ASTM E1421-99(2009)

(Practice)Standard Practice for Describing and Measuring Performance of Fourier Transform Mid-Infrared (FT-MIR) Spectrometers: Level Zero and Level One Tests

Standard Practice for Describing and Measuring Performance of Fourier Transform Mid-Infrared (FT-MIR) Spectrometers: Level Zero and Level One Tests

SIGNIFICANCE AND USE

This practice permits an analyst to compare the general performance of an instrument on any given day with the prior performance of an instrument. This practice is not necessarily meant for comparison of different instruments with each other even if the instruments are of the same type and model. This practice is not meant for comparison of the performance of one instrument operated under differing conditions.

SCOPE

1.1 This practice describes two levels of tests to measure the performance of laboratory Fourier transform mid-infrared (FT-MIR) spectrometers equipped with a standard sample holder used for transmission measurements.

1.2 This practice is not directly applicable to Fourier transform infrared (FT-IR) spectrometers equipped with various specialized sampling accessories such as flow cells or reflectance optics, nor to Fourier transform near-infrared (FT-NIR) spectrometers, nor to FT-IR spectrometers run in step scan mode.

1.2.1 If the specialized sampling accessory can be removed and replaced with a standard transmission sample holder, then this practice can be used. However, the user should recognize that the performance measured may not reflect that which is achieved when the specialized accessory is in use.

1.2.2 If the specialized sampling accessory cannot be removed, then it may be possible to employ a modified version of this practice to measure spectrometer performance. The user is referred to Guide E 1866 for a discussion of how these tests may be modified.

1.2.3 Spectrometer performance tests for FT-NIR spectrometers are described in Practice E 1944.

1.2.4 Performance tests for dispersive MIR instruments are described in Practice E 932.

1.2.5 For FT-IR spectrometers run in a step scan mode, variations on this practice and information provided by the instrument vendor should be used.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1421 − 99 (Reapproved2009)

Standard Practice for

Describing and Measuring Performance of Fourier

Transform Mid-Infrared (FT-MIR) Spectrometers: Level Zero

and Level One Tests

This standard is issued under the fixed designation E1421; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E932PracticeforDescribingandMeasuringPerformanceof

Dispersive Infrared Spectrometers

1.1 Thispracticedescribestwolevelsofteststomeasurethe

E1866Guide for Establishing Spectrophotometer Perfor-

performance of laboratory Fourier transform mid-infrared

mance Tests

(FT-MIR) spectrometers equipped with a standard sample

E1944Practice for Describing and Measuring Performance

holder used for transmission measurements.

of Laboratory Fourier Transform Near-Infrared (FT-NIR)

1.2 This practice is not directly applicable to Fourier trans-

Spectrometers: Level Zero and Level One Tests

form infrared (FT-IR) spectrometers equipped with various

specialized sampling accessories such as flow cells or reflec-

3. Terminology

tance optics, nor to Fourier transform near-infrared (FT-NIR)

3.1 Definitions—For definitions of terms used in this

spectrometers, nor to FT-IR spectrometers run in step scan

practice, refer to Terminology E131. All identifications of

mode.

spectral regions and absorption band positions are given in

1.2.1 If the specialized sampling accessory can be removed −1

wavenumbers (cm ), and spectral energy, transmittance, and

and replaced with a standard transmission sample holder, then

absorbance are signified in equations by the letters E, T, and A

this practice can be used. However, the user should recognize

respectively. The ratio of two transmittance or absorbance

that the performance measured may not reflect that which is

values, and the ratio of energy levels at two different wave-

achieved when the specialized accessory is in use.

numbers are signified by the letter R. A subscripted number

1.2.2 If the specialized sampling accessory cannot be

signifies a spectral position in wavenumbers (for example,

removed,thenitmaybepossibletoemployamodifiedversion −1

A , the absorbance at 3082 cm ).

ofthispracticetomeasurespectrometerperformance.Theuser

3.1.1 level one (1) test, n—a simple series of measurements

is referred to Guide E1866 for a discussion of how these tests

designed to provide quantitative data on various aspects of

may be modified.

instrument performance and information on which to base the

1.2.3 SpectrometerperformancetestsforFT-NIRspectrom-

diagnosis of problems.

eters are described in Practice E1944.

