ASTM D3575-00

(Test Method)Standard Test Methods for Flexible Cellular Materials Made From Olefin Polymers

Standard Test Methods for Flexible Cellular Materials Made From Olefin Polymers

SCOPE

1.1 These test methods apply to flexible closed cell materials made from olefin polymers or blends of olefin polymers with other polymers as defined in Section 3.

1.2 This test method covers test procedures only. Product requirements are outlined in Specification D4819.

1.3 Unless specifically stated otherwise, by agreement between the purchaser and supplier, all tests shall be performed in accordance with the test methods specified in this standard.

1.4 The values stated in SI units are to be regarded as the standard.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability or regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 3575 – 00

Standard Test Methods for

Flexible Cellular Materials Made From Olefin Polymers

This standard is issued under the fixed designation D 3575; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Vinyl Chloride Polymers and Copolymers (Closed-Cell

Foam)

1.1 These test methods apply to flexible closed cell materi-

D 2863 Test Method for Measuring the Minimum Oxygen

als made from olefin polymers or blends of olefin polymers

Concentration to Support Candle-Like Combustion of

with other polymers as defined in Section 3.

Plastics (Oxygen Index)

1.2 This test method covers test procedures only. Product

D 4483 Practice for Determining Precision for Test Method

requirements are outlined in Specification D 4819.

Standards in the Rubber and Carbon Black Industries

1.3 Unless specifically stated otherwise, by agreement be-

D 4819 Specification for Flexible Cellular Materials Made

tween the purchaser and supplier, all tests shall be performed in

from Polyolefin Plastics

accordance with the test methods specified in this standard.

F 355 Test Method for Shock-Absorbing Properties of Play-

1.4 The values stated in SI units are to be regarded as the

ing Surface Systems and Materials

standard.

1.5 This standard does not purport to address all of the

3. Terminology

safety concerns, if any, associated with its use. It is the

3.1 Definitions of Terms Specific to This Standard:

responsibility of the user of this standard to establish appro-

3.1.1 blend—mixture of olefin polymers with other mono-

priate safety and health practices and determine the applica-

mer(s) or polymer(s) in which at least 51 mass percent is the

bility or regulatory limitations prior to use.

olefin polymer.

2. Referenced Documents 3.1.2 cellular material, flexible—a cellular organic poly-

meric material that will not rupture when a specimen 200 by 25

2.1 ASTM Standards:

by 25 mm (8 by 1 by 1 in.) is bent around a 25-mm (1-in.)

C 177 Test Method for Steady-State Heat Flux Measure-

diameter mandrel at a uniform rate of one lap in5sata

ments and Thermal Transmission Properties by Means of

temperature between 18 and 29°C.

the Guarded-Hot-Plate Apparatus

3.1.3 constant compression creep—the time-dependent

C 518 Test Method for Steady-State Heat Flux Measure-

change in thickness of a material under a constant compressive

ments and Thermal Transmission Properties by Means of

stress or compression force.

the Heat Flow Meter Apparatus

3.1.4 olefin polymers—polymers made by the polymeriza-

D 412 Test Methods for Vulcanized Rubber and Thermo-

tion of olefins or copolymerization of olefins with other

plastic Rubbers and Thermoplastic Elastomers—Tension

monomers, the olefins being at least 51 mass percent.

D 624 Test Method for Tear Strength of Conventional

Vulcanized Rubber and Thermoplastic Elastomers

4. Summary of Test Methods

D 1056 Specification for Flexible Cellular Materials—

4 4.1 Table 1 contains a list of all the assigned suffix letters

Sponge or Expanded Rubber

that may be used in describing the cellular products covered by

D 1349 Practice for Rubber—Standard Temperatures for

3 these test methods.

Testing

4.2 These test methods do not contain test methods for all

D 1596 Test Method for Absorbing Shock Cushioning

5 the suffix letters listed in Table 1. Where the test method is not

Characteristics of Package Cushioning Materials

included, it shall be arranged between the purchaser and

D 1667 Specification for Flexible Cellular Materials—

supplier.

4.3 Test methods included in this standard are indicated in

Table 1 by showing the applicable section numbers after the

These test methods are under the jurisdiction of ASTM Committee D20 on

suffix letter.

