ASTM E328-02

(Test Method)Standard Test Methods for Stress Relaxation Tests for Materials and Structures

Standard Test Methods for Stress Relaxation Tests for Materials and Structures

SIGNIFICANCE AND USE

Relaxation test data are necessary when designing most mechanically fastened joints to assure the permanent tightness of bolted or riveted assemblies, press or shrink-fit components, rolled-in tubes, etc. Other applications include predicting the decrease in the tightness of gaskets, in the hoop stress of solderless wrapped connections, in the constraining force of springs, and the stability of wire tendons in prestressed concrete.

The ability of a material to relax at high-stress concentrations such as are present at notches, inclusions, cracks, holes, fillets, etc., may be predicted from stress relaxation data. Such test data are also useful to judge the heat-treatment condition necessary for the thermal relief of residual internal stresses in forgings, castings, weldments, machined or cold-worked surfaces, etc. The tests outlined in these methods are limited to conditions of approximately constant constraint and environment.

The test results are highly sensitive to small changes in environmental conditions and thus require precise control of test conditions and methods.

The reproducibility of data will depend on the manner with which all test conditions are controlled. The effects of aging or residual stress may significantly affect results, as may variations in material composition.

SCOPE

Note 1—The method of testing for the stress relaxation of plastics has been withdrawn from this standard, and the responsibility has been transferred to Practice D 2991.

1.1 These test methods cover the determination of the time dependence of stress (stress relaxation) in materials and structures under conditions of approximately constant constraint, constant environment, and negligible vibration. In the procedures recommended, the material or structure is initially constrained by externally applied forces, and the change in the external force necessary to maintain this constraint is determined as a function of time.

1.2 Specific methods for conducting stress relaxation tests on materials subjected to tension, compression, bending and torsion stresses are described in Parts A, B, C, and D, respectively. These test methods also include recommendations for the necessary testing equipment and for the analysis of the test data.

1.3 It is recognized that the long time periods required for these types of tests are often unsuited for routine testing or for specification in the purchase of material. However, these tests are valuable tools in obtaining practical design information on the stress relaxation of materials subjected to the conditions enumerated, and in investigations of the fundamental behavior of materials.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E328–02

Standard Test Methods for

1

Stress Relaxation for Materials and Structures

This standard is issued under the fixed designation E328; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

These test methods cover a broad range of testing activities. To aid in locating the subject matter

pertinent to a particular test, the standard is divided into a general section, which applies to all stress

relaxationtestsformaterialsandstructures.Thisgeneralsectionisfollowedbyletter-designatedparts

that apply to tests for material characteristics when subjected to specific, simple stresses, such as

uniform tension, uniform compression, bending or torsion. To choose from among these types of

stress, the following factors should be considered:

(1) When the material data are to be applied to the design of a particular class of component, the

stress during the relaxation test should be similar to that imposed on the component. For example,

tension tests are suitable for bolting applications and bending tests for leaf springs.

(2) Tension and compression relaxation tests have the advantage that the stress can be reported

simply and unequivocally. During bending relaxation tests, the state of stress is complex, but can be

accurately determined when the initial strains are elastic. If plastic strains occur on application of

force, stresses can usually be determined within a bounded range only.Tension relaxation tests, when

compared to compression tests, have the advantage that it is unnecessary to guard against buckling.

Therefore,whenthetestmethodisnotrestrictedbythetypeofstressinthecomponent,tensiontesting

is recommended.

(3) Bending tests for relaxation, when compared to tension and compression tests, have the

advantage of using lighter and simpler apparatus for specimens of the same cross-sectional area.

Strains are usually calculated from deflection or curvature measurements. Since the specimens can

usually be designed so that these quantities are much greater than the axial deformation in a direct

stress test, strain is more easily measured and more readily used for machine control in the bending

tests.Duetothesmallforcesnormallyrequiredandthesimplicityoftheapparatuswhenstaticfixtures

are sufficient, many specimens can be placed in a single oven or furnace when tests are made at

elevated temperatures.

