ASTM C648-04(2009)

(Test Method)Standard Test Method for Breaking Strength of Ceramic Tile

Standard Test Method for Breaking Strength of Ceramic Tile

SIGNIFICANCE AND USE

The test method provides means for establishing whether or not a lot of ceramic tile meets the strength requirements which may appear in tile specifications. Tile strength is the force in pounds-force (or newtons), as read from the pressure gage, necessary to cause the tile to break.

SCOPE

1.1 This test method covers the determination of the breaking strength of glazed ceramic wall tile, ceramic mosaic tile, quarry tile, and paver tile, having a facial area of at least 1 in.2 (6.4 cm2).

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C648 − 04(Reapproved 2009)

Standard Test Method for

Breaking Strength of Ceramic Tile

This standard is issued under the fixed designation C648; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

NOTE 1—The size (facial dimensions) of otherwise equal tile affects the

1. Scope

value of breaking strength obtained by this test method. For instance, a 6

1.1 This test method covers the determination of the break-

by 6-in. (152 by 152-mm) tile equal in mature body properties and

1 1

ing strength of glazed ceramic wall tile, ceramic mosaic tile, thickness to a 4 ⁄4 by 4 ⁄4-in. (108 by 108-mm) tile will have a breaking

1 1

strength higher than the 4 ⁄4 by 4 ⁄4-in. tile.

quarry tile, and paver tile, having a facial area of at least 1 in.

(6.4 cm ).

5. Significance and Use

1.2 The values stated in inch-pound units are to be regarded

5.1 The test method provides means for establishing

as standard. The values given in parentheses are mathematical

whether or not a lot of ceramic tile meets the strength

conversions to SI units that are provided for information only

requirements which may appear in tile specifications. Tile

and are not considered standard.

strength is the force in pounds-force (or newtons), as read from

1.3 This standard does not purport to address all of the

the pressure gage, necessary to cause the tile to break.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 6. Apparatus