Plastics and are the direct responsibility of Subcommittee D20.22 on Cellular

4.4 In cases involving referee decisions, SI units shall be

Plastics.

Current edition approved Aug. 10, 2000. Published November 2000. Originally used.

published as D 3575 – 77. Last previous edition D 3575 – 93.

Annual Book of ASTM Standards, Vol 04.06.

3 6

Annual Book of ASTM Standards, Vol 09.01. Annual Book of ASTM Standards, Vol 08.02.

4 7

Annual Book of ASTM Standards, Vol 08.01. Annual Book of ASTM Standards, Vol 08.03.

5 8

Annual Book of ASTM Standards, Vol 15.09. Annual Book of ASTM Standards, Vol 15.07.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 3575

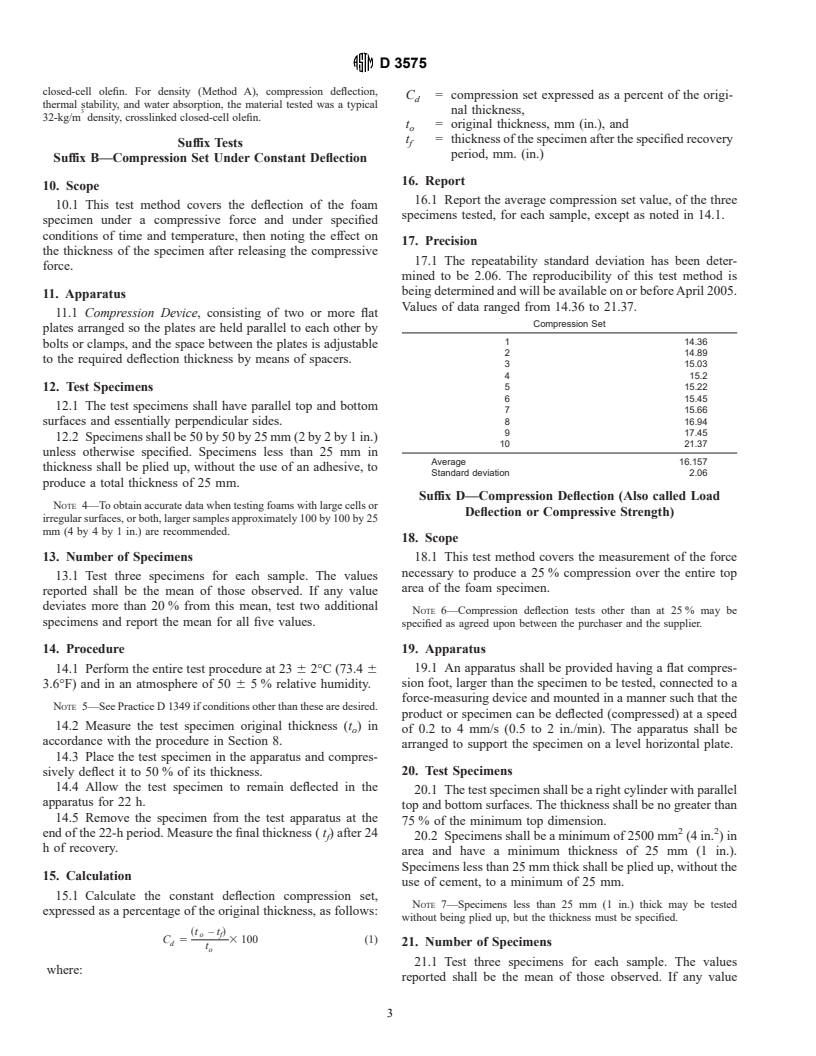

TABLE 1 Suffix Letter Designations

article is of complicated shape or of varying thickness, and

these factors affect the physical properties of the specimens.

NOTE 1—These suffix letters have been assigned by Subcommittee

Also, the apparent density is affected by the number of cut

D11.33 and are consistent with those in Specifications D 1056 and

D 1667. surfaces as opposed to the number of skin-covered surfaces on

the test specimen.

Suffix

Property Section

Letter

6.4 When the finished product does not lend itself to testing

A Heat resistance 10-16 or to the taking of test specimens because of complicated

B Compression set under constant deflection

shape, small size, metal or fabric inserts, solid covers, adhesion

C Ozone or weather resistance

to metal, or other reasons, prepare standard test sheets. When

D Compression deflection 17-23

E Oil resistance differences due to the difficulty in obtaining suitable test

F Low temperature

specimens from the finished part arise, the manufacturer and

G Tear resistance 24

purchaser may agree on acceptable deviations. This can be

H Flex resistance

I Not assigned because of similarity to done by comparing the results of standard test specimens and

numeral 1

those obtained on actual parts.

