ASTM D3328-00

(Test Method)Standard Test Methods for Comparison of Waterborne Petroleum Oils by Gas Chromatography

Standard Test Methods for Comparison of Waterborne Petroleum Oils by Gas Chromatography

SCOPE

1.1 This test method covers the comparison of petroleum oils recovered from water or beaches with oils from suspect sources by means of gas chromatography (1,2 ,3 ). Such oils include distillate fuel, lubricating oil, and crude oil. The test method described is for capillary column analyses using either single detection (flame ionization) or dual detection (flame ionization and flame photometric) for sulfur containing species.

1.2 This test method provides high resolution for critical examination of fine structure that is resistant to weathering. The flame-photometric detection for sulfur components is an adjunct, not a substitute, for flame-ionization detection in the identification of waterborne petroleum oils (4-12). For this reason, flame photometric detection is optional.

1.3This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation:D 3328–00

Standard Test Methods for

Comparison of Waterborne Petroleum Oils by Gas

Chromatography

This standard is issued under the fixed designation D 3328; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* D 4489 Practices for Sampling of Waterborne Oils

D 5739 Practice for Oil Spill Source Identification by Gas

1.1 This test method covers the comparison of petroleum

Chromotography and Positive Ion Electron Impact Low

oils recovered from water or beaches with oils from suspect

2 Resolution Mass Spectrometry

sources by means of gas chromatography (1, 2, 3). Such oils

E 355 Practice for Gas Chromatography Terms and Rela-

include distillate fuel, lubricating oil, and crude oil. The test

tionships

method described is for capillary column analyses using either

single detection (flame ionization) or dual detection (flame

3. Terminology

ionization and flame photometric) for sulfur containing spe-

3.1 Definitions—For definitions of terms used in this test

cies.

method, refer to Practice D 3415, Terminology D 1129, and

1.2 This test method provides high resolution for critical

Practice E 355.

examination of fine structure that is resistant to weathering.

The flame-photometric detection for sulfur components is an

4. Significance and Use

adjunct, not a substitute, for flame-ionization detection in the

4.1 Identification of a recovered oil is determined by com-

identification of waterborne petroleum oils (4-12). For this

parison with known oils, selected because of their possible

reason, flame photometric detection is optional.

relationship to the particular recovered oil. The known oils are

1.3 This standard does not purport to address the safety

collected from suspected sources. Samples of such known oils

concerns, if any, associated with its use. It is the responsibility

must be collected and submitted along with the unknown for

of the user of this standard to establish appropriate safety and

analysis.At present, identification of the source of an unknown

health practices and determine the applicability of regulatory

oil by itself cannot be made (for example, from a library of

limitations prior to use.

known oils).

4.2 The use of a flame-photometric detector in addition to

2. Referenced Documents

the flame-ionization detector provides a second, independent

2.1 ASTM Standards:

3 profileofthesameoil,thatis,significantlymoreinformationis

D 1129 Terminology Relating to Water

3 available from a single analysis with dual detection.

D 1193 Specification for Reagent Water

4.3 Many close similarities (within uncertainties of sam-

D 2549 Test Method for Separation of Representative Aro-

pling and analysis) will be needed to establish identity beyond

matics and Nonaromatics Fractions of High-Boiling Oils

4 a reasonable doubt. The analyses described will distinguish

by Elution Chromatography

many, but not all samples. For cases in which this method does

D 3325 Practice for Preservation of Waterborne Oil

5 not clearly identify a pair of samples, and for important cases

Samples

where additional comparisons are needed to strengthen con-

D 3326 Practices for Preparation of Samples for Identifica-

5 clusions, other analyses will be required (refer to Practice

tion of Waterborne Oils

5 D 3415).Inparticular,PracticeD 5739isusefulforsuchcases.

D 3415 Practice for Identification of Waterborne Oils

5. Interferences

5.1 Compounds that have the same retention time as petro-

These test methods are under the jurisdiction of ASTM Committee D19 on

leum hydrocarbons will interfere in the comparison of the

Water and are the direct responsibility of Subcommittee D19.06 on Methods for

unknownwithknownoils.Thisisparticularlytrueifanimalfat

Analysis for Organic Substances in Water.

