ASTM D4151-92(2001)

(Test Method)Standard Test Method for Flammability of Blankets (Withdrawn 2010)

Standard Test Method for Flammability of Blankets (Withdrawn 2010)

SIGNIFICANCE AND USE

This test method for the determination of the flammability of blankets is considered satisfactory for acceptance testing of commercial shipments of blankets since this test method has been used extensively in the trade for acceptance testing.

This test method may be used to evaluate electric blanket fabric, but tests should be performed on the fabric itself without the resistance heating wires inserted.

All fabrics made of natural or regenerated cellulose, as well as many made from other natural or synthetic fibers, are combustible. Some combustible fabrics when used for blankets are potentially dangerous to the user because of the ease of ignition, rapidity, and intensity of burning. The first characteristic can be judged with the aid of the flammability tester.

SCOPE

1.1 This test method provides a means to identify blanket fabrics which ignite easily and propagate flame across the surface.

1.2 This test method specifies the procedures described in the "Voluntary Blanket Flammability Standard" which has been used by the blanket industry in the United States since 1972.

1.3 This test method should be used to measure and describe the properties of materials, products, or assemblies in response to heat and flame under controlled laboratory conditions and should not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire risk assessment which takes into account all of the factors which are pertinent to an assessment of the fire hazard of a particular end use.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method for the determination of the flammability of blankets is considered satisfactory for acceptance testing of commercial shipments of blankets since this test method has been used extensively in the trade for acceptance testing.

Formerly under the jurisdiction of Committee D13 on Textiles and the direct responsibility of Subcommittee D13.52 on Flammability, this test method was withdrawn in January 2010 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D4151–92 (Reapproved 2001)

Standard Test Method for

Flammability of Blankets

This standard is issued under the fixed designation D4151; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method provides a means to identify blanket 3.1 Definitions:

fabrics which ignite easily and propagate flame across the 3.1.1 blanket, n—for bedding, an unquilted fabric covering

surface. designed primarily to provide thermal insulation.

1.2 This test method specifies the procedures described in 3.1.1.1 Discussion—Blankets may be made by any textile

the“ Voluntary Blanket Flammability Standard” which has process from various types of fibers and may or may not have

been used by the blanket industry in the United States since a raised fiber surface. Construction may be woven, knitted,

1972. flocked, or nonwoven.

1.3 This test method should be used to measure and describe 3.1.1.2 Discussion—Electric blankets include resistance

the properties of materials, products, or assemblies in response heating wires and can provide heat as well as thermal insula-

to heat and flame under controlled laboratory conditions and tion.

should not be used to describe or appraise the fire hazard or 3.1.2 flammability, n—those characteristics of a material

fire risk of materials, products, or assemblies under actual fire that pertain to its relative ease of ignition and relative ability to

conditions. However, results of this test may be used as sustain combustion.

elements of a fire risk assessment which takes into account all

NOTE 1—In this test, evidence of ignition is shown by discoloration,

of the factors which are pertinent to an assessment of the fire

charring, or burning of the paper monitor.

hazard of a particular end use.

3.1.3 ignition, n—initiation of combustion.

1.4 This standard does not purport to address all of the

3.2 For definitions of other textile terms used in this test

safety problems, if any, associated with its use. It is the

method, refer to Terminology D123.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Summary of Test Method

bility of regulatory limitations prior to use.

4.1 Specimens cut from the blanket fabric are prepared by

brushing if they have a raised fiber surface and by drying. The

2. Referenced Documents

dried specimen is held in a special apparatus, a standardized

2.1 ASTM Standards:

flame is applied to the surface for a specified time under

D123 Terminology Relating to Textiles

controlled conditions, and burning, charring, or discoloration

D1230 Test Method for Flammability of Apparel Textiles

of a paper monitor is noted. Two classes of flammability are

D1776 Practice for Conditioning and Testing Textiles

described.

D3411 Test Methods for Flammability of Textile Materials

4.1.1 A burn of sufficient intensity to discolor a paper

2.2 Federal Specification:

monitor in specified contact with the surface of the test

NNN-P-40b

specimen indicates ignition of the blanket surface (see 11.4.1).

5. Significance and Use

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

and is the direct responsibility of Subcommittee D13.52 on Flammability.

5.1 This test method for the determination of the flamma-

Current edition approved July 30, 1982. Published September 1982. Originally

bility of blankets is considered satisfactory for acceptance

published as D4151 – 82. Last previous edition D4151 – 82. DOI: 10.1520/D4151-

testing of commercial shipments of blankets since this test

92R01.

method has been used extensively in the trade for acceptance

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

testing.

Standards volume information, refer to the standard’s Document Summary page on

5.2 This test method may be used to evaluate electric

the ASTM website.

blanketfabric,buttestsshouldbeperformedonthefabricitself

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS. without the resistance heating wires inserted.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4151–92 (2001)

5.3 All fabrics made of natural or regenerated cellulose, as 6.2 Specimen Holder and Base, as shown in Figs. 5 and 6.

well as many made from other natural or synthetic fibers, are 6.2.1 The base shall be mounted on the floor of the cabinet

combustible. Some combustible fabrics when used for blankets approximately center on both axes. The position of the base

are potentially dangerous to the user because of the ease of shall be adjustable along both the length and width axes of the

ignition, rapidity, and intensity of burning. The first character- flammability test cabinet.

istic can be judged with the aid of the flammability tester. 6.3 Burner, as shown in Fig. 7.

6.3.1 The burner is a No. 18 hypodermic needle.The needle

6. Apparatus and Materials

is cut off below the ferrule approximately 1.5 mm ( ⁄16 in.)