priate safety and health practices and determine the applica-

1 1

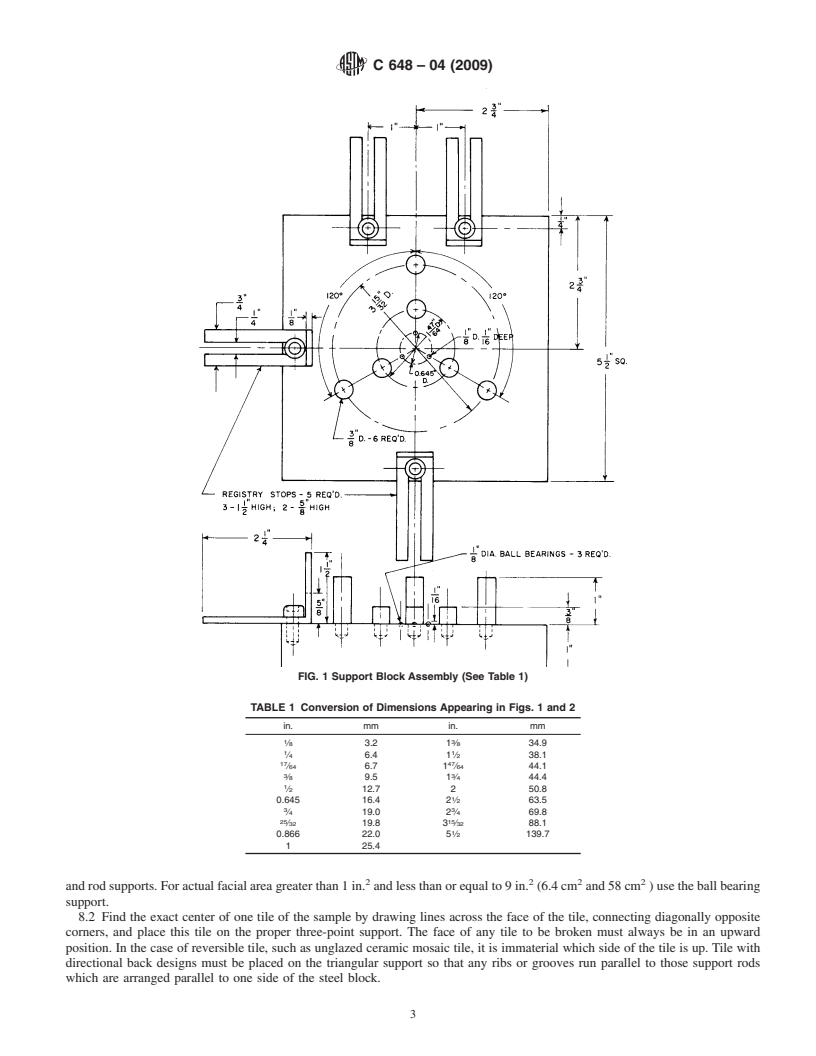

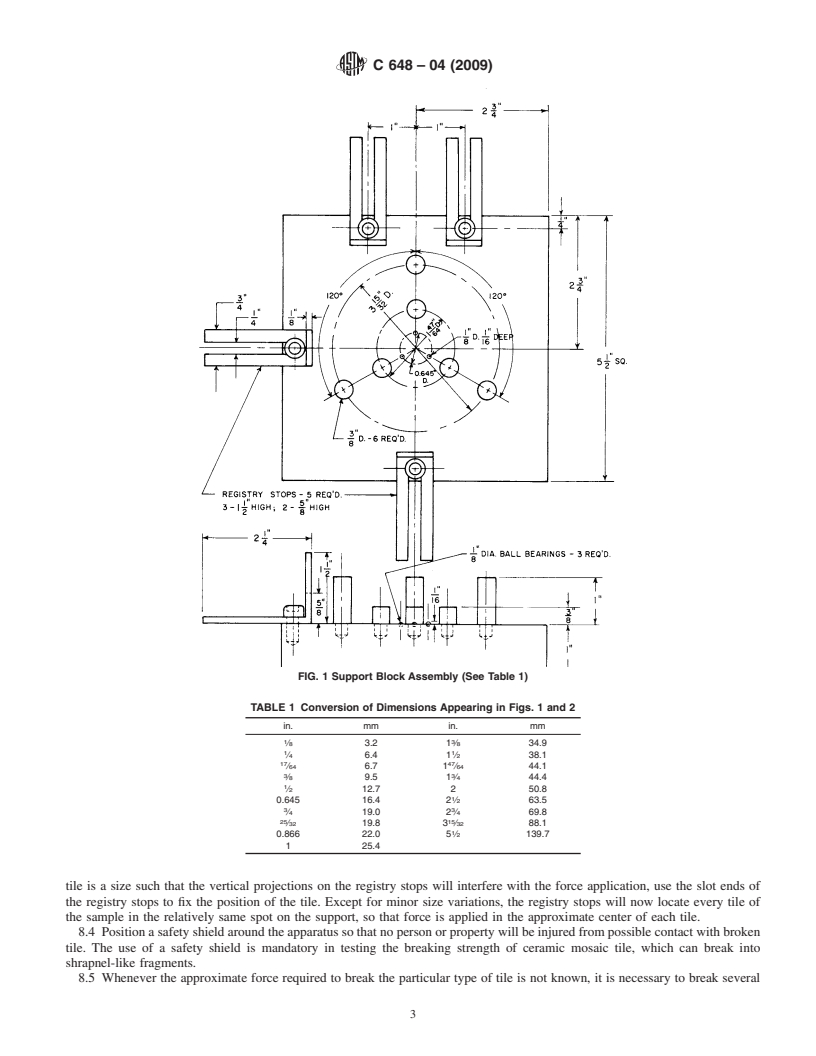

6.1 Specimen-Support, consisting of a 5 ⁄2 by 5 ⁄2 by 1-in.

bility of regulatory limitations prior to use.

