ASTM B858-01

(Test Method)Standard Test Method for Ammonia Vapor Test for Determination Susceptibility to Stress Corrosion Cracking in Copper Alloys

Standard Test Method for Ammonia Vapor Test for Determination Susceptibility to Stress Corrosion Cracking in Copper Alloys

SCOPE

1.1 This test method describes a procedure to determine the presence of residual stresses in wrought copper alloy products that may lead to stress corrosion cracking. An ammonia vapor atmosphere is used as an accelerated test.

1.2 This test method is only suitable for products fabricated from copper alloys that are known to be susceptible to stress corrosion cracking in ammonia vapor atmospheres. It is intended to create an environmental condition of reproducible severity.

Note 1—It is well known that the critical step in the cracking mechanism is the development of an environment in the condensate film that occurs on the surface of the test specimen, and is rich in copper complex ions.

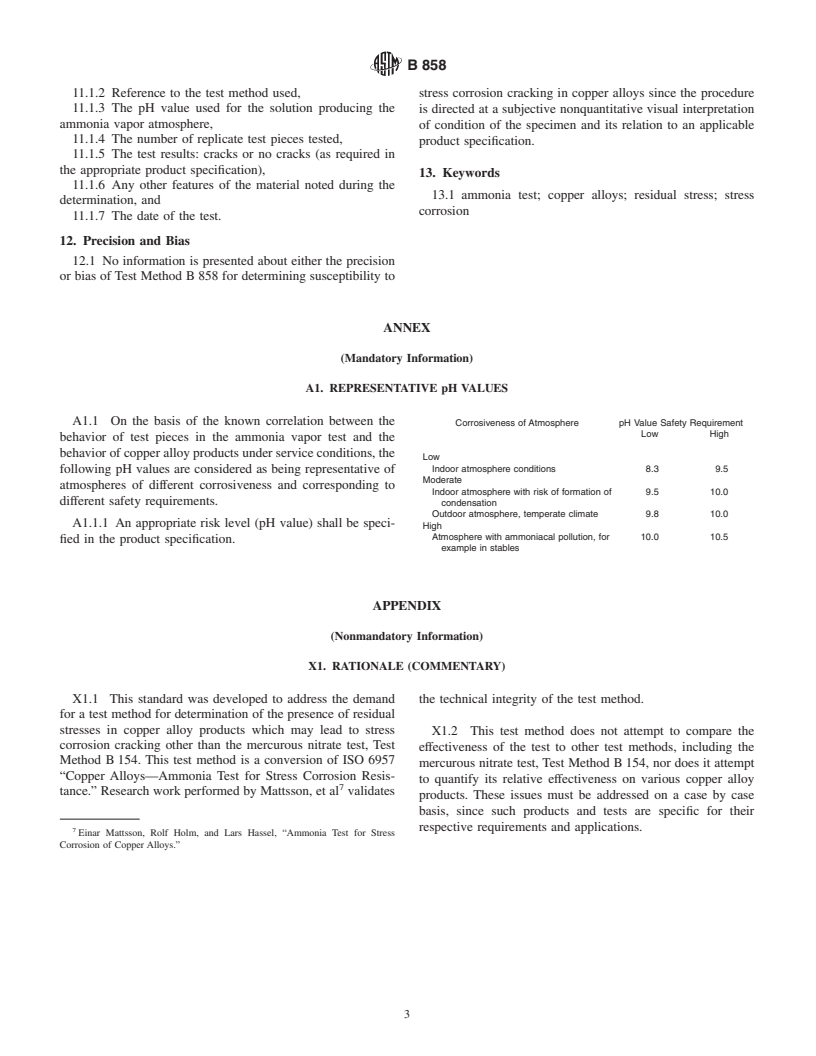

1.3 The severity of this test method depends upon the pH of the corrosive solution. In are given four different atmospheres to which the product may be exposed, and the appropriate pH of the solution to be used for the test, depending on the risk level associated with the intended application.

1.3.1 The appropriate pH value for the test shall be specified in the product specification, or as per established agreement between the supplier and purchaser, with respect to the alloy and its intended application.

