ASTM F2866-10

(Test Method)Standard Test Method for Flammability of a Membrane Switch in Defined Assembly

Standard Test Method for Flammability of a Membrane Switch in Defined Assembly

SIGNIFICANCE AND USE

There are numerous flammability ratings and tests. Almost without fail, these standards and tests are focused on very specific industries or results, many of which are not applicable to the membrane switch/human machine interface assembly. This test is designed to provide relative results between membrane switches that have been assembled to the unit's final enclosure, housing, etc.

In addition to the test's measurement of the rate of burn, a laboratory can also observe the effects of burning material falling from the test specimen onto other materials (typically a gauze test area) not directly part of the test specimen. The indirect burning is an issue of interest to see if the test specimen will be able to act as an initiator for a far greater and more damaging flame event (fire). Observations should be noted, as qualitative descriptions, as appropriate.

This test can measure the flammability via the use of high-speed photographic or video equipment.

Temperature of the ignition source can be measured via a calibrated thermocouple pyrometer, calorimeter or IR thermometer with an appropriate range.

This test is not designed to provide a PASS or NO PASS status for a switch, rather, it is designed to provide a “grade” for the level of flammability of a membrane switch assembly (as defined in 3.1.10). The end user should make the final determination if the level of flammability is acceptable for the particular application.

SCOPE

1.1 This test method covers the determination of the flammability characteristics of a membrane switch.

1.2 This test method defines the MSB rating of a membrane switch. Each character of the MSB rating represents a discrete characteristic of a membrane switch performance under destructive thermal loading.

1.3 This test procedure will be destructive, but should provide an insight into the relative performance flame-resistance characteristics of differing designs or assemblies, or both.

1.4 This test method will focus on the use of convective contact (burner flame) method for ignition, though other methods of ignition are available.

1.5 This test method is designed to determine if the membrane switch assembly will add (or detract) from the flame propagation from an exterior flame/fire source.

1.6 If this test is intended to be used for an internal flammability source then set up the unit under test (UUT) appropriately and note it in the test scope and results.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2866 – 10

Standard Test Method for

Flammability of a Membrane Switch in Defined Assembly

This standard is issued under the fixed designation F2866; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Rates for Materials and Products Using a Thermopile

Method

1.1 This test method covers the determination of the flam-

mability characteristics of a membrane switch.

3. Terminology

1.2 This test method defines the MSB rating of a membrane

3.1 Definitions:

switch. Each character of the MSB rating represents a discrete

3.1.1 burn damage—percentage of the UUT that is dam-

characteristic of a membrane switch performance under de-

aged due to burn test. This is a visiual observation.

structive thermal loading.

3.1.2 flame propagation—refers to patterns in the flame

1.3 This test procedure will be destructive, but should

front that are examined (for example, uniform rate of advance,

provide an insight into the relative performance flame-

spotty ignition or charring, etc.). These observations are

resistance characteristics of differing designs or assemblies, or

qualitative and should be noted in the data field.

both.

3.1.3 flame spread rate (FSR)—described as the rate at

1.4 This test method will focus on the use of convective

which a flame front will travel along the surfaces of tested

contact (burner flame) method for ignition, though other

materials/assemblies. Typically measured in mm/s or in./min.

methods of ignition are available.

3.1.4 flame target area—refers to the normalized target area

1.5 This test method is designed to determine if the mem-

of a UUTthat will be used for ignition location.Any variations

brane switch assembly will add (or detract) from the flame

should be noted.

propagation from an exterior flame/fire source.

3.1.5 flame time (F ) or flame endurance—amount of

time

1.6 If this test is intended to be used for an internal

time, usually in seconds, that a self-sustaining flame will

flammability source then set up the unit under test (UUT)

endure after removal of initial ignition source before flame on

appropriately and note it in the test scope and results.

UUT is extinguished.

1.7 This standard does not purport to address all of the

3.1.6 flame time of drippings (F )—amount of time

time,drip

safety concerns, if any, associated with its use. It is the

that burning drippings, if any, remain burning. Typically

responsibility of the user of this standard to establish appro-

measured in seconds.

priate safety and health practices and determine the applica-

3.1.7 gauze ignition—this is a verification that UUT ignites

bility of regulatory limitations prior to use.

the gauze.