(139.7 by 139.7 by 25.4-mm) steel block. Three ⁄4-in. (6.4-

mm) diameter and ⁄8-in. (9.5-mm) deep tapped holes are

2. Referenced Documents

arrangedinanequilateraltrianglehaving3-in.(76.2-mm)sides

2.1 ASTM Standards:

and whose circumscribed circle has a radius of 1.732 in. (44.0

C242 Terminology of Ceramic Whitewares and Related

mm). The equilateral triangle is located on the steel block so

Products

thatitscentercoincideswiththatofthesteelblockandoneside

E178 Practice for Dealing With Outlying Observations

of the triangle runs parallel to one side of the steel block.Three

3 3

⁄8-in. diameter steel rods, 1 ⁄8 in. with (34.9 mm) long, one end

3. Terminology

3 1

threaded for a distance of ⁄8 in. with the same ⁄4-in. thread as

3.1 Definitions: the tapped holes, and the other end ground flat, fit into the three

3.1.1 For definitions of the types of tile listed in Section 1, holes. In a similar manner, a second set of three ⁄8-in. diameter

refer to Terminology C242. steel rods, but ⁄4 in. (19.0 mm) long only, are threaded on one

end for a distance of ⁄8-in., are ground flat on the other end and

1 1

4. Summary of Test Method

fitthreeother ⁄4-in.tappedholes.Thethree ⁄4-in.holes,tapped

for a distance of ⁄8 in. to receive this second set of steel rods

4.1 The test method consists of supporting the tile on the

are located at the apexes of an equilateral triangle having

ends of three cylindrical rods, or on three ball bearings for tiles

2 2

1 ⁄2-in. (38.1-mm) long sides and whose circumscribed circle

having an actual facial area of 9 in. (58 cm ) (or less),

has a radius of 0.866 in. (22.0 mm). This second equilateral

arranged in an equilateral triangle, and applying force at a

triangle is located within the first one in such a manner that its

definite rate to the center of the tile, which coincides with the

circumscribed circle is identical with the inscribed circle of the

center of the triangular support, until the specimen breaks.

first triangle, and its sides are parallel to those of the larger

triangle. The ball bearing support consists of three ⁄8-in.

This test method is under the jurisdiction ofASTM Committee C21 on Ceramic

(3.2-mm) ball bearings arranged in an equilateral triangle, with

Whitewares and Related Productsand is the direct responsibility of Subcommittee

sides of 14 mm concentric and parallel with the other triangles.

C21.06 on Ceramic Tile.

The bearings are embedded in the block to the extent of half

Current edition approved Jan. 1, 2009. Published February 2009. Originally

their volume.The steel block has four more ⁄4-in. tapped holes

approved in 1970. Last previous edition approved in 2004 as C648 – 04. DOI:

10.1520/C0648-04R09.

to receive socket head cap screws for holding four registry

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

stops. One of these holes is located in the center of one side, ⁄4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in. in from the edge. Another of these is located in the center

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. of an adjacent side ⁄4 in. from the edge. The other two are

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C648 − 04 (2009)

locatedonanadjacentside, ⁄4 in.infromtheedge,spaced2in. screw through its slot in any one of numerous positions. Being

(50.8 mm) apart, with one located 1 ⁄4 in. (44.4 mm) from one adjustable, they serve as registry stops for the different sizes of

of the corners of the first side. The two single hole registry

tile which may be broken over these supports. For tile of

stops are used with the ball bearing support. The double hole

dimensions 4 ⁄4 in. (107.9 mm) or smaller, the projections will

registry stop and the adjacent edge single stop are to be used

be located on that end of the strip nearest to the support block;

with the sets of rod supports. Three of the registry stops

for tile having dimensions larger than 4 ⁄4 in., the strips are

designed for use with the cylindrical rod supports consist of

reversed so that the projections are located on the end of the

1 3

⁄8-in. (3.2-mm) thick steel strips, ⁄4 in. wide, 2 in. long, with

steel strips away from the support block (see Fig. 1). For

a ⁄4-in. wide slot extending for the full 2-in. length of the strip.

certain mosaic tiles with dimensions of less than 1 in. (25.4

The slot is open on one end and the other end of each steel strip

mm) length, it is necessary to reverse the position of the

3 1 1

has a ⁄4 in. wide and 1 ⁄2 in. high projection, ⁄8 in. thick, which

registry stops so that the tile is supported with the slot ends in

will contact the edges of the tile when in proper position for

order to avoid interference with the force applicator.

