ASTM D5226-98(2003)

(Practice)Standard Practice for Dissolving Polymer Materials

Standard Practice for Dissolving Polymer Materials

SIGNIFICANCE AND USE

This practice embodies the specifications to describe the preparation of a polymeric solution.

SCOPE

1.1 This practice outlines the parameters applicable to the preparation of a polymeric solution, such as solvent, concentration, temperature, pressure, time, agitation, and heating mode.

1.2 The proper use of this practice requires a knowledge of solvents and their effect on polymeric materials.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1

There is no equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D5226–98 (Reapproved 2003)

Standard Practice for

Dissolving Polymer Materials

This standard is issued under the fixed designation D5226; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 4.1.1 Apolymer and a list of suggested solvents for making

a solution are listed in Annex A1.

1.1 This practice outlines the parameters applicable to the

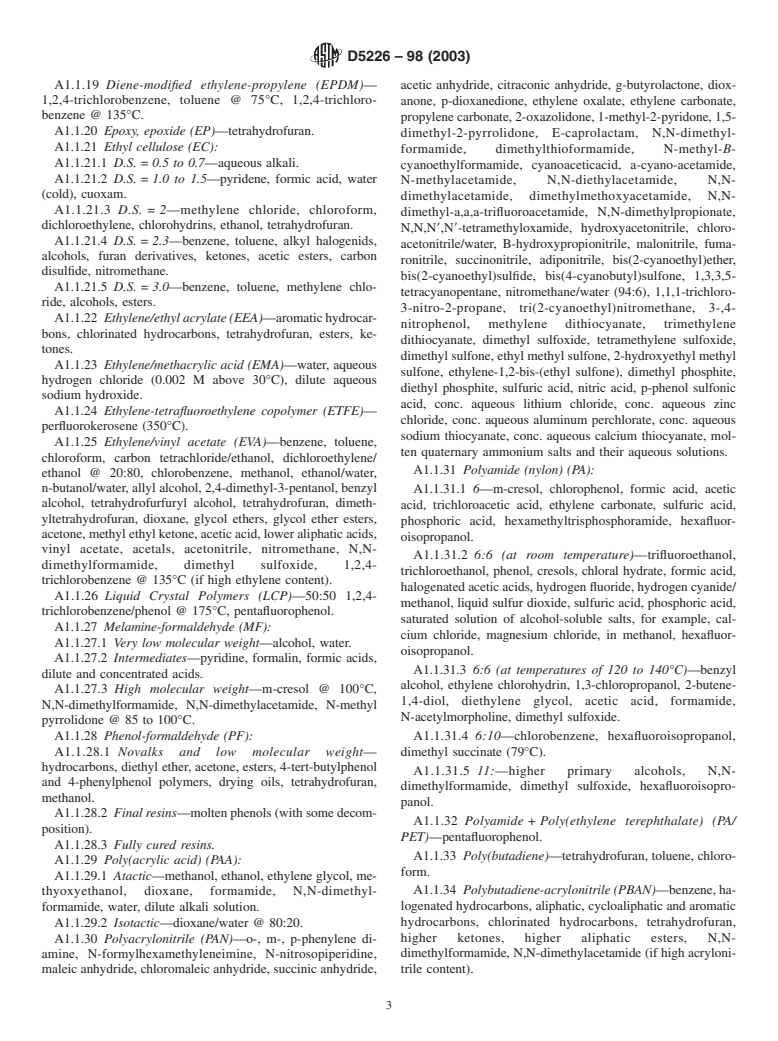

4.1.2 Table 1 designates the parameters for container, heat-

preparation of a polymeric solution, such as solvent, concen-

ing mode, and type of agitation.

tration, temperature, pressure, time, agitation, and heating

mode.

NOTE 2—To illustrate the use of the cell classifications with Table 1,a

1.2 The proper use of this practice requires a knowledge of

2 % solution of poly(vinyl chloride) using cyclohexanone would be

written as:

solvents and their effect on polymeric materials.

1.3 This standard does not purport to address all of the

PVC2cyclohexanone2202662402BEC

safety concerns, if any, associated with its use. It is the

where:

responsibility of the user of this standard to establish appro-

PVC = the abbreviation of the polymer from Annex A1,

priate safety and health practices and determine the applica-

cyclohexanone = the solvent from Annex A1,

bility of regulatory limitations prior to use.