3.1.2 level zero (0) test, n—a routine check of instrument

1.2.4 Performance tests for dispersive MIR instruments are

performance, that can be done in a few minutes, designed to

described in Practice E932.

visually detect significant changes in instrument performance

1.2.5 For FT-IR spectrometers run in a step scan mode,

and provide a database to determine instrument function over

variations on this practice and information provided by the

time.

instrument vendor should be used.

4. Significance and Use

2. Referenced Documents

4.1 This practice permits an analyst to compare the general

2.1 ASTM Standards:

E131Terminology Relating to Molecular Spectroscopy performance of an instrument on any given day with the prior

performance of an instrument. This practice is not necessarily

This practice is under the jurisdiction ofASTM Committee E13 on Molecular meant for comparison of different instruments with each other

Spectroscopy and Separation Science and is the direct responsibility of Subcom-

even if the instruments are of the same type and model. This

mittee E13.03 on Infrared and Near Infrared Spectroscopy.

practiceisnotmeantforcomparisonoftheperformanceofone

Current edition approved March 1, 2009. Published March 2009. Originally

instrument operated under differing conditions.

approved in 1991. Last previous edition approved in 2004 as E1421–99(2004).

DOI: 10.1520/E1421-99R09.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 5. Test Conditions

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1 Operating Conditions—A record should be kept to

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. document the operating conditions selected so that they can be

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1421 − 99 (2009)

duplicated. In obtaining spectrophotometric data, the analyst 6. Level Zero Tests

must select proper instrumental operating conditions such as

6.1 Nature of Tests—Routine checks of instrument

warm-uptime,purgerate,andbeamsplitteralignmentinorder

performance, these tests can be performed in a few minutes.

to realize satisfactory instrument performance. Operating con-

Theyaredesignedtouncovermalfunctionsorotherchangesin

ditions for individual instruments are best obtained from the

instrument operation but not to specifically diagnose or quan-

manufacturer’sliteraturebecauseofvariationswithinstrument

titatively assess any malfunction. It is recommended that the

design. It should be noted that many FT-IR instruments are

levelzerotestsbeconductedatthehighest(smallestnumerical

designed to work best when left on or in the standby mode.

value) resolution at which the instrument is typically used in

Also note that spectrometers are to be tested only within their

normal operation.Anominal measurement time of 30 s should

respective wavenumber ranges.

be used. The exact measurement time, along with the date,

NOTE 1—This practice is designed to be used in situations where the time, sample identification, number of scans, exact data col-

detector is not saturated. In some instruments, with some combinations of

lection and computation parameters, and operator’s name,

optics and detectors, the detector electronics are saturated with an empty

should always be recorded.

beam. These instruments are designed to have the infrared beam attenu-

ated in the spectrometer or sample compartment to eliminate detector

6.2 Philosphy—The philosophy of the tests is to use previ-

saturation. Consult your instrument manual or discuss appropriate attenu-

ously stored test results as bases for comparison and the visual

ation techniques with the instrument vendor.

display screen or plotter to overlay the current test results with

5.2 The environment in which a spectrometer is operated

the known, good results. If the old and new results agree, they

can affects its performance. Spectrometers should only be

are simply reported as no change. Level zero consists of three

operated in environments consistent with manufacturer’s rec-

tests. The tests are run under the same conditions that are

ommendations.Changesintheinstrumentenvironmentinclud-

normally used to run a sample (that is, purge time, warm-up

ing variations in temperature, vibration or sound levels, elec-

time, detector, etc.).

trical power or magnetic fields should be recorded.

6.3 Variations in Operating Procedure for Different

5.3 Instrumental characteristics can influence these mea-

Instruments—MostoftheexistingFT-IRinstrumentsshouldbe

surements in several ways.

able to use the tests in this practice without modification.

5.3.1 Vignetting of the beam reduces the transmittance

However, a few instruments may not be able to perform the

value measured in nonabsorbing regions, and on most instru-

tests exactly as they are written. In these cases, it should be

ments can change the apparent wavenumber scale by a small

possible to obtain the same final data using a slightly different

−1

amount, usually less than 0.1 cm . Make sure that the film

procedure. Practice E1866 and the FT-IR manufacturer should

holder does not vignet the beam.

be consulted for appropriate alternative procedures.

