ASTM D7594-16

(Test Method)Standard Test Method for Determining Fretting Wear Resistance of Lubricating Greases Under High Hertzian Contact Pressures Using a High-Frequency, Linear-Oscillation (SRV) Test Machine

Standard Test Method for Determining Fretting Wear Resistance of Lubricating Greases Under High Hertzian Contact Pressures Using a High-Frequency, Linear-Oscillation (SRV) Test Machine

SIGNIFICANCE AND USE

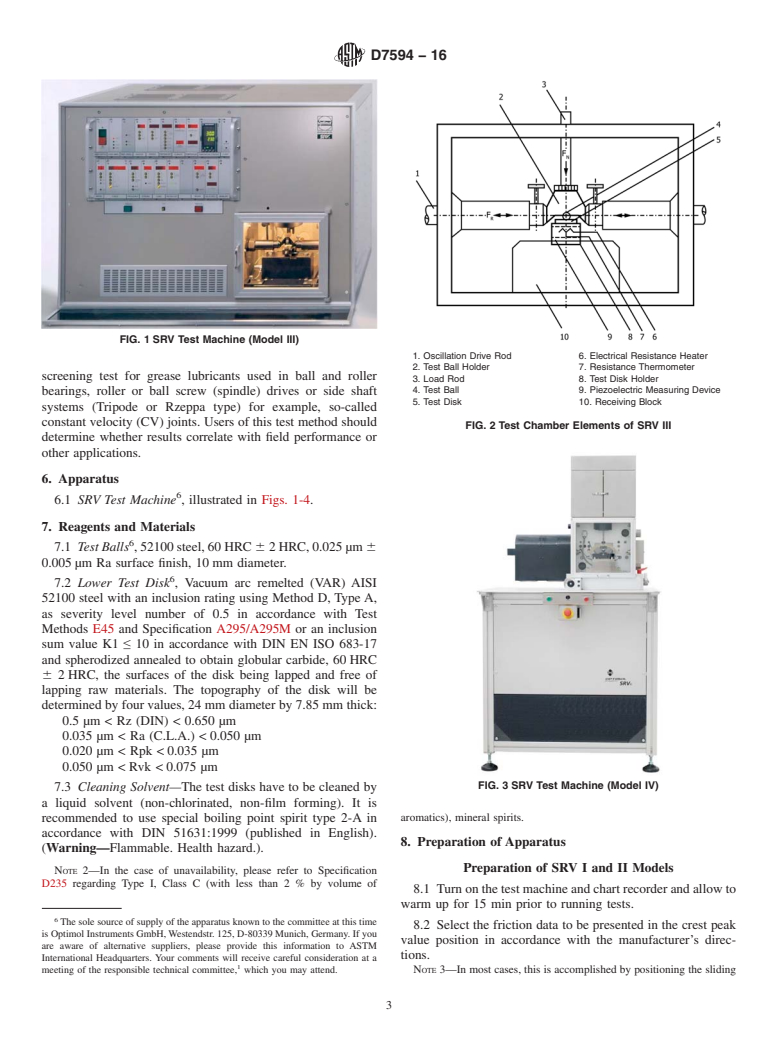

5.1 This test method can be used to determine anti-wear properties and coefficient of friction of greases in order to prevent “fretting” wear under linear oscillation with associated low strokes and high Hertzian contact pressures at selected temperatures and loads specified for use in applications in which induced, high-speed vibrational motions are present for extended periods of time. It has found application as a screening test for grease lubricants used in ball and roller bearings, roller or ball screw (spindle) drives or side shaft systems (Tripode or Rzeppa type) for example, so-called constant velocity (CV) joints. Users of this test method should determine whether results correlate with field performance or other applications.

SCOPE

1.1 This test method covers a procedure for determining the lubricating action of greases in order to prevent “fretting” wear under linear oscillation with associated low strokes and high Hertzian contact pressures under high-frequency linear-oscillation motion using the SRV test machine. By performing additional, nonmandatory extreme-pressure tests in accordance with Test Method D5706, the test grease should be shown to be able to withstand a Hertzian contact pressure of at least 2200 MPa without adhesive failure.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7594 − 16

Standard Test Method for

Determining Fretting Wear Resistance of Lubricating

Greases Under High Hertzian Contact Pressures Using a

1

High-Frequency, Linear-Oscillation (SRV) Test Machine

This standard is issued under the fixed designation D7594; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Frequency, Linear-Oscillation (SRV) Test Machine

D6425 Test Method for Measuring Friction and Wear Prop-

1.1 This test method covers a procedure for determining the

erties of Extreme Pressure (EP) Lubricating Oils Using

lubricating action of greases in order to prevent “fretting” wear

SRV Test Machine

under linear oscillation with associated low strokes and high

D7421 Test Method for Determining Extreme Pressure

Hertzian contact pressures under high-frequency linear-

Properties of Lubricating Oils Using High-Frequency,

oscillation motion using the SRV test machine. By performing

Linear-Oscillation (SRV) Test Machine

additional, nonmandatory extreme-pressure tests in accordance

D7755 Practice for Determining the Wear Volume on Stan-

withTestMethodD5706,thetestgreaseshouldbeshowntobe

dard Test Pieces Used by High-Frequency, Linear-

able to withstand a Hertzian contact pressure of at least

Oscillation (SRV) Test Machine

2200 MPa without adhesive failure.

E45 Test Methods for Determining the Inclusion Content of

1.2 The values stated in SI units are to be regarded as

Steel

standard. No other units of measurement are included in this

G40 Terminology Relating to Wear and Erosion

standard.

3

2.2 Other Standards:

1.3 This standard does not purport to address all of the

DIN 51834-3:2008-12 Testing of Lubricants—Tribological

safety concerns, if any, associated with its use. It is the

Test in Translatory Oscillation Apparatus—Part 3: Deter-

responsibility of the user of this standard to establish appro-

mination of Tribological Behaviour of Materials in Coop-

priate safety and health practices and determine the applica-

eration with Lubricants

bility of regulatory limitations prior to use.

DIN 51631:1999 Special-Boiling-Point Spirits—

Requirements and Testing

2. Referenced Documents

DIN EN ISO 683-17 Heat-Treated Steels, Alloy Steels and

2

2.1 ASTM Standards:

Free-Cutting Steels—Part 17: Ball and Roller Bearing

A295/A295M Specification for High-Carbon Anti-Friction

Steels [Replaces DIN 17230-1980]

Bearing Steel

DIN EN ISO 13565-2:1998 Geometrical Product Specifica-

D217 Test Methods for Cone Penetration of Lubricating

tions (GPS)—Surface Texture: Profile Method—Surfaces

Grease

Having Stratified Functional Properties—Part 2: Height

D235 Specification for Mineral Spirits (Petroleum Spirits)

Characterization Using the Linear Material Ratio Curve

(Hydrocarbon Dry Cleaning Solvent)

[Replaces DIN 4776-1990]

D4175 Terminology Relating to Petroleum Products, Liquid

Fuels, and Lubricants

3. Terminology

D5706 Test Method for Determining Extreme Pressure

3.1 Definitions:

Properties of Lubricating Greases Using a High-

3.1.1 break-in, n—in tribology, an initial transition process

occurring in newly established wearing contacts, often accom-

1

This test method is under the jurisdiction of ASTM Committee D02 on

panied by transients in coefficient of friction or wear rate, or

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

both,thatareuncharacteristicofthegiventribologicalsystem’s

Subcommittee D02.G0.04 on Functional Tests - Tribology.

long-term behavior. G40

Current edition approved Dec. 1, 2016. Published March 2017. Originally

approved in 2010. Last previous edition approved in 2011 as D7594 – 11.

DOI:10.1520/D7594-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Available from Beuth Verlag GmbH (DIN-- DIN Deutsches

Standards volume information, refer to the standard’s Document Summary page on Institut fur Normung e.V.), Burggrafenstrasse 6, 10787, Berlin, Germany, http://

the ASTM website. www.en.din.de.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7594 − 16

3.1.2 coeffıcient of friction, µ or ƒ, n—in tribology, the 3.2.2 fretting wear, n—wear arising as a result of fretting.

dimensionless ratio of the friction force (F) between two Small amplitude oscillatory motion, usually tangential, be-

bodies to the normal force (N) pressing these bodies together. t

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7594 − 11 D7594 − 16

Standard Test Method for

Determining Fretting Wear Resistance of Lubricating

Greases Under High Hertzian Contact Pressures Using a

1

High-Frequency, Linear-Oscillation (SRV) Test Machine

This standard is issued under the fixed designation D7594; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers a procedure for determining the lubricating action of greases in order to prevent “fretting” wear

under linear oscillation with associated low strokes and high Hertzian contact pressures under high-frequency linear-oscillation

motion using the SRV test machine. By performing additional, nonmandatory extreme-pressure tests in accordance with Test

Method D5706, the test grease should be shown to be able to withstand a Hertzian contact pressure of at least 2200 MPa without

adhesive failure.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

A295/A295M Specification for High-Carbon Anti-Friction Bearing Steel

D217 Test Methods for Cone Penetration of Lubricating Grease

D235 Specification for Mineral Spirits (Petroleum Spirits) (Hydrocarbon Dry Cleaning Solvent)

D4175 Terminology Relating to Petroleum Products, Liquid Fuels, and Lubricants

D5706 Test Method for Determining Extreme Pressure Properties of Lubricating Greases Using a High-Frequency, Linear-

Oscillation (SRV) Test Machine

D6425 Test Method for Measuring Friction and Wear Properties of Extreme Pressure (EP) Lubricating Oils Using SRV Test

Machine

D7421 Test Method for Determining Extreme Pressure Properties of Lubricating Oils Using High-Frequency, Linear-Oscillation

(SRV) Test Machine

D7755 Practice for Determining the Wear Volume on Standard Test Pieces Used by High-Frequency, Linear-Oscillation (SRV)

Test Machine

E45 Test Methods for Determining the Inclusion Content of Steel

G40 Terminology Relating to Wear and Erosion

3

2.2 DINOther Standards:

DIN 51834-3:2008-12 Testing of lubricants – Tribological test in translatory oscillation apparatus – Part Lubricants—

Tribological Test in Translatory Oscillation Apparatus—Part 3: Determination of tribological behaviourTribological

Behaviour of materialsMaterials in cooperationCooperation with lubricantsLubricants

DIN 51631:1999 Special-boiling-point spirits - Requirements and testingSpecial-Boiling-Point Spirits—Requirements and

Testing

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.G0.04 on Functional Tests - Tribology.

Current edition approved Dec. 1, 2011Dec. 1, 2016. Published March 2012March 2017. Originally approved in 2010. Last previous edition approved in 20102011 as

D7594D7594 – 11.–10. DOI:10.1520/D7594-11. DOI:10.1520/D7594-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Available from Beuth Verlag GmbH (DIN-- DIN Deutsches Institut fur Normung e.V.), Burggrafenstrasse 6, 10787, Berlin, Germany, http://

www.en.din.de.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7594 − 16

DIN EN ISO 683-17 Heat-treated steels, alloy steels and free-cutting steels - Part Heat-Treated Steels, Alloy Steels and

Free-Cutting Steels—Part 17: Ball and roller bearing steels (replaces DIN 17230-1980)Roller Bearing Steels [Replaces DIN

17230-1980]

DIN EN ISO 13565-2:1998 Geometrical Product Specifications (GPS) - Surface texture: Profile method - Surfaces having

stratified functional properties - Part 2: Height characterization using the linear mater

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.