20 = the weight of polymer in tenths of a percent,

66 = the temperature in degrees Celsius,

NOTE 1—There is no equivalent ISO standard.

40 = the time in tenths of an hour,

B = glass container from Table 1,

2. Referenced Documents

E = bath heater from Table 1, and

2.1 ASTM Standards:

C = random agitation from Table 1.

D883 Terminology Relating to Plastics

5. Significance and Use

D1600 Terminology for Abbreviated Terms Relating to

Plastics

5.1 This practice embodies the specifications to describe the

2.2 Other Document:

preparation of a polymeric solution.

Polymer Handbook

6. Procedure

3. Terminology

6.1 Polymer—Select the applicable polymer from Annex

3.1 Definitions are in accordance with Terminology D883.

A1 and write its abbreviation.

3.2 Abbreviations are in accordance with Terminology

6.2 Solvent—Select the solvent applicable to the polymer

D1600.

from Annex A1.

6.3 Concentration—Write the polymer gram weight in

4. Summary of Practice

tenths of a percent per milliliter of solvent.

4.1 A polymer solution can be described or prepared using

6.4 Temperature—Writethesolutiontemperatureindegrees

the cell classifications listing the parameters relative to solvate

Celsius.

the polymer. The cell classifications are listed in the following

6.5 Time—Write the time for solution in tenths of an hour.

order: polymer, solvent, concentration, temperature, time, con-

6.6 Container—Select the type of container from Table 1.

tainer, heating mode, and agitation.

6.7 Heating Mode—Select the heating mode from Table 1.

6.8 Agitation—Select the agitation mode from Table 1.

7. Precision and Bias

Thispracticeisunderthe jurisdiction ofASTM CommitteeD20onPlasticsand

is the direct responsibility of Subcommittee D20.70 on Analytical Methods.

7.1 No statement is made about the precision or bias of this

Current edition approved November 1, 2003. Published December 2003.

practice since the procedure is descriptive with no measure-

Originally approved in 1992. Last previous edition approved in 1998 as D5226 - 98.

ments being made.

DOI: 10.1520/D5226-98R03.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

8. Keywords

Standards volume information, refer to the standard’s Document Summary page on

8.1 polymer solutions; solution preparation; solutions;

the ASTM website.

Available from John Wiley and Sons, New York, NY. solvents

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5226–98 (2003)

TABLE 1 Parameters

Designation Container Heater Mode Agitation Mode

A unspecified unspecified unspecified

B glass none none

C sealed glass vial oven random

D metal hot plate magnetic stirrer

E fluoropolymer bath propeller blade

F block heater wrist action

G electric mantle ultrasonic

H microwave

ANNEX

(Mandatory Information)

A1. SUGGESTED SOLVENTS FOR POLYMERIC SOLUTIONS

A1.1 Note the following: A1.1.12.2 S.C.=15to30%—water (sodium salt).

A1.1.12.3 S.C. = high—benzene/alcohol, benzene/acetone,

A1.1.1 The solvents are listed in random order.

chloroform, pyridine, acetone, esters, tetrahydrofuran.

A1.1.2 An increase in polymer molecular weight reduces

A1.1.13 Cellulose Acetate (CA):

solubility.

A1.1.3 Branching increases the solubility compared to a A1.1.13.1 D.S. = 0.6 to 0.8—water.

linear polymer of the same molecular weight.

A1.1.13.2 D.S. = 1.3 to 1.7—2-methoxyethanol.

A1.1.4 Solubility normally increases with rising tempera-

A1.1.13.3 D.S. = 2.0 to 2.3—methylene chloride/methanol

ture.

@ 80:20, chloroform/methanol, benzyl alcohol, phenols, eth-

A1.1.5 The temperature is for room temperature unless

yleneglycolethers,dioxane,diethanolamine,pyridine,analine,

noted.

acetone, cyclohexanone, formic acid, acetic acid (glacial),

A1.1.6 The following abbreviations are used:

methyl acetate, ethyl acetate/nitrobenzene, glycol monoethyl

D.S. degree of substitution

ether acetate, nitromethane, tetrahydrofuran.