use.The other two registry stops, designed for use with the ball

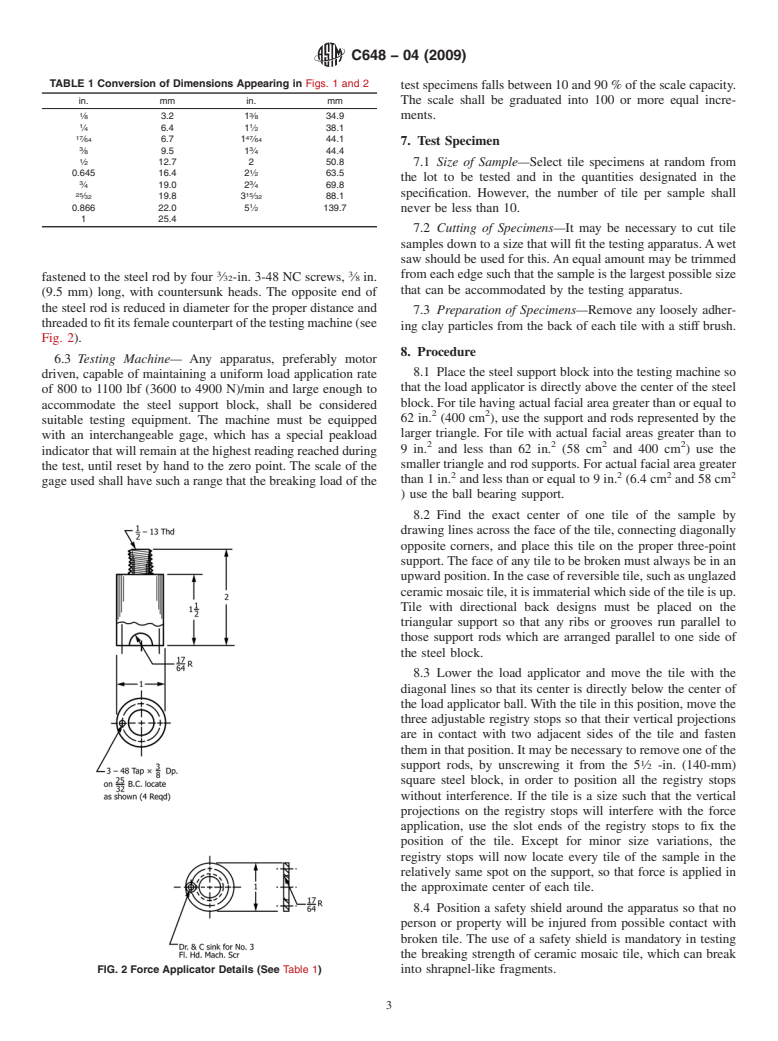

6.2 Force Applicator— Force is applied in the exact center

bearing support, have exactly the same dimensions except for

of the triangular support by means of a ⁄2-in. (12.7-mm)

their projection height which is ⁄8 in. The projection is

obtained by making the steel strips actually 3 ⁄2 in. (88.9 mm) diameter stainless steel ball bearing, countersunk to a depth of

1 17

⁄64 in. (6.7 mm) into one end of a 1-in. (25.4-mm) diameter

long and bending them at right angles to obtain the 1 ⁄2-in. or

⁄8-in.(38.1-mmor15.9-mm)highprojection.Eachofthethree and 2-in. long steel rod. A ⁄32-in. (2.4-mm) thick retaining

registry stops can be fastened with washer and socket head cap collar prevents the ball from falling out of its recess and is

FIG. 1 Support Block Assembly (See Table 1)

C648 − 04 (2009)

TABLE 1 Conversion of Dimensions Appearing in Figs. 1 and 2

test specimens falls between 10 and 90 % o

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C 648–98 Designation:C 648–04 (Reapproved 2009)

Standard Test Method for

Breaking Strength of Ceramic Tile

This standard is issued under the fixed designation C 648; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the breaking strength of glazed ceramic wall tile, ceramic mosaic tile, quarry

2 2

tile, and paver tile, having a facial area of at least 1 in. (6.4 cm ).

1.2The values stated in inch-pound units are to be regarded as the standard. The metric equivalents of inch-pound units may be

approximate.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C 242 Terminology of Ceramic Whitewares and Related Products

E 178 Practice for Dealing withWith Outlying Observations

3. Terminology

3.1 Definitions:

3.1.1 For definitions of the types of tile listed in Section 1, refer to Terminology C 242.

4. Summary of Test Method

4.1 The test method consists of supporting the tile on the ends of three cylindrical rods, or on three ball bearings for tiles having

2 2

an actual facial area of 9 in. (58 cm ) (or less), arranged in an equilateral triangle, and applying force at a definite rate to the center

of the tile, which coincides with the center of the triangular support, until the specimen breaks.