J Abrasion resistance

6.5 If the material to be tested is anisotropic, prepare the test

K Adhesion capability

L Water absorption 25-29

specimens so as to measure the property in the direction of

M Flammability resistance 31

interest in the application.

N Impact resistance

O Electrical properties

P Staining resistance 7. Conditioning

Q Not assigned because of similarity to

7.1 Conduct tests under known conditions of temperature

letter O

and humidity or as specified in the individual test procedure. In

R1 Resilience

R2 Energy absorption 32

case of dispute, conduct the test at a temperature of 23 6 2°C

S Thermal stability 33-39

(73.4 6 3.6°F) and in an atmosphere of 50 6 5 % relative

T Tensile strength and elongation 40

U Not assigned humidity. The product shall be conditioned, undeflected, and

V Thermal conductivity 41 and 42

undistorted, at the temperature and humidity of test for at least

W Density 43

24 h before being tested.

X Not assigned

Y Not assigned 7.2 It is recommended, for referee purposes, that all tests

Z Special requirements

shall be performed 96 h or more after the foam has been

AA Buoyancy 45-50

manufactured.

BB Constant compressive creep 51-58

CC Dynamic cushioning 59

DD Open cell

8. Measurement of Test Specimens

EE Not assigned

8.1 Measure dimensions up to and including 25 mm (1 in.)

FF Water vapor transmission

using a dial-type gage with a minimum foot area of 650 mm

(1 in. ). Pressure on the foot shall be held to 190 6 50 Pa

(0.028 6 0.007 psi).

5. Significance and Use

NOTE 1—Where foam is appreciably compressed by this test method,

5.1 The test procedures provide a standard method of

foot area and loading shall be as agreed upon between the purchaser and

obtaining data for research and development, quality control,

the supplier.

acceptance and rejection under specifications, and special

NOTE 2—Thickness of materials having irregular surface characteristics

purposes.

shall be measured as agreed upon between the purchaser and the supplier.

5.2 The data obtained by these test methods are applicable

8.2 Dimensions over 25 mm (1 in.) may be measured with

to the material under conditions of the particular test and are

a dial gage, scale, or tape. Take care not to distort the test

not necessarily the same as obtained in other environments or

specimen.

use conditions.

8.3 The scale, tape, or gage shall be graduated to permit

6. Sampling measurements within 61 % of the dimension to be measured.

8.4 Results reported shall be the average of a minimum of

6.1 When possible, use the completed manufactured prod-

three equally spaced measurements of length and width and for

uct for the tests specified. Randomly select representative

thickness shall be the average of the center and four equally

samples of the lot being examined, as required.

spaced measurements around the perimeter of the specimens.

6.2 Extruded or molded shapes or sizes too small for cutting

standard test specimens are difficult to classify or test by these

9. Precision

test methods and will usually require special testing procedures

9.1 The repeatability standard deviations for each test

or the use of standard test sheets.

method has been determined. The reproducibility of these test

6.3 When it is necessary or advisable to obtain test speci-

methods is being determined and will be available on or before

mens from the article, as in those cases where the entire sample

April 2005.

is not required or adaptable for testing, specify the method of

cutting and the exact position from which specimens are to be

NOTE 3—The repeatability study was performed on two materials in

taken. The apparent density and the state of crosslinking may

two laboratories. For density (Method B), buoyancy, and compression

vary in different parts of the finished product, especially if the creep, the material tested was a typical 64-kg/m density, crosslinked

D 3575

closed-cell olefin. For density (Method A), compression deflection,

C = compression set expressed as a percent of the origi-

d

thermal stability, and water absorption, the material tested was a typical

nal thickness,

32-kg/m density, crosslinked closed-cell olefin.

t = original thickness, mm (in.), and

o

t = thickness of the specimen after the specified recovery

Suffix Tests f

period, mm. (in.)