5.3.2 Focus changes can also change transmittance values,

6.4 Sample—The recommended sample is described in 5.3.

so the sample should be positioned in approximately the same

It is a matte-finish polystyrene film (approximately 38-µm

location in the sample compartment each time.

thick, in a 2.5-cm aperture). The same sample should be used

5.3.3 The angle of acceptance (established by the f number)

for all comparisons (note serial number).

of the optics between the sample and detector significantly

affects apparent transmittance. Changes to the optical path

6.5 Reference Spectra—Two spectra acquired and stored

including the introduction of samples can alter the acceptance

following the last major instrument maintenance are used as

angle.

references. Major maintenance could include changes in

5.3.4 Heating of the sample by the beam or by the higher

source, laser, detector, or optical alignment. These spectra will

temperatures which exist inside most spectrometers changes

be identified as Reference 1 and Reference 2.

absorbances somewhat, and even changes band ratios and

6.5.1 Reference Spectrum 1 is a single-beam energy spec-

locations slightly. Allow the sample to come to thermal

trum of an empty beam. (In this and all later usage, empty

equilibrium before measurement.

beam means that nothing is in the sample path except air or

the purge gas normally present within the spectrometer sample

5.4 The recommended sample of matte-finish polystyrene

compartment). If possible, the interferogram corresponding to

usedforthesetestsisapproximately38-µm(1.5-mil)thickfilm

Reference Spectrum 1 should also be saved.

mounted on a card. The sample is mounted in a 2.5-cm (1-in.)

circularaperturecenteredwithinthe5-cm(2.5-in.)widthofthe 6.5.2 Reference Spectrum 2 is a transmittance spectrum of

the polystyrene sample. Optionally, an absorbance spectrum

card,andcentered3.8cm(1.5in.)fromthebottomofthecard.

The card should be approximately 0.25-cm (0.1-in.) thick and may also be stored.

individually and unambiguously identified.Apolystyrene film

NOTE 3—If the instrument software will not allow for subtraction of

meeting these requirements is available from the National

transmittance spectra, Reference Spectrum 2 should be saved as an

Institute of Standards and Technology (NIST) as SRM 1921.

absorbance spectrum.

NOTE 2—Very small beam diameters can defeat the interference fringe

6.6 Reproducibility of Procedures—Care should be taken

suppression provided by the matte finish on the sample.

that each of the spectral measurements is made in a consistent

and reproducible manner, including sample orientation (al-

though different spectral measurements do not necessarily use

SRM 1921 is available from the Standard Reference Materials Program,

the identical procedure). In particular, for those instruments

NationalInstituteofStandardsandTechnology(NIST),100BureauDr.,Stop1070,

Gaithersburg, MD 20899-1070, http://www.nist.gov. having more than one sample beam or path in the main sample

E1421 − 99 (2009)