NOTE 1—The size (facial dimensions) of otherwise equal tile affects the value of breaking strength obtained by this test method. For instance,a6by

1 1

6-in. (152 by 152-mm) tile equal in mature body properties and thickness to a 4 ⁄4 by 4 ⁄4-in. (108 by 108-mm) tile will have a breaking strength higher

1 1

than the 4 ⁄4 by 4 ⁄4-in. tile.

5. Significance and Use

5.1 The test method provides means for establishing whether or not a lot of ceramic tile meets the strength requirements which

may appear in tile specifications. Tile strength is the force in pounds-force (or newtons), as read from the pressure gage, necessary

to cause the tile to break.

6. Apparatus

1 1 1

6.1 Specimen-Support, consisting of a 5 ⁄2 by 5 ⁄2 by 1-in. (139.7 by 139.7 by 25.4-mm) steel block. Three ⁄4-in. (6.4-mm)

diameter and ⁄8-in. (9.5-mm) deep tapped holes are arranged in an equilateral triangle having 3-in. (76.2-mm) sides and whose

circumscribed circle has a radius of 1.732 in. (44.0 mm). The equilateral triangle is located on the steel block so that its center

coincides with that of the steel block and one side of the triangle runs parallel to one side of the steel block. Three ⁄8-in. diameter

3 3 1

steel rods, 1 ⁄8 in. with (34.9 mm) long, one end threaded for a distance of ⁄8 in. with the same ⁄4-in. thread as the tapped holes,

This test method is under the jurisdiction ofASTM Committee C-21C21 on Ceramic Whitewares and Related Products and is the direct responsibility of Subcommittee

C21.06 on Ceramic Tile.

Current edition approved July 10, 1998.Jan. 1, 2009. Published January 1999.February 2009. Originally published as C648–70.approved in 1970. Last previous edition

C648–84 (1994).approved in 2004 as C 648 – 04.

Annual Book of ASTM Standards, Vol 15.02.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C 648–04 (2009)

3 3

and the other end ground flat, fit into the three holes. In a similar manner, a second set of three ⁄8-in. diameter steel rods, but ⁄4

3 1

in. (19.0 mm) long only, are threaded on one end for a distance of ⁄8-in., are ground flat on the other end and fit three other ⁄4-in.

1 3

tapped holes. The three ⁄4-in. holes, tapped for a distance of ⁄8 in. to receive this second set of steel rods are located at the apexes

of an equilateral triangle having 1 ⁄2-in. (38.1-mm) long sides and whose circumscribed circle has a radius of 0.866 in. (22.0 mm).

This second equilateral triangle is located within the first one in such a manner that its circumscribed circle is identical with the

inscribed circle of the first triangle, and its sides are parallel to those of the larger triangle. The ball bearing support consists of

three ⁄8-in. (3.2-mm) ball bearings arranged in an equilateral triangle, with sides of 14 mm concentric and parallel with the other

triangles. The bearings are embedded in the block to the extent of half their volume. The steel block has four more ⁄4-in. tapped

holes to receive socket head cap screws for holding four registry stops. One of these holes is located in the center of one side, ⁄4

in. in from the edge. Another of these is located in the center of an adjacent side ⁄4 in. from the edge. The other two are located

1 3

on an adjacent side, ⁄4 in. in from the edge, spaced 2 in. (50.8 mm) apart, with one located 1 ⁄4 in. (44.4 mm) from one of the

corners of the first side. The two single hole registry stops are used with the ball bearing support. The double hole registry stop

and the adjacent edge single stop are to be used with the sets of rod supports. Three of the registry stops designed for use with

1 3 1

the cylindrical rod supports consist of ⁄8-in. (3.2-mm) thick steel strips, ⁄4 in. wide, 2 in. long, with a ⁄4-in. wide slot extending

3 1

for the full 2-in. length of the strip. The slot is open on one end and the other end of each steel strip has a ⁄4 in. wide and 1 ⁄2

in. high projection, ⁄8 in. thick, which will contact the edges of the tile when in proper position for use. The other two registry

stops, designed for use with the ball bearing support, have exactly the same dimensions except for their projection height which