S.C. substituent content

A1.1.14 Cellulose acetate-butyrate (CAB):

conc. concentrated

A1.1.14.1 D.S. (acetate) = 0.8 and D.S. (butyrate) = 2.35—

A1.2 Solvents:

benzene, toluene (hot), chloroform, carbon tetrachloride, tetra-

A1.1.7 Acrylonitrile-butadiene-acrylate (ABA)—aromatic

chloroethane, methanol (hot), acetone, cyclo-hexanone, diox-

hydrocarbons, chlorinated hydrocarbons, tetrahydrofuran, es-

ane, aliphatic esters, nitroethane.

ters, ketones, N,N-dimethylformamide, N,N-dimethyl-

A1.1.14.2 D.S. (acetate) = 2.1 and D.S. (butyrate) = 0.7—

acetamide (if high acrylonitrile).

chloroform, dichloroethane, tetrachloroethane, dioxane, ac-

A1.1.8 Acrylonitrile-butadiene-styrene (ABS)—N,N-

etone, cyclohexanone, methyl acetate, ethyl acetate, nitroet-

dimethylformamide, N,N-dimethylacetamide (if high acryloni-

hane.

trile), cyclohexanone (above 35°C), cyclohexanone/acetone,

A1.1.15 Cellulose acetate propionate (CAP)—benzene,

methylcyclohexane/acetone, decahydronaphthalene/dimethyl

dichloromethane, chlorobenzene, acetone, ethyl acetate.

oxalate, benzene, toluene, ethylbenzene, styrene, lower chlori-

A1.1.16 Cellulose nitrate (CN):

nated hydrocarbons, phenol/acetone, tetrahydrofuran, dimeth-

A1.1.16.1 N = 6.8 %—water.

yltetrahydrofuran, dioxane, methyl ethyl ketone, diisopropyl

A1.1.16.2 N = 10.5 to 12 %—alcohol (lower), alcohol/

ketone, glycol formal, ethyl acetate, butyl acetate, methyl-,

diethyl ether, acetone, amyl acetate, ethylene glycol ethers,

ethyl-, n-butyl phthalate, 1-nitropropane, carbon disulfide,

acetic acid (glacial).

tributyl phosphate, phosphorus trichloride.

A1.1.16.3 N = 12.7 %—halogenated hydrocarbons,

A1.1.9 Alkydes—tetrahydrofuran.

ethanol/diethyl ether, acetone, methyl amyl acetone, cyclo-

A1.1.10 Arylonitrile/methyl methacrylate (AMMA)—

hexanone, methyl acetate, ethyl acetate, ethyl butyrate, ethyl

benzene, toluene, xylene, methylene chloride, chloroform,

lactate, ethylene glycol ether acetates, ethylene carbonate,

ethylene chloride, chlorobenzene, isobutanol (hot), cyclohex-

furan derivatives, nitrobenzene.

anol (hot), B-ethoxyethanol, dioxane, methyl ethyl ketone,

A1.1.17 Cellulose propionate (CP)—benzene, dichloro-

diisopropylketone,cyclohexanone,aceticacid,isobutyricacid,

ethane, chlorobenzene, acetone, ethyl acetate.

methyl formate, ethyl acetate, cyclohexyl acetate, isobutyl

propionate, butyl lactate. A1.1.18 Cellulose triacetate (CTA)—methylene chloride,

A1.1.11 Allyl diglycol carbonate (ADC)—benzene, chloro- methylene chloride/ethanol @ 80:20, chloroform, chloroform/

form, acetone. alcohol, trichloroethane, tetrahydrofuran, dioxane, acetone,

A1.1.12 Carboxymethyl cellulose (CMC): acetone/water @ 80:20, methyl acetate, ethylene glycol ether

A1.1.12.1 S.C. = 5 to 10 %—alkali. acetates, ethylene carbonate.

