ASTM A48/A48M-03(2016)

(Specification)Standard Specification for Gray Iron Castings

Standard Specification for Gray Iron Castings

ABSTRACT

This specification covers gray iron castings intended for general engineering use where tensile strength is a major consideration. Castings are classified on the basis of the tensile strength of the iron in separately cast test bars. The surface of the casting shall be free of adhering sand, scale, cracks, and hot tears, as determined by visual examination. The test bars are designated into S, A, B, and C categories, according to the thickness of its controlling wall section. The casting shall be subjected to a tension test to determine its tensile strength.

SCOPE

1.1 This specification covers gray iron castings intended for general engineering use where tensile strength is a major consideration. Castings are classified on the basis of the tensile strength of the iron in separately cast test bars.

1.1.1 This specification subordinates chemical composition to tensile strength.

1.2 Castings produced to this specification are graded on the basis of minimum tensile strength obtained in special test coupons designed to standardize cooling rate. The tensile strength developed in certain casting sections may vary from test coupon values (see X1.2).

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A48/A48M −03 (Reapproved 2016)

Standard Specification for

1

Gray Iron Castings

This standard is issued under the fixed designation A48/A48M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

This specification replaces Federal Specification QQ-I-652.

1. Scope 3.1.1 Definitions for many terms common to gray iron

castings are found in Terminology A644.

1.1 This specification covers gray iron castings intended for

general engineering use where tensile strength is a major

4. Classification

consideration. Castings are classified on the basis of the tensile

4.1 Castings ordered and produced in accordance with this

strength of the iron in separately cast test bars.

specificationareclassifiedintoanumberofgradesbasedonthe

1.1.1 This specification subordinates chemical composition

properties of separately cast test bars (Tables 1 and 2). Each

to tensile strength.

class is designated by a number followed by a letter. The

1.2 Castings produced to this specification are graded on the

number indicates the minimum tensile strength of the sepa-

basis of minimum tensile strength obtained in special test

rately cast test bar, and the letter indicates the size of the test

coupons designed to standardize cooling rate. The tensile

bar. Examples of proper designations are as follows:

strength developed in certain casting sections may vary from

Gray Iron Castings, ASTM Specification A48, Class 30B.

test coupon values (see X1.2).

Gray Iron Castings, ASTM Specification A48, Class 40C.

1.3 The values stated in either SI units or inch-pound units

5. Ordering Information

are to be regarded separately as standard. The values stated in

5.1 Orders for material to this specification shall include the

each system may not be exact equivalents; therefore, each

following information:

system shall be used independently of the other. Combining

5.1.1 ASTM designation number and year of issue,

values from the two systems may result in non-conformance

5.1.2 Class of iron required (see 4.1, and Tables 1 and 2),

with the standard.

5.1.3 The size of the separately cast test bar (letter

classification—A, B, C, or S) that best represents the thickness

2. Referenced Documents

of the controlling section of the casting (see Table 3),

2.1 ASTM Standards:

5.1.4 The tension test specimen (B or C) to be machined

A644 Terminology Relating to Iron Castings

from test bar C (see 13.3, Table 4, and Fig. 1),

E8 Test Methods for Tension Testing of Metallic Materials

5.1.5 The tension test specimen to be machined from test

2.2 Military Standard:

bar S (see 13.4, Table 4, and Fig. 1),

2

MIL-STD-129 Marking for Shipment and Storage

5.1.6 Lot size (see Section 10),

5.1.7 Special requirements (see Section 6),

2.3 Federal Standard:

5.1.8 Saving tested specimens or unbroken test bars (see

Federal Standard No. 123 Marking for Shipment (Civil

2

15.1), and

Agencies)

5.1.9 Special preparation for delivery (see Section 19).

3. Terminology

6. Special Requirements

3.1 Definitions:

6.1 When agreed upon in writing between the manufacturer

and the purchaser, it may be necessary for the castings to meet

special requirements as to hardness, chemical composition,

1

This specification is under the jurisdiction of ASTM Committee A04 on Iron

microstructure, pressure tightness, radiographic soundness,

CastingsandisthedirectresponsibilityofSubcommitteeA04.01onGreyandWhite

dimensions, surface finish, and so forth.

Iron Castings.

Current edition approved Nov. 1, 2016. Published November 2016. Originally

7. Tensile Requirements

approved in 1905. Last previous edition approved in 2012 as A48/

A48M – 03 (2012). DOI: 10.1520/A0048_A0048M-03R16.