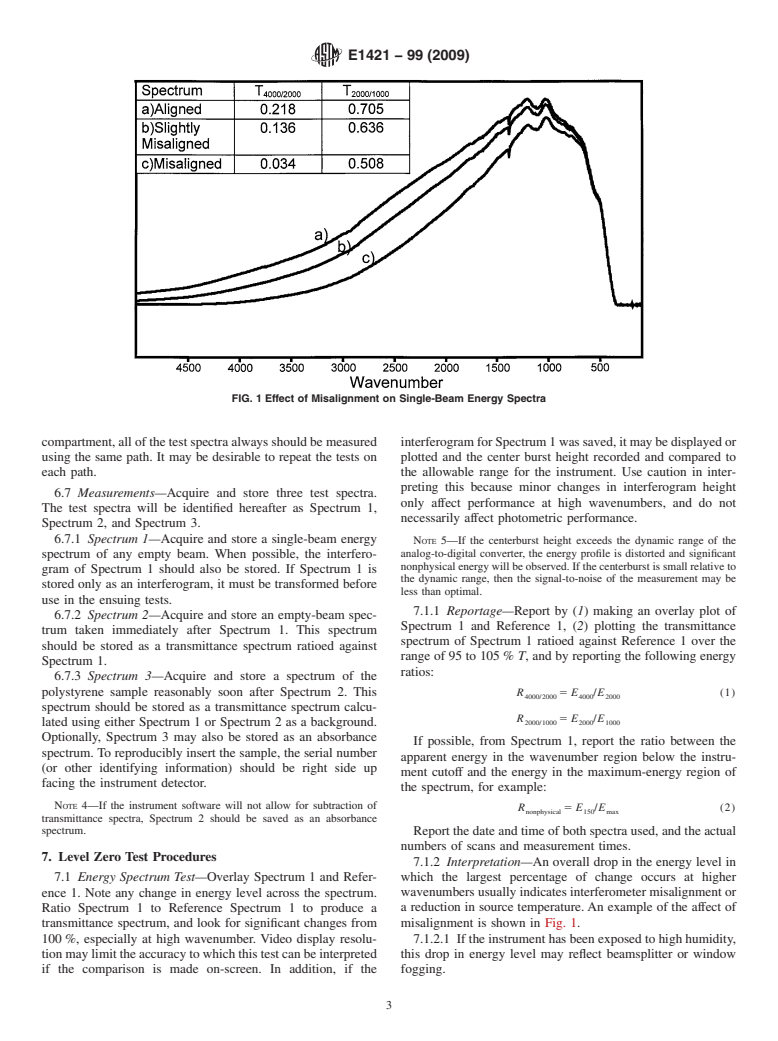

FIG. 1 Effect of Misalignment on Single-Beam Energy Spectra

compartment,allofthetestspectraalwaysshouldbemeasured interferogramforSpectrum1wassaved,itmaybedisplayedor

using the same path. It may be desirable to repeat the tests on plotted and the center burst height recorded and compared to

each path. the allowable range for the instrument. Use caution in inter-

preting this because minor changes in interferogram height

6.7 Measurements—Acquire and store three test spectra.

only affect performance at high wavenumbers, and do not

The test spectra will be identified hereafter as Spectrum 1,

necessarily affect photometric performance.

Spectrum 2, and Spectrum 3.

6.7.1 Spectrum 1—Acquire and store a single-beam energy

NOTE 5—If the centerburst height exceeds the dynamic range of the

spectrum of any empty beam. When possible, the interfero- analog-to-digital converter, the energy profile is distorted and significant

nonphysicalenergywillbeobserved.Ifthecenterburstissmallrelativeto

gram of Spectrum 1 should also be stored. If Spectrum 1 is

the dynamic range, then the signal-to-noise of the measurement may be

stored only as an interferogram, it must be transformed before

less than optimal.

use in the ensuing tests.

7.1.1 Reportage—Report by (1) making an overlay plot of

6.7.2 Spectrum 2—Acquire and store an empty-beam spec-

Spectrum 1 and Reference 1, (2) plotting the transmittance

trum taken immediately after Spectrum 1. This spectrum

spectrum of Spectrum 1 ratioed against Reference 1 over the

should be stored as a transmittance spectrum ratioed against

range of 95 to 105% T, and by reporting the following energy

Spectrum 1.

ratios:

6.7.3 Spectrum 3—Acquire and store a spectrum of the

polystyrene sample reasonably soon after Spectrum 2. This R 5 E /E (1)

4000/2000 4000 2000

spectrum should be stored as a transmittance spectrum calcu-

R 5 E /E

2000/1000 2000 1000

lated using either Spectrum 1 or Spectrum 2 as a background.

Optionally, Spectrum 3 may also be stored as an absorbance

If possible, from Spectrum 1, report the ratio between the

spectrum.To reproducibly insert the sample, the serial number

apparent energy in the wavenumber region below the instru-

(or other identifying information) should be right side up

ment cutoff and the energy in the maximum-energy region of

facing the instrument detector.

the spectrum, for example:

NOTE 4—If the instrument software will not allow for subtraction of

R 5 E /E (2)

nonphysical 150 max

transmittance spectra, Spectrum 2 should be saved as an absorbance

spectrum. Reportthedateandtimeofbothspectraused,andtheactual

numbers of scans and measurement times.

7. Level Zero Test Procedures

7.1.2 Interpretation—An overall drop in the energy level in

7.1 Energy Spectrum Test—Overlay Spectrum 1 and Refer- which the largest percentage of change occurs at higher

wavenumbersusuallyindicatesinterferometermisalignmentor

ence 1. Note any change in energy level across the spectrum.

Ratio Spectrum 1 to Reference Spectrum 1 to produce a a reduction in source temperature.An example of the affect of

misalignment is shown in Fig. 1.

transmittance spectrum, and look for significant changes from

100%, especially at high wavenumber. Video display resolu- 7.1.2.1 Iftheinstrumenthasbeenexposedtohighhumidity,

tionmaylimittheaccuracytowhichthistestcanbeinterpreted this drop in energy level may reflect beamsplitter or window

if the comparison is made on-screen. In addition, if the fogging.

