ASTM F2328-17(2022)

(Test Method)Standard Test Method for Determining Decarburization and Carburization in Hardened and Tempered Threaded Steel Bolts, Screws, Studs, and Nuts

Standard Test Method for Determining Decarburization and Carburization in Hardened and Tempered Threaded Steel Bolts, Screws, Studs, and Nuts

SIGNIFICANCE AND USE

4.1 Decarburization and carburization are two surface conditions created, either intentionally or unintentionally, as with a pre-existing condition created during the rod rolling process, the rod/wire annealing process, or while heat treating threaded steel products. Too much of either will adversely affect the safety and performance of the threaded product. Therefore, limits have been established for three different product groups: the harder and greater the tensile strength of the product, the more susceptible to failure the product becomes if these limits are exceeded.

4.2 When testing to a particular product specification that lists the dimensions and microindentation data to be used, that data shall take precedence over the tables in this test method.

4.3 There are only two viable methods available to detect these deficiencies, either by the visual method or the microindentation method. Both methods are used for routine inspections when evaluations are conducted at a single location on the product sample.

4.3.1 Because an evaluation at a specific location may not be representative of the whole part, the referee method employs the microindentation method taken as an average of evaluations conducted on four adjacent threads. This procedure significantly reduces the random test variables when compared to testing on a single thread.

4.4 Specifying this test method does not specify or imply that testing shall be for either decarburization or carburization alone or for both conditions. When either test method is performed, both conditions will be apparent and shall be reported. For example, if an order is placed to test for decarburization and none is found, but the presence of carburization is detected, it shall be reported on the test report that carburization was found.

SCOPE

1.1 This test method covers procedures for measuring, classifying, and determining the presence of decarburization and carburization in the threaded section of hardened and tempered inch series steel bolts, screws, studs, nuts, and similar parts which have been heated to facilitate fabrication or to modify their mechanical properties. This test method is not intended to address products which are intentionally carburized to achieve specific results.

1.2 Two routine methods are described for measuring the limits of and determining the presence of decarburization or carburization—the optical method and the microindentation method 1. Either method is appropriate for routine examinations. The microindentation method 2 shall be considered the referee method.

1.3 For the purpose of these tests, there are four classes of hardened and tempered steel products for which specific measurements must be made with respect to their physical properties.

1.4 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2328 − 17 (Reapproved 2022)

Standard Test Method for

Determining Decarburization and Carburization in Hardened

and Tempered Threaded Steel Bolts, Screws, Studs, and

Nuts

This standard is issued under the fixed designation F2328; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method covers procedures for measuring,

E3Guide for Preparation of Metallographic Specimens

classifying, and determining the presence of decarburization

E384Test Method for Microindentation Hardness of Mate-

and carburization in the threaded section of hardened and

rials

temperedinchseriessteelbolts,screws,studs,nuts,andsimilar

F1789Terminology for F16 Mechanical Fasteners

parts which have been heated to facilitate fabrication or to

modify their mechanical properties. This test method is not

3. Terminology

intendedtoaddressproductswhichareintentionallycarburized

to achieve specific results.

3.1 Definitions:

3.1.1 carburization—process or result of increasing the

1.2 Two routine methods are described for measuring the

carbon content of the surface layers of the steel fastener

limits of and determining the presence of decarburization or

product.

carburization—the optical method and the microindentation

method 1. Either method is appropriate for routine examina- 3.1.2 decarburization—in accordance with Terminology

F1789,isalossofcarbonfromthesurfacelayerofthefastener,

tions. The microindentation method 2 shall be considered the

normally associated with heat treatment.

referee method.

3.1.3 gross decarburization—also known as complete

1.3 For the purpose of these tests, there are four classes of

decarburization, is characterized by a sufficient carbon loss to

hardened and tempered steel products for which specific

show only clearly defined ferrite grains.

measurements must be made with respect to their physical

properties. 3.1.4 partial decarburization—characterized as a loss of

carbon sufficient to cause a lighter shade of tempered marten-

1.4 Thevaluesstatedininch-poundunitsaretoberegarded

site than that of the immediately adjacent base metal, but as

asstandard.Nootherunitsofmeasurementareincludedinthis

being of insufficient carbon loss to show clearly defined ferrite

standard.

grains.

