ASTM D2621-87(2005)

(Test Method)Standard Test Method for Infrared Identification of Vehicle Solids From Solvent-Reducible Paints

Standard Test Method for Infrared Identification of Vehicle Solids From Solvent-Reducible Paints

SIGNIFICANCE AND USE

The ability to qualitatively identify paint vehicles is useful for characterizing unknown or competitive coatings, for complaint investigations, and for in-process control.

SCOPE

1.1 This test method covers the qualitative characterization or identification of separated paint vehicle solids by infrared spectroscopy within the limitations of infrared spectroscopy.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2621 – 87 (Reapproved 2005)

Standard Test Method for

Infrared Identification of Vehicle Solids From Solvent-

1

Reducible Paints

This standard is issued under the fixed designation D2621; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 5. Significance and Use

1.1 This test method covers the qualitative characterization 5.1 The ability to qualitatively identify paint vehicles is

or identification of separated paint vehicle solids by infrared useful for characterizing unknown or competitive coatings, for

spectroscopy within the limitations of infrared spectroscopy. complaint investigations, and for in-process control.

1.2 This standard does not purport to address all of the

6. Apparatus

safety concerns, if any, associated with its use. It is the

6.1 Spectrophotometer—A recording double-beam infrared

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- spectrophotometerwithawavelengthrangefromatleast2.5to

15 µ m and a spectral resolution of at least 0.04 µm over that

bility of regulatory limitations prior to use.

range. See Practice E275.

2. Referenced Documents

6.2 Demountable Cell Mount, with NaCl window.

2

2.1 ASTM Standards: 6.3 Vacuum Drying Oven thermostatically controlled to

D1467 Guide for Testing Fatty Acids Used in Protective operate at 60 6 2°C. A water aspirator vacuum source is

3

Coatings satisfactory.

D1962 Test Method for Saponification Value of Drying 6.4 Oven, Gravity or Forced Draft, capable of maintaining

3

Oils, Fatty Acids, and Polymerized Fatty Acids temperature from 105 to 110°C.

D2372 Practice for Separation of Vehicle From Solvent-

7. Procedure

Reducible Paints

E131 Terminology Relating to Molecular Spectroscopy 7.1 Placethevehicle,separatedfromthepaintinaccordance

E275 Practice for Describing and Measuring Performance with Practice D2372, on a NaCl window and spread to form a

uniform film. Make sure that the thickness of the film is such

of Ultraviolet and Visible Spectrophotometers

that when the infrared spectrum is recorded, the transmittance

3. Terminology

of the strongest band falls between 5 and 15% (Note). Dry the

3.1 Definitions: film in an oven at 105 to 110°C for 15 min and cool in a

3.1.1 For definitions of terms and symbols, refer to Termi- desiccator.Inspectthefilmvisuallyfordefectssuchasbubbles,

nology E131. wrinkles, contamination, etc. If defects are present, cast an-

other film. If easily oxidizable substances are present such as

4. Summary of Test Method

tung,oiticica,orlinseedoils,makesurethatthefilmisdriedat

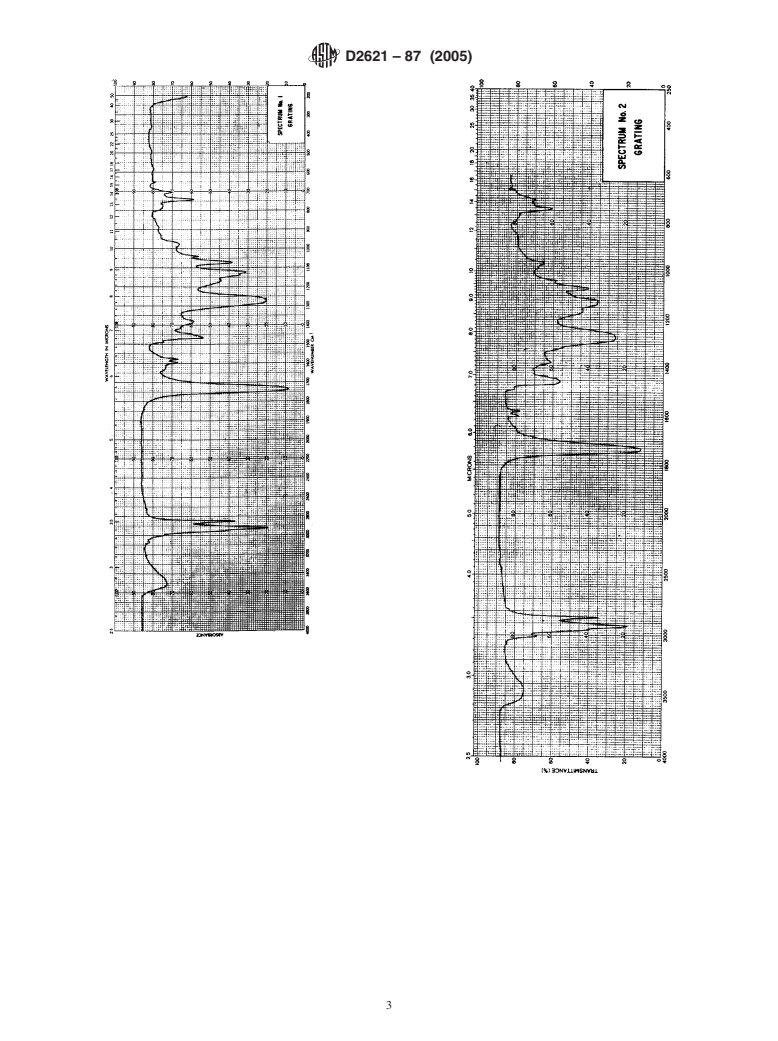

4.1 Infraredspectraarepreparedfromdriedfilmsofisolated 60 62°Cinavacuumovenfor1h.Ifsolventsoflowvolatility

paint vehicles. Vehicle types are identified by comparing the

such as cyclohexanone or isophorone are present, the film may

spectra to a collection of reference infrared spectra. need to be dried for several hours in a 60°C vacuum oven.

NOTE 1—Numerous procedures and variations may be used to obtain a

1

film on which to prepare a suitable spectrum. These include liquid

This test method is under the jurisdiction of ASTM Committee D01 on Paint

mounting between two NaCl plates, transmission through free films, and

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials. reflectance from highly polished surfaces.

Current edition approved July 1, 2005. Published August 2005. Originally

7.2 Immediatelyrecordtheinfraredspectrumfrom2.5to15

approved in 1967. Last previous edition approved in 2000 as D2621–87(2000).

µm so that a spectral resolution of 0.04 µm is maintained

DOI: 10.1520/D2621-87R05.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

throughout that range (methods for achieving this resolution

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

willvaryaccordingtothedirectionsofthemanufacturerofthe

Standards volume information, refer to the standard’s Document Summary page on

instrument used).

the ASTM website.

3

Withdrawn. The last approved version of this historical standard is referenced

on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2621 – 87 (2005)

TABLE 1 Correlation of Absorption Bands in Alkyd Spectra

−1

Wavelength, µm Wavenumbers, cm Group Vibration

2.9 3448 O–H stretch

3.4 to 3.5 2941 to 2857 alkane C–H stretch

5.8 1724 ester, C=O stretch

6.2, 6.3, 6.6, 6.7 1613, 1587, 151

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.