ASTM D2904-97(2002)

(Practice)Standard Practice for Interlaboratory Testing of a Textile Test Method that Produces Normally Distributed Data (Withdrawn 2008)

Standard Practice for Interlaboratory Testing of a Textile Test Method that Produces Normally Distributed Data (Withdrawn 2008)

SIGNIFICANCE AND USE

Interlaboratory testing is a means of securing estimates of the variability in results obtained by different laboratories, operators, equipment, and environments when following procedures prescribed in a specific test method and of determining that the method produces results of essentially uniform variability and at a consistent level when the same materials are tested in a number of laboratories.

The estimates of the components of variance from the interlaboratory test provide the information needed for the preparation of statements on the number of specimens and on precision as directed in Practices D 2905 and D 2906.

SCOPE

1.1 This practice serves as a guide for planning interlaboratory tests in preparation for the calculation of the number of tests to determine the average quality of a textile material as discussed in Practice D 2905 and for the development of statements on precision as required in Practice D 2906.

1.2 The planning of interlaboratory tests requires a general knowledge of statistical principles including the use of variance components estimated from an analysis of variance. Interlaboratory tests should be planned, conducted, and analyzed after consultation with statisticians who are experienced in the design and analysis of experiments and who have some knowledge of the nature of the variability likely to be encountered in the test method.

1.3 The instructions in this practice are specifically applicable to design and analysis of:

1.3.1 Single laboratory preliminary trial,

1.3.2 Pilot-scale interlaboratory tests, and

1.3.3 Full-scale interlaboratory tests.

1.4 Guides for decisions pertaining to data transformations prior to analysis, the handling of missing data, and handling of outlying observations are provided.

1.5 Procedures given in this practice are applicable to test methods based on the measurement of continuous variates from normal distributions or from distributions which can be made normal by a transformation. Get qualified statistical help to (1) decide if the data are from another known distribution, such as the Poisson distribution, (2) make a judgment on normality, ( 3) transform data to a more nearly normal distribution, or ( 4) use Practice D 4467. Use the procedures in Practice D 4467 for test methods that produce data that are (1) continuous data that are not normally distributed or (2) discrete data, such as ratings on an arbitrary scale, counts that may be modelled by use of the Poisson distribution, or proportions or counts of successes in a specified number of trials that may be modelled by the binomial distribution.

Note 1—Additional information on interlaboratory testing and on statistical treatment of data can be found in Practice D 1749, D 3040, E 173, E 177, E 691, and Terminology E 456.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2904–97 (Reapproved 2002)

Standard Practice for

Interlaboratory Testing of a Textile Test Method that

Produces Normally Distributed Data

This standard is issued under the fixed designation D2904; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

E173, E177, E691, and Terminology E456.

1. Scope

1.1 This practice serves as a guide for planning interlabo-

2. Referenced Documents

ratory tests in preparation for the calculation of the number of

2.1 ASTM Standards:

tests to determine the average quality of a textile material as

D123 Terminology Relating to Textiles

discussed in Practice D2905 and for the development of

D1749 Practice for Interlaboratory Evaluation of Test

statements on precision as required in Practice D2906.

Methods Used with Paper and Paper Products

1.2 The planning of interlaboratory tests requires a general

D2905 Practice for Statements on Number of Specimens

knowledge of statistical principles including the use of vari-

for Textiles

ance components estimated from an analysis of variance.

D2906 Practice for Statements on Precision and Bias for

Interlaboratory tests should be planned, conducted, and ana-

Textiles

lyzed after consultation with statisticians who are experienced

D3025 PracticeforStandardizingCottonFiberTestResults

in the design and analysis of experiments and who have some

by Use of Calibration Cotton Standards

knowledge of the nature of the variability likely to be encoun-

D3040 Practice for Preparing Statements for Standards

tered in the test method.

Related to Rubber and Rubber Testing

1.3 The instructions in this practice are specifically appli-

D4270 Guide for Using Existing Practices in Developing

cable to design and analysis of:

and Writing Test Methods

1.3.1 Single laboratory preliminary trial,

D4467 PracticeforInterlaboratoryTestingofaTextileTest

1.3.2 Pilot-scale interlaboratory tests, and

Method that Produces Non-Normally Distributed Data

1.3.3 Full-scale interlaboratory tests.

5,6

D4853 Guide for Reducing Test Variability

1.4 Guides for decisions pertaining to data transformations

E173 Practices for Conducting Interlaboratory Studies of

prior to analysis, the handling of missing data, and handling of

Methods for Chemical Analysis of Metals

outlying observations are provided.