2. Referenced Documents 3.1.8 ignition source—the source that provides the heat-flux

2 to begin the flammability test. This test method will recom-

2.1 ASTM Standards:

mend a convective flame for the ignition source, however, care

E906 Test Method for Heat and Visible Smoke Release

should be taken that any comparative tests should use the same

method of ignition.

3.1.9 mass-loss (m )—the mass from a test specimen it

loss

This test method is under the jurisdiction of ASTM Committee F01 on

lost to smoke, vaporization and char debris carried away or

Electronics and is the direct responsibility of Subcommittee F01.18 on Membrane

fallen away, or both, during the flammability test cycle.

Switches.

Typically measured in grams (average).

Current edition approved Dec. 1, 2010. Published January 2011. DOI: 10.1520/

F2866-10.

3.1.10 membrane switch assembly—the membrane switch

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

should not be tested in its unmounted state. The switch sample

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

should be mounted onto the final end-use enclosure, panel,

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. bezel, or agreed upon material.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2866 – 10

3.1.10.1 Discussion—Assembly Specimen: This test method 4.5 This test is not designed to provide a PASS or NO PASS

is trying to provide a practical world analog for the results status for a switch, rather, it is designed to provide a “grade”

herein obtained.As a result, the unit under test (UUT) must in for the level of flammability of a membrane switch assembly

the final mounted condition. The test is able to show flame- (as defined in 3.1.10). The end user should make the final

resistance in the final assembly as it interacts with the determination if the level of flammability is acceptable for the

membrane switch’s construction. particular application.

3.1.11 MSB—rating to quantify the burn characteristics of a

5. Interferences

membrane switch. Each character of the MSB rating represents

a discrete characteristic of a membrane switch performance

5.1 Method of Ignition—Results compared between differ-

under destructive thermal loading. (see Table 1.)

ent methods of ignition (radiant versus convective) may

3.1.12 time-to-ignition (t ) —the time it takes for a target

provide different results for t . Therefore any comparative

ign

ign

specimento“ignite”underthermalloadingwithaself-standing

samples should use the same calibrated method of ignition.

flame front. The method for ignition (source) can be conduc-

5.2 Mounted in Final Assembly—Mounting the membrane

tive contact (super-heated filament), radiant energy (electrical

switchtotheendusesubstrateorenclosurewillaccountforthe

or gas) or convective (free flame). Typically measured in

thermal heat sink effect provided by the mounting substrate or

seconds.

enclosure.

3.1.12.1 Discussion—A “perfect” incombustible material

5.3 Rigid Fixture Support—Themembraneswitchassembly

will have infinite time to ignition; similarly a UUT with no

should have rigid fixture support in order to allow remote

sustained flame within the length of the ignition exposure

testing during the burn cycle. UUT should be mounted to

would be reported as “no ignition time observed”.

insure that the parts to do not fall while under test.

3.1.12.2 Discussion—Using a convective (free flame) igni-

5.4 Venting of the FPA Test Booth—The type and placement

tion source the time to ignition may be difficult to determine

of venting and exhausting for airflow in test booth should be

(due to the fact that there is interference between the ignition

noted or documented by photos or drawings, or both. Dupli-

source and the ignition of the UUT).

cation of test results may be achieved only with the same

amount of air-flow and air-to-fuel mixture in the test booth.

4. Significance and Use

5.5 Oxygen Concentration—The concentration of the oxy-

gen in the FPA chamber atmosphere (normal air, concentrated

4.1 There are numerous flammability ratings and tests.

O , pressurized, etc.) during the test or oxidizers, or both,

Almost without fail, these standards and tests are focused on

found in the test material(s) will affect the results.

very specific industries or results, many of which are not

5.6 Duration of Ignition—The longer the ignition burn test

applicable to the membrane switch/human machine interface

the greater the chance the part will ignite and begin to exhibit

assembly. This test is designed to provide relative results

flame propagation.

between membrane switches that have been assembled to the

5.7 Relative Humidity in FPA—It is thought this will have

unit’s final enclosure, housing, etc.

some effect on the results, however the extent of which is to be

4.2 In addition to the test’s measurement of the rate of burn,

determined.