E1421 − 99 (2009)

FIG. 2 Example of Nonphysical Energy

7.1.2.2 An overall drop in the energy level without wave- somet

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E1421–99(Reapproved2004) Designation:E1421–99(Reapproved2009)

Standard Practice for

Describing and Measuring Performance of Fourier

Transform Mid-Infrared (FT-MIR) Spectrometers: Level Zero

and Level One Tests

This standard is issued under the fixed designation E1421; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice describes two levels of tests to measure the performance of laboratory Fourier transform mid-infrared

(FT-MIR) spectrometers equipped with a standard sample holder used for transmission measurements.

1.2 This practice is not directly applicable to Fourier transform infrared (FT-IR) spectrometers equipped with various

specialized sampling accessories such as flow cells or reflectance optics, nor to Fourier Transform Near-Infraredtransform

near-infrared (FT-NIR) spectrometers, nor to FT-IR spectrometers run in step scan mode.

1.2.1 If the specialized sampling accessory can be removed and replaced with a standard transmission sample holder, then this

practice can be used. However, the user should recognize that the performance measured may not reflect that which is achieved

when the specialized accessory is in use.

1.2.2 If the specialized sampling accessory cannot be removed, then it may be possible to employ a modified version of this

practice to measure spectrometer performance. The user is referred to Guide E1866 for a discussion of how these tests may be

modified.

1.2.3 Spectrometer performance tests for FT-NIR spectrometers are described in Practice E1944.

1.2.4 Performance tests for dispersive MIR instruments are described in Practice E932.

1.2.5 For FT-IR spectrometers run in a step scan mode, variations on this practice and information provided by the instrument

vendor should be used.

2. Referenced Documents

2.1 ASTM Standards:

E131 Terminology Relating to Molecular Spectroscopy

E932 Practice for Describing and Measuring Performance of Dispersive Infrared SpectrophotometersSpectrometers

E1866 Guide for Establishing Spectrophotometer Performance Tests

E1944 Practice for Describing and Measuring Performance of Laboratory Fourier Transform Near-Infrared (FT-NIR)

Spectrometers: Level Zero and Level One Tests

3. Terminology

3.1 Definitions—Fordefinitionsoftermsusedinthispractice,refertoTerminologyE131.Allidentificationsofspectralregions

−1

and absorption band positions are given in wavenumbers (cm ), and spectral energy, transmittance, and absorbance are signified

inequationsbythelettersE,Tand,andArespectively.Theratiooftwotransmittanceorabsorbancevalues,andtheratioofenergy

levelsattwodifferentwavenumbersaresignifiedbytheletterR.Asubscriptednumbersignifiesaspectralpositioninwavenumbers

−1

(for example, A , the absorbance at 3082 cm ).

3.1.1 level one (1) test, n—a simple series of measurements designed to provide quantitative data on various aspects of

instrument performance and information on which to base the diagnosis of problems.

3.1.2 level zero (0) test, n—a routine check of instrument performance, that can be done in a few minutes, designed to visually

detect significant changes in instrument performance and provide a database to determine instrument function over time.

This practice is under the jurisdiction of ASTM Committee E13 on Molecular Spectroscopy and Separation Science and is the direct responsibility of Subcommittee

E13.03 on Infrared and Near Infrared Spectroscopy.

Current edition approved Feb.March 1, 2004.2009. Published March 2004.2009. Originally approved in 1991. Last previous edition approved in 19992004 as

E1421-–99(2004).

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1421–99 (2009)

4. Significance and Use

4.1 This practice permits an analyst to compare the general performance of an instrument on any given day with the prior

performance of an instrument.This practice is not necessarily meant for comparison of different instruments with each other even

iftheinstrumentsareofthesametypeandmodel.Thispracticeisnotmeantforcomparisonoftheperformanceofoneinstrument

operated under differing conditions.

5. Test Conditions

5.1 Operating Conditions—A record should be kept to document the operating conditions selected so that they can be

duplicated.Inobtainingspectrophotometricdata,theanalystmustselectproperinstrumentaloperatingconditionssuchaswarm-up

time, purge rate, and beam splitter alignment in order to realize satisfactory instrument performance. Operating conditions for

individual instruments are best obtained from the manufacturer’s literature because of variations with instrument design. It should

benotedthatmanyFT-IRinstrumentsaredesignedtoworkbestwhenleftonorinthestandbymode.Alsonotethatspectrometers

are to be tested only within their respective wavenumber ranges.

