1000 ppm each of

2.1 ASTM Standards:

dichloromethane and 1,1,1-trichloroethane is present in the

E180 Practice for Determining the Precision of ASTM

injected specimen.

Methods for Analysis and Testing of Industrial and Spe-

5.2 Recorder, a recording potentiometer with a full-scale

cialty Chemicals (Withdrawn 2009)

deflection of 10 mV, a full-scale response time of 2 s or less,

E260 Practice for Packed Column Gas Chromatography

and a maximum noise of 60.03 % of full scale.

5.3 Pre-Column, 40 in. (100 mm) long by ⁄8 in. (3.2 mm)

outside diameter stainless steel, packed with glass wool, fitted

This test method is under the jurisdiction of ASTM Committee D01 on Paint

on the entrance end of the column to retain any nonvolatile

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials. materials and minimize sludge buildup in the column.

Current edition approved Feb. 1, 2008. Published March 2008. Originally

5.4 Column, 4 ft (1.22 m) long by ⁄8 in. (3.2 mm) outside

approved in 1985. Last previous edition approved in 2002 as D4457 - 02. DOI:

10.1520/D4457-02R08. diameter stainless steel, packed with 80/100 mesh (150 to

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

180 µm) porous polymer packing material, or other suitable

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

The last approved version of this historical standard is referenced on Porapak R, a registered trademark ofWatersAssociates, Inc., Milford, MA, has

www.astm.org. been found satisfactory for this purpose.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4457 − 02 (Reapproved2008)

material.

D4457 − 02 (2008)

TABLE 1 Typical Instrument Conditions

8. Preparation of Apparatus

Detector thermal conductivity

8.1 Column Conditioning—The packed column is installed

Column 4 ft (1.22 m) by ⁄8 in. (3.2 mm) outside

diameter packed with 80–100 mesh

in the gas chromatographic unit leaving the exit end discon-

porous polymer packing

nected from the detector. This will prevent any contamination

Temperature, °C

of the detector with the column bleed. Set the helium flow rate

Injection port 200

Detector block 250 1

at 30 mL/min if a ⁄8 in. (3.2 mm) outside diameter column is

Column

used. Purge the column 5 to 10 min before heating. Heat the

Initial 100

Final 230 (for 8 min) column from room temperature to 200°C at 5°C/min and hold

°C/min 8

this temperature for at least 12 h (overnight).At the end of this

Carrier gas helium

period of time, heat the column to 240°C at a 5°C/min rate and

Flow rate, mL/min 30

Specimen size, µL 1

hold this temperature for several hours. The maximum tem-

perature for this packing is 250°C. Cool the column to 100°C

and reheat to 240°C at 5°C/min to observe the column bleed.

5.5 Liquid Charging Devices,suchasmicrosyringesof5-µL

Optimum conditioning of this column may take several cycles

or 10-µL capacity, cleaned with acetone or other suitable

of the heating program before a good recorder baseline is

solvent. Visually inspect for plugs or cracks before and after

achieved. Conditioning of any column other than that sug-

each injection.

gested (5.4) should be in accordance with the manufacturer’s

5.6 Vials, 25-mL to minimize head space, capable of being recommendations.

septum sealed.

8.2 Install the column in the chromatograph and use the

information in Table 1 as a guide to establish the conditions

6. Reagents and Materials

required to give the desired separation. Allow sufficient time

6.1 Purity of Reagents—Reagent grade chemicals shall be

for the instrument to reach equilibrium as indicated by a stable

used in all tests, unless otherwise specified (as in 6.7). Unless

recorder baseline.Adjust the carrier-gas flow to a constant rate.

otherwise indicated, it is intended that all reagents shall

Before each calibration and series of determinations (or daily),

conform to the specifications of the Committee on Analytical

condition the column at 200°C for 1 h with carrier-gas flow.

Reagents of the American Chemical Society, where such

specifications are available. Other grades may be used pro-

9. Calibration

vided it is first ascertained that the reagent is of sufficient high

purity to permit its use without lessening the accuracy of the

9.1 Preparation of Standards—All standards, as well as

determination.

samples and blanks, should be at a constant temperature. The

given order of ingredient addition should be observed to

6.2 Carrier Gas, helium of 99.995 % or higher purity. High

minimize loss of volatile ingredients.

purity nitrogen may also be used.

9.1.1 Weighingto1.0mg,add16.0gofdimethylformamide

6.3 Dimethylformamide (DMF), reagent grade.

to a vial capable of being septum sealed. Add 2.0 g of

6.4 1-Propanol, gas chromatography spectrophotometric

1,1,1-trichloroethane, 2.0 g of 1-propanol (see 10.5) and 2.0 g

quality (see 10.5).

of dichloromethane. Seal the vial with a crimp-on or septum

6.5 1,1,1-Trichloroethane (see 6.7).

seal.

