ASTM D8519-23

(Test Method)Standard Test Method for Determination of Hydrocarbon Types in Waste Plastic Process Oil Using Gas Chromatography with Vacuum Ultraviolet Absorption Spectroscopy Detection (GC-VUV)

Standard Test Method for Determination of Hydrocarbon Types in Waste Plastic Process Oil Using Gas Chromatography with Vacuum Ultraviolet Absorption Spectroscopy Detection (GC-VUV)

SIGNIFICANCE AND USE

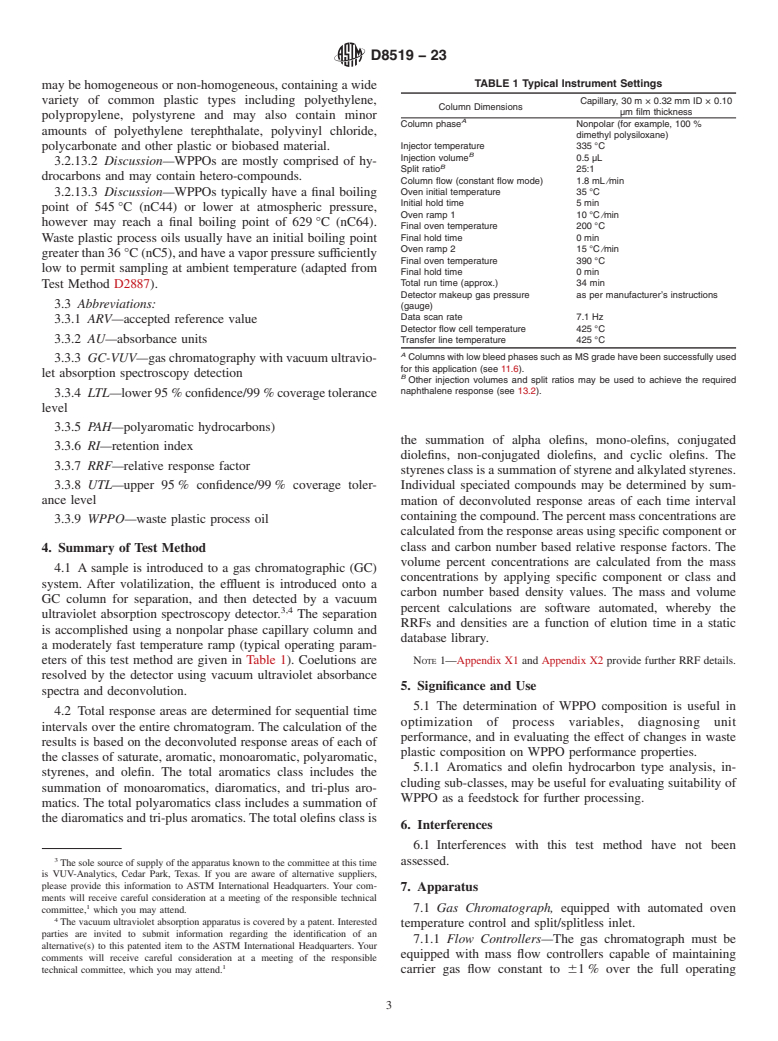

5.1 The determination of WPPO composition is useful in optimization of process variables, diagnosing unit performance, and in evaluating the effect of changes in waste plastic composition on WPPO performance properties.

5.1.1 Aromatics and olefin hydrocarbon type analysis, including sub-classes, may be useful for evaluating suitability of WPPO as a feedstock for further processing.

SCOPE

1.1 This test method covers a standard procedure for the determination of hydrocarbon types (saturates, olefins, styrenes, aromatics and polyaromatics) of waste plastic process oil (WPPO) from chemical or thermal processes using gas chromatography and vacuum ultraviolet absorption spectroscopy detection (GC-VUV).

1.1.1 This test method is applicable for plastic recycling and circular schemes including wide range density material from polyethylene and polypropylene.

1.1.2 The test method is applicable to waste plastic process oil having a final boiling point of 545 °C or lower at atmospheric pressure as measured by this test or Test Method D2887. This test method is limited to samples having a boiling range greater than 36 °C, and having a vapor pressure sufficiently low to permit sampling at ambient temperature.

1.1.3 WPPOs with initial boiling points less than nC5 (36 °C) and final boiling point less than nC15 (271 °C) may be analyzed by Test Method D8369.

1.1.4 Appendix X3 is applicable to waste plastic process oils that are predominantly hydrocarbons in the boiling range of pentane, nC5 (36 °C) to tetrahexacontane, nC64 (629 °C).

1.2 Concentrations of group type totals are determined by percent mass or percent volume. The applicable working ranges are as follows:

Total Aromatics

%Mass

1 to 50

Monoaromatics

%Mass

1 to 50

Diaromatics

%Mass

1 to 15

Tri-plus aromatics

%Mass

0.5 to 5

PAH

%Mass

0.5 to 15

Saturates

%Mass

5 to 99

Olefins

%Mass

1 to 80

Conjugated diolefins

%Mass

0.2 to 5

Styrenes

%Mass

0.2 to 5The final precision concentration ranges will be defined by a future ILS.