a laboratory can also observe the effects of burning material

falling from the test specimen onto other materials (typically a

6. Apparatus

gauze test area) not directly part of the test specimen. The

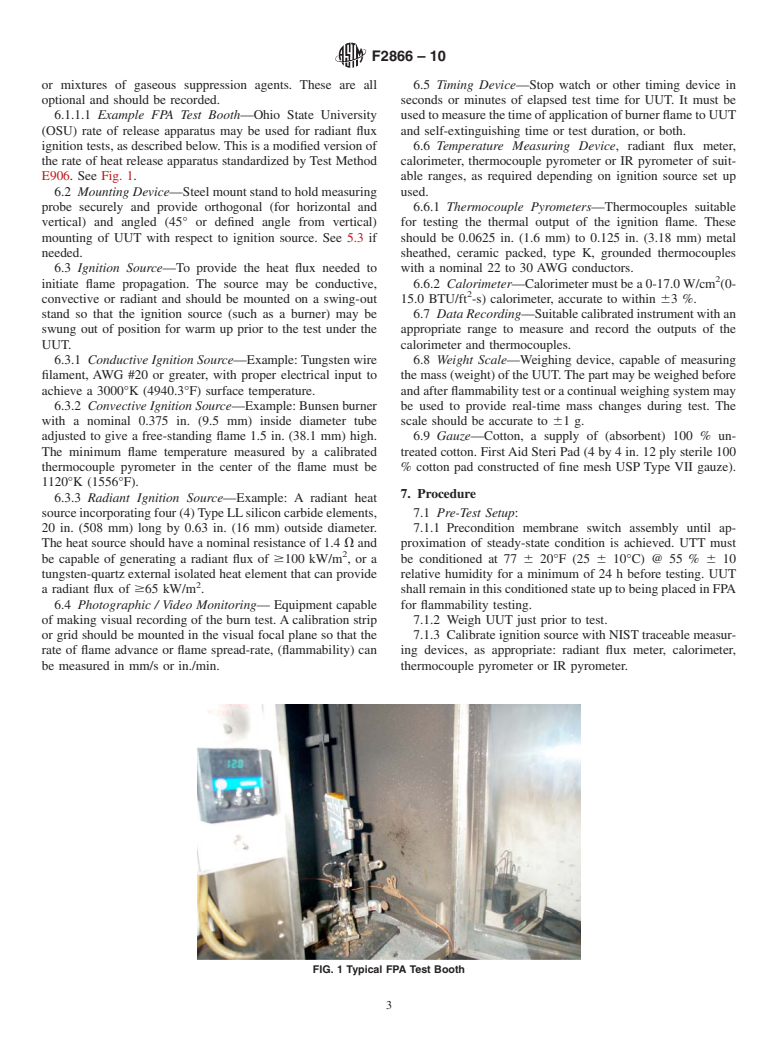

indirect burning is an issue of interest to see if the test 6.1 Fire Propagation Apparatus (FPA)—Draft-free booth

specimen will be able to act as an initiator for a far greater and made of non-flammable material (high-temp Pyrex, ceramic or

more damaging flame event (fire). Observations should be steel) rectangular or cylindrical space with proper: (1) ventila-

noted, as qualitative descriptions, as appropriate. tion for exhaust fumes, smoke, etc., (2) free empty area for

4.3 This test can measure the flammability via the use of mounting rigs and UUT and (3) appropriate fixings and

high-speed photographic or video equipment. mounts, as needed for ignition source and (4) vent holes or

4.4 Temperature of the ignition source can be measured via ventilation, or both, for inflow of fresh air.

a calibrated thermocouple pyrometer, calorimeter or IR ther- 6.1.1 FPA—may also provide oxygen in standard sea-level

mometer with an appropriate range. normal air concentration, 40 % oxygen, air with pure nitrogen

TABLE 1 MSB Rating

Model t Time to ignition FSR Flame Spread Rate F Continuation of burn m Mass loss Burn Damage % Gauze Ignition

(ign) (time) (loss)

The following >> 0 = no ignition 0 = no burn 0 = self extinguishing 0 = no loss 0=0% damage 0 = no

should be 1 = 10 s> 1=1mm/s 1=1s 1=10%loss 1=10% damage

considered 2=9s 2=2mm/s 2=2s 2=20%loss 2=20% damage

when deciding 3=8s 3=3mm/s 3=3s 3=30%loss 3=30% damage

onaswitch 4=7s 4=4mm/s 4=4s 4=40%loss 4=40% damage

MSBrating 5=6s 5=5mm/s 5=5s 5=50%loss 5=50% damage

6=5s 6=6mm/s 6=6s 6=60%loss 6=60% damage

7=4s 7=7mm/s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.