ASTM C881/C881M-10

(Specification)Standard Specification for Epoxy-Resin-Base Bonding Systems for Concrete

Standard Specification for Epoxy-Resin-Base Bonding Systems for Concrete

ABSTRACT

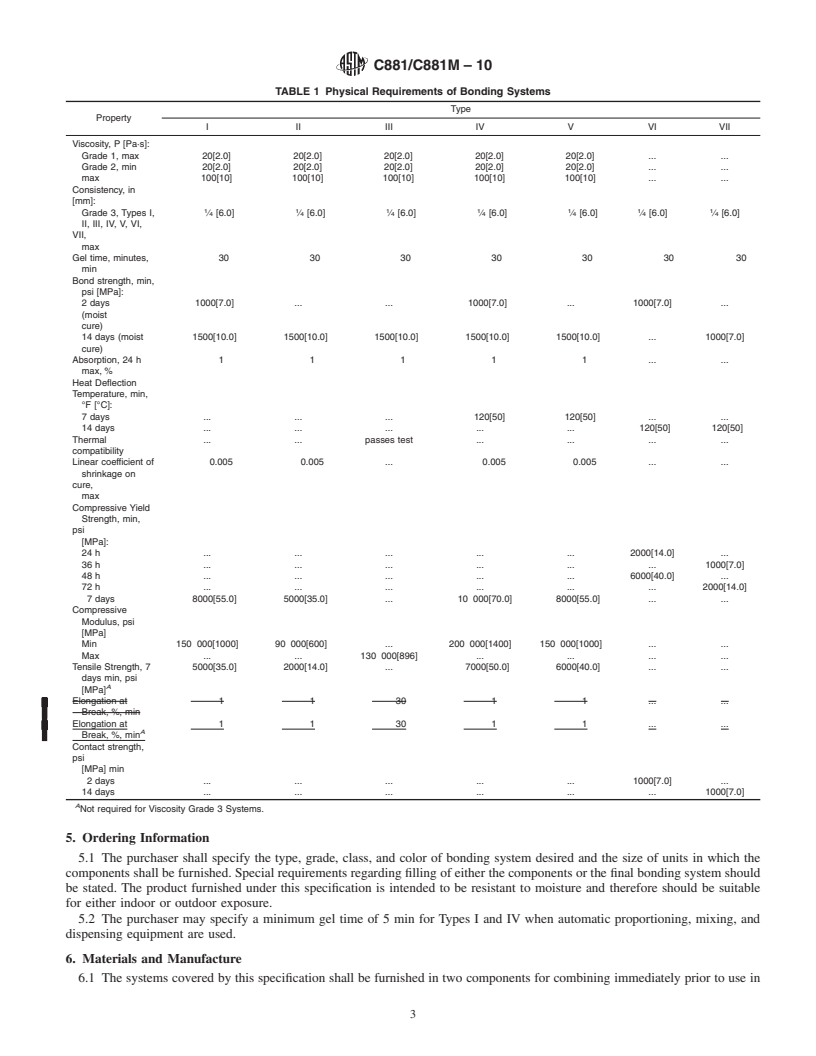

This specification covers two-component, epoxy-resin bonding systems for application to Portland-cement concrete, which are able to cure under humid conditions and bond to damp surfaces. The epoxy-resin bonding systems are classified according to type, grade, class, and color. The bonding systems can be classified as Type I, Type II, Type III, Type IV, Type V, Type VI, and Type VII according to their physical requirements. According to their flow characteristics and viscosity, the bonding systems can be classified as Grade 1, Grade 2, and Grade 3. Also, in accordance with the range of temperatures for which they are suitable, these materials can be designated as Class A, Class B, Class C, Class D, Class E, and Class F. Classes A, B, and C are defined for Types I through V, and Classes D, E, and F are defined for Types VI and VII. Epoxy resin systems are normally unpigmented, but they can be colored or darkened. These bonding systems shall be furnished in two components for combining immediately prior to use in accordance with written instructions formulated Component A shall contain an epoxy resin with or without a reactive diluent. Component B shall contain one or more curing agents, which on mixing with Component A shall cause the mixture to harden. A suitable inert filler may be uniformly incorporated in one or both components. The filler shall be either nonsettling or readily dispersible in any component in which it is incorporated. All systems shall cure under humid conditions, and bond to damp surfaces. Different test methods shall be performed to determine the following properties: consistency, gel time, filler content, epoxy equivalent, viscosity, absorption, bond strength, thermal compatibility, heat deflection temperature, linear coefficient of shrinkage, compressive yield strength and modulus, tensile strength and elongation at break, and contact strength.

SCOPE

1.1 This specification covers two-component, epoxy-resin bonding systems for application to portland-cement concrete, which are able to cure under humid conditions and bond to damp surfaces.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Some values have only SI units because the inch-pound equivalents are not used in practice. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazards statements, see Section 9.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C881/C881M −10

StandardSpecification for

1

Epoxy-Resin-Base Bonding Systems for Concrete

This standard is issued under the fixed designation C881/C881M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2566Test Method for Linear Shrinkage of Cured Thermo-

3

setting Casting Resins During Cure (Withdrawn 1993)

1.1 This specification covers two-component, epoxy-resin

bonding systems for application to portland-cement concrete,

3. Terminology

which are able to cure under humid conditions and bond to

3.1 Definitions of Terms Specific to This Standard:

damp surfaces.

3.1.1 binder, n—the cementitious part of a grout, mortar, or

1.2 The values stated in either SI units or inch-pound units

concrete that binds the aggregate or filler into a cohesive mass.

are to be regarded separately as standard. Some values have

3.1.2 bonding system, n—the product resulting from the

only SI units because the inch-pound equivalents are not used

combination of all the components supplied for use as a

in practice. Within the text, the SI units are shown in brackets.

bonding material.