Current edition approved June 10, 2000. Published September 2000. Originally or vegetable oil, naturally occurring hydrocarbons, or spill-

published as D 3328 – 74a T. Last previous edition D 3328 – 98.

treatment chemicals are present in relatively large amounts.

The boldface numbers in parentheses refer to the references at the end of these

Independent analysis, for example, infrared spectroscopy, will

test methods.

Annual Book of ASTM Standards, Vol 11.01.

Annual Book of ASTM Standards, Vol 05.01.

5 6

Annual Book of ASTM Standards, Vol 11.02. Annual Book of ASTM Standards, Vol 14.02.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

D 3328–00

establishthepresenceofthesecontaminantsiftheirpresenceis 9. Summary of Test Method

suspected.Animal or vegetable oils can be removed effectively

9.1 This test method uses a gas chromatographic capillary

by Test Method D 2549 or by Practices D 3326 (Method D).

column system for the separation of petroleum hydrocarbons.

The effluent of the column may be detected with a flame-

NOTE 1—Test Method D 2549 will also remove the aromatic fraction.

ionization detector, or it may be split (1 + 2) between a flame

6. Reagents and Materials

ionization and a flame-photometric detector. The flame photo-

metric detector is equipped with a narrow bandpass interfer-

6.1 Purity of Reagents—Reagent grade chemicals shall be

ence filter for spectral isolation of the sulfur emission at 394

used in all tests. Unless otherwise indicated it is intended that

nm. The relative peak size of each component (as indicated by

all reagents shall conform to the specifications of the Commit-

retention time) of recovered oil is compared visually with the

tee on Analytical Reagents of the American Chemical Soci-

relative peak size of each component (of like retention time) of

ety.

the suspected source.

6.2 Unless otherwise indicated references to water shall be

understood to mean reagent water conforming to Specification

NOTE 2—This duel detector method is based on the early work done by

D 1193, Type II.

Kahn (13), Garza (4), and Adlard (7).

6.3 Air—For use with the flame-ionization and flame-

9.2 In this test method, elution of characteristic hydrocar-

photometricdetectors;maybeobtainedusingalaboratorypure

bons occurs generally in order of increasing boiling point.

air generator, or from a zero grade tank supply.

6.4 Carrier Gas— High-purity grade helium is used as

10. Apparatus

carrier gas.

10.1 Chromatographic Column—Fused silica capillary col-

6.5 Cyclohexane— High-purity (HPLC-grade). For sample

umnwithbondedphaseSE-30orequivalent,30mby0.32mm

preparation and for use in reference standards.

inside diameter (0.1 µm film thickness).

6.6 Hydrogen—For use with the flame-ionization and

flame-photometric detectors; may be obtained using a hydro-

NOTE 3—Other columns, providing equivalent or better resolution may

gen generator, or from a prepurified grade tank supply.

besubstituted(seeAnnexA1),buttheanalysistimewillbeincreasedwith

6.7 Methylene Chloride—Foruseinreferencestandardsand

longer columns.

glassware cleaning.

10.2 Gas Chromatograph—A commercial or custom de-

6.8 Normal Alkane Standards—Normal alkanes, decane

signed gas chromatograph with heated injection and detector

through hexatriacontane, for use as reference compounds.

zones and a column oven capable of being programmed from

6.9 Thiophene—For use in optimization of flame-

75°C to at least 325°C for heavier oils (higher boiling than

photometric detector.

gasolines, jet fuels, etc.).

10.2.1 For light distillate fuels, the chromatograph must be

7. Reference Standards

capable of programming from 50°C and also be capable of

7.1 Normal Paraffınic Hydrocarbons—Preparedmixturesof

maintaining isothermal control at 50°C.

approximately decane to hexatriacontane, or selected indi-

10.2.2 Carrier Gas Pressure Regulator is substituted pres-

vidual normal paraffins, are run under normal analysis condi-

sure regulator for the mass flow controllers to give more

tions to determine retention times of compounds.

precise rates in the low flow ranges (1 to 5 mL/mm).

7.2 Resolution Mixture—Equal mixtures of n-heptadecane,

10.2.3 Injection Port—The use of glass injector inserts that

n-octadecane, pristane and phytane in solution. See Annex A1

can be replaced or cleaned frequently, or both, will prolong the

for details (A1.2.1).

useful life of the column (3).