NOTE 1—This practice is designed to be used in situations where the detector is not saturated. In some instruments, with some combinations of optics

and detectors, the detector electronics are saturated with an empty beam. These instruments are designed to have the infrared beam attenuated in the

spectrometer or sample compartment to eliminate detector saturation. Consult your instrument manual or discuss appropriate attenuation techniques with

the instrument vendor.

5.2 The environment in which a spectrometer is operated can affects its performance. Spectrometers should only be operated

in environments consistent with manufacturer’s recommendations. Changes in the instrument environment including variations in

temperature, vibration or sound levels, electrical power or magnetic fields should be recorded.

5.3 Instrumental characteristics can influence these measurements in several ways.

5.3.1 Vignetting of the beam reduces the transmittance value measured in nonabsorbing regions, and on most instruments can

−1

change the apparent wavenumber scale by a small amount, usually less than 0.1 cm . Make sure that the film holder does not

vignet the beam.

5.3.2 Focus changes can also change transmittance values, so the sample should be positioned in approximately the same

location in the sample compartment each time.

5.3.3 The angle of acceptance (established by the f number) of the optics between the sample and detector significantly affects

apparent transmittance. Changes to the optical path including the introduction of samples can alter the acceptance angle.

5.3.4 Heating of the sample by the beam or by the higher temperatures which exist inside most spectrometers changes

absorbances somewhat, and even changes band ratios and locations slightly. Allow the sample to come to thermal equilibrium

before measurement.

5.4 The recommended sample of matte-finish polystyrene used for these tests is approximately 38-µm (1.5-mil) thick film

mountedonacard.Thesampleismountedina2.5-cm(1-in.)circularaperturecenteredwithinthe5-cm(2.5-in.)widthofthecard,

and centered 3.8 cm (1.5 in.) from the bottom of the card. The card should be approximately 0.25-cm (0.1-in.) thick and

individually and unambiguously identified.Apolystyrene film meeting these requirements is available from the National Institute

of Standards and Technology (NIST) as SRM 1921.

NOTE 2—Very small beam diameters can defeat the interference fringe suppression provided by the matte finish on the sample.

6. Level Zero Tests

6.1 Nature of Tests— Routine checks of instrument performance, these tests can be performed in a few minutes. They are

designedtouncovermalfunctionsorotherchangesininstrumentoperationbutnottospecificallydiagnoseorquantitativelyassess

any malfunction. It is recommended that the level zero tests be conducted at the highest (smallest numerical value) resolution at

which the instrument is typically used in normal operation. A nominal measurement time of 30 s should be used. The exact

measurement time, along with the date, time, sample identification, number of scans, exact data collection and computation

parameters, and operator’s name, should always be recorded.

6.2 Philosphy—Thephilosophyofthetestsistousepreviouslystoredtestresultsasbasesforcomparisonandthevisualdisplay

screen or plotter to overlay the current test results with the known, good results. If the old and new results agree, they are simply

reported as no change. Level zero consists of three tests.The tests are run under the same conditions that are normally used to run

a sample (that is, purge time, warm-up time, detector, etc.).

6.3 Variations in Operating Procedure for Different Instruments—Most of the existing FT-IR instruments should be able to use

the tests in this practice without modification. However, a few instruments may not be able to perform the tests exactly as they

are written. In these cases, it should be possible to obtain the same final data using a slightly different procedure. Practice E1866

and the FT-IR manufacturer should be consulted for appropriate alternative procedures.

SRM 1921 is available from the Standard Reference Materials Program, Building 202, Room 204, National Institute of Standards and Technology, Gaithersburg, MD

20899-0001.

SRM1921isavailablefromtheStandardReferenceMaterialsProgram,NationalInstituteofStandardsandTechnology(NIST),100BureauDr.,Stop1070,Gaithersburg,

MD 20899-1070, http://www.nist.gov.

E1421–99 (2009)

6.4 Sample—The recommended sample is described in 5.3. It is a matte-finish polystyrene film (approximately 38-µm thick,

in a 2.5-cm aperture). The same sample should be used for all comparisons (note serial number).

