ASTM F1665-95

(Specification)Standard Specification for Poly(Vinyl Chloride) (PVC)and Other Conforming Organic Polymer-Coated Steel Barbed Wire Used With Chain-Link Fence

Standard Specification for Poly(Vinyl Chloride) (PVC)and Other Conforming Organic Polymer-Coated Steel Barbed Wire Used With Chain-Link Fence

SCOPE

1.1 This specification covers poly(vinyl chloride)-coated steel barbed wire consisting of two poly(vinyl chloride)-coated strands, with four-point barbs of zinc-coated steel or aluminum alloy wire. Poly(vinyl chloride) hereinafter will be designated PVC.

1.2 Barbed wire strand wire, produced from three classes of wire coatings, is covered as follows:

1.2.1 Class 1 , consisting of PVC coating extruded over zinc-coated or aluminum-coated or zinc-5% aluminum-mischmetal alloy-coated steel wire;

1.2.2 Class 2a , consisting of PVC coating extruded and adhered to zinc-coated or aluminum-coated or zinc-5% aluminum-mischmetal alloy-coated steel wire; and

1.2.3 Class 2b , consisting of PVC coating fused and adhered to zinc-coated or aluminum-coated or zinc-5% aluminum-mischmetal alloy-coated steel wire.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1665 – 95

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Poly(Vinyl Chloride) (PVC)-Coated Steel Barbed Wire Used

1

With Chain-Link Fence

This standard is issued under the fixed designation F 1665; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope F 934 Specification for Standard Colors for Polymer Coated

2

Chain Link Fence Materials

1.1 This specification covers poly(vinyl chloride)-coated

G 23 Practice for Operating Light-Exposure Apparatus

steel barbed wire consisting of two poly(vinyl chloride)-coated

(Carbon-Arc Type) With and Without Water for Exposure

strands, with four-point barbs of zinc-coated steel or aluminum

6

of Nonmetallic Materials

alloy wire. Poly(vinyl chloride) hereinafter will be designated

G 26 Practice for Operating Light-Exposure Apparatus

PVC.

(Xenon-Arc Type) With and Without Water for Exposure

1.2 Barbed wire strand wire, produced from three classes of

6

of Nonmetallic Materials

wire coatings, is covered as follows:

7

2.2 Federal Standard:

1.2.1 Class 1, consisting of PVC coating extruded over

Fed. Std. No. 123 Marking for Shipments (Civil Agencies)

zinc-coated or aluminum-coated or zinc-5 % aluminum-

7

2.3 Military Standards:

mischmetal alloy-coated steel wire;

MIL-STD-129 Marking for Shipment and Storage

1.2.2 Class 2a, consisting of PVC coating extruded and

MIL-STD-163 Steel Mill Products, Preparation for Ship-

adhered to zinc-coated or aluminum-coated or zinc-5 %

ment and Storage

aluminum-mischmetal alloy-coated steel wire; and

1.2.3 Class 2b, consisting of PVC coating fused and ad-

3. Terminology

hered to zinc-coated or aluminum-coated or zinc-5 %

3.1 Definitions—For definitions of terms such as fabric

aluminum-mischmetal alloy-coated steel wire.

(chain-link fence) and PVC, see Terminology F 552.

1.3 The values stated in inch-pound units are to be regarded

as the standard. The values given in parentheses are for

4. Classification

information only.

4.1 PVC-coated steel barbed wire is supplied in a choice of

2. Referenced Documents

two types as follows:

4.1.1 Type I (Standard), with barbs spaced on 5-in. (127-

2.1 ASTM Standards:

mm) centers; and

A 90/A90M Test Method for Weight [Mass] of Coating on

2

4.1.2 Type II (High Security), with barbs spaced on 3-in.

Iron and Steel Articles with Zinc or Zinc-Alloy Coatings

(76-mm) centers.