10.2.4 Detectors—A hydrogen-flame ionization detector is

8. Sampling

always used for analyses.Aflame-photometric detector with a

8.1 Collect a representative sample in accordance with

394nmbandpassfilterisusedfordualdetection(9,10, 11,12).

Practice D 4489.

10.2.5 Carrier Gas Makeup is required at the effluent of the

8.2 If the sample is not to be analyzed within 1 week, it

column with a temperature independent mass flow controller.

should be preserved in accordance with Practice D 3325

10.2.6 Effluent Splitter—An effluent splitter with a split

because of the possibility of bacterial decomposition of normal

ratio of 1 + 2 (FID/FPD) is required for dual detection.

paraffins in the sample.

10.2.7 Bleeder for Reference Compound—A device for

8.3 The sample should be prepared for analysis in accor-

in-line bleed of a reference compound (thiophene and cyclo-

dance with Practices D 3326, because of the great variety of

hexane) into the carrier flow for detector optimization is

materials and circumstances associated with collecting petro-

required, when using a flame-photometric detector.

leum oils from the environment. For heavier oils, a procedure

10.2.8 Recorder, or an integrator or computer data handling

to deasphalt the oil may be necessary.

system capable of acquiring data at a rate compatible with the

high resolution of the capillary column. Alternatively, a strip-

chart recorder is required to measure detector response at

“Reagent Chemicals,American Chemical Society Specifications,”Am. Chemi-

full-scale range of 1 mV with a response time of 1 s (or less).

cal Soc., Washington, DC. For suggestions on the testing of reagents not listed by

A second recorder, or dual-pen recorder, is required for dual

theAmerican Chemical Society, see “Reagent Chemicals and Standards,” by Joseph

detection.

Rosin, D. Van Nostrand Co., Inc., New York, NY, and the “United States

Pharmacopeia.” 10.3 Syringe—A microsyringe of 0.5 to 1 µL capacity.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

D 3328–00

10.4 Gas Traps—Any commerically available gas filter there is minimal baseline shift at high temperatures, then the

traps to be placed in line to remove trace hydrocarbon and column is ready for use; otherwise, recondition it.

water impurities from the helium, hydrogen, nitrogen, and air 11.3.7 Return the oven temperature to 75°C.

gas supplies. 11.3.8 If the column is to be moved or stored, disconnect

10.5 FPD Linearizer— Optional accessory to facilitate and seal the ends of the column. When the column is to be

comparison of FPD chromatograms. reused, even after conditioning, it is always necessary to cycle

10.6 Glass Insert, packed with glass wool (optional). through the temperature program to remove any accumulated

volatiles.

NOTE 4—For instruments that can use this instrument, splitless injec-

11.4 Optimization of Detectors—Adjust hydrogen and air

tion of an oil in cyclohexane solution simplifies the analysis by eliminat-

flows to give optimal detector responses for a given signal

ing the need to deasphalt most oil samples.

provided by the reference compound bleeder (10.2.7). Use

11. Preparation of Chromatograph

cyclohexane for FID optimization and thiophene for the FDP

optimization.

11.1 Install the column in the chromatograph, as described

in the manufacturer’s instructions.

12. Operating Conditions for Analysis (Notes 6-8)

11.2 Shut off the downstream end of the system and

pressurize the carrier gas supply to a gage pressure of approxi-

NOTE 6—One of the problems frequently encountered with the flame

mately 15 psi (103 kPa) above the operating pressure. Shut off

photometric detector is “flameout” when large amounts of solvent are

the cylinder valve and observe the pressure gage. Consider the injectedwiththesample.Therecommendedsamplepreparationprocedure

avoids this problem at the same time that it permits the use of small

system tight if no pressure drop is noted in 10 to 15 min. Use

samples. For those who may encounter this problem, a simple modifica-

a small amount of aqueous soap solution to locate minor leaks.

tion has been suggested (8) which consists of reversing the hydrogen gas

Do not use the soap solution near the ionization detector.

and air/oxygen gas inlets to the detector.

11.3 Column Conditioning for New Columns:

NOTE 7—For oil identification under the recommended procedure, air

has been found satisfactory for combustion for the FPD, that is, oxygen is

NOTE 5—For previously conditioned columns, proceed to 11.3.4.

not necessary.