6.5 Reference Spectra—Two spectra acquired and stored following the last major instrument maintenance are used as

references. Major maintenance could include changes in source, laser, detector, or optical alignment. These spectra will be

identified as Reference 1 and Reference 2.

6.5.1 ReferenceSpectrum1isasingle-beamenergyspectrumofanemptybeam.(Inthisandalllaterusage,emptybeammeans

that nothing is in the sample path except air or the purge gas normally present within the spectrometer sample compartment). If

possible, the interferogram corresponding to Reference Spectrum 1 should also be saved.

6.5.2 Reference Spectrum 2 is a transmittance spectrum of the polystyrene sample. Optionally, an absorbance spectrum may

also be stored.

NOTE 3—If the instrument software will not allow for subtraction of transmittance spectra, Reference Spectrum 2 should be saved as an absorbance

spectrum.

6.6 Reproducibility of Procedures —Care should be taken that each of the spectral measurements is made in a consistent and

reproducible manner, including sample orientation (although different spectral measurements do not necessarily use the identical

procedure). In particular, for those instruments having more than one sample beam or path in the main sample compartment, all

of the test spectra always should be measured using the same path. It may be desirable to repeat the tests on each path.

6.7 Measurements—Acquire and store three test spectra. The test spectra will be identified hereafter as Spectrum 1, Spectrum

2, and Spectrum 3.

6.7.1 Spectrum 1—Acquire and store a single-beam energy spectrum of any empty beam. When possible, the interferogram of

Spectrum1shouldalsobestored.IfSpectrum1isstoredonlyasaninterferogram,itmustbetransformedbeforeuseintheensuing

tests.

6.7.2 Spectrum 2—Acquire and store an empty-beam spectrum taken immediately after Spectrum 1. This spectrum should be

stored as a transmittance spectrum ratioed against Spectrum 1.

6.7.3 Spectrum 3—Acquire and store a spectrum of the polystyrene sample reasonably soon after Spectrum 2. This spectrum

should be stored as a transmittance spectrum calculated using either Spectrum 1 or Spectrum 2 as a background. Optionally,

Spectrum 3 may also be stored as an absorbance spectrum. To reproducibly insert the sample, the serial number (or other

identifying information) should be right side up facing the instrument detector.

NOTE 4—If the instrument software will not allow for subtraction of transmittance spectra, Spectrum 2 should be saved as an absorbance spectrum.

7. Level Zero Test Procedures

7.1 Energy Spectrum Test—Overlay Spectrum 1 and Reference 1. Note any change in energy level across the spectrum. Ratio

Spectrum1toReferenceSpectrum1toproduceatransmittancespectrum,andlookforsignificantchangesfrom100%,especially

athighwavenumber.Videodisplayresolutionmaylimittheaccuracytowhichthistestcanbeinterpretedifthecomparisonismade

on-screen. In addition, if the interferogram for Spectrum 1 was saved, it may be displayed or plotted and the center burst height

recorded and compared to the allowable range for the instrument. Use caution in interpreting this because minor changes in

interferogram height only affect performance at high wavenumbers, and do not necessarily affect photometric performance.

NOTE 5—If the centerburst height exceeds the dynamic range of the analog-to-digital converter, the energy profile is distorted and significant

nonphysical energy will be observed. If the centerburst is small relative to the dynamic range, then the signal-to-noise of the measurement may be less

than optimal.

7.1.1 Reportage—Reportby(1)makinganoverlayplotofSpectrum1andReference1,(2)plottingthetransmittancespectrum

of Spectrum 1 ratioed against Reference 1 over the range of 95 to 105% T, and by reporting the following energy ratios:

R 5 E /E (1)

4000/2000 4000 2000

R 5 E /E

2000/1000 2000 1000

Ifpossible,fromSpectrum1,reporttheratiobetweentheapparentenergyinthewavenumberregionbelowtheinstrumentcutoff

and the energy in the maximum-energy region of the spectrum, for example:

R 5 E /E (2)

nonphysical 150 max

Report the date and time of both spectra used, and the actual numbers of scans and measurement times.

7.1.2 Interpretation— An overall drop in the energy level in which the largest percentage of change occurs at higher

wavenumbers usually indicates interferometer misalignment or a reduction in source temperature. An example of the affect of

misalignment is shown in Fig. 1.

7.1.2.1 If the instrument has

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.