5 1

is ⁄8 in. The projection is obtained by making the steel strips actually 3 ⁄2 in. (88.9 mm) long and bending them at right angles

1 5

to obtain the 1 ⁄2-in. or ⁄8-in. (38.1-mm or 15.9-mm) high projection. Each of the three registry stops can be fastened with washer

and socket head cap screw through its slot in any one of numerous positions. Being adjustable, they serve as registry stops for the

different sizes of tile which may be broken over these supports. For tile of dimensions 4 ⁄4 in. (107.9 mm) or smaller, the

projections will be located on that end of the strip nearest to the support block; for tile having dimensions larger than 4 ⁄4 in., the

strips are reversed so that the projections are located on the end of the steel strips away from the support block (see Fig. 1). For

certain mosaic tiles with dimensions of less than 1 in. (25.4 mm) length, it is necessary to reverse the position of the registry stops

so that the tile is supported with the slot ends in order to avoid interference with the force applicator.

6.2 Force Applicator— Force is applied in the exact center of the triangular support by means of a ⁄2-in. (12.7-mm) diameter

stainless steel ball bearing, countersunk to a depth of ⁄64 in. (6.7 mm) into one end of a 1-in. (25.4-mm) diameter and 2-in. long

steel rod. A ⁄32-in. (2.4-mm) thick retaining collar prevents the ball from falling out of its recess and is fastened to the steel rod

3 3

by four ⁄32-in. 3-48 NC screws, ⁄8 in. (9.5 mm) long, with countersunk heads. The opposite end of the steel rod is reduced in

diameter for the proper distance and threaded to fit its female counterpart of the testing machine (see Fig. 2).

6.3 Testing Machine— Any apparatus, preferably motor driven, capable of maintaining a uniform load application rate of 800

to 1100 lbf (3600 to 4900 N)/min and large enough to accommodate the

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C 648–04 Designation:C 648–04 (Reapproved 2009)

Standard Test Method for

Breaking Strength of Ceramic Tile

This standard is issued under the fixed designation C 648; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the breaking strength of glazed ceramic wall tile, ceramic mosaic tile, quarry

2 2

tile, and paver tile, having a facial area of at least 1 in. (6.4 cm ).

1.2The values stated in inch-pound units are to be regarded as the standard. The metric equivalents of inch-pound units may be

approximate.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C 242 Terminology of Ceramic Whitewares and Related Products

E 178 Practice for Dealing withWith Outlying Observations

3. Terminology

3.1 Definitions:

3.1.1 For definitions of the types of tile listed in Section 1, refer to Terminology C 242.

4. Summary of Test Method

4.1 The test method consists of supporting the tile on the ends of three cylindrical rods, or on three ball bearings for tiles having

2 2

an actual facial area of 9 in. (58 cm ) (or less), arranged in an equilateral triangle, and applying force at a definite rate to the center

of the tile, which coincides with the center of the triangular support, until the specimen breaks.

NOTE 1—The size (facial dimensions) of otherwise equal tile affects the value of breaking strength obtained by this test method. For instance,a6by

1 1

6-in. (152 by 152-mm) tile equal in mature body properties and thickness to a 4 ⁄4 by 4 ⁄4-in. (108 by 108-mm) tile will have a breaking strength higher

1 1

than the 4 ⁄4 by 4 ⁄4-in. tile.

5. Significance and Use

5.1 The test method provides means for establishing whether or not a lot of ceramic tile meets the strength requirements which

may appear in tile specifications. Tile strength is the force in pounds-force (or newtons), as read from the pressure gage, necessary

to cause the tile to break.