E177 Practice for Use of the Terms Precision and Bias in

1.5 Procedures given in this practice are applicable to test

ASTM Test Methods

methods based on the measurement of continuous variates

E178 Practice for Dealing with Outlying Observations

from normal distributions or from distributions which can be

E456 Terminology Relating to Quality and Statistics

made normal by a transformation. Get qualified statistical help

E691 Practice for Conducting an Interlaboratory Study to

to (1) decide if the data are from another known distribution,

Determine the Precision of a Test Method

such as the Poisson distribution, (2) make a judgment on

2.2 ASTM Adjuncts:

normality, ( 3) transform data to a more nearly normal

TEX-PAC

distribution, or ( 4) use Practice D4467. Use the procedures in

Practice D4467 for test methods that produce data that are (1) NOTE 2—Tex-Pac is a group of PC programs on floppy disks, available

through ASTM International Headquarters. The calculations required by

continuousdatathatarenotnormallydistributedor(2)discrete

the Annexes of this practice can be performed using this adjunct and the

data, such as ratings on an arbitrary scale, counts that may be

ouput is printed in a format suitable for direct insertion in the Research

modelled by use of the Poisson distribution, or proportions or

counts of successes in a specified number of trials that may be

modelled by the binomial distribution.

Annual Book of ASTM Standards, Vol 07.01.

NOTE 1—Additional information on interlaboratory testing and on

Annual Book of ASTM Standards, Vol 15.09.

statistical treatment of data can be found in Practice D1749, D3040,

Discontinued. See 1988 Annual Book of ASTM Standards, Vol 09.01.

Annual Book of ASTM Standards, Vol 07.02.

Discontinued. See 1993 Annual Book of ASTM Standards, Vol 07.02.

1 7

ThispracticeisunderthejurisdictionofASTMCommitteeD13onTextilesand Annual Book of ASTM Standards, Vol 03.05.

is the direct responsibility of Subcommittee D13.93 on Statistics. Annual Book of ASTM Standards, Vol 14.02.

Current edition approved Nov. 10, 1997. Published August 1998. Originally PC programs on floppy disks are available through ASTM International.

published as D2904–73T. Last previous edition D2904–91. Request ADJD2904.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D2904–97 (2002)

Report required when an interlaboratory evaluation is conducted for the

operators, equipment, and environments when following pro-

purpose of establishing the precision of a Test Method.

ceduresprescribedinaspecifictestmethodandofdetermining

that the method produces results of essentially uniform vari-

3. Terminology

ability and at a consistent level when the same materials are

3.1 Fordefinitionsoftextileandstatisticaltermsusedinthis

tested in a number of laboratories.

practice, and discussions of their use, refer to Terminologies

5.2 The estimates of the components of variance from the

D123, and E456 and appropriate textbooks on statistics

interlaboratory test provide the information needed for the

(1-9).

preparation of statements on the number of specimens and on

precision as directed in Practices D2905 and D2906.

4. Summary of Practice

4.1 Planning and running an interlaboratory test program

6. Basic Statistical Design

presumes that the test method has been adequately developed

6.1 It is desirable to keep the design as simple as possible,

as directed in Sections 1–7 of Guide D4270.

yet to obtain estimates of within and between-laboratory

4.2 In this practice, directions are given on how to run a

variability unconfounded with secondary effects. Provisions

pilot-scale interlaboratory test to validate the state of control

also should be made for estimates of the variability due to:

for a test procedure.Apilot-scale test is run to decide whether

materials times laboratories, operators times materials interac-

( 1) the procedures for the test method and for the interlabo-

tions, and instruments within laboratories where two or more

ratorytestprogramareadequateor(2)moredevelopmentwork

instruments may be used in one laboratory.

needs to be done on one or both of the procedures.

NOTE 3—Generally, for a test method, there are only a limited or fixed

4.3 Directions are given on how to run a full-scale inter-

number of laboratories or operators in each laboratory who participate in

laboratory test.

the interlaboratory tests. Since all do not participate, one assumes that the

4.4 Directions are given on making data transformations,

samplingoflaboratories,andoperatorswithinlaboratoriesaredrawnfrom

handling missing data, testing outlying observations, and

a larger population of such laboratories or operators. For this reason, an

running auxiliary tests.

analysis of variance (ANOVA) model based on random effects is used (1,

4.5 InAnnexA1, the following steps are described on how

3, 4, and 8). Since specimens are always a random effect, a fixedANOVA

model does not normally apply.

to examine the data from either the pilot-scale or full-scale

interlaboratory tests.

