ASTM F2228-02(2007)

(Test Method)Standard Test Method for Non-Destructive Detection of Leaks in Medical Packaging Which Incorporates Porous Barrier Material by CO2 Tracer Gas Method

Standard Test Method for Non-Destructive Detection of Leaks in Medical Packaging Which Incorporates Porous Barrier Material by CO<sub>2</sub> Tracer Gas Method

SIGNIFICANCE AND USE

Harmful biological or particulate contaminants may enter the package through incomplete seals or imperfections such as pinholes or cracks in the trays.

After initial instrument set-up and calibration, the operations of individual tests and test results do not need operator interpretation. The non-destructive nature of the test may be important when testing high value added products.

Leak test results that exceed the permissible threshold setting are indicated by audible or visual signal responses, or both, or by other means.

This non-destructive test method may be performed in either laboratory or production environments. This testing may be undertaken on either a 100 % or a statistical sampling basis. This test method, in single instrument use and current implementation, may not be fast enough to work on a production packaging line, but is well suited for statistical testing as well as package developmental design work.

SCOPE

1.1 This non-destructive test method detects leaks in non-porous rigid thermoformed trays, as well as the seal between the porous lid and the tray. The test method detects channel leaks in packages as small as 100 m (0.004 in.) diameter in the seal as well as 50 m (0.002 in.) diameter pinholes, or equivalently sized cracks in the tray, subject to trace gas concentration in the package, package design and manufacturing tolerances.

Note 1—This test method does not claim to challenge the porous (breathable) lidding material. Any defects that may exist in the porous portion of the package will not be detected by this test method.

1.2 The values stated in SI units are to be regarded as standard units. Values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2228 − 02(Reapproved 2007)

Standard Test Method for

Non-Destructive Detection of Leaks in Medical Packaging

Which Incorporates Porous Barrier Material by CO Tracer

2

1

Gas Method

This standard is issued under the fixed designation F2228; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

3.1 General Term Definitions—For definitions used in this

1.1 This non-destructive test method detects leaks in non-

standard, see Terminologies D996, F17, and F1327.

porous rigid thermoformed trays, as well as the seal between

the porous lid and the tray. The test method detects channel

3.2 Definitions of Terms Specific to This Standard:

leaksinpackagesassmallas100µm(0.004in.)diameterinthe

3.2.1 basal flow—transversetransportoftracegasacrossthe

seal as well as 50 µm (0.002 in.) diameter pinholes, or

seal due to gas flow within the plane of the porous barrier

equivalently sized cracks in the tray, subject to trace gas

material as well as flow between the porous barrier and the

concentration in the package, package design and manufactur-

temporary gasketing. This is an expected property of the

ing tolerances.

porous barrier material and does not represent a leak.

Experimentally, this flow may be thought of as noise, which

NOTE 1—This test method does not claim to challenge the porous

willalwaysbepresent,tosomedegree,duringtestingandmust

(breathable) lidding material. Any defects that may exist in the porous

be accounted for.

portion of the package will not be detected by this test method.

3.2.2 trace gas—a compound selected solely for use to

1.2 The values stated in SI units are to be regarded as

identify leakage flow.

standard units. Values in parentheses are for information only.

1.3 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

4.1 This test method utilizes CO sensing techniques in the

responsibility of the user of this standard to establish appro-

2

detection of a CO trace gas to quantify leaks in medical

priate safety and health practices and determine the applica- 2

packaging, which incorporates porous barrier material. This

bility of regulatory limitations prior to use.

test method provides a qualitative (accept/reject) inspection

method to evaluate packages for pinhole, crack and channel

2. Referenced Documents

leaks. Further information on the “Leak Test Theory” may be

2

2.1 ASTM Standards:

found in Annex A1.

D996 Terminology of Packaging and Distribution Environ-

ments

5. Significance and Use

F17 Terminology Relating to Flexible Barrier Packaging

5.1 Harmful biological or particulate contaminants may

F1327 Terminology Relating to Barrier Materials for Medi-

3

enter the package through incomplete seals or imperfections

cal Packaging (Withdrawn 2007)

such as pinholes or cracks in the trays.