Thevaluesstatedineachsystemmaynotbeexactequivalents;

3.1.3 component, n—a constituent that is intended to be

therefore,eachsystemshallbeusedindependentlyoftheother.

Combining values from the two systems may result in non- combined with one or more other constituents to form a

bonding system.

conformance with this standard.

3.1.4 contact strength, n—bond strength measured by slant

1.3 This standard does not purport to address all of the

shear after a specified contact and cure time.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.1.5 contact time, n—specified time between when the

priate safety and health practices and determine the applica-

epoxy system is applied and when the two segments are

bility of regulatory limitations prior to use.Forspecifichazards

bonded together and still achieve a specified bond strength

statements, see Section 9.

after a specified curing time and temperature.

3.1.6 curing agent, n—a substance that causes the conver-

2. Referenced Documents

sion of a fluid resin system to a solid cured resin by means of

2

2.1 ASTM Standards:

a chemical reaction.

C882Test Method for Bond Strength of Epoxy-Resin Sys-

3.1.7 epoxy equivalent, n—the weight of resin containing

tems Used With Concrete By Slant Shear

one molecular weight of epoxy groups.

C884/C884MTest Method for Thermal Compatibility Be-

3.1.8 epoxy resin, n—a resin that contains or did contain

tween Concrete and an Epoxy-Resin Overlay

epoxy groups principally responsible for its polymerization.

D570Test Method for Water Absorption of Plastics

D638Test Method for Tensile Properties of Plastics 3.1.9 filler, n—a finely divided solid, predominantly passing

D648Test Method for Deflection Temperature of Plastics the No. 200 [75-µm] sieve, that is used to improve certain

Under Flexural Load in the Edgewise Position properties of the bonding system or to reduce cost.

D695Test Method for Compressive Properties of Rigid

3.1.10 formulator, n—the agency responsible for preparing

Plastics

the separate components and for recommending the propor-

D1084Test Methods for Viscosity of Adhesives

tions to be used in preparing the final bonding system.

3.1.11 lot or batch, n—that quantity of manufactured mate-

rial which has been subjected to the same unit chemical or

1

This specification is under the jurisdiction of ASTM Committee C09 on

physical processes intended to make the final product substan-

Concrete and ConcreteAggregatesand is the direct responsibility of Subcommittee

tially uniform.

C09.25 on Organic Materials for Bonding.

Current edition approved Aug. 1, 2010. Published September 2010. Originally

3.1.12 manufacturer, n—a producer of a basic constituent

approved in 1978. Last previous edition approved in 2002 as C881–02. DOI:

part of a component.

10.1520/C0881_C0881M-10.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C881/C881M − 10

3.1.13 reactive diluent, n—a relatively free flowing liquid 4.2 Types—Seventypesofsystemsthataredistinguishedby

usedtore

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C881/C881M–02 Designation: C881/C881M – 10

Standard Specification for

1

Epoxy-Resin-Base Bonding Systems for Concrete

This standard is issued under the fixed designation C881/C881M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This specification covers two-component, epoxy-resin bonding systems for application to portland-cement concrete, which

are able to cure under humid conditions and bond to damp surfaces.

1.2 The values stated in either inch-poundSI units or SIinch-pound units are to be regarded separately as standard. Some values

have only SI units because the inch-pound equivalents are not used in practice. Within the text, the SI units are shown in brackets.

The values stated in each system aremay not be exact equivalents,; therefore, each system shall be used independently of the other.

Combining values from the two systems may result in non-conformance with this specification. standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific hazards statements, see Section 9.

2. Referenced Documents

2

2.1 ASTM Standards:

C882 Test Method for Bond Strength of Epoxy-Resin Systems Used With Concrete By Slant Shear

C884/C884M Test Method for Thermal Compatibility Between Concrete and an Epoxy-Resin Overlay

D570 Test Method for Water Absorption of Plastics

D638 Test Method for Tensile Properties of Plastics

D648 Test Method for Deflection Temperature of Plastics Under Flexural Load in the Edgewise Position

D695 Test Method for Compressive Properties of Rigid Plastics

D1259Test Methods for Nonvolatile Content of Resin Solutions

D1652Test Method for Epoxy Content of Epoxy Resins

D2393Test Method for Viscosity of Epoxy Resins and Related Components 1084 Test Methods for Viscosity of Adhesives

3

D2566 Test Method for Linear Shrinkage of Cured Thermosetting Casting Resins During Cure

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 binder, n—the cementitious part of a grout, mortar, or concrete that binds the aggregate or filler into a cohesive mass.

3.1.2 bonding system, n—the product resulting from the combination of all the components supplied for use as a bonding

material.

3.1.3 component, n—a constituent that is intended to be combined with one or more other constituents to form a bonding

system.

3.1.4 contact strength, n—bond strength measured by slant shear after a specified contact and cure time.

3.1.5 contact time, n—specifiedtimebetweenwhentheepoxysystemisappliedandwhenthetwosegmentsarebondedtogether

and still achieve a specified bond strength after a specified curing time and temperature.

1

This specification is under the jurisdiction ofASTM Committee C09 on Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee C09.25 on

Organic Materials for Bonding.

Current edition approved July 10, 2002. Published August 2002. Originally published as C881–78. Last previous edition C881–99. DOI: 10.1520/C0881_C0881M-02.

Current edition approved Aug. 1, 2010. Published September 2010. Originally approved in 1978. Last previous edition approved in 2002 as C881–02. DOI:

10.1520/C0881_C0881M-10.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Reagent Chemicals, American Chemical Society Specifications, American Chemical Society, Washington, DC. For suggestions on the testing of reagents not listed by

the American Chemical Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

3

Withdrawn. The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

------------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.