6.2 The basic statistical design should include: a minimum

4.5.1 Analyzethedatabymaterialsbypreparingananalysis

of two or more materials spanning the range of interest for the

of variance table for each material.

property being measured, a minimum of five laboratories, and

4.5.2 Validate a state of statistical control by testing the

a minimum of two operators per laboratory with each operator

mean squares in the analysis of variance tables for significant

testing at least two specimens of each material in a designated

effects.Ifsignificanteffectsarefound,adecisionmustbemade

order. There is, generally, no major advantage in having the

on whether to (1) return to further development of the test

degrees of freedom for error exceeding 40, but it is desirable

procedure or the instructions for the interlaboratory test, or

for the degrees of freedom for all other mean squares to be as

both, or ( 2) continue with the analysis of the data from the

large as practical. This basic design may be expanded accord-

interlaboratory test.

ing to the experience of the task group, the number of

4.5.3 Make a decision on whether to ( 1) combine the data

laboratories available to perform the specified tests and the

from all materials into a single analysis of variance, (2)

degree of heterogeneity (or homogeneity) of the test materials.

combine the data into a single analysis of variance with

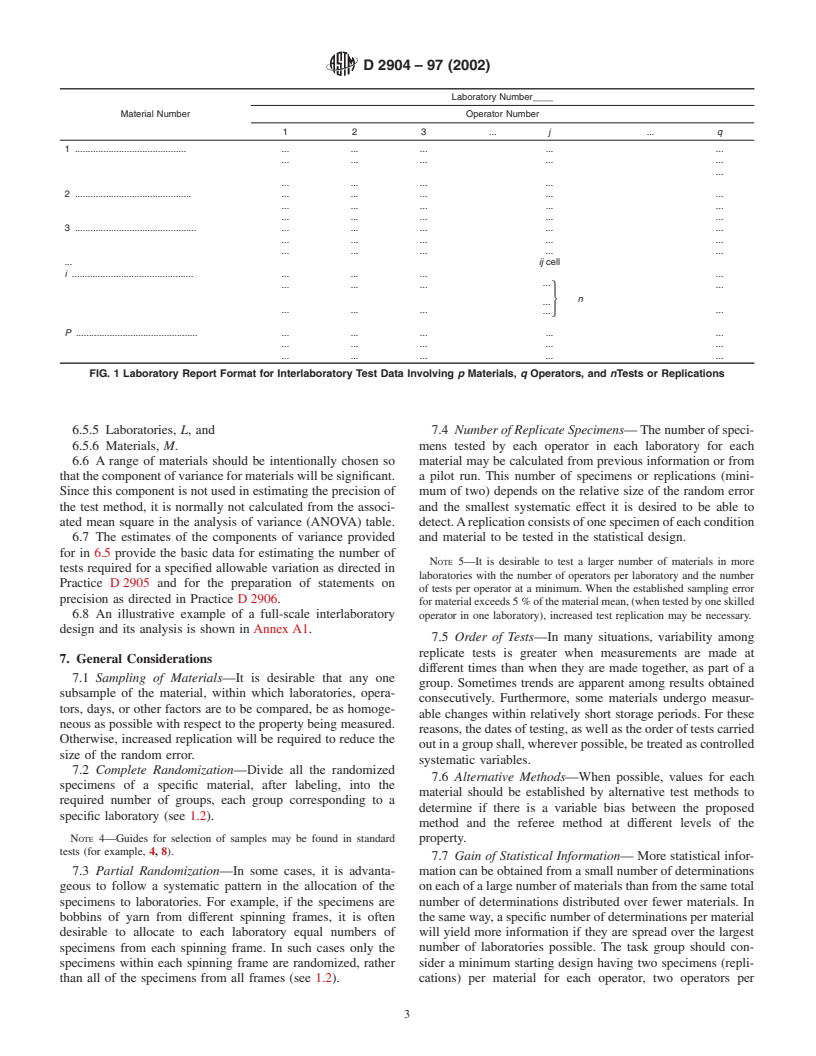

6.3 The Laboratory Report Format is represented in Fig. 1

variabilityexpressedasatransformationsuchascoefficientsof

by a two-way classification table in which the rows represent

variation or (3) stop the analysis and write separate statements

the materials and the columns represent the operators in the

on precision for each material.

laboratory. Each cell contains the replicate observations per

4.5.4 If a decision is made to combine the data from all

operator.

materials, analyze the data from all materials as a single

6.4 Abasicanalysisofvariance(ANOVA)designshouldbe

analysis of variance and validate a state of control by testing

a randomized complete-block design or other more suitable

forsignificanteffects.Ifsignificanteffectsarefound,adecision

factorial, having the following successive subsets:

must be made on whether to (1) return to further development

6.4.1 Materials, M,

of the test procedure or the instructions for the interlaboratory

6.4.2 Laboratories, L,

test,orboth,or( 2)continuewiththeanalysisofthedatafrom

6.4.3 Operators in laboratories, O(L), and

the interlaboratory test.