5.2 After initial instrument set-up and calibration, the op-

erations of individual tests and test results do not need operator

1

This test method is under the jurisdiction ofASTM Committee F02 on Flexible

Barrier Packaging and is the direct responsibility of Subcommittee F02.40 on interpretation. The non-destructive nature of the test may be

Package Integrity.

important when testing high value added products.

Current edition approved April 1, 2007. Published May 2007. Originally

approved in 2002. Last previous edition approved in 2002 as F2228 – 02. DOI:

5.3 Leak test results that exceed the permissible threshold

10.1520/F2228-02R07.

setting are indicated by audible or visual signal responses, or

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

both, or by other means.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

5.4 This non-destructive test method may be performed in

the ASTM website.

3

either laboratory or production environments. This testing may

The last approved version of this historical standard is referenced on

www.astm.org. be undertaken on either a 100 % or a statistical sampling basis.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2228 − 02 (2007)

This test method, in single instrument use and current imple- minimum of 206.84 kPa (30 psi) pressure is required for

mentation, may not be fast enough to work on a production calibration and testing.

packaging line, but is well suited for statistical testing as well

8.2 Sealing Membrane—Th

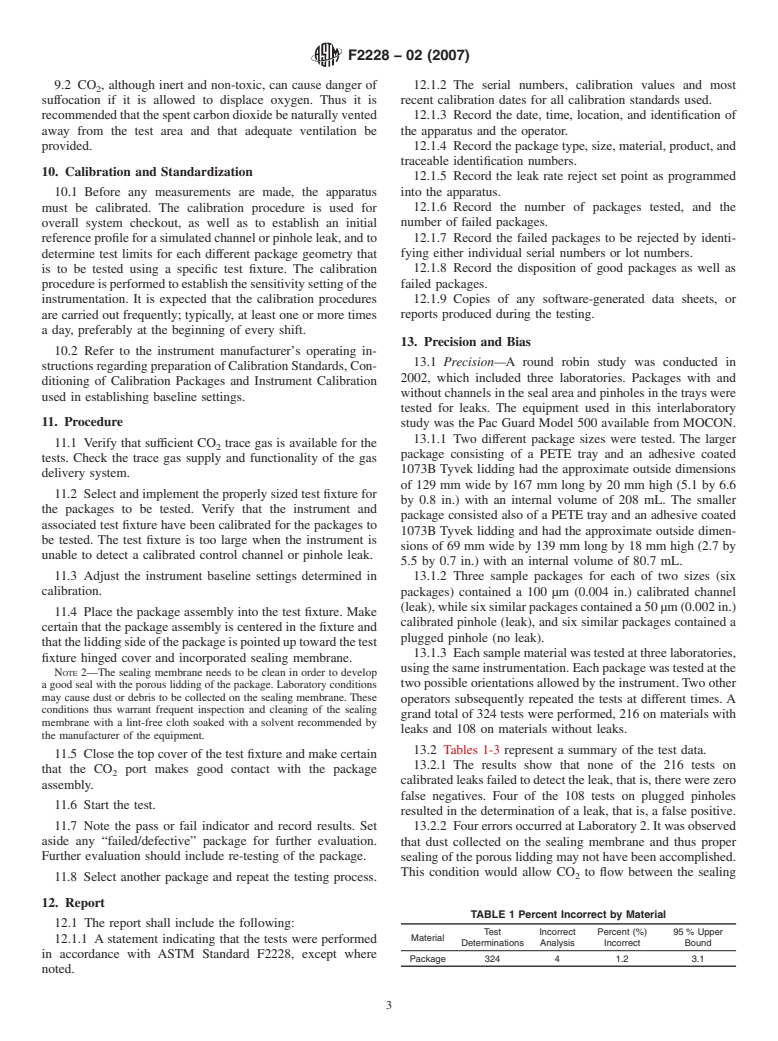

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.