ASTM F2013-00

(Test Method)Standard Test Method for Determination of Residual Acetaldehyde in Polyethylene Terephthalate Bottle Polymer Using an Automated Static Head-Space Sampling Device and a Capillary GC with a Flame Ionization Detector

Standard Test Method for Determination of Residual Acetaldehyde in Polyethylene Terephthalate Bottle Polymer Using an Automated Static Head-Space Sampling Device and a Capillary GC with a Flame Ionization Detector

SCOPE

1.1 This test method covers a gas chromatographic procedure for the determination of the ppm residual acetaldehyde (AA) present in poly(ethylene terephthalate) (PET) homo-polymers and co-polymers which are used in the manufacture of beverage bottles. This includes sample types of both amorphous and solid-stated pellet and preform samples.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 2013 – 00

Standard Test Method for

Determination of Residual Acetaldehyde in Polyethylene

Terephthalate Bottle Polymer Using an Automated Static

Head-Space Sampling Device and a Capillary GC with a

Flame Ionization Detector

This standard is issued under the fixed designation F 2013; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope of PET. Thus, it becomes trapped in the sidewalls of a molded

article and desorbs slowly into the contents packaged therein.

1.1 This test method covers a gas chromatographic proce-

In some foods and beverages AA can impart an off-taste that is

dure for the determination of the ppm residual acetaldehyde

undesirable, thus, it is important to know its concentration in

(AA) present in poly(ethylene terephthalate) (PET) homo-

PET articles that are to be used in food contact applications.

polymers and co-polymers which are used in the manufacture

5.2 The desorption conditions of 150 C for 60 min are such

of beverage bottles. This includes sample types of both

that no measurable AA is generated by the sample during the

amorphous and solid-stated pellet and preform samples.

desorption process.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

6. Sources of Error

responsibility of the user of this standard to establish appro-

6.1 A bias is known to exist if the ratio of sample mass (mg)

priate safety and health practices and determine the applica-

to head-space vial volume (mL) exceeds a value of ten.

bility of regulatory limitations prior to use.

6.2 Acetaldehyde is very volatile and must be handled

2. Referenced Documents carefully to avoid sample loss during the calibration procedure.

Storing the standard vials in a refrigerator is a must to

2.1 ASTM Standards:

minimize the error due to volatility.

D 4509 Test Method for Determining the 24-Hour Gas (Air)

6.3 Failure to achieve a tight seal on the head-space vial will

Space Acetaldehyde Content of Freshly Blown PET

result in the loss of acetaldehyde during storage and desorp-

Bottles

tion, producing a false low value.

3. Terminology 6.4 Failure to grind the sample to the appropriate particle

size may lead to a false low value for residual AA due to the

3.1 The terms employed in this test method are commonly

increased path length for desorption.

used in normal laboratory practice and require no special

6.5 Samples submitted for 8residual AA measurement’

comment.

should be stored in a freezer until they are tested. Failure to do

4. Summary of Test Method

so can result in lower than expected results.

6.6 Excessive grinding of samples can cause residual AA

4.1 A specified size (800 to 1000 μm) of granulated sample

contained therein to be desorbed. Extensive excessive grinding

is weighed into a 20-mL head-space vial, sealed, and then

can lead to actual melting of the polymer and AA generation.

heated at 150°C for 60 min. After heating, the gas above the

Samples which have been chilled in liquid nitrogen properly

sealed sample of PET polymer is injected onto a capillary GC

should only be in the grinder for ;30 s or less.

column. The acetaldehyde is separated, and the ppm of

acetaldehyde is calculated.