6.6 Dichloromethane (see 6.7).

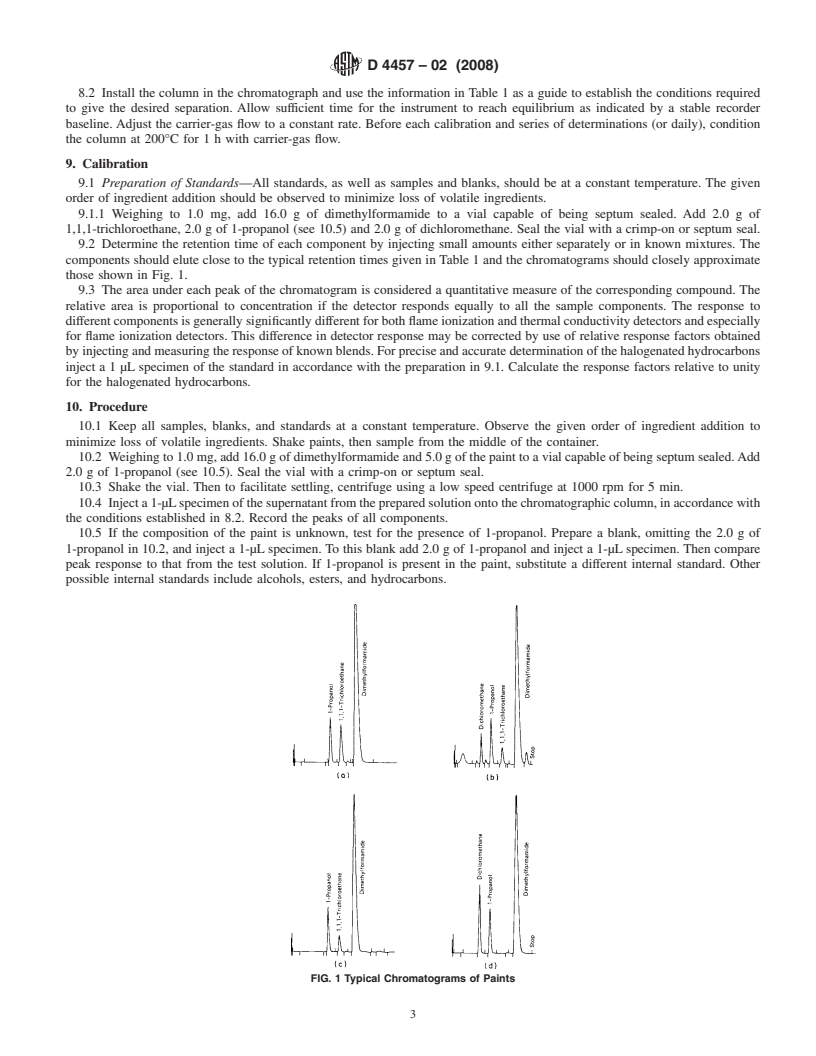

9.2 Determine the retention time of each component by

6.7 Halogenated Hydrocarbon Stabilizers—All commercial injecting small amounts either separately or in known mix-

grades of these halogenated hydrocarbons contain stabilizers. tures. The components should elute close to the typical

Eitherobtainthesamesolventusedinthecoatingforuseasthe retention times given in Table 1 and the chro

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

e1

Designation:D4457–85 (Reapproved 1996)

Designation: D 4457 – 02 (Reapproved 2008)

Standard Test Method for

Determination of Dichloromethane and 1,1,1-Trichloroethane

in Paints and Coatings by Direct Injection into a Gas

Chromatograph

This standard is issued under the fixed designation D 4457; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Unit of measurement statement added to the Scope Section editorially in May 1997.

1. Scope

1.1 This test method covers the determination of total amount of dichloromethane or 1,1,1-trichloroethane, or both, in paints

and coatings. It has been evaluated for cellulose nitrate, alkyd, vinyl, and styrene-butadiene systems. It has not yet been

evaulatedevaluated for other formulations, but is believed to be applicable. The established working range of this test method is

from 31 to 65 % for 1,1,1-trichloroethane and 32 to 78 % for dichloromethane. There is no reason to believe it will not work

outside of these ranges. The presence of 1-propanol in paints and coatings requires the use of a different internal standard. (See

also Practice E 260.)

1.2 The values stated in inch-pound units are to be regarded as the standard.The values given in parentheses are for information

only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific hazard statements are given in Section 7.

2. Referenced Documents

2.1 ASTM Standards:

E 180 Practice for Determining the Precision ofASTM Methods forAnalysis andTesting of Industrial and Specialty Chemicals

E 260 Practice for Packed Column Gas Chromatography

3. Summary of Test Method

3.1 Anhydrous 1-propanol (see 10.5) is added as an internal standard to suitable aliquot of the whole paint. The aliquot is then

diluted with dimethylformamide and injected onto a gas chromatographic column containing a porous polymer packing that

separates dichloromethane and 1,1,1-trichloroethane from other volatile compounds.

4. Significance and Use

4.1 Use of 1,1,1-trichloroethane and dichloromethane, which do not measurably contribute to the atmospheric oxidant level, is

a way for industry to meet government or other regulations on volatile organic compounds. This test method is designed to

determine the content of these halohydrocarbon solvents in paints and coatings. That content can subsequently be used in

calculating the volatile organic compound content of a coating.