1.2.1 Saturates totals are the result of the summation of normal paraffins, isoparaffins, and naphthenes.

1.2.2 Aromatics are the summation of monoaromatic and polyaromatic group types. Polyaromatic totals are the result of the summation of diaromatic and tri-plus aromatic group types.

1.2.3 Olefin totals are the result of the sum of mono-olefins, conjugated diolefins, non-conjugated diolefins, and cyclic olefins.

1.2.4 Styrenes totals are the sum of styrene and alkylated styrenes. Styrenes are classified separately, neither as aromatic nor olefin.

1.3 Waste plastic process oil containing mixed plastic types such as polyethylene terephthalate PET and polyvinyl chloride or other material may yield compounds including hetero-compounds that are not speciated by this test method.

1.4 Individual components are typically not baseline separated by the procedure described in this test method. The coelutions are resolved at the detector using VUV absorbance spectra and deconvolution algorithms.

1.5 This test method may apply to other process oils from sources such as tires and bio-mass boiling between pentane (36 °C) and tetratetracontane (545 °C), but has not been extensively tested for such applications.

1.6 Units—The values stated in SI units are to be regarded as standard. No other units of measurement, other than the boiling point of normal paraffins (°F) in Table 2 and Table X.3.1, are included in this standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized pri...

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8519 − 23

Standard Test Method for

Determination of Hydrocarbon Types in Waste Plastic

Process Oil Using Gas Chromatography with Vacuum

1

Ultraviolet Absorption Spectroscopy Detection (GC-VUV)

This standard is issued under the fixed designation D8519; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.2.1 Saturates totals are the result of the summation of

normal paraffins, isoparaffins, and naphthenes.

1.1 This test method covers a standard procedure for the

1.2.2 Aromatics are the summation of monoaromatic and

determination of hydrocarbon types (saturates, olefins,

polyaromatic group types. Polyaromatic totals are the result of

styrenes, aromatics and polyaromatics) of waste plastic process

the summation of diaromatic and tri-plus aromatic group types.

oil (WPPO) from chemical or thermal processes using gas

chromatography and vacuum ultraviolet absorption spectros-

1.2.3 Olefin totals are the result of the sum of mono-olefins,

copy detection (GC-VUV). conjugated diolefins, non-conjugated diolefins, and cyclic ole-

1.1.1 This test method is applicable for plastic recycling and

fins.

circular schemes including wide range density material from

1.2.4 Styrenes totals are the sum of styrene and alkylated

polyethylene and polypropylene.

styrenes. Styrenes are classified separately, neither as aromatic

1.1.2 The test method is applicable to waste plastic process

nor olefin.

oil having a final boiling point of 545 °C or lower at atmo-

1.3 Waste plastic process oil containing mixed plastic types

spheric pressure as measured by this test or Test Method

such as polyethylene terephthalate PET and polyvinyl chloride

D2887. This test method is limited to samples having a boiling

or other material may yield compounds including hetero-

range greater than 36 °C, and having a vapor pressure suffi-

compounds that are not speciated by this test method.

ciently low to permit sampling at ambient temperature.

1.1.3 WPPOs with initial boiling points less than nC5

1.4 Individual components are typically not baseline sepa-

(36 °C) and final boiling point less than nC15 (271 °C) may be

rated by the procedure described in this test method. The

analyzed by Test Method D8369.

coelutions are resolved at the detector using VUV absorbance

1.1.4 Appendix X3 is applicable to waste plastic process

spectra and deconvolution algorithms.

oils that are predominantly hydrocarbons in the boiling range

1.5 This test method may apply to other process oils from

of pentane, nC5 (36 °C) to tetrahexacontane, nC64 (629 °C).

sources such as tires and bio-mass boiling between pentane

1.2 Concentrations of group type totals are determined by

(36 °C) and tetratetracontane (545 °C), but has not been

percent mass or percent volume. The applicable working

extensively tested for such applications.

ranges are as follows:

1.6 Units—The values stated in SI units are to be regarded

Total Aromatics %Mass 1 to 50

Monoaromatics %Mass 1 to 50

as standard. No other units of measurement, other than the

Diaromatics %Mass 1 to 15

boiling point of normal paraffins (°F) in Table 2 and Table

Tri-plus aromatics %Mass 0.5 to 5

PAH %Mass 0.5 to 15 X.3.1, are included in this standard.

Saturates %Mass 5 to 99

1.7 This standard does not purport to address all of the

Olefins %Mass 1 to 80

Conjugated diolefins %Mass 0.2 to 5

safety concerns, if any, associated with its use. It is the

Styrenes %Mass 0.2 to 5

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

The final precision concentration ranges will be defined by a

future ILS.

mine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1

This test method is under the jurisdiction of ASTM Committee D02 on

ization established in the Decision on Principles for the

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Development of International Standards, Guides and Recom-

Subcommittee D02.04.0L on Gas Chromatography Methods.

mendations issued by the World Trade Organization Technical

Current edition approved July 1, 2023. Published August 2023. DOI: 10.1520/

D8519-23. Barriers to Trade (TBT) Committee.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

-----------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.