6.4.4 Specimens per operator within laboratories and mate-

4.5.5 Calculate the necessary components of variance for

rials, S (MLO).

use as directed in Practice D2905 and Practice D2906.

6.5 The basic statistical design outlined in 6.2-6.4 will

provide the following estimated components of variance:

5. Significance and Use

6.5.1 Specimens within operators, laboratories, and materi-

5.1 Interlaboratory testing is a means of securing estimates

als, S·MLO,

of the variability in results obtained by different laboratories,

6.5.2 Operator times materials interactions within laborato-

ries, MO·L,

6.5.3 Operators within laboratories, O·L,

The boldface numbers in parentheses refer to the references listed at the end

of this practice. 6.5.4 Materials times laboratories interactions, ML,

D2904–97 (2002)

Laboratory Number____

Material Number Operator Number

123 . j . q

1 . . . . . .

... ... ... ... ...

...

... ... ... ...

2 . . . . . .

... ... ... ... ...

... ... ... ... ...

3 . . . . . .

... ... ... ... ...

... ... ... ... ...

... ij cell

i . . . . .

...

... ... ... ...

n

...

... ... ... ...

...

P . . . . . .

... ... ... ... ...

... ... ... ... ...

FIG. 1 Laboratory Report Format for Interlaboratory Test Data Involving p Materials, q Operators, and nTests or Replications

6.5.5 Laboratories, L, and 7.4 Number of Replicate Specimens—Thenumberofspeci-

6.5.6 Materials, M. mens tested by each operator in each laboratory for each

6.6 A range of materials should be intentionally chosen so material may be calculated from previous information or from

thatthecomponentofvarianceformaterialswillbesignificant. a pilot run. This number of specimens or replications (mini-

Since this component is not used in estimating the precision of mum of two) depends on the relative size of the random error

the test method, it is normally not calculated from the associ- and the smallest systematic effect it is desired to be able to

ated mean square in the analysis of variance (ANOVA) table. detect.Areplicationconsistsofonespecimenofeachcondition

6.7 The estimates of the components of variance provided and material to be tested in the statistical design.

for in 6.5 provide the basic data for estimating the number of

NOTE 5—It is desirable to test a larger number of materials in more

tests required for a specified allowable variation as directed in

laboratories with the number of operators per laboratory and the number

Practice D2905 and for the preparation of statements on

of tests per operator at a minimum. When the established sampling error

precision as directed in Practice D2906.

formaterialexceeds5%ofthematerialmean,(whentestedbyoneskilled

6.8 An illustrative example of a full-scale interlaboratory operator in one laboratory), increased test replication may be necessary.

design and its analysis is shown in Annex A1.

7.5 Order of Tests—In many situations, variability among

replicate tests is greater when measurements are made at

7. General Considerations

different times than when they are made together, as part of a

7.1 Sampling of Materials—It is desirable that any one

group. Sometimes trends are apparent among results obtained

subsample of the material, within which laboratories, opera-

consecutively. Furthermore, some materials undergo measur-

tors, days, or other factors are to be compared, be as homoge-

able changes within relatively short storage periods. For these

neous as possible with respect to the property being measured.

reasons,thedatesoftesting,aswellastheorderoftestscarried

Otherwise, increased replication will be required to reduce the

outinagroupshall,whereverpossible,betreatedascontrolled

size of the random error.

systematic variables.

7.2 Complete Randomization—Divide all the randomized

7.6 Alternative Methods—When possible, values for each

specimens of a specific material, after labeling, into the

material should be established by alternative test methods to

required number of groups, each group corresponding to a

determine if there is a variable bias between the proposed

specific laboratory (see 1.2).

method and the referee method at different levels of the

NOTE 4—Guides for selection of samples may be found in standard property.

tests (for example, 4, 8).

7.7 Gain of Statistical Information— More statistical infor-

7.3 Partial Randomization—In some cas

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.