D5226–98 (2003)

A1.1.19 Diene-modified ethylene-propylene (EPDM)— acetic anhydride, citraconic anhydride, g-butyrolactone, diox-

1,2,4-trichlorobenzene, toluene @ 75°C, 1,2,4-trichloro- anone, p-dioxanedione, ethylene oxalate, ethylene carbonate,

benzene @ 135°C.

propylenecarbonate,2-oxazolidone,1-methyl-2-pyridone,1,5-

A1.1.20 Epoxy, epoxide (EP)—tetrahydrofuran.

dimethyl-2-pyrrolidone, E-caprolactam, N,N-dimethyl-

A1.1.21 Ethyl cellulose (EC):

formamide, dimethylthioformamide, N-methyl-B-

A1.1.21.1 D.S. = 0.5 to 0.7—aqueous alkali.

cyanoethylformamide, cyanoaceticacid, a-cyano-acetamide,

A1.1.21.2 D.S. = 1.0 to 1.5—pyridene, formic acid, water

N-methylacetamide, N,N-diethylacetamide, N,N-

(cold), cuoxam.

dimethylacetamide, dimethylmethoxyacetamide, N,N-

A1.1.21.3 D.S. = 2—methylene chloride, chloroform,

dimethyl-a,a,a-trifluoroacetamide, N,N-dimethylpropionate,

dichloroethylene, chlorohydrins, ethanol, tetrahydrofuran.

N,N,N8,N8-tetramethyloxamide, hydroxyacetonitrile, chloro-

A1.1.21.4 D.S. = 2.3—benzene, toluene, alkyl halogenids,

acetonitrile/water, B-hydroxypropionitrile, malonitrile, fuma-

alcohols, furan derivatives, ketones, acetic esters, carbon

ronitrile, succinonitrile, adiponitrile, bis(2-cyanoethyl)ether,

disulfide, nitromethane.

bis(2-cyanoethyl)sulfide, bis(4-cyanobutyl)sulfone, 1,3,3,5-

A1.1.21.5 D.S. = 3.0—benzene, toluene, methylene chlo-

tetracyanopentane, nitromethane/water (94:6), 1,1,1-trichloro-

ride, alcohols, esters.

3-nitro-2-propane, tri(2-cyanoethyl)nitromethane, 3-,4-

A1.1.22 Ethylene/ethylacrylate(EEA)—aromatichydrocar-

nitrophenol, methylene dithiocyanate, trimethylene

bons, chlorinated hydrocarbons, tetrahydrofuran, esters, ke-

dithiocyanate, dimethyl sulfoxide, tetramethylene sulfoxide,

tones.

dimethyl sulfone, ethyl methyl sulfone, 2-hydroxyethyl methyl

A1.1.23 Ethylene/methacrylic acid (EMA)—water, aqueous

sulfone, ethylene-1,2-bis-(ethyl sulfone), dimethyl phosphite,

hydrogen chloride (0.002 M above 30°C), dilute aqueous

diethyl phosphite, sulfuric acid, nitric acid, p-phenol sulfonic

sodium hydroxide.

acid, conc. aqueous lithium chloride, conc. aqueous zinc

A1.1.24 Ethylene-tetrafluoroethylene copolymer (ETFE)—

chloride, conc. aqueous aluminum perchlorate, conc. aqueous

perfluorokerosene (350°C).

sodium thiocyanate, conc. aqueous calcium thiocyanate, mol-

A1.1.25 Ethylene/vinyl acetate (EVA)—benzene, toluene,

ten quaternary ammonium salts and their aqueous solutions.

chloroform, carbon tetrachloride/ethanol, dichloroethylene/

A1.1.31 Polyamide (nylon) (PA):

ethanol @ 20:80, chlorobenzene, methanol, ethanol/water,

n-butanol/water, allyl alcohol, 2,4-dimethyl-3-pentanol, benzyl

A1.1.31.1 6—m-cresol, chlorophenol, formic acid, acetic

alcohol, tetrahydrofurfuryl alcohol, tetrahydrofuran, dimeth-

acid, trichloroacetic acid, ethylene carbonate, sulfuric acid,

yltetrahydrofuran, dioxane, glycol ethers, glycol ether esters,

phosphoric acid, hexamethyltrisphosphoramide, hexafluor-

acetone, methyl ethyl ketone, acetic acid, lower aliphatic acids,

oisopropanol.

vinyl acetate, acetals, acetonitrile, nitromethane, N,N-

A1.1.31.2 6:6 (at room temperature)—trifluoroethanol,

dimethylformamide, dimethyl sulfoxide, 1,2,4-

trichloroethanol, phenol, cresols, chloral hydrate, formic acid,

trichlorobenzene @ 135°C (if high ethylene content).

halogenated acetic acids, hydrogen fluoride, hydrogen cyanide/

A1.1.26 Liquid Crystal Polymers (LCP)—50:50 1,2,4-

methanol, liquid sulfur dioxide, sulfuric acid, phosphoric acid,

trichlorobenzene/phenol @ 175°C, pentafluorophenol.

saturated solution of alcohol-soluble salts, for example, cal-

A1.1.27 Melamine-formaldehyde (MF):

cium chloride, magnesium chloride, in methanol, hexafluor-

A1.1.27.1 Very low molecular weight—alcohol, water.

oisopropanol.