6. Apparatus

1 1 1

6.1 Specimen-Support, consisting of a 5 ⁄2 by 5 ⁄2 by 1-in. (139.7 by 139.7 by 25.4-mm) steel block. Three ⁄4-in. (6.4-mm)

diameter and ⁄8-in. (9.5-mm) deep tapped holes are arranged in an equilateral triangle having 3-in. (76.2-mm) sides and whose

circumscribed circle has a radius of 1.732 in. (44.0 mm). The equilateral triangle is located on the steel block so that its center

coincides with that of the steel block and one side of the triangle runs parallel to one side of the steel block. Three ⁄8-in. diameter

3 3 1

steel rods, 1 ⁄8 in. with (34.9 mm) long, one end threaded for a distance of ⁄8 in. with the same ⁄4-in. thread as the tapped holes,

3 3

and the other end ground flat, fit into the three holes. In a similar manner, a second set of three ⁄8-in. diameter steel rods, but ⁄4

ThistestmethodisunderthejurisdictionofASTMCommitteeC21onCeramicWhitewaresandRelatedProductsandisthedirectresponsibilityofSubcommitteeC21.06

on Ceramic Tile.

Current edition approved AprilJan. 1, 2004.2009. Published May 2004.February 2009. Originally approved in 1970. Last previous edition approved in 19982004 as

C648–98.C 648 – 04.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C 648–04 (2009)

3 1

in. (19.0 mm) long only, are threaded on one end for a distance of ⁄8-in., are ground flat on the other end and fit three other ⁄4-in.

1 3

tapped holes. The three ⁄4-in. holes, tapped for a distance of ⁄8 in. to receive this second set of steel rods are located at the apexes

of an equilateral triangle having 1 ⁄2-in. (38.1-mm) long sides and whose circumscribed circle has a radius of 0.866 in. (22.0 mm).

This second equilateral triangle is located within the first one in such a manner that its circumscribed circle is identical with the

inscribed circle of the first triangle, and its sides are parallel to those of the larger triangle. The ball bearing support consists of

three ⁄8-in. (3.2-mm) ball bearings arranged in an equilateral triangle, with sides of 14 mm concentric and parallel with the other

triangles. The bearings are embedded in the block to the extent of half their volume. The steel block has four more ⁄4-in. tapped

holes to receive socket head cap screws for holding four registry stops. One of these holes is located in the center of one side, ⁄4

in. in from the edge. Another of these is located in the center of an adjacent side ⁄4 in. from the edge. The other two are located

1 3

on an adjacent side, ⁄4 in. in from the edge, spaced 2 in. (50.8 mm) apart, with one located 1 ⁄4 in. (44.4 mm) from one of the

corners of the first side. The two single hole registry stops are used with the ball bearing support. The double hole registry stop

and the adjacent edge single stop are to be used with the sets of rod supports. Three of the registry stops designed for use with

1 3 1

the cylindrical rod supports consist of ⁄8-in. (3.2-mm) thick steel strips, ⁄4 in. wide, 2 in. long, with a ⁄4-in. wide slot extending

3 1

for the full 2-in. length of the strip. The slot is open on one end and the other end of each steel strip has a ⁄4 in. wide and 1 ⁄2

in. high projection, ⁄8 in. thick, which will contact the edges of the tile when in proper position for use. The other two registry

stops, designed for use with the ball bearing support, have exactly the same dimensions except for their projection height which

5 1

is ⁄8 in. The projection is obtained by making the steel strips actually 3 ⁄2 in. (88.9 mm) long and bending them at right angles

1 5

to obtain the 1 ⁄2-in. or ⁄8-in. (38.1-mm or 15.9-mm) high projection. Each of the three registry stops can be fastened with washer

and socket head cap screw through its slot in any one of numerous positions. Being adjustable, they serve as registry stops for the

different sizes of tile which may be broken over these supports. For tile of dimensions 4 ⁄4 in. (107.9 mm) or smaller, the

projections will be located on that end of the strip nearest to the support block; for tile having dimensions larger than 4 ⁄4 in., the

strips are reversed so that the projections are located on the end of the steel strips away from the support block (see Fig. 1). For

certain mosaic tiles with dimensions of less than 1 in. (25.4 mm) length, it is necessary to reverse the position of the registry stops

so that the tile is supported with the slot ends in order to avoid interference with the force applicator.

6.2 Force Applicator— Force is applied in the exact center of the triangular support by means of a ⁄2-in. (12.7-mm) diameter

stainless steel ball bearing, countersunk to a depth of ⁄64 in. (6.7 mm) into one end of a 1-in. (25.4-mm) diameter and 2-in. long

steel rod. A ⁄32-in. (2.4-mm) thick ret

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.