5. Apparatus

5.1 Chromatograph, any gas-liquid chromatographic instrument equipped with a thermal conductivity detector and capable of

being temperature programmed (see Table 1). Optionally, a flame ionization detector may be used if the sample is diluted so that

no more than 1000 ppm each of dichloromethane and 1,1,1-trichloroethane is present in the injected specimen.

This test method is under the jurisdiction of ASTM Committee D-1 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.21 on Chemical Analysis of Paint and Paint Materials.

Current edition approved July 16, 1985. Published October 1985.

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials.

Current edition approved Feb. 1, 2008. Published March 2008. Originally approved in 1985. Last previous edition approved in 2002 as D 4457 - 02.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 15.05.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 4457 – 02 (2008)

TABLE 1 Typical Instrument Conditions

Detector thermal conductivity

Column 4 ft (1.22 m) by ⁄8 in. (3.2 mm) outside

diameter packed with 80–100 mesh

porous polymer packing

Temperature, °C

Injection port 200

Detector block 250

Column

Initial 100

Final 230 (for 8 min)

°C/min 8

Carrier gas helium

Flow rate, mL/min 30

Specimen size, µL 1

5.2 Recorder, a recording potentiometer with a full-scale deflection of 10 mV, a full-scale response time of2sor less, and a

maximum noise of 60.03 % of full scale.

5.3 Pre-Column, 40 in. (100 mm) long by ⁄8 in. (3.2 mm) outside diameter stainless steel, packed with glass wool, fitted on the

entrance end of the column to retain any nonvolatile materials and minimize sludge buildup in the column.

5.4 Column, 4 ft (1.22 m) long by ⁄8 in. (3.2 mm) outside diameter stainless steel, packed with 80/100 mesh (150 to

180 µ m) porous polymer packing material, or other suitable material.

5.5 Liquid Charging Devices, such as microsyringes of 5-µL or 10-µL capacity, cleaned with acetone or other suitable solvent.

Visually inspect for plugs or cracks before and after each injection.

5.6 Vials, 25-mL to minimize head space, capable of being septum sealed.

6. Reagents and Materials

6.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests, unless otherwise specified (as in 6.7). Unless

otherwise indicated, it is intended that all reagents shall conform to the specifications of the Committee on Analytical Reagents

of the American Chemical Society, where such specifications are available. Other grades may be used provided it is first

ascertained that the reagent is of sufficient high purity to permit its use without lessening the accuracy of the determination.

6.2 Carrier Gas, helium of 99.995 % or higher purity. High purity nitrogen may also be used.

6.3 Dimethylformamide (DMF), reagent grade.

6.4 1-Propanol, gas chromatography spectrophotometric quality (see 10.5).

6.5 1,1,1-Trichloroethane (see 6.7).

6.6 Dichloromethane (see 6.7).

6.7 Halogenated Hydrocarbon Stabilizers—All commercial grades of these halogenated hydrocarbons contain stabilizers.

Either obtain the same solvent used in the coating for use as the standard, or find the type and quantity of stabilizer specified for

use in the solvent of interest and add the appropriate quantity to the pure solvent.

7. Hazards

7.1 Dimethylformamide is harmful if inhaled or absorbed through skin. Use only with adequate ventilation.Avoid contact with

skin, eyes, and clothing.

8. Preparation of Apparatus

8.1 Column Conditioning—The packed column is installed in the gas chromatographic unit leaving the exit end disconnected

fromthedetector.Thiswillpreventanycontaminationofthedetectorwiththecolumnbleed.Settheheliumflowrateat30mL/min

if a ⁄8 in. (3.2 mm) outside diameter column is used. Purge the column 5 to 10 min before heating. Heat the column from room

temperature to 200°C at 5°C/min and hold this temperature for at least 12 h (overnight). At the end of this period of time, heat

the column to 240°C at a 5°C/min rate and hold this temperature for several hours. The maximum temperature for this packing

is 250°C. Cool the column to 100°C and reheat to 240°C at 5°C/min to observe the column bleed. Optimum conditioning of this

column may take several cycles of the heating program before a good recorder baseline is achieved. Conditioning of any column

other than that suggested (5.4) should be in accordance with the manufacturer’s recommendations.

Annual Book of ASTM Standards, Vol 14.02.

Porapak R, a registered trademark of Waters Associates, Inc., Milford, MA, has been found satisfactory for this purpose.

Porapak Rt, available from Waters Associates, Inc., Milford, MA, has been found satisfactory for this purpose.

Miniert valves, available from The Pierce Chemical Co., Box 117, Rockford, IL 61105, have been found satisfactory for this purpose.

Mininert valves, available from The Pierce Chemical Co., Box 117, Rockford, IL 61105, have been found satisfactory for this purpose.

Reagent Chemicals, American Chemical Society Specifications , American Chemical Society, Washington, DC. For suggestions on the testing of reagents not listed by

the American Chemical Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

D 4457 – 02 (2008)

8.2 Install the column in the chromatograph and use the information in Table 1 as a guide to establish the conditions required

to give the desired separation. Allow sufficient time for the instrument to reach equilibrium as indicated by a stable recorder

baseli

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.