A 370 Test Methods and Definitions for Mechanical Testing

3

of Steel Products

5. Ordering Information

A 428 Test Method for Weight of Coating on Aluminum-

2

5.1 Orders for barbed wire purchased in accordance with

Coated Iron or Steel Articles

this specification shall include the following information:

A 700 Practices for Packaging, Marking, and Loading

4

5.1.1 Quantity (expressed in number of spools);

Methods for Steel Products for Domestic Shipment

5.1.2 Length of spools (1320 or 1000 ft (402 or 305 m); see

D 1499 Practice for Operating Light- and Water-Exposure

5

9.4);

Apparatus (Carbon-Arc Type) for Exposure of Plastics

2

5.1.3 Class of PVC coating to be applied to metallic-coated

F 552 Terminology Relating to Chain Link Fencing

steel strand wire;

F 668 Specification for Poly(Vinyl Chloride) (PVC)-Coated

2

5.1.4 Color of coating;

Steel Chain-Link Fence Fabric

5.1.5 Type of barbs (galvanized steel or aluminum alloy; see

6.3);

1

This specification is under the jurisdiction of ASTM Committee F-14 on Fences

5.1.6 Type of barbed wire (Type I or II; see 4.1.1 and 4.1.2);

and is the direct responsibility of Subcommittee F14.40 on Chain Link Fence and

5.1.7 Selection of type of metallic coating on the steel strand

Wire Accessories.

Current edition approved Nov. 10, 1995. Published January 1996.

2

Annual Book of ASTM Standards, Vol 01.06.

3 6

Annual Book of ASTM Standards, Vol 01.03. Annual Book of ASTM Standards, Vol 06.01.

4 7

Annual Book of ASTM Standards, Vol 01.05. Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

5

Annual Book of ASTM Standards, Vol 08.01. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

1

---------------------- Page: 1 ----------------------

F 1665

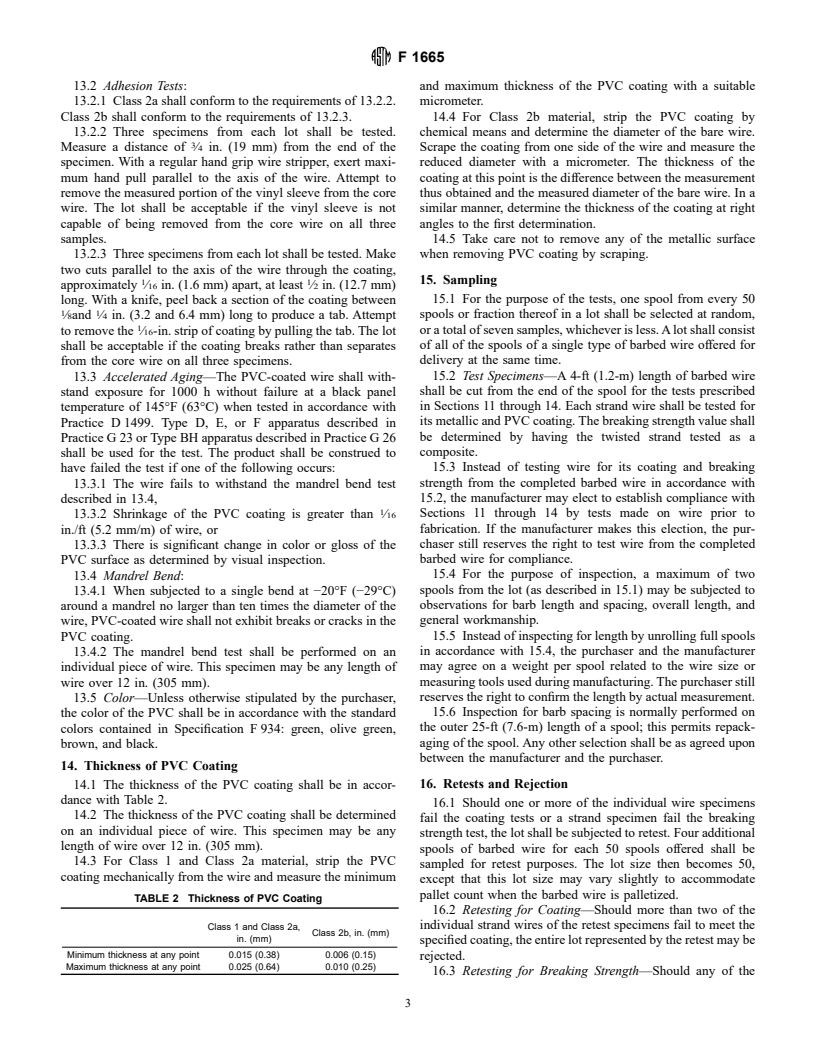

wire substrate, which shall be the choice of the producer unless specification shall be fabricated from two strands of 14 gage,

otherwise specified; 0.080-in. (2.03-mm) metallic-coated core, PVC-coated steel

5.1.8 Packaging requirements; wire, with four-point barbs of 14 gage, 0.080-in. zinc-coated

5.1.9 ASTM designation and year of issue; and steel or aluminum alloy wire.

5.1.10 Certification, if re

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.