ASTM A823-99(2008)

(Specification)Standard Specification for Statically Cast Permanent Mold Gray Iron Castings

Standard Specification for Statically Cast Permanent Mold Gray Iron Castings

ABSTRACT

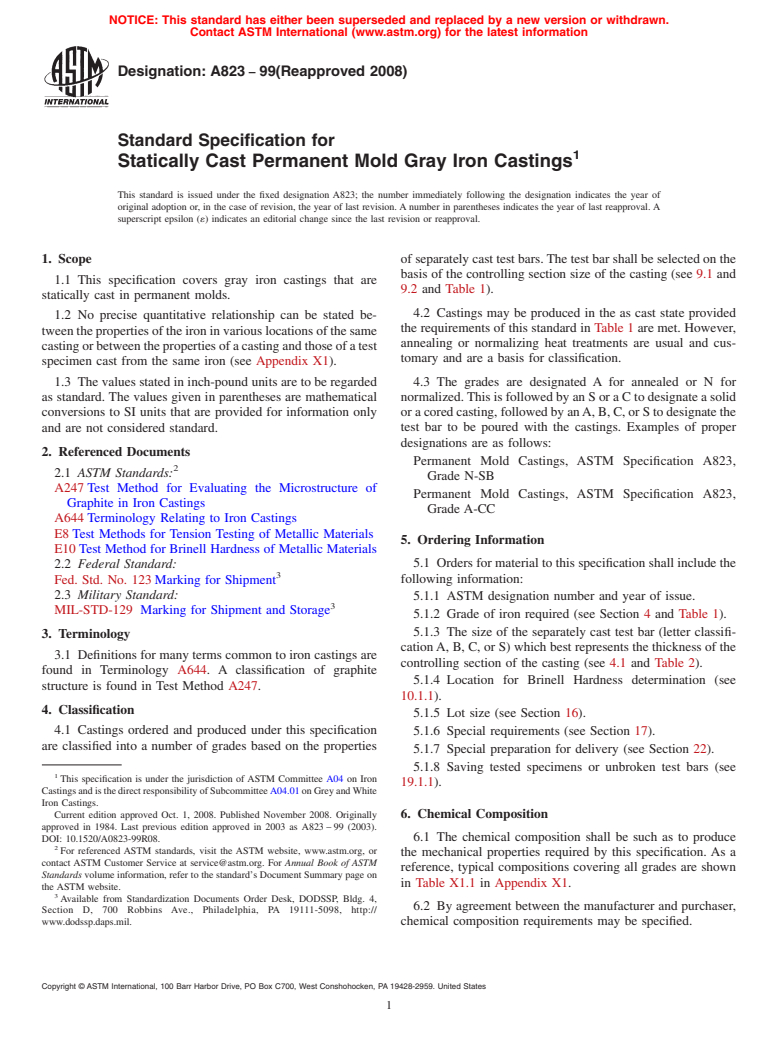

This specification covers gray iron castings that are statically cast in permanent molds. Castings under this specification are classified into a number of grades (A-SA, A-SB, A-SC, A-SS, A-CA, A-CB, A-CC, N-SA, N-SB, N-SC,N-SS, N-CA, N-CB and N-CC) based on the properties of separately cast test bars. The grades are designated A for annealed or N for normalized; followed by an S or a C to designate a solid or a cored casting; followed by an A, B, C, or S to designate the test bar to be poured with the castings. The cast test bar shall be selected on the basis of the controlling section size of the casting and shall have the specified dimensions (diameter and length). Castings may be produced in the as cast state provided the tensile strength and Brinell hardness requirements are met. The chemical composition and heat treatment shall be such as to produce these mechanical requirements as well. A suitable permanent mold design for separately cast test bars is described and the tension test requirements are detailed.

SCOPE

1.1 This specification covers gray iron castings that are statically cast in permanent molds.

1.2 No precise quantitative relationship can be stated between the properties of the iron in various locations of the same casting or between the properties of a casting and those of a test specimen cast from the same iron (see Appendix X1).

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A823 −99(Reapproved 2008)

Standard Specification for

1

Statically Cast Permanent Mold Gray Iron Castings

This standard is issued under the fixed designation A823; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