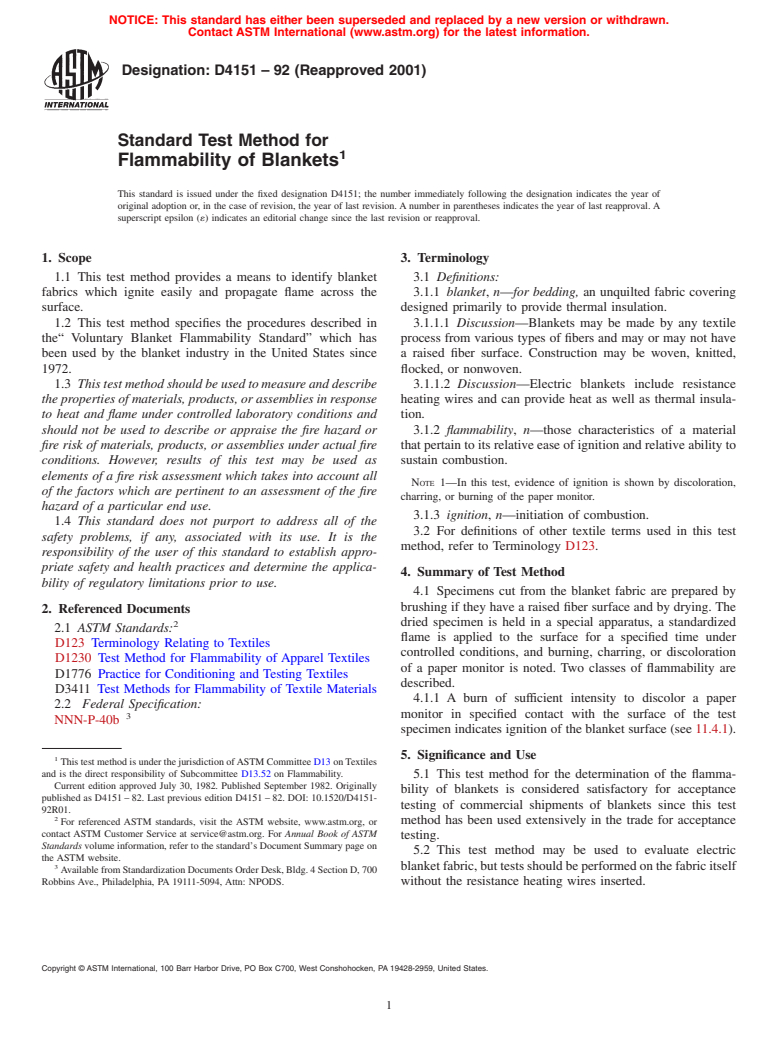

6.1 Flammability Tester, as shown in Figs. 1-4 and de-

long. One end of an 3-mm ( ⁄8-in.) OD copper tube approxi-

scribed in A1.1.1, A1.1.2, and A1.1.9 of Test Method D1230.

mately200mm(8in.)longissolderedorcementedwithepoxy

6.1.1 The test cabinet shall be equipped with a system to

adhesive into the ferrule of the hypodermic needle. The other

control the time of flame impingment on the specimen to 1 6

end is soldered to the gas feeding tube which is part of the

0.05 s. A system found to be suitable is:

mechanism used to impinge the flame on the specimen (see

6.1.1.1 Adjustable electronic timer controlling a burner

Figs. 1-7).

solenoid to activate the burner mechanism.

6.4 Methane, technical grade (at least 97 % pure).

6.1.1.2 Electronic Counter (digital clock reading to 0.01 s),

6.4.1 The gas line to the burner shall be equipped with a

started by a switch that is activated by the burner mechanism

needle valve to control the flame length.

when the burner is in the position to impinge flame on the

6.4.2 Gas shall be supplied to the burner at a pressure of

specimen and is stopped when the burner retracts from the

17.2 6 3.4 kPa (2.5 6 0.5 psig) at the needle valve inlet.

specimen.

6.5 Brushing Device, as shown in Fig. 8 and described in

A1.2 of Test Method D1230, except that the brush rests on the

NOTE 2—Aflammability tester made for use inTest Method D1230 has

carriage vertically with a pressure of 75 6 10 g instead of 150

to be modified when used with Test Method D4151 by changing the

burner, specimen holder, and timing mechanism. g as described in A1.2.1 of Test Method D1230.

FIG. 1 Flammability Tester

D4151–92 (2001)

FIG. 2 Flammability Tester (Cabinet Details)

FIG. 3 Flammability Tester (Additional Cabinet Details)

6.6 Laboratory Drying Oven, forced-draft.

D4151–92 (2001)

FIG. 4 Flammability Tester Arrangement

FIG. 5 Specimen Holder Assembly

6.7 Desiccator(s) of sufficient size to hold five mounted 6.8 Silica Gel Desiccant, indicating type.

specimens at one time.

D4151–92 (2001)

FIG. 6 Specimen Holder Details

FIG. 7 Burner Details

D4151–92 (2001)

FIG. 8 Brushing Device

6.9 Paper Monitor, conforming to Federal Specification 7.3 Laboratory Sample—For fabric in rolls or pieces, take

NNN-P-40b, Type II. asalaboratorysampleafullwidthswatch1m(1yd)longfrom

6.10 Laboratory Hood, or other suitable enclosure, to pro-

the outside of each roll in the lot sample or from one end of

vide a draft free environment surrounding the flammability each piece in the lot sample, after first discarding a full width

tester.

lengthof1mfromtheveryendofeachrollorpiece.Forfabric

already made up into end-use items, such as blankets, all of the

7. Sampling

items in the lot sample will c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.