11.3.1 Disconnect the column at the detector end to avoid

NOTE 8—See the manufacturer’s manual for maintenance information

deposition of volatiles on the detector(s) during conditioning.

for the FPD. Present flame photometric units should not be heated above

250°C, unless the photometer is removed from the heated zone by fiber

11.3.2 For new columns, follow the manufacturer’s instruc-

optics.

tions for column conditioning.

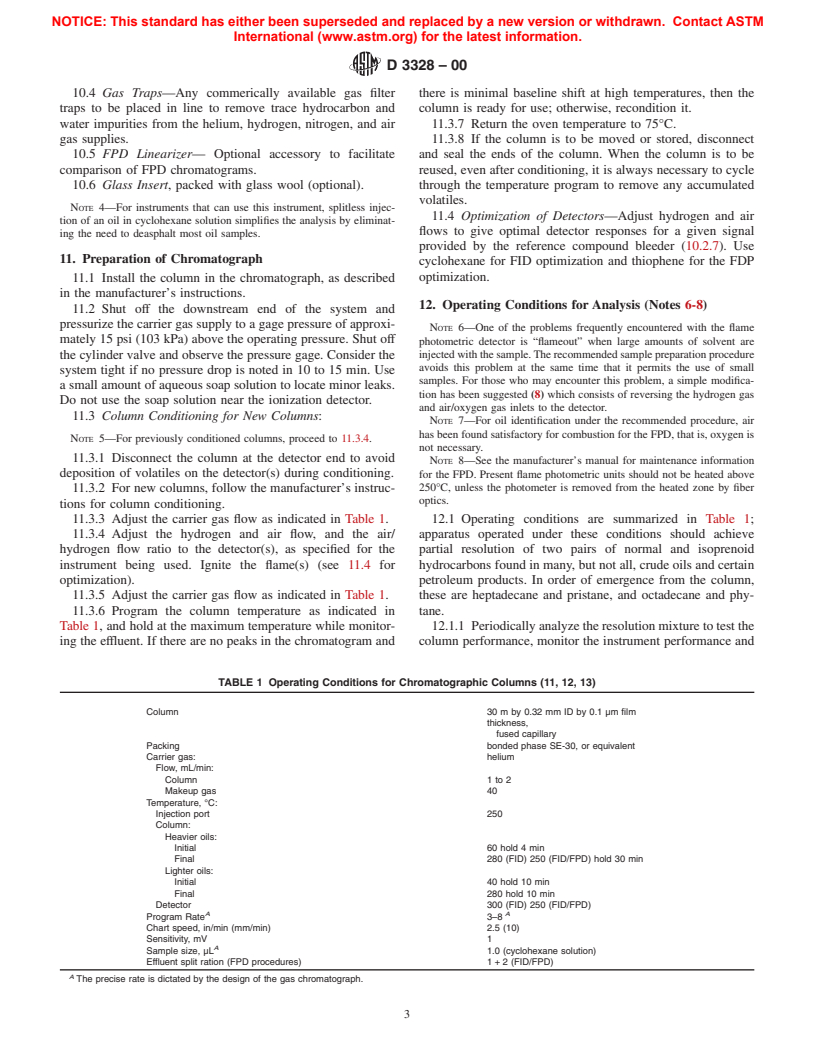

11.3.3 Adjust the carrier gas flow as indicated in Table 1. 12.1 Operating conditions are summarized in Table 1;

11.3.4 Adjust the hydrogen and air flow, and the air/ apparatus operated under these conditions should achieve

hydrogen flow ratio to the detector(s), as specified for the partial resolution of two pairs of normal and isoprenoid

instrument being used. Ignite the flame(s) (see 11.4 for hydrocarbons found in many, but not all, crude oils and certain

optimization). petroleum products. In order of emergence from the column,

11.3.5 Adjust the carrier gas flow as indicated in Table 1. these are heptadecane and pristane, and octadecane and phy-

11.3.6 Program the column temperature as indicated in tane.

Table 1, and hold at the maximum temperature while monitor- 12.1.1 Periodicallyanalyzetheresolutionmixturetotestthe

ing the effluent. If there are no peaks in the chromatogram and column performance, monitor the instrument performance and

TABLE 1 Operating Conditions for Chromatographic Columns (11, 12, 13)

Column 30mby0.32mmI

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.