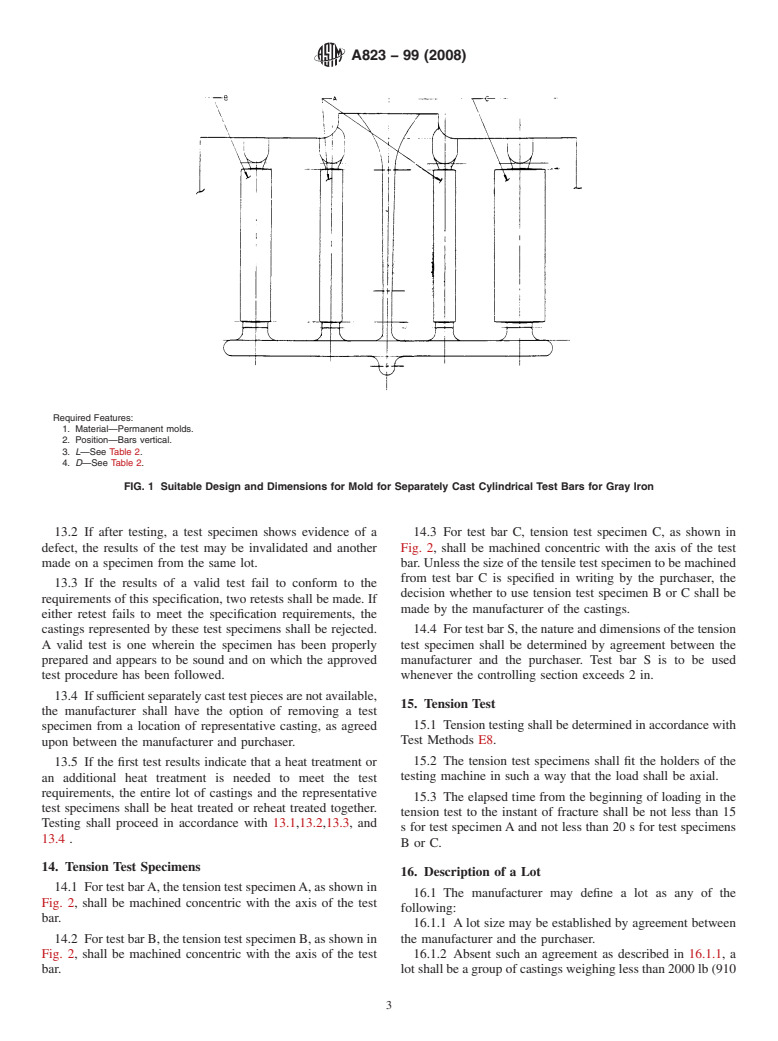

1. Scope of separately cast test bars.The test bar shall be selected on the

basis of the controlling section size of the casting (see 9.1 and

1.1 This specification covers gray iron castings that are

9.2 and Table 1).

statically cast in permanent molds.

4.2 Castings may be produced in the as cast state provided

1.2 No precise quantitative relationship can be stated be-

the requirements of this standard in Table 1 are met. However,

tweenthepropertiesoftheironinvariouslocationsofthesame

annealing or normalizing heat treatments are usual and cus-

castingorbetweenthepropertiesofacastingandthoseofatest

tomary and are a basis for classification.

specimen cast from the same iron (see Appendix X1).

1.3 The values stated in inch-pound units are to be regarded 4.3 The grades are designated A for annealed or N for

as standard. The values given in parentheses are mathematical normalized.This is followed by an S oraCto designate a solid

conversions to SI units that are provided for information only oracoredcasting,followedbyanA,B,C,orStodesignatethe

and are not considered standard. test bar to be poured with the castings. Examples of proper

designations are as follows:

2. Referenced Documents

Permanent Mold Castings, ASTM Specification A823,

2

2.1 ASTM Standards:

Grade N-SB

A247 Test Method for Evaluating the Microstructure of

Permanent Mold Castings, ASTM Specification A823,

Graphite in Iron Castings

Grade A-CC

A644 Terminology Relating to Iron Castings

E8 Test Methods for Tension Testing of Metallic Materials

5. Ordering Information

E10 Test Method for Brinell Hardness of Metallic Materials

5.1 Orders for material to this specification shall include the

2.2 Federal Standard:

3

following information:

Fed. Std. No. 123 Marking for Shipment

2.3 Military Standard:

5.1.1 ASTM designation number and year of issue.

3

MIL-STD-129 Marking for Shipment and Storage

5.1.2 Grade of iron required (see Section 4 and Table 1).

5.1.3 The size of the separately cast test bar (letter classifi-

3. Terminology

cationA, B, C, or S) which best represents the thickness of the

3.1 Definitions for many terms common to iron castings are

controlling section of the casting (see 4.1 and Table 2).

found in Terminology A644. A classification of graphite

5.1.4 Location for Brinell Hardness determination (see

structure is found in Test Method A247.

10.1.1).

4. Classification

5.1.5 Lot size (see Section 16).

4.1 Castings ordered and produced under this specification

5.1.6 Special requirements (see Section 17).

are classified into a number of grades based on the properties

5.1.7 Special preparation for delivery (see Section 22).

5.1.8 Saving tested specimens or unbroken test bars (see

1

This specification is under the jurisdiction of ASTM Committee A04 on Iron

19.1.1).

CastingsandisthedirectresponsibilityofSubcommitteeA04.01onGreyandWhite

Iron Castings.

Current edition approved Oct. 1, 2008. Published November 2008. Originally 6. Chemical Composition

approved in 1984. Last previous edition approved in 2003 as A823 – 99 (2003).

DOI: 10.1520/A0823-99R08. 6.1 The chemical composition shall be such as to produce

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

the mechanical properties required by this specification. As a

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

reference, typical compositions covering all grades are shown

Standards volume information, refer to the standard’s Document Summary page on

in Table X1.1 in Appendix X1.

the ASTM website.

3

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

6.2 By agreement between the manufacturer and purchaser,

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

www.dodssp.daps.mil. chemical composition requirements may be specified.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A823−99 (2008)

TABLE 1 Permanent Mold Gray Iron Specifications

9.3 The test bars shall be cast in a permanent mold. The

Grade Tensile Strength, min, ksi BHN mold shall be of similar material, design, and construction as

A

(MPa)

that used to make the production castings. The test bar

permanent mold shall be preheated with three consecutive

Uncored—Annealed

pours,afterwhich,startingwiththefourthpour,thebarscanb

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.