7. Apparatus

5. Significance and Use

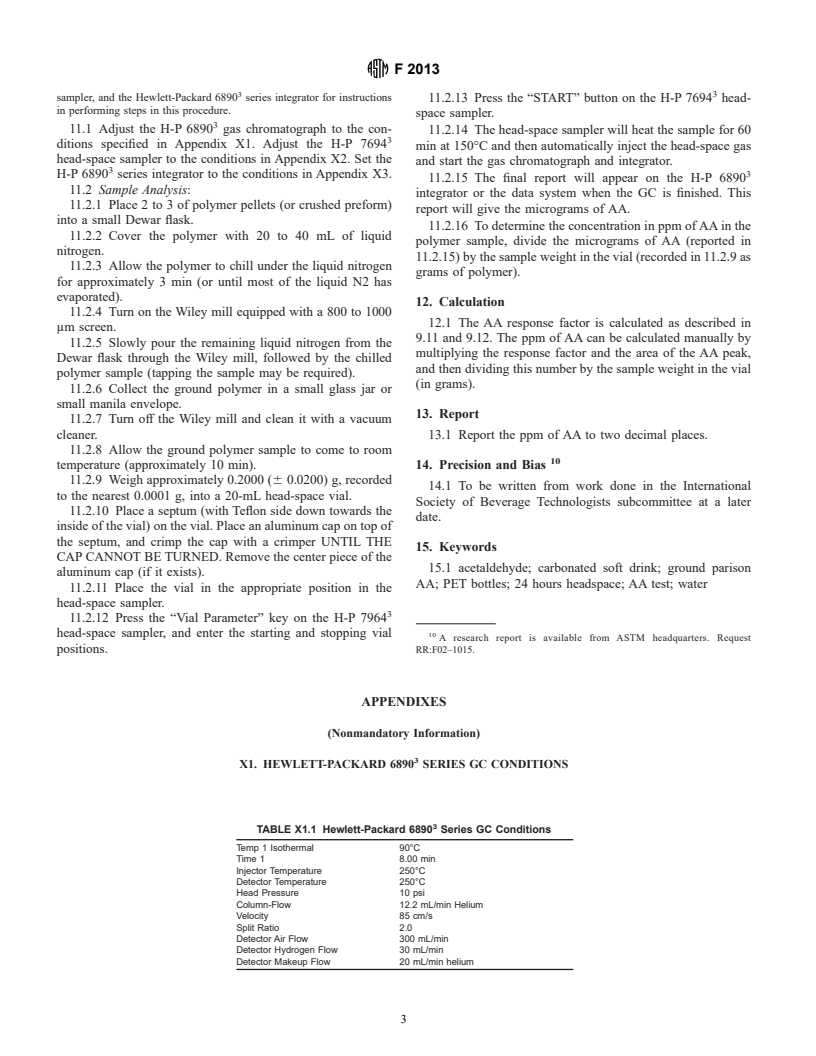

7.1 Gas Chromatograph, Hewlett-Packard 6890 series

7.2 Integrator, Hewlett-Packard Model 6890 series, H-P

5.1 This test method is of particular use as a quality control

ChemStation, H-P LAN.

tool for a molding or synthesis operation. Acetaldehyde is a

7.3 Head-Space Sampler, Hewlett-Packard 7694.

volatile degradation product generated during melt processing

1 3

This test method is under the jurisdiction of ASTM Committee F02 on Flexible Hewlett-Packard apparatus, website: hewlett-packard.com, was used in the

Barrier Materials and is the direct responsibility of Subcommittee F02.30 on Test development of this standard. If you are aware of alternative suppliers, please

Methods. provide this information to ASTM headquarters. Your comments will receive careful

Curren edition approved April 10, 2000. Published August 2000. consideration at a meeting of the responsible technical committee, which you may

Annual Book of ASTM Standards, Vol 08.03. attend.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

F 2013

7.4 Column, 30-m by 0.53-mm i.d. (megabore capillary 9.4 Depress the plunger until the digital readout is 2.000 μL.

column). 9.5 Smear the excess liquid that is on the syringe tip on the

7.5 Vials, 20-mL, head-space, with 20-mm septa, 20-mm OUTSIDE of the headspace vial.

aluminum caps, and crimper for 20-mm caps 9.6 Place the syringe inside of the vial so that the tip just

7.5.1 Vials: touches the bottom of the vial.

Perkin-Elmer Part Numer 0105–0129 , or Kimble Glass Inc. 9.7 Quickly inject the liquid standard into the vial and swirl

Part Number 60827A-2375 , or Hewlett-Packard Part Number the syringe tip around the inside of the vial to smear all liquid

5182–0837 . on the vial walls.

7.5.2 Septa: 9.8 Remove the syringe and IMMEDIATELY cap the vial.

Pierce Part Number 12720, or Hewlett-Packard Part Number 9.9 Calculate the weight of AA based on the standard’s

9301–0807. certified value and a 2.000-μL injection volume.

7.5.3 Caps:

NOTE 2—Acetaldehyde is very volatile. The AA ampules must be

Pierce Part Number 13214, or Hewlett-Packard Part Number

stored in a refrigerator, and the standards prepared immediately after

9301–0721.

breaking open an ampule.

7.6 Crimper, 20-mm, Wheaton Part Number 224303.

9.10 Analyze the working standard by the procedure de-

7.7 Decrimper, 20-mm, Kimble Part Number 69903–20.

scribed in Section 11, starting with 11.2.11.

7.8 Wiley Mill, equipped with an 800 to 1000 μm screen, or

9.11 Calculate an AA response factor for the standard using

equivalent

the following equation:

7.9 Syringe, calibrated, with certificate of calibration.

response factor of AA 5 Wt of AA in μg/area of AA (1)

7.10 Small Vacuum Cleaner, with host attachment for clean-

ing. NOTE 3—Due to the error associated with the certified standard,

9.1-9.11 should be performed five times using five different standard

7.11 Analytical Balance, capable of accurately weighing to

ampules.

at least 60.0001 g.

9.12 Average the five response factors obtained, and use this

7.12 Hammer.

value for the sample analyses.

8. Reagents and Materials

9.13 Manually enter the calculated response factor in the

calibration list of the Hewlett-Packard 6890 integrator or data

8.1 Acetaldehyde (AA), 500 ppm AA in water (or 1000

system.

ppm), purchased certified standard.

8.2 Liquid Nitrogen, plant grade (R-3, S-3).

NOTE 4—During a series of sample analyses, a periodic check of

instrument performance is recommended by placing a few liquid standard

9. Calibration and Standardization

samples throughout the sample set. If these values fall out of the

acceptable range as specified by the certificate of analysis, recalibration

NOTE 1—The following procedure should be performed and recorded

(9.1-9.12) should be performed.

once every three months.

10. Sample Preparation

9.1 Break open a certified AA standard ampule. (Ampules

must be stored in a refrigerator.)

10.1 Parisons or Preforms or Plaques—May be cryogeni-

9.2 Using the syringe, fill it by placing the tip in the liquid

cally ground whole, or can be broken into small pieces with a

standard and quickly moving the plunger up and down several

hammer (using liquid nitrogen) and then ground with the aid of

time to evacuate any bubbles, then pull the plunger back past

grinding mill equipped with a 20 mesh or 850 μm screen. The

the 2.000-μL mark to 2.200 to 2.250 μL.

grind should be thoroughly homogenized before sampling for

9.3 Wipe the syringe needle with a tissue.

AA. If the appropriate size screen is not available on the large

grinding mill, then it is suggested that the sample be ground to

3 to 6 mm on the large mill and the s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.