Suffix B—Compression Set Under Constant Deflection

16. Report

10. Scope

16.1 Report the average compression set value, of the three

10.1 This test method covers the deflection of the foam

specimens tested, for each sample, except as noted in 14.1.

specimen under a compressive force and under specified

conditions of time and temperature, then noting the effect on

17. Precision

the thickness of the specimen after releasing the compressive

17.1 The repeatability standard deviation has been deter-

force.

mined to be 2.06. The reproducibility of this test method is

being determined and will be available on or before April 2005.

11. Apparatus

Values of data ranged from 14.36 to 21.37.

11.1 Compression Device, consisting of two or more flat

Compression Set

plates arranged so the plates are held parallel to each other by

1 14.36

bolts or clamps, and the space between the plates is adjustable

2 14.89

to the required deflection thickness by means of spacers.

3 15.03

4 15.2

5 15.22

12. Test Specimens

6 15.45

12.1 The test specimens shall have parallel top and bottom

7 15.66

8 16.94

surfaces and essentially perpendicular sides.

9 17.45

12.2 Specimens shall be 50 by 50 by 25 mm (2 by 2 by 1 in.)

10 21.37

unless otherwise specified. Specimens less than 25 mm in

Average 16.157

thickness shall be plied up, without the use of an adhesive, to

Standard deviation 2.06

produce a total thickness of 25 mm.

Suffix D—Compression Deflection (Also called Load

NOTE 4—To obtain accurate data when testing foams with large cells or

Deflection or Compressive Strength)

irregular surfaces, or both, larger samples approximately 100 by 100 by 25

mm (4 by 4 by 1 in.) are recommended.

18. Scope

13. Number of Specimens

18.1 This test method covers the measurement of the force

necessary to produce a 25 % compression over the entire top

13.1 Test three specimens for each sample. The values

area of the foam specimen.

reported shall be the mean of those observed. If any value

deviates more than 20 % from this mean, test two additional

NOTE 6—Compression deflection tests other than at 25 % may be

specimens and report the mean for all five values.

specified as agreed upon between the purchaser and the supplier.

19. Apparatus

14. Procedure

19.1 An apparatus shall be provided having a flat compres-

14.1 Perform the entire test procedure at 23 6 2°C (73.4 6

sion foot, larger than the specimen to be tested, connected to a

3.6°F) and in an atmosphere of 50 6 5 % relative humidity.

force-measuring device and mounted in a manner such that the

NOTE 5—See Practice D 1349 if conditions other than these are desired.

product or specimen can be deflected (compressed) at a speed

14.2 Measure the test specimen original thickness (t )in

o of 0.2 to 4 mm/s (0.5 to 2 in./min). The apparatus shall be

accordance with the procedure in Section 8.

arranged to support the specimen on a level horizontal plate.

14.3 Place the test specimen in the apparatus and compres-

sively deflect it to 50 % of its thickness. 20. Test Specimens

14.4 Allow the test specimen to remain deflected in the

20.1 The test specimen shall be a right cylinder with parallel

apparatus for 22 h.

top and bottom surfaces. The thickness shall be no greater than

14.5 Remove the specimen from the test apparatus at the

75 % of the minimum top dimension.

2 2

end of the 22-h period. Measure the final thickness ( t ) after 24

20.2 Specimens shall be a minimum of 2500 mm (4 in. )in

f

h of recovery.

area and have a minimum thickness of 25 mm (1 in.).

Specimens less than 25 mm thick shall be plied up, without the

15. Calculation

use of cement, to a minimum of 25 mm.

15.1 Calculate the constant deflection compression set,

NOTE 7—Specimens less than 25 mm (1 in.) thick may be tested

expressed as a percentage of the original thickness, as follows:

without being plied up, but the thickness must be specified.

t – t

~ !

o f

C 5 3 100 (1)

d 21. Number of Specimens

t

o

21.1 Test three specimens for each sample. The values

where:

reported shall be the mean of those observed. If any value

D 3575

deviates more than 20 % from this mean, test two additional Suffix G—Tear Resistance, Test Method D 624

specimens and report the mean for all five values.

26. Test Method D 624

26.1 Die C shall be used.

22. Procedure

26.2 Test the material at the thickness to be supplied, unless

22.1 Place the specimen centered in the line of the axial load

otherwise arranged by agreement between the purchaser and

on the supporting plate of the apparatus.

the supplier.

22.2 Brin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.