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Significance and Use

responsibility of the user of this standard to establish appro-

4.1 Decarburization and carburization are two surface con-

priate safety, health, and environmental practices and deter-

ditions created, either intentionally or unintentionally, as with

mine the applicability of regulatory limitations prior to use.

a pre-existing condition created during the rod rolling process,

1.6 This international standard was developed in accor-

the rod/wire annealing process, or while heat treating threaded

dance with internationally recognized principles on standard-

steel products. Too much of either will adversely affect the

ization established in the Decision on Principles for the

safety and performance of the threaded product. Therefore,

Development of International Standards, Guides and Recom-

limits have been established for three different product groups:

mendations issued by the World Trade Organization Technical

the harder and greater the tensile strength of the product, the

Barriers to Trade (TBT) Committee.

more susceptible to failure the product becomes if these limits

are exceeded.

This test method is under the jurisdiction of ASTM Committee F16 on

Fasteners and is the direct responsibility of Subcommittee F16.01 on Test Methods. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Aug. 1, 2022. Published December 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2004. Last previous edition approved in 2017 as F2328–17. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F2328-17R22. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2328 − 17 (2022)

4.2 When testing to a particular product specification that of any light-etching band of martensite defines the depth of

lists the dimensions and microindentation data to be used, that decarburization. Compare the image with Fig. 1 for the

data shall take precedence over the tables in this test method. maximum limits for G by taking a measurement on a line

perpendicular to the flank of the thread midway between the

4.3 There are only two viable methods available to detect

thread crest and root (pitch diameter).

these deficiencies, either by the visual method or the microin-

dentation method. Both methods are used for routine inspec- 7.2 Interpretation of Results:

tionswhenevaluationsareconductedatasinglelocationonthe 7.2.1 Allowablelimitsforpartialdecarburizationshallbein