7.1 Test bars representing castings conforming to this speci-

2

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

fication shall meet the requirements for tensile strength as

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

www.dodssp.daps.mil. described in Tables 1 and 2.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A48/A48M−03 (2016)

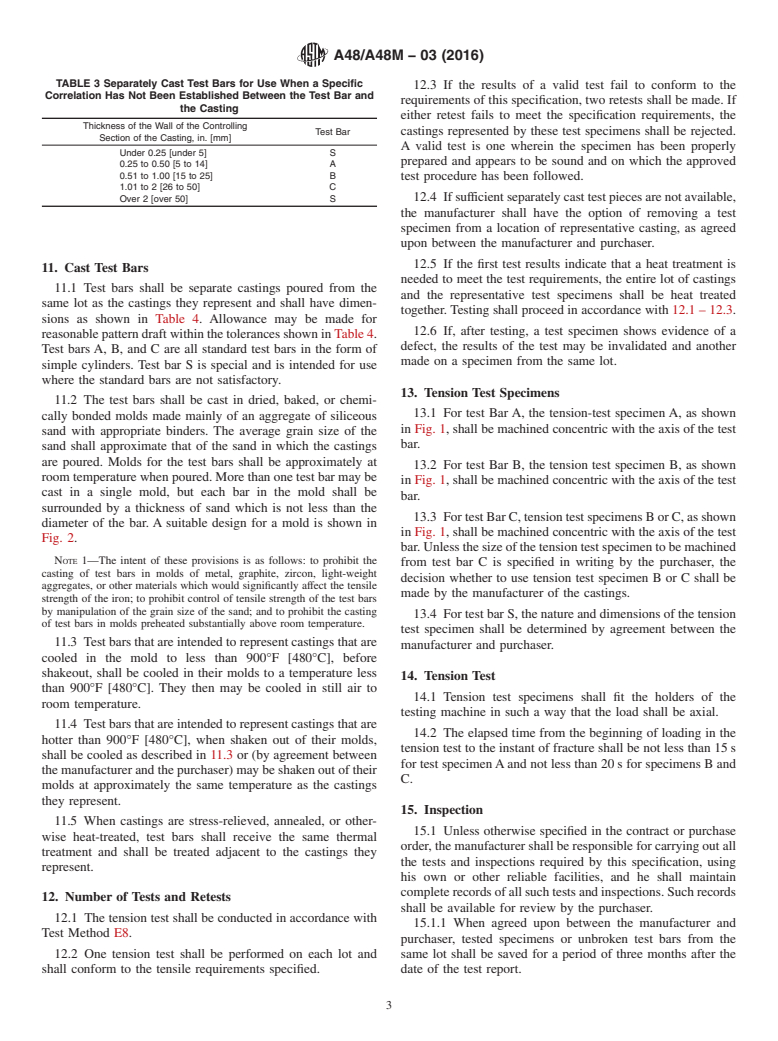

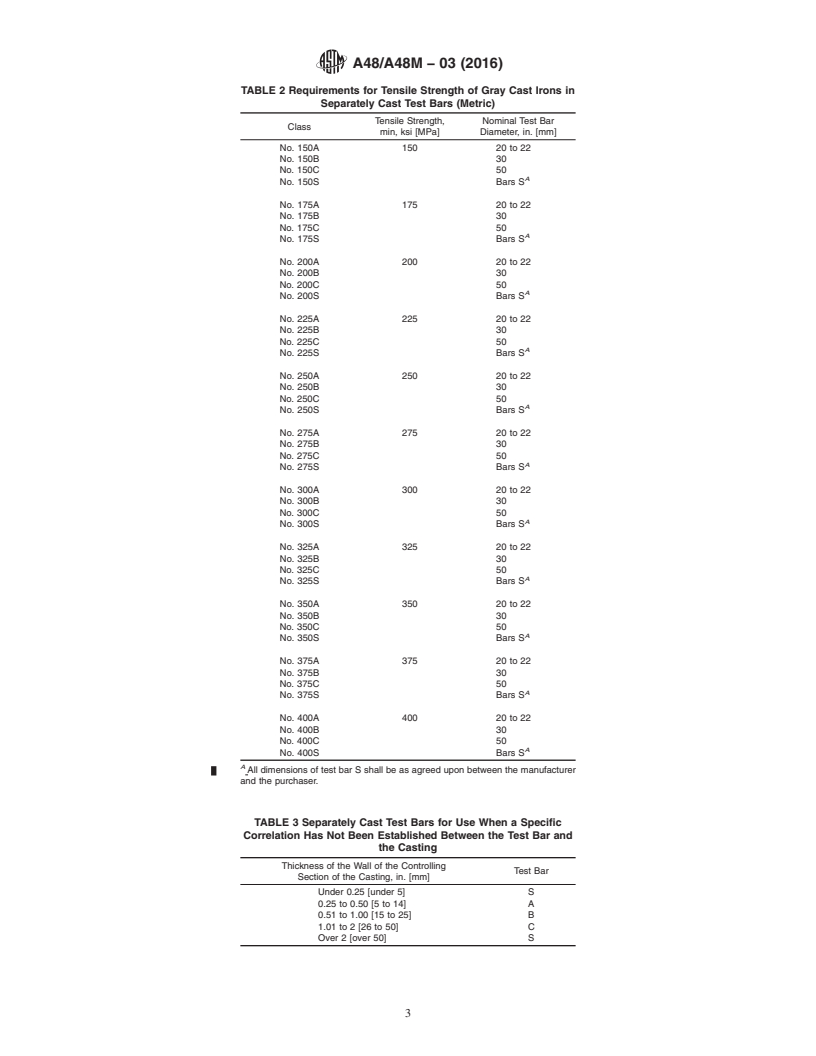

TABLE 1 Requirements for Tensile Strength of Gray Cast Irons in TABLE 2 Requirements for Tensile Strength of Gray Cast Irons in