1.4 Units—The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B858–01

Standard Test Method for

Ammonia Vapor Test for Determining Susceptibility to

1

Stress Corrosion Cracking in Copper Alloys

This standard is issued under the fixed designation B 858; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope B 154 Test Method for Mercurous Nitrate Test for Copper

3

2

and Copper Alloys

1.1 Thistestmethod describesaproceduretodeterminethe

3

B 846 Terminology for Copper and Copper Alloys

presence of residual stresses in wrought copper alloy products

4

D 1193 Specification for Reagent Water

that may lead to stress corrosion cracking. An ammonia vapor

2.2 Other Documents:

atmosphere is used as an accelerated test.

ISO 6957 CopperAlloys—Ammonia Test for Stress Corro-

1.2 This test method is only suitable for products fabricated

5

sion Resistance

from copper alloys that are known to be susceptible to stress

corrosion cracking in ammonia vapor atmospheres. It is in-

3. Terminology

tended to create an environmental condition of reproducible

3.1 For definitions of terms related to copper and copper

severity.

alloys, refer to Terminology B 846.

NOTE 1—It is well known that the critical step in the cracking

3.2 Definitions:

mechanism is the development of an environment in the condensate film

3.2.1 applied stress, n—stress in a body as a result of

that occurs on the surface of the test specimen, and is rich in copper

application of an external load.

complex ions.

3.2.2 residual stress, n—stresses that remain within a body

1.3 The severity of this test method depends upon the pH of

as the result of processing, which may include plastic defor-

the corrosive solution. In Annex A1 are given four different

mation or casting.

atmospheres to which the product may be exposed, and the

3.2.3 stress-corrosion crack, n—spontaneousfailureofmet-

appropriate pH of the solution to be used for the test,

als by cracking under combined action of corrosion and stress,

depending on the risk level associated with the intended

residual or applied.

application.

1.3.1 TheappropriatepHvalueforthetestshallbespecified 4. Summary of Test Method

in the product specification, or as per established agreement

4.1 The prepared test specimen is placed in a closed

between the supplier and purchaser, with respect to the alloy

container and exposed to ammonia vapor at ambient tempera-

and its intended application.

ture for 24 h. Upon removal from the test atmosphere, the test

1.4 Units—The values stated in SI units are to be regarded

specimen is examined for the presence of cracks.

as the standard. No other units of measurement are included in

this standard. 5. Significance and Use

1.5 This standard does not purport to address all of the

5.1 This test method is an accelerated test to determine if a

safety concerns, if any, associated with its use. It is the

copper alloy product in a specific stress condition will be

responsibility of the user of this standard to establish appro-

susceptible to stress-corrosion cracking when exposed to a

priate safety and health practices and determine the applica-

particular atmospheric condition during service with the ap-

bility of regulatory limitations prior to use.

propriate risk level—see Annex A1. This test method is

generally intended to determine if a copper alloy product will

2. Referenced Documents

crack because of internal stresses when subjected to the test,

2.1 ASTM Standards:

and is not intended for testing assemblies under applied stress.

If used for this purpose, it shall be for information only and not

1 a cause for rejection of the assembly, its component parts, or

This test method is under the jurisdiction ofASTM Committee B05 on Copper

and Copper Alloys and is the direct responsibility of Subcommittee B05.06 on the original mill product.

Methods of Test.

Current edition approved Oct. 10, 2001. Published December 2001. Originally

3

published as B 858 – 95. Last previous edition B 858 – 95. Annual Book of ASTM Standards, Vol 02.01.

2 4

This test method is a conversion of ISO 6957 “CopperAlloys—Ammonia Test Annual Book of ASTM Standards, Vol 11.01.

5

for Stress Corrosion Resistance.” Additional information is included in Appendix Available from American National Standards Institute, 25 W. 43rd St., 4th

X1. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B858

6. Apparatus peroxide solution may be added to the pickling solution (for

example, 20 to 30 mL of hydrogen peroxide solution per litre

6.1 pH met

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.