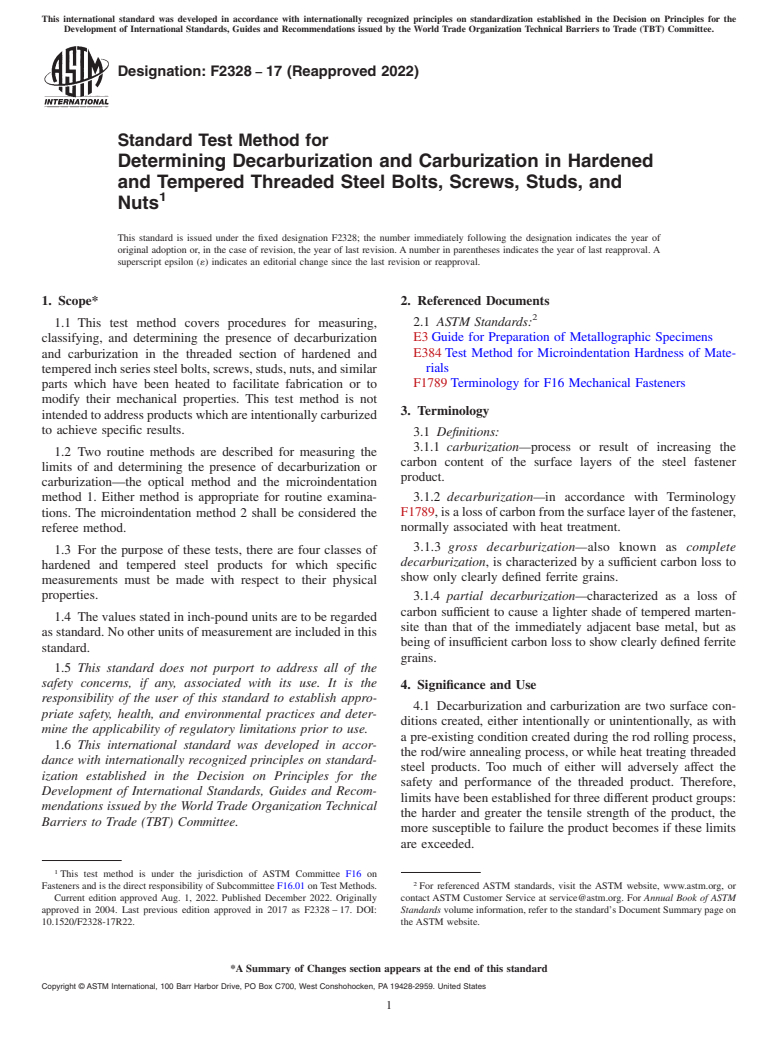

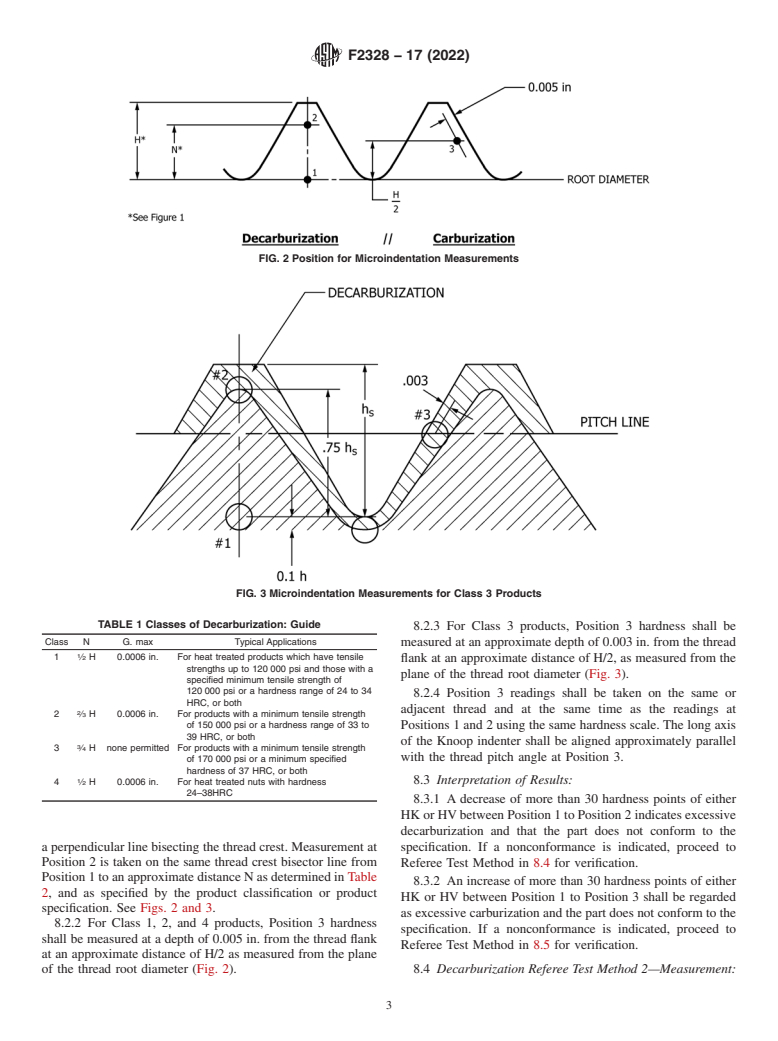

product sample. accordancewith3.1.4andFig.1,andthemeasuredvaluesshall

4.3.1 Because an evaluation at a specific location may not be in accordance with Table 2, when measured in accordance

be representative of the whole part, the referee method em- with the illustrations in Figs. 2 and 3.

ploys the microindentation method taken as an average of 7.2.2 Allowablelimitsforgrossdecarburization(G)shallbe

evaluationsconductedonfouradjacentthreads.Thisprocedure inaccordancewith3.1.3andthemeasuredvaluesasdefinedin

significantlyreducestherandomtestvariableswhencompared Table 1. The optical method is the only valid method for

to testing on a single thread. evaluating the depth of gross decarburization. Gross decarbur-

ization is prohibited in Class 3 products.

4.4 Specifying this test method does not specify or imply

7.2.3 Carburization is identified when the tempered marten-

that testing shall be for either decarburization or carburization

siteisadarkershadethantheimmediatelyadjacentbasemetal.

alone or for both conditions. When either test method is

If visible evidence of surface carburization is present on the

performed, both conditions will be apparent and shall be

surfacezone,themicroindentationmethod,inaccordancewith

reported. For example, if an order is placed to test for

Section 8, shall be used.

decarburization and none is found, but the presence of carbur-

7.2.4 The optical method may not be appropriate for speci-

ization is detected, it shall be reported on the test report that

menswithcertaincoatings,suchaszinc,wherethecoatingcan

carburization was found.

affecttheetchingprocessanddistorttheappearanceofthebase

material microstructure.These coatings shall be removed prior

5. Class of Decarburization

to mounting if the coating prevents proper etching. Care must

5.1 Class Determination—These measurements by Class

also be exercised to not alter the surface condition of the

arepredicatedupontheirrelationshipbetweentheheight(H)of

substrate during the coating removal process.

the external thread at its maximum boundary, disregarding any

7.2.5 If the results of the optical method indicate a possible

surface coating, and N, which is the minimum thread height in

nonconformanceinthemeasurementofpartialdecarburization

the non-decarburized zone (see Figs. 1-3). The dimensions for

or carburization, or are otherwise inconclusive, the microin-

N and H are listed in Table 2 for each Class. Dimension G

dentation method (Section 8) shall be performed after the

(Table 1 and Fig. 1) represents the maximum depth of gross or

specimens are repolished.

complete decarburization.

NOTE1—Refertotheproductstandardforspecificrequirements.When

8. Evaluation by the Microi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.