A1.1.27.2 Intermediates—pyridine, formalin, formic acids,

A1.1.31.3 6:6 (at temperatures of 120 to 140°C)—benzyl

dilute and concentrated acids.

alcohol, ethylene chlorohydrin, 1,3-chloropropanol, 2-butene-

A1.1.27.3 High molecular weight—m-cresol @ 100°C,

1,4-diol, diethylene glycol, acetic acid, formamide,

N,N-dimethylformamide, N,N-dimethylacetamide, N-methyl

N-acetylmorpholine, dimethyl sulfoxide.

pyrrolidone @ 85 to 100°C.

A1.1.28 Phenol-formaldehyde (PF): A1.1.31.4 6:10—chlorobenzene, hexafluoroisopropanol,

A1.1.28.1 Novalks and low molecular weight— dimethyl succinate (79°C).

hydrocarbons, diethyl ether, acetone, esters, 4-tert-butylphenol

A1.1.31.5 11:—higher primary alcohols, N,N-

and 4-phenylphenol polymers, drying oils, tetrahydrofuran,

dimethylformamide, dimethyl sulfoxide, hexafluoroisopro-

methanol.

panol.

A1.1.28.2 Finalresins—moltenphenols(withsomedecom-

A1.1.32 Polyamide + Poly(ethylene terephthalate) (PA/

position).

PET)—pentafluorophenol.

A1.1.28.3 Fully cured resins.

A1.1.33 Poly(butadiene)—tetrahydrofuran, toluene, chloro-

A1.1.29 Poly(acrylic acid) (PAA):

form.

A1.1.29.1 Atactic—methanol, ethanol, ethylene glycol, me-

A1.1.34 Polybutadiene-acrylonitrile(PBAN)—benzene,ha-

thyoxyethanol, dioxane, formamide, N,N-dimethyl-

formamide, water, dilute alkali solution. logenated hydrocarbons, aliphatic, cycloaliphatic and aromatic

A1.1.29.2 Isotactic—dioxane/water @ 80:20. hydrocarbons, chlorinated hydrocarbons, tetrahydrofuran,

higher ketones, higher aliphatic esters, N,N-

A1.1.30 Polyacrylonitrile (PAN)—o-, m-, p-phenylene di-

dimethylformamide, N,N-dimethylacetamide (if high acryloni-

amine, N-formylhexamethyleneimine, N-nitrosopiperidine,

maleic anhydride, chloromaleic anhydride, succinic anhydride, trile content).

D5226–98 (2003)

A1.1.35 Polybutadiene-styrene (PBS)—benzene, haloge- A1.1.54 Poly(4-methylpentene-1), isotactic (PMP)—see

nated hydrocarbons, aliphatic, cycloaliphatic and aromatic Poly(ethylene).

hydrocarbons, chlorinated hydrocarbons, tetrahydrofuran,

A1.1.55 Polymonochlorotrifluoroethylene (PCTFE)—

higher ketones, higher aliphatic esters.

cyclohexane (235°C), benzene (200°C), toluene (142°C),

A1.1.36 Poly(butylene terephthalate) (PBT)—m-cresol @

p-xylene (140°C), 1,1,1-trichloroethane (120°C), carbon tetra-

100°C, hexafluoroisopropanol.

chloride (114°C), 1,2,3-trifluoropentachloropropane, 1,1,2,2-

A1.1.37 Polybutene-1 (PB)—see polyethylene.

tetrafluoro-3,3,4,4-tetrachlorocyclobutane, 1,2-

A1.1.38 Polycarbonate (PC)—benzene, chloroform, ac-

dichlorotrifluorobenzene, 2,5-

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.