Separately Cast Test Bars (Inch-Pound) Separately Cast Test Bars (Metric)

Tensile Strength, Nominal Test Bar Tensile Strength, Nominal Test Bar

Class Class

min, ksi Diameter, in. min, ksi [MPa] Diameter, in. [mm]

No. 20 A 20 0.8 No. 150A 150 20 to 2

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A48/A48M − 03 (Reapproved 2012) A48/A48M − 03 (Reapproved 2016)

Standard Specification for

1

Gray Iron Castings

This standard is issued under the fixed designation A48/A48M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

This specification replaces Federal Specification QQ-I-652.

1. Scope

1.1 This specification covers gray iron castings intended for general engineering use where tensile strength is a major

consideration. Castings are classified on the basis of the tensile strength of the iron in separately cast test bars.

1.1.1 This specification subordinates chemical composition to tensile strength.

1.2 Castings produced to this specification are graded on the basis of minimum tensile strength obtained in special test coupons

designed to standardize cooling rate. The tensile strength developed in certain casting sections may vary from test coupon values

(see X1.2).

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

2. Referenced Documents

2.1 ASTM Standards:

A644 Terminology Relating to Iron Castings

E8 Test Methods for Tension Testing of Metallic Materials

2.2 Military Standard:

2

MIL-STD-129 Marking for Shipment and Storage

2.3 Federal Standard:

2

Federal Standard No. 123 Marking for Shipment (Civil Agencies)

3. Terminology

3.1 Definitions:

3.1.1 Definitions for many terms common to gray iron castings are found in Terminology A644.

4. Classification

4.1 Castings ordered and produced in accordance with this specification are classified into a number of grades based on the

properties of separately cast test bars (Table 1Tables 1 and 2, Table 2). Each class is designated by a number followed by a letter.

The number indicates the minimum tensile strength of the separately cast test bar, and the letter indicates the size of the test bar.

Examples of proper designations are as follows:

Gray Iron Castings, ASTM Specification A48, Class 30B.

Gray Iron Castings, ASTM Specification A48, Class 40C.

5. Ordering Information

5.1 Orders for material to this specification shall include the following information:

5.1.1 ASTM designation number and year of issue,

5.1.2 Class of iron required (see 4.1, Table 1, and Table 2Tables 1 and 2),

1

This specification is under the jurisdiction of ASTM Committee A04 on Iron Castings and is the direct responsibility of Subcommittee A04.01 on Grey and White Iron

Castings.

Current edition approved Oct. 1, 2012Nov. 1, 2016. Published November 2012November 2016. Originally approved in 1905. Last previous edition approved in 20082012

as A48/A48M – 03 (2008).(2012). DOI: 10.1520/A0048_A0048M-03R12.10.1520/A0048_A0048M-03R16.

2

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://www.dodssp.daps.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A48/A48M − 03 (2016)

TABLE 1 Requirements for Tensile Strength of Gray Cast Irons in

Separately Cast Test Bars (Inch-Pound)

Tensile Strength, Nominal Test Bar

Class

min, ksi Diameter, in.

No. 20 A 20 0.8

No. 20 B 1.2

No. 20 C 2.0

A

No. 20 S Bars S

No. 25 A 25 0.88

No. 25 B 1.2

No. 25 C 2.0

A

No. 25 S Bars S

No. 30 A 30 0.88

No. 30 B 1.2

No. 30 C 2.0

A

No. 30 S Bars S

No. 35 A 35 0.88

No. 35 B 1.2

No. 35 C 2.0

A

No. 35 S Bars S

No. 40 A 40 0.88

No. 40 B 1.2

No. 40 C 2.0

A

No. 40 S Bars S

No. 45 A 45 0.88

No. 45 B 1.2

No. 45 C 2.0

A

No. 45 S Bars S

No. 50 A 50 0.88

No. 50 B 1.2

No. 50 C 2.0

A

No. 50 S Bars S

No. 55 A 55 0.88

No. 55 B 1.2

No. 55 C 2.0

A

No. 55 S Bars S

No. 60 A 60 0.88

No. 60 B 1.2

No. 60 C 2.0

A

No. 60 S Bars S

A

All dimensions of test bar S shall be as agreed upon between the manufacturer

and the purchaser.

5.1.3 The size of the separately cast test bar (letter classification—A, B, C, or S) that best represents the thickness of the

controlling section of the casting (see Table 3),

5.1.4 The tension

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.