1. Scope 1.2 Specific methods for conducting stress relaxation tests

on materials subjected to tension, compression, bending and

NOTE 1—The method of testing for the stress relaxation of plastics has

torsion stresses are described in Parts A, B, C, and D,

been withdrawn from this standard, and the responsibility has been

respectively.Thesetestmethodsalsoincluderecommendations

transferred to Practice D2991.

for the necessary testing equipment and for the analysis of the

1.1 These test methods cover the determination of the time

test data.

dependence of stress (stress relaxation) in materials and

1.3 It is recognized that the long time periods required for

structures under conditions of approximately constant con-

these types of tests are often unsuited for routine testing or for

straint, constant environment, and negligible vibration. In the

specification in the purchase of material. However, these tests

procedures recommended, the material or structure is initially

are valuable tools in obtaining practical design information on

constrained by externally applied forces, and the change in the

the stress relaxation of materials subjected to the conditions

external force necessary to maintain this constraint is deter-

enumerated, and in investigations of the fundamental behavior

mined as a function of time.

of materials.

1.4 This standard does not purport to address all of the

1

These test methods are under the jurisdiction of ASTM Committee E28 on

safety concerns, if any, associated with its use. It is the

Mechanical Testing and is the direct responsibility of Subcommittee E28.04 on

responsibility of the user of this standard to establish appro-

Uniaxial Testing.

priate safety and health practices and determine the applica-

Current edition approved Nov. 15, 2005. Published April 2003. Originally

e1

approved in 1967. Last previous approved 1986 as E328–86(96) . bility of regulatory limitations prior to use.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E328–02

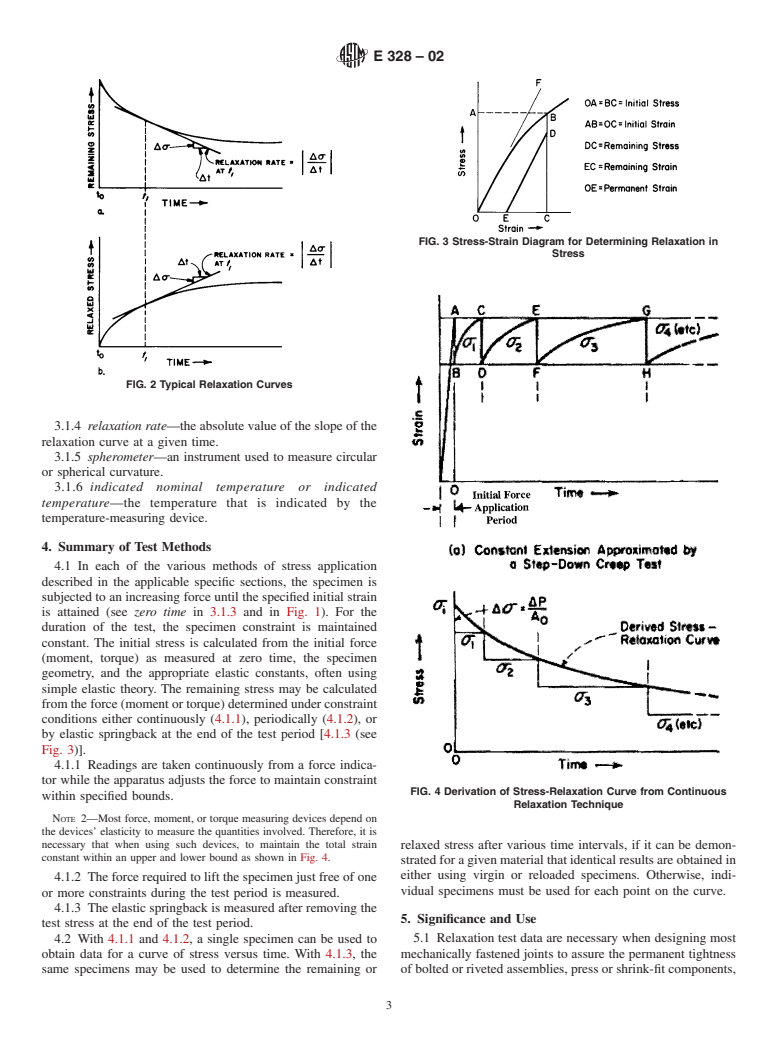

FIG. 1 Characteristic Behavior During Force Application Period in a Relaxation Test

2. Referenced Documents should

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.