ASTM D7954/D7954M-15

(Practice)Standard Practice for Moisture Surveying of Roofing and Waterproofing Systems Using Non-Destructive Electrical Impedance Scanners

Standard Practice for Moisture Surveying of Roofing and Waterproofing Systems Using Non-Destructive Electrical Impedance Scanners

SIGNIFICANCE AND USE

5.1 Excess moisture trapped in roofing or waterproofing systems can adversely affect performance and lead to premature failure of roofing or waterproofing systems and its components. It also reduces thermal resistance, resulting in reduced energy efficiency and inflated energy costs. Impedance scans can be effective in identifying concealed and entrapped moisture within roofing or waterproofing systems.

5.2 This practice is intended to be used at various stages of the roofing and waterproofing system’s life such as: completion of installation of roofing system to determine if there was moisture intrusion into the roofing system or materials for quality control purposes, at regular intervals as part of a preventative maintenance program, and before re-roofing or repair work to assist in determining the extent of work and replacement materials.

5.3 This practice alone does not determine the cause of moisture infiltration into roofing or waterproofing systems; however, it can be used to help tracing excess moisture to the point of ingress.

SCOPE

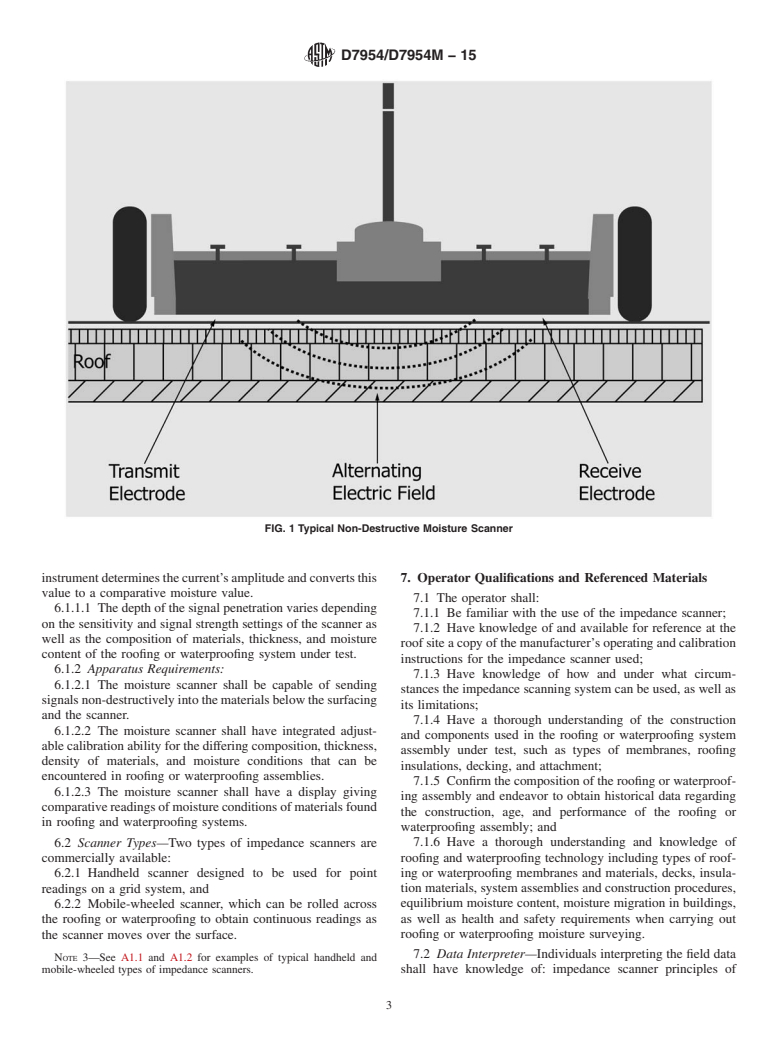

1.1 This practice applies to techniques that use non-destructive electrical impedance (EI) scanners to locate moisture and evaluate the comparitive moisture content within insulated low-slope roofing and waterproofing systems.

1.2 This practice is applicable to roofing and waterproofing systems wherein insulation is placed above the deck and positioned underneath and in contact with electrically nonconductive single-ply or built-up roofing and waterproofing membranes and systems such as coal tar, asphalt, modified bitumen, thermoplastics, spray polyurethane foam, and similar electrically non-conductive membrane materials. This practice is also applicable to roofing and waterproofing systems without insulation placed above moisture absorbing decks such as wood, concrete, or gypsum, that are in contact with single-ply or built-up roofing and waterproofing membranes as described above.

1.3 This practice is applicable to roofing and waterproofing systems incorporating electrically nonconductive rigid board insulation made from materials such as organic fibers, perlite, cork, fiberglass, wood-fiber, polyisocyanurate, polystyrene, phenolic foam, composite boards, gypsum substrate boards, and other electrically nonconductive roofing and waterproofing systems such as spray-applied polyurethane foam.

1.4 This practice is not appropriate for all combinations of materials used in roofing and waterproofing systems.

1.4.1 Metal and other electrically conductive surface coverings and near-surface embedded metallic components are not suitable for surveying with impedance scanners because of the electrical conductivity of these materials.

1.4.2 Black ethylene propylene diene terpolymer (EPDM) produces false positive readings when tested because of the material’s high dielectric constant.

1.4.3 Aluminum foil on top-faced insulation, roofing, or waterproofing membranes gives a false positive reading and is not suitable for surveying with impedance scanners; however, liquid-applied aluminum pigmented emulsified asphalt-based coatings shall not normally affect impedance scanner readings.

1.4.4 See A1.4 for some cautionary notes on roofing anomalies and limitations that affect the impedance test practice.

1.5 Moisture scanners using impedance based technology are classified as EI scanners.

Note 1: The term capacitance is sometimes used when describing impedance scanners. Capacitance scanners are purely capacitive as they do not have a resistive component. Impedance scanners combine both capacitance and resistance for testing; thus, they are well suited to the measurement of different types of materials and constructions found in roofing and waterproofing systems as the combination of both components allows for a more versatile testing, calibration, and measurement arrangement.

1.6 This practice also addresses necessary verification of impe...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7954/D7954M −15

StandardPractice for

Moisture Surveying of Roofing and Waterproofing Systems

1

Using Non-Destructive Electrical Impedance Scanners

This standard is issued under the fixed designation D7954/D7954M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope not suitable for surveying with impedance scanners; however,

liquid-applied aluminum pigmented emulsified asphalt-based

1.1 This practice applies to techniques that use non-

coatings shall not normally affect impedance scanner readings.

destructive electrical impedance (EI) scanners to locate mois-

1.4.4 SeeA1.4forsomecautionarynotesonroofinganoma-

ture and evaluate the comparitive moisture content within

lies and limitations that affect the impedance test practice.

insulated low-slope roofing and waterproofing systems.

1.5 Moisture scanners using impedance based technology

1.2 This practice is applicable to roofing and waterproofing

are classified as EI scanners.

systems wherein insulation is placed above the deck and

positioned underneath and in contact with electrically noncon-

NOTE 1—The term capacitance is sometimes used when describing

impedance scanners. Capacitance scanners are purely capacitive as they

ductive single-ply or built-up roofing and waterproofing mem-

do not have a resistive component. Impedance scanners combine both

branes and systems such as coal tar, asphalt, modified bitumen,

capacitance and resistance for testing; thus, they are well suited to the

thermoplastics, spray polyurethane foam, and similar electri-

measurement of different types of materials and constructions found in

cally non-conductive membrane materials.This practice is also

roofingandwaterproofingsystemsasthecombinationofbothcomponents

applicable to roofing and waterproofing systems without insu- allows for a more versatile testing, calibration, and measurement arrange-

ment.

lation placed above moisture absorbing decks such as wood,

concrete, or gypsum, that are in contact with single-ply or

1.6 This practice also addresses necessary verification of

built-up roofing and waterproofing membranes as described

impedance data involving invasive test procedures using core

above.

samples.

1.3 This practice is applicable to roofing and waterproofing

1.7 This practice addresses two generally accepted scanning

systems incorporating electrically nonconductive rigid board

techniques for conducting moisture surveys using electrical

insulation made from materials such as organic fibers, perlite,

impedance scanners:

cork, fiberglass, wood-fiber, polyisocyanurate, polystyrene,

1.7.1 Technique A—Continuous systematic scanning and

phenolic foam, composite boards, gypsum substrate boards,

recording (see 8.2), and

andotherelectricallynonconductiveroofingandwaterproofing

1.7.2 Technique B—Grid format scanning and recording

systems such as spray-applied polyurethane foam.

(see 8.3).

1.4 This practice is not appropriate for all combinations of

1.8 This practice addresses some meteorological conditions

materials used in roofing and waterproofing systems.

and limitations for performing impedance inspections.

1.4.1 Metal and other electrically conductive surface cover-

1.9 This practice addresses the effect of the roofing or

ings and near-surface embedded metallic components are not

waterproofing construction, material differences, and exterior

suitable for surveying with impedance scanners because of the

surface conditions on the moisture inspections.

electrical conductivity of these materials.

1.10 This practice addresses operating procedures, operator

1.4.2 Black ethylene propylene diene terpolymer (EPDM)

qualifications, operating methods, scanning, surveying, and

produces false positive readings when tested because of the

recording techniques.

material’s high dielectric constant.

1.4.3 Aluminum foil on top-faced insulation, roofing, or

1.11 Units—The values stated in either SI units or inch-

waterproofing membranes gives a false positive reading and is

pound units are to be regarded separately as standard. The

values stated in each system may not be exact equivalents;

therefore,eachsystemshallbeusedindependentlyoftheother.

1

ThispracticeisunderthejurisdictionofASTMCommitteeD08onRoofingand

Combining values from the two systems may result in non-

Waterproofing and is the direct responsibility of Subcommittee D08.20 on Roofing

Membrane Systems.

conformance with the standard.

Current edition approved Feb. 15, 2015. Published March 2015. Originally

1.12 This standard does not purport to address all of the

approved in 2014. Last previous edition approved in 2014 as D7954/D7954M – 14.

DOI: 10.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7954/D7954M − 14 D7954/D7954M − 15

Standard Practice for

Moisture Surveying of Roofing and Waterproofing Systems

1

Using Non-Destructive Electrical Impedance Scanners

This standard is issued under the fixed designation D7954/D7954M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice applies to techniques that use non-destructive electrical impedance (EI) scanners to locate moisture and

evaluate the comparitive moisture content within insulated low-slope roofing and waterproofing systems.

1.2 This practice is applicable to roofing and waterproofing systems wherein insulation is placed above the deck and positioned

underneath and in contact with electrically nonconductive single-ply or built-up roofing and waterproofing membranes and systems

such as coal tar, asphalt, modified bitumen, thermoplastics, spray polyurethane foam, and similar electrically nonconductivenon-

conductive membrane materials. This practice is also applicable to roofing and waterproofing systems without insulation placed

above moisture absorbing decks such as wood, concrete, or gypsum, that are in contact with single-ply or built-up roofing and

waterproofing membranes as described above.

1.3 This practice is applicable to roofing and waterproofing systems incorporating electrically nonconductive rigid board

insulation made from materials such as organic fibers, perlite, cork, fiberglass, wood-fiber, polyisocyanurate, polystyrene, phenolic

foam, composite boards, gypsum substrate boards, and other electrically nonconductive roofing and waterproofing systems such

as spray-applied polyurethane foam.

1.4 This practice is not appropriate for all combinations of materials used in roofing and waterproofing systems.

1.4.1 Metal and other electrically conductive surface coverings and near-surface embedded metallic components are not suitable

for surveying with impedance scanners because of the electrical conductivity of these materials.

1.4.2 This practice is not appropriate for use with Black EPDM membranes or coatings because of its high dielectric content

and will give false positives.Black ethylene propylene diene terpolymer (EPDM) produces false positive readings when tested

because of the material’s high dielectric constant.

1.4.3 Aluminum foil on top-faced insulation, roofing, or waterproofing membranes gives a false positive reading and is not

suitable for surveying with impedance scanners; however, liquid-applied aluminum pigmented emulsified asphalt-based coatings

shall not normally affect impedance scanner readings.

1.4.4 See A1.4 for some cautionary notes on roofing anomalies and limitations that affect the impedance test practice.

1.5 Moisture scanners using impedance based technology are classified as EI scanners.

NOTE 1—The term capacitance is sometimes used when describing impedance scanners. Capacitance scanners are purely capacitive as they do not have

a resistive component. Impedance scanners combine both capacitance and resistance for testing; thus, they are well suited to the measurement of different

types of materials and constructions found in roofing and waterproofing systems as the combination of both components allows for a more versatile

testing, calibration, and measurement arrangement.

1.6 This practice also addresses necessary verification of impedance data involving invasive test procedures using core samples.

1.7 This practice addresses two generally accepted scanning techniques for conducting moisture surveys using electrical

impedance scanners:

1.7.1 Technique A—Continuous systematic scanning and recording (see 8.2), and

1.7.2 Technique B—Grid format scanning and recording (see 8.3).

1.8 This practice addresses some meteorological conditions and limitations for performing impedance inspections.

1.9 This practice addresses the effect of the roofing or waterproofing construction, material differences, and exterior surface

conditions on the moisture inspections.

1

This practice is under the jurisdiction of ASTM Committee D08 on Roofing and Waterproofing and is the direct responsibility of Subcommittee D08.20 on Roofing

Membrane Systems.

Current edition approved July 15, 2014Feb. 15, 2015. Published August 2014March 2015. Originally approved in 2014. Last previous edition approved in 2014 as

D7954/D7954M – 14. DOI